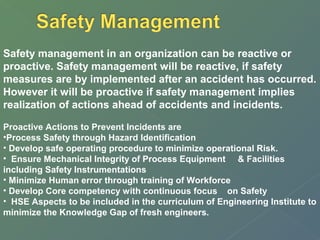

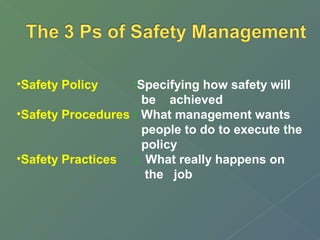

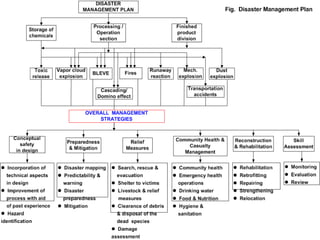

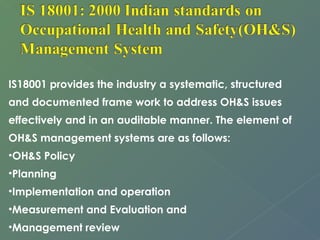

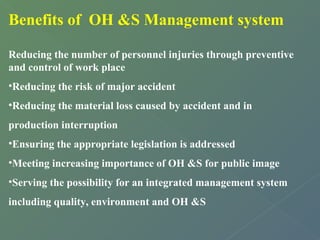

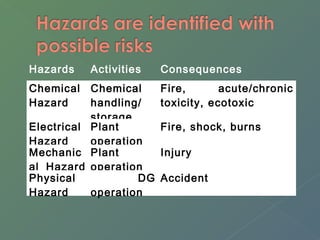

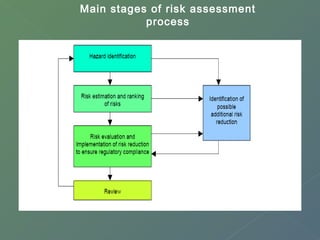

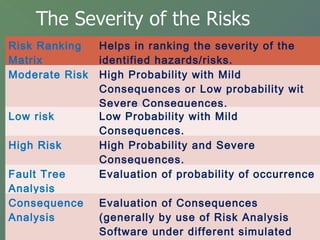

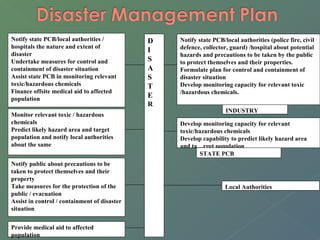

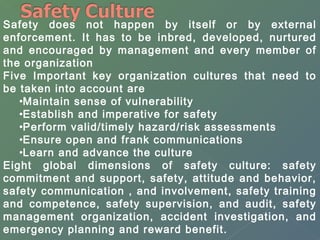

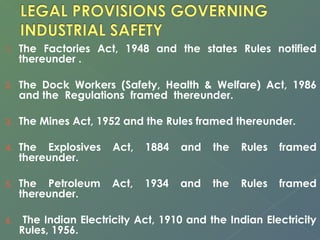

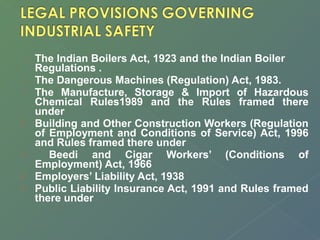

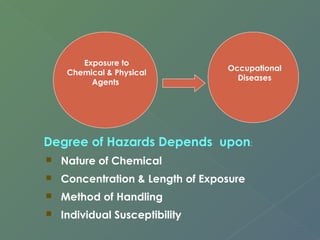

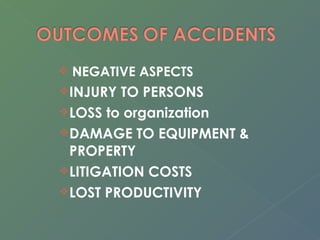

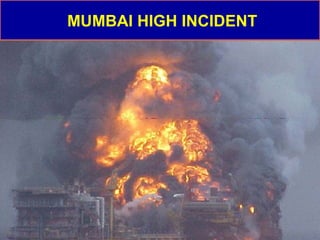

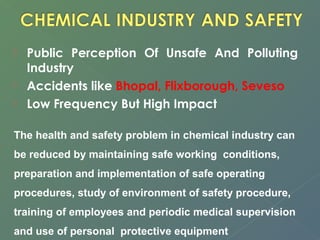

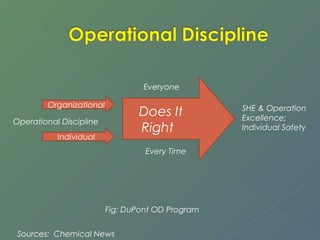

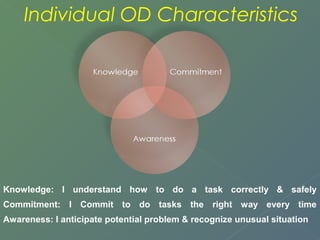

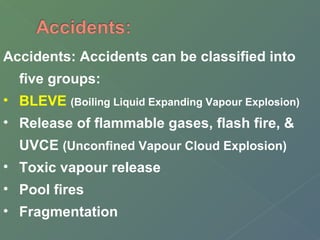

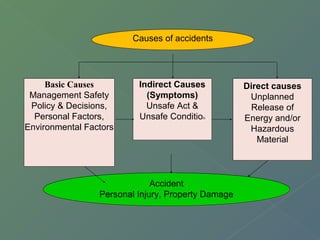

This document discusses various issues related to environment, health, and safety management. It covers topics like process safety, occupational health, safety management, hazards identification, risk assessment, safety standards and regulations, accident analysis, safety training, and benefits of occupational health and safety management systems. The key aspects of developing a proactive safety culture in organizations are also highlighted.

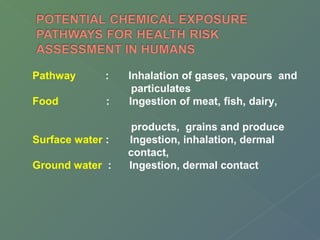

![Adverse exposure of the chemicals can be acute

exposure (acute poisoning), chronic exposure (chronic

poisoning), site of toxic effects of chemicals, local,

Systemic, cumulative, synergistic or potentiating effect.

Some of the commonly occupational exposure limits are

Threshold limit values (TLV), Permissible Exposure limit,

Maximum allowable concentrations.

Commonly three types of TLVs are prescribed: TLV-TWA(

time weighted average), STEL( short term exposure

limit), TLV-C(ceiling limit)

[ ISC,2008].](https://image.slidesharecdn.com/ehsmanagementissueschallengessafety-140920133315-phpapp01/85/Ehs-management-issues-challenges-safety-22-320.jpg)