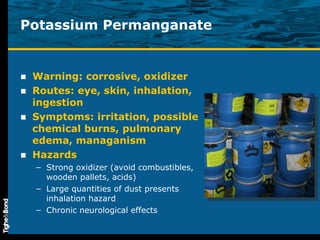

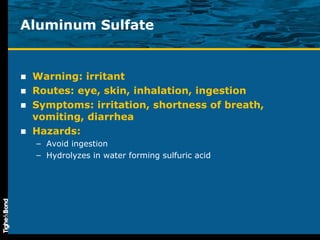

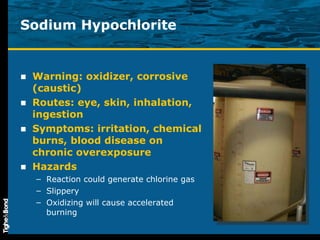

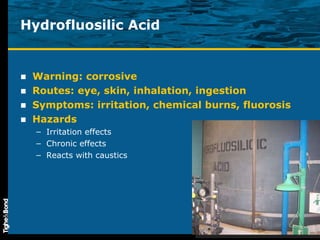

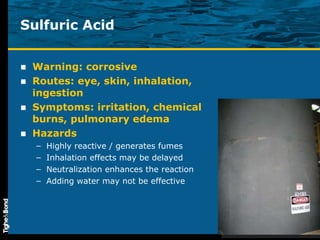

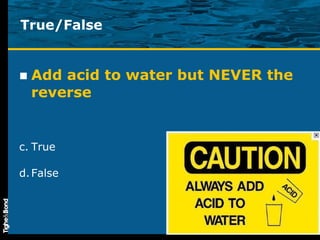

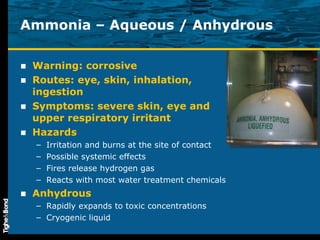

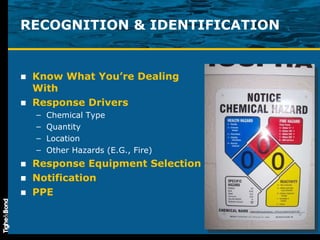

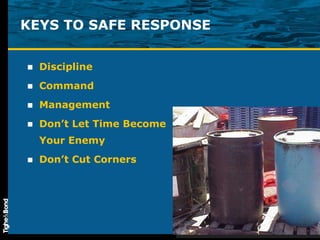

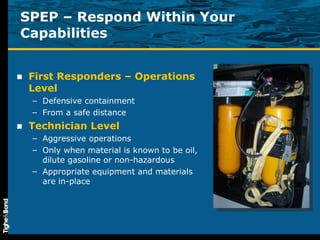

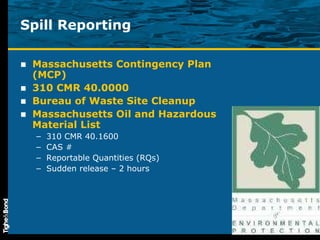

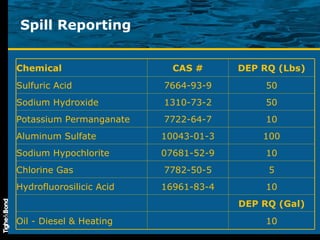

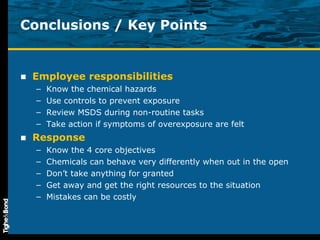

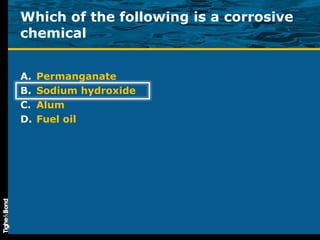

The document outlines safe chemical handling and initial spill response for water utilities, emphasizing the importance of protecting personnel, the environment, and ensuring compliance with hazard communication standards. It covers various chemical hazards, emergency procedures, and the Globally Harmonized System (GHS) for classifying and labeling chemicals. Key recommendations include using personal protective equipment, maintaining situational awareness during spills, and following specific response protocols to mitigate risks.

![Barnstable County Water Utilities Association Safe Chemical Handling and Initial Spill Response June 16, 2011 David P. Horowitz, P.E., CSP Tighe & Bond, Inc. 413.572.3211 [email_address] @dphorowitz on Twitter & YouTube](https://image.slidesharecdn.com/safechemicalbcwua-110617052746-phpapp02/85/Safe-Chemical-Handling-Initial-Spill-Response-1-320.jpg)

![Questions / Thanks David P. Horowitz, P.E., CSP Tighe & Bond, Inc. 413.572.3211 [email_address]](https://image.slidesharecdn.com/safechemicalbcwua-110617052746-phpapp02/85/Safe-Chemical-Handling-Initial-Spill-Response-84-320.jpg)