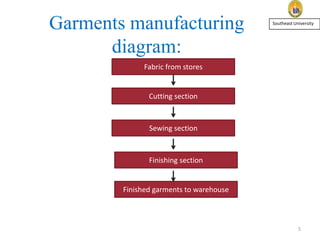

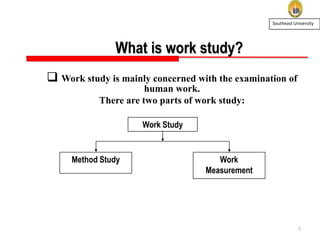

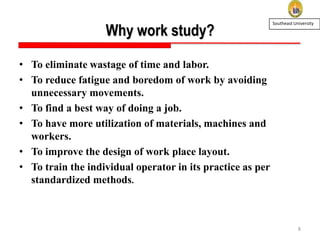

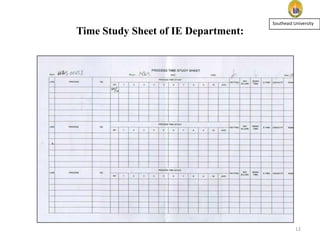

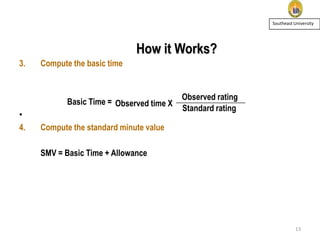

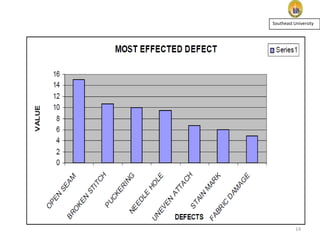

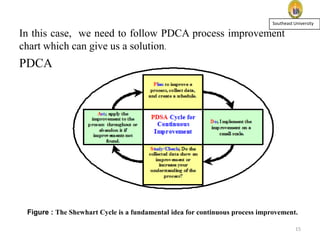

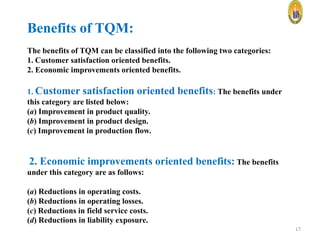

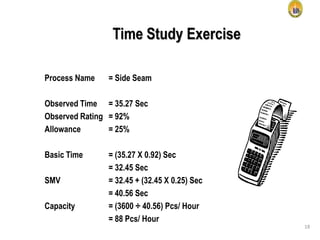

This document discusses the use of work study and time study techniques to improve production and quality in an apparel manufacturing setting. It outlines the objectives of implementing work study charts to maximize resource utilization and optimize workplaces. It then describes the importance of industrial engineering tools in improving productivity and profits for garment companies. Specific techniques discussed include method study to determine the best work methods, time study to set standard times, and analyzing productivity data. The conclusion states that applying work study charts can effectively utilize resources and find low-cost solutions to increase efficiency.