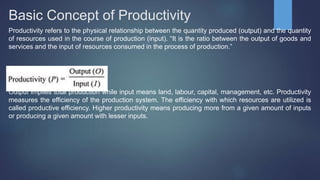

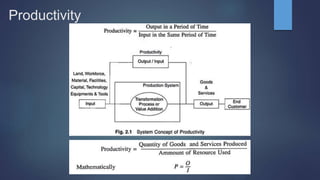

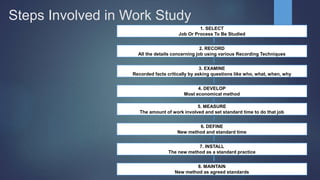

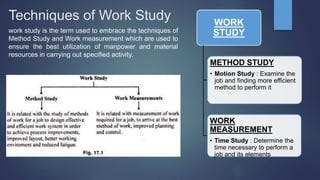

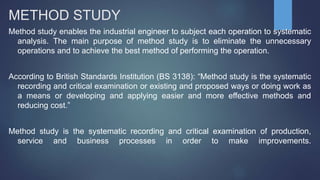

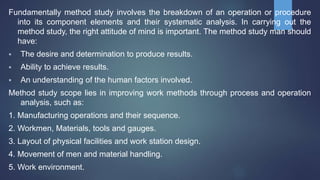

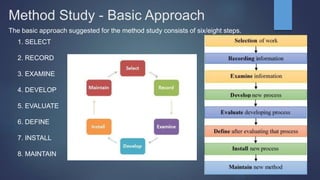

The document provides an overview of method study, which is a technique used in work study to analyze and improve work methods. It discusses the basic approach and steps in method study, which include selecting a process to study, recording the current process using charts and diagrams, examining each activity through a series of questions, developing alternative methods, evaluating the alternatives, defining the new method, installing it, and maintaining it. The objectives and scope of method study are also outlined. Method study aims to systematically analyze work processes and eliminate unnecessary operations to develop more efficient methods of performing work.

![Method Study: Brief explanation

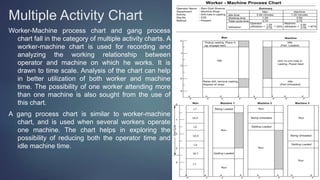

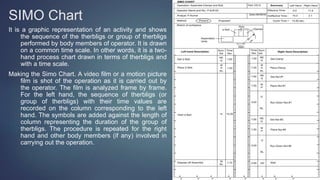

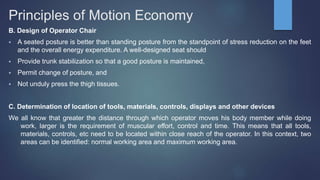

2. RECORD

The process is to be recorded in specified charts and diagrams.

Process charts

Flow charts

Flow diagram

A variety of techniques for analysis and charting have for a long time been established as IE

techniques. Among the methods of analysis, process analysis, operation analysis, motion study,

time study, work sampling, and flow analysis are widely used. Similarly, among the charting

techniques, process charts, pitch diagrams, multiple activity charts, process charts, and machine

sequential charts are used. From among these various techniques, the appropriate one will be

chosen, based on the object being analyzed [3].

Process charts were used and advocated by Frank Gilbreth in a paper presented to ASME in 1921.](https://image.slidesharecdn.com/iee-methodstudy-210825090004/85/Industrial-Engineering-Method-Study-26-320.jpg)