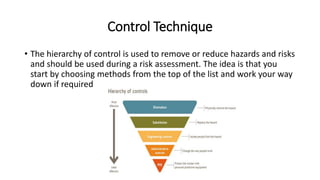

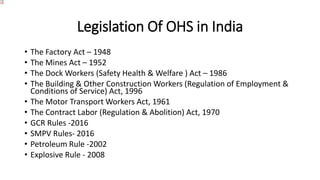

Industrial safety focuses on eliminating hazards in the workplace to prevent accidents and improve employee morale. It incorporates risk assessment, hazard identification, and control techniques, with various regulations governing occupational health and safety. Industrial hygiene plays a crucial role in recognizing and mitigating physical, chemical, biological, and ergonomic hazards to protect workers' health.