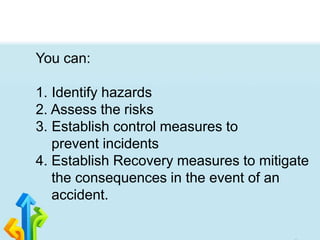

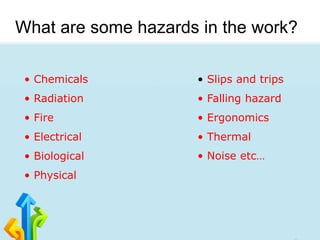

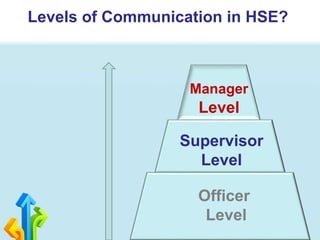

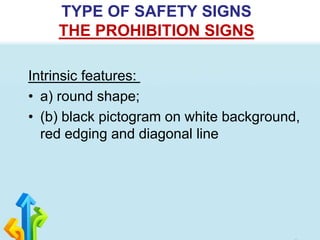

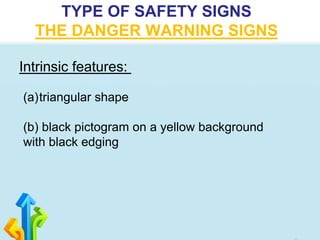

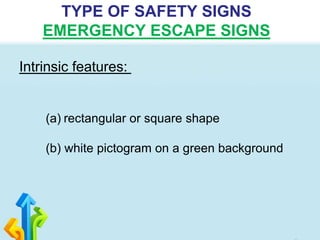

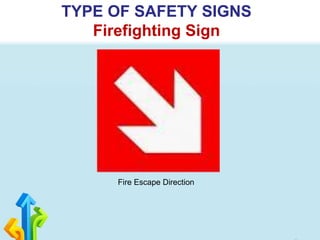

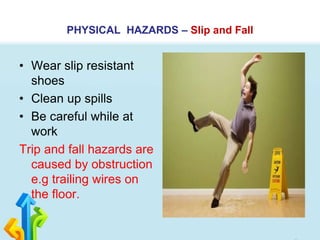

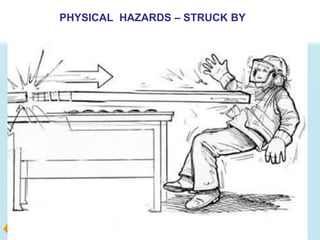

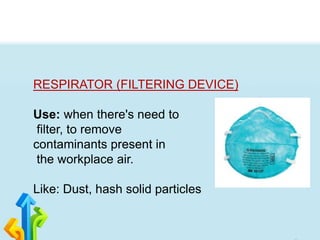

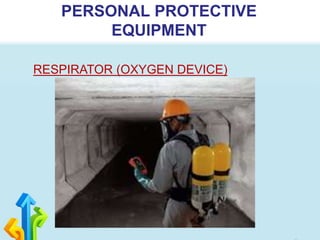

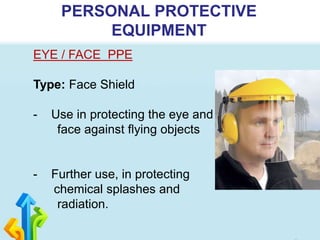

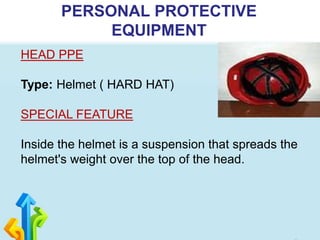

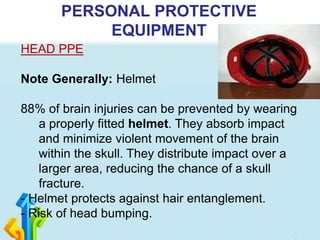

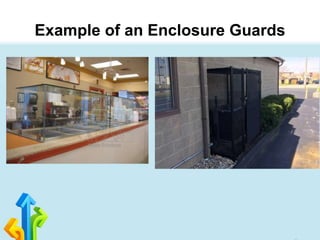

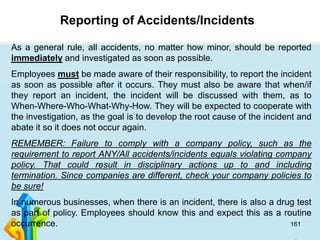

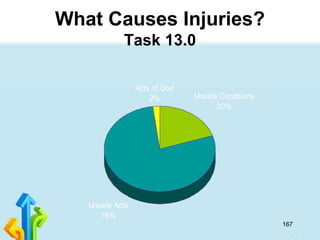

The document outlines a comprehensive health, safety, and environment (HSE) training course aimed at improving workforce competence in identifying hazards and implementing control measures. It covers essential definitions, responsibilities of safety officers, types of hazards, and the legal framework governing workplace safety, emphasizing the necessity of safety training and compliance for both employers and employees. Additionally, it highlights various personal protective equipment (PPE) and safety legislation, addressing the importance of safety culture in reducing incidents and promoting a safe work environment.