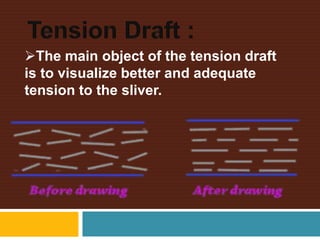

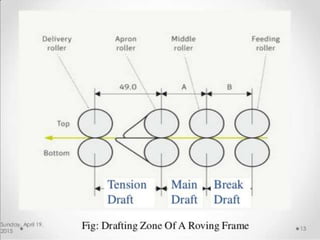

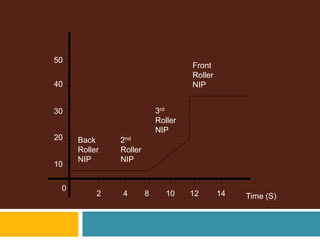

The document discusses drafting in textile manufacturing. It defines drafting as reducing the mass per unit length of sliver by passing it over rotating rollers of increasing speed. The drafting process involves three stages - break draft, main draft, and tension draft. In the main draft stage, where the bulk of drafting occurs, methods like aprons and pressure bars are used to control fibers. A roving frame inserts twist and winds the roving onto bobbins after drafting. Calculations are provided to determine the ratch, or distance between rollers, based on parameters like roller diameter, winding rate, and angular velocity. Drafting results in fibers becoming more compact and chemically stable with improved strength and lower moisture absorption.