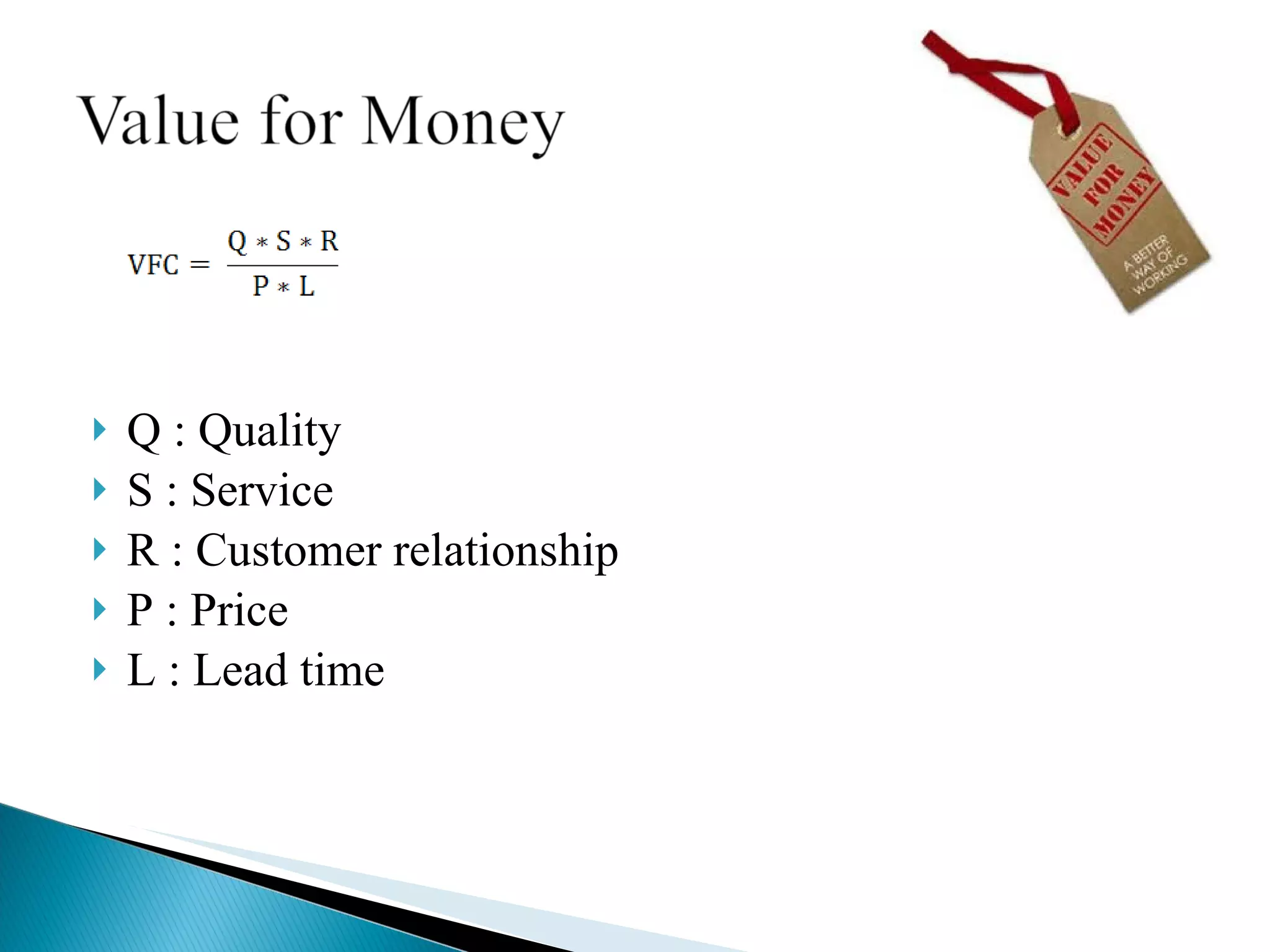

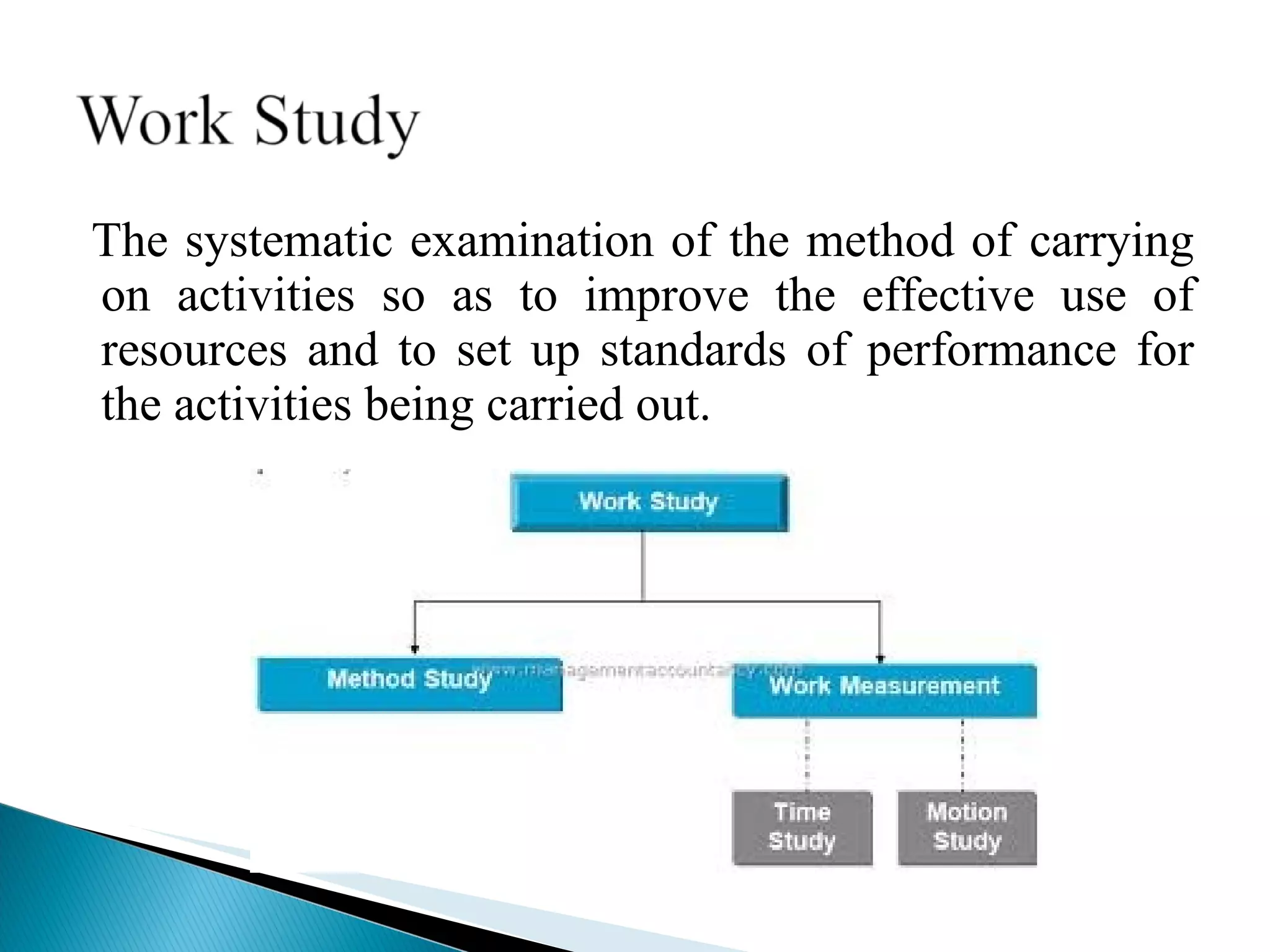

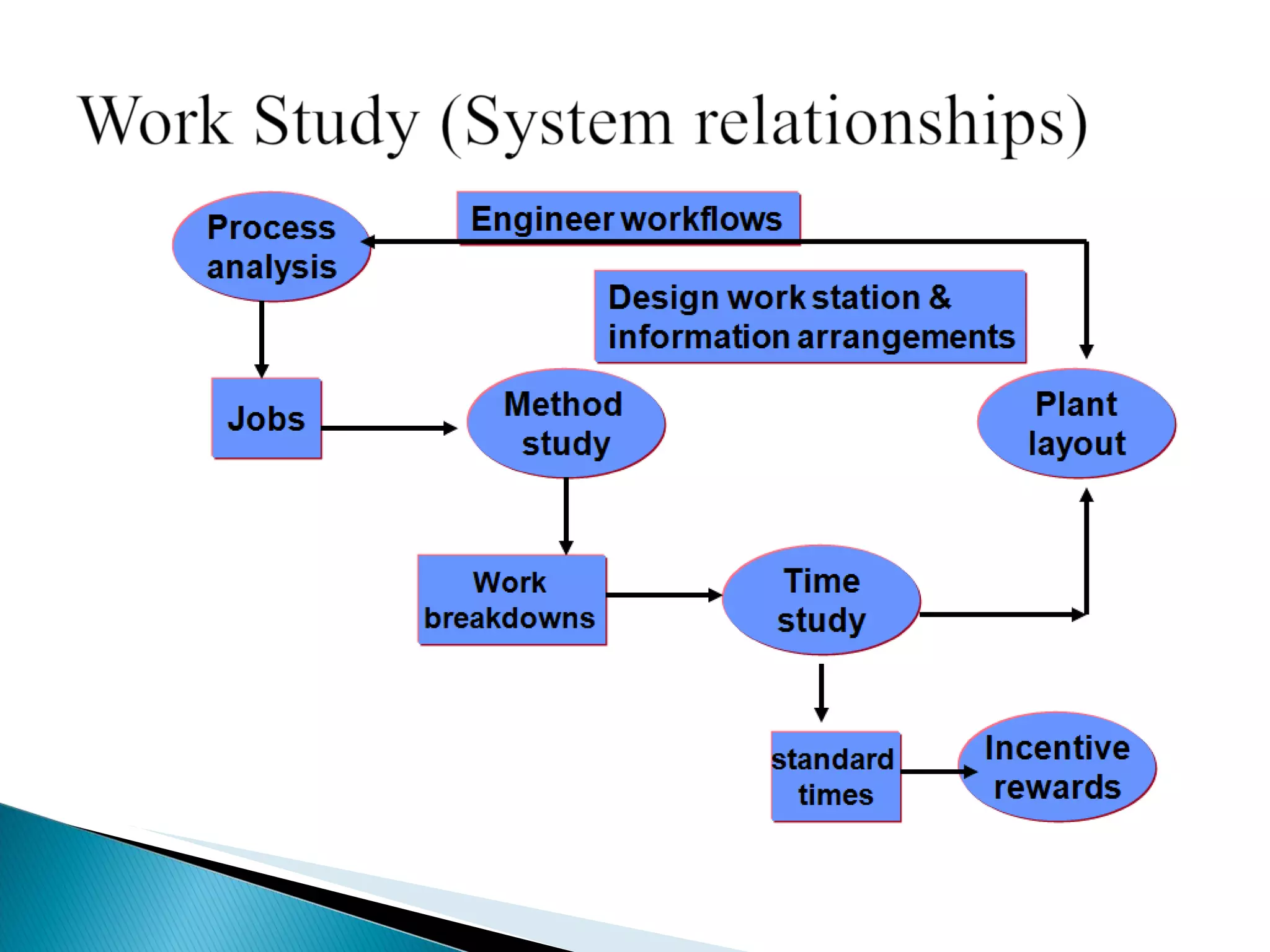

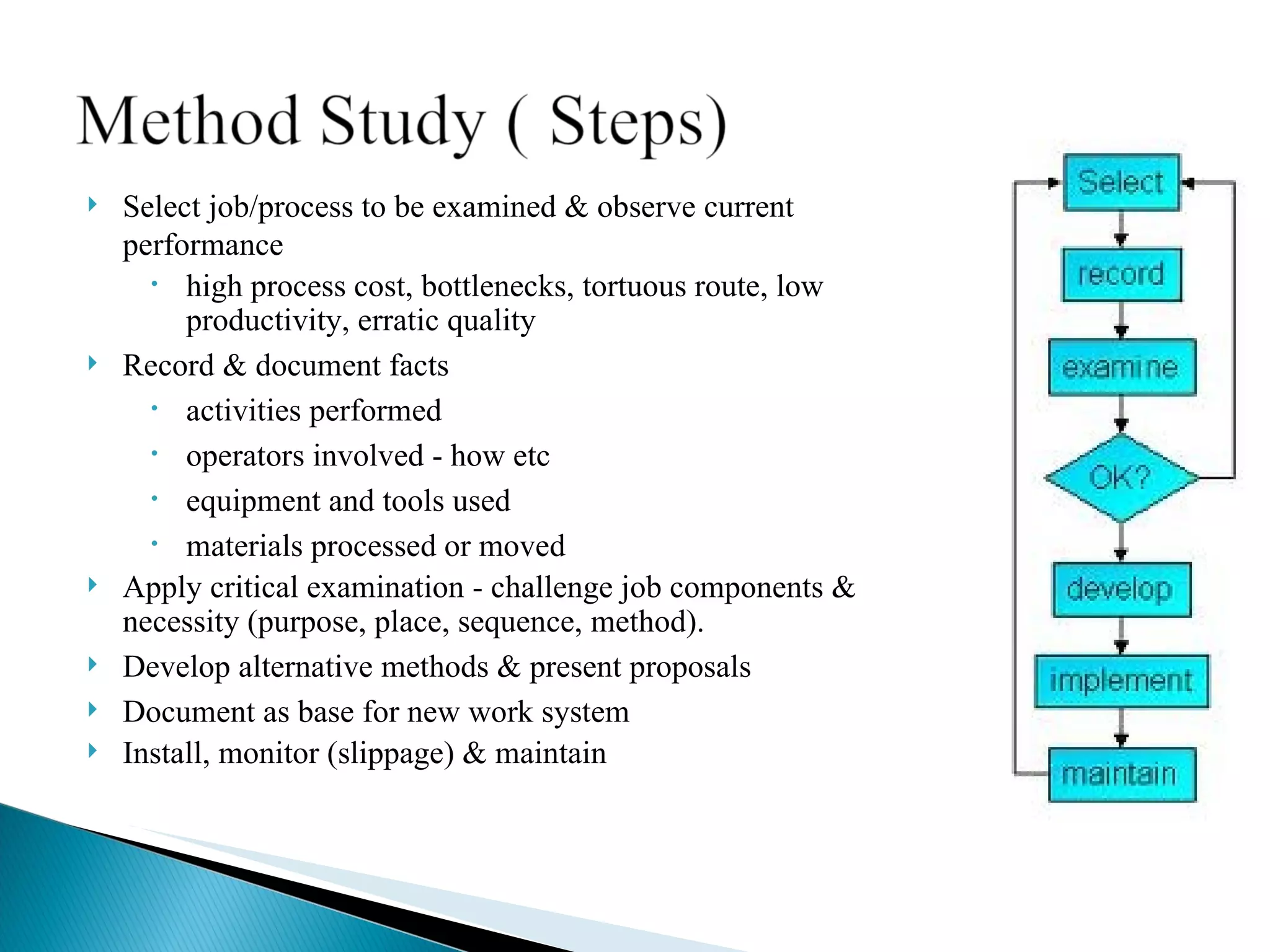

The document discusses techniques for improving value for money (VFM) for customers through improving productivity using methods from industrial engineering. It describes conducting a systematic examination of work methods to develop more effective and efficient processes, setting performance standards, and using time and motion studies to establish standard times for tasks. The overall goal is to increase productivity and efficiency while improving working conditions.