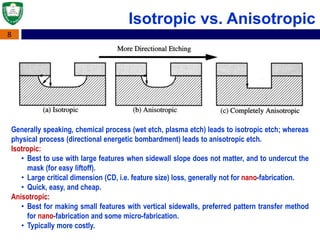

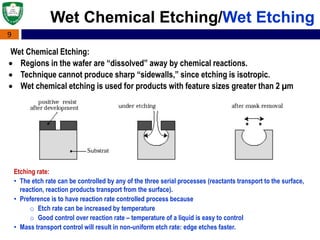

Etching is a process used in semiconductor fabrication to remove unwanted material. There are two main types of etching: wet etching uses liquid chemicals while dry etching uses gases, often in a plasma. Reactive ion etching (RIE) is a commonly used dry etching technique that combines chemical and physical etching for better control over etching profiles. RIE allows for both isotropic and anisotropic etching depending on process parameters. Impurity doping techniques like diffusion and ion implantation are used to introduce dopants into semiconductors to control electrical conductivity.