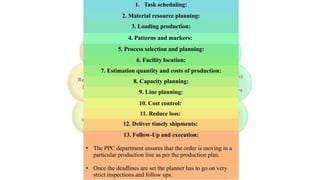

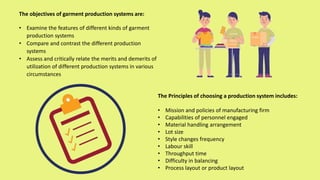

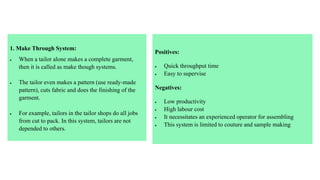

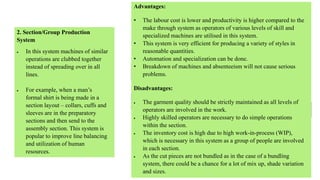

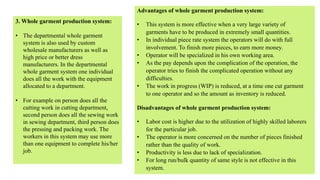

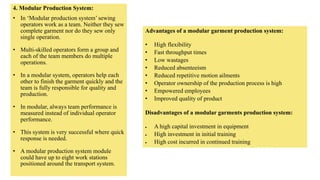

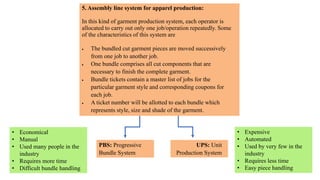

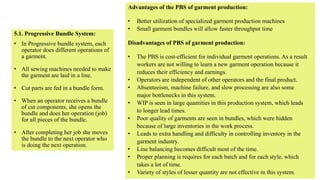

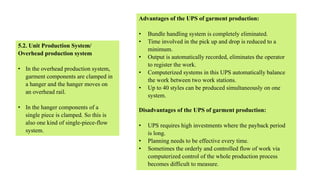

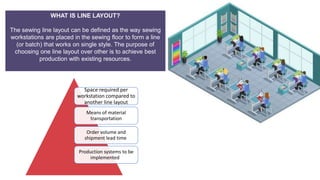

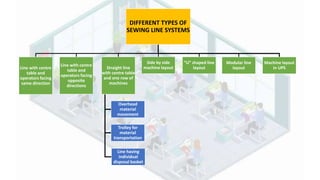

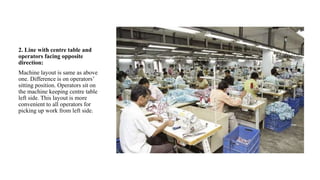

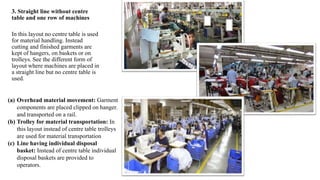

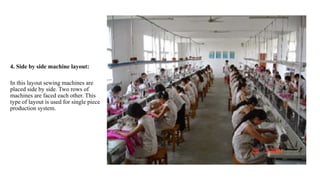

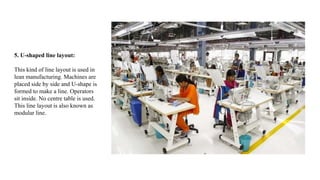

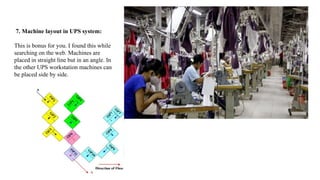

The document discusses the importance of production planning and control (PPC) in the garment industry, detailing various production systems and their characteristics. It highlights the objectives of different apparel production systems, such as make through, modular, section/group, and assembly line systems, along with their advantages and disadvantages. Additionally, it emphasizes the significance of accurate scheduling, material resource planning, and facility location to ensure timely deliveries and efficient production processes.