Spinning Rings & Ring Travellers

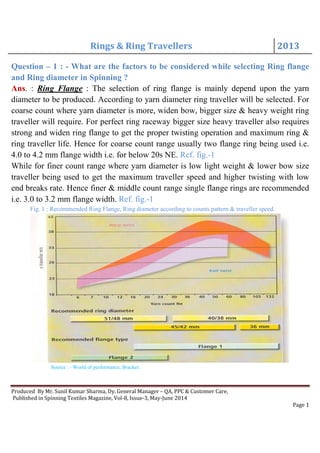

- 1. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 1 Question – 1 : - What are the factors to be considered while selecting Ring flange and Ring diameter in Spinning ? Ans. : Ring Flange : The selection of ring flange is mainly depend upon the yarn diameter to be produced. According to yarn diameter ring traveller will be selected. For coarse count where yarn diameter is more, widen bow, bigger size & heavy weight ring traveller will require. For perfect ring raceway bigger size heavy traveller also requires strong and widen ring flange to get the proper twisting operation and maximum ring & ring traveller life. Hence for coarse count range usually two flange ring being used i.e. 4.0 to 4.2 mm flange width i.e. for below 20s NE. Ref. fig.-1 While for finer count range where yarn diameter is low light weight & lower bow size traveller being used to get the maximum traveller speed and higher twisting with low end breaks rate. Hence finer & middle count range single flange rings are recommended i.e. 3.0 to 3.2 mm flange width. Ref. fig.-1 Fig. 1 : Recommended Ring Flange, Ring diameter according to counts pattern & traveller speed. Source : - World of performance, Bracker.

- 2. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 2 Ring Diameter : - Selection of ring diameter for spinning is depends on following factors : - 1. Spindle - Spindle gauge : - The first important point to be consider for selecting the ring diameter is spinning frame spindle to spindle gauge. The ring diameter can be chosen 25 mm smaller at a maximum with regard to the spindle gauge. Which is requires for necessary freedom of balloon movement, inserting the traveller, repairing end breakages and exchanging the cop with fewer obstacles. Ring dia = t – 25 mm, where t = Spindle to Spindle gauge. Fig.2 : Graphical representation of Spinning geometry w.r.t. Rings & Spindles. 2. Tube diameter : - The ring diameter (D) should be in between 1.8 to 2.1 times of top of spinning tubes (d). If the value d:D is too small a high traveller strain occurs, causes the high traveller wear and end breakages will increases. If the

- 3. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 3 value d:D is too large, it will results in disturbance of the yarn balloon and increased yarn hairiness and end breakages. 3. Tube length : - The ring diameter (D) should be maximum 1/5th of the spinning tube length (H). If a too long bobbin or spindle is chosen (e.g. H = 5.5 x D), the yarn balloon will contact the tip of the bobbin. Besides increased end breakages a worse yarn quality will be produced. 4. Balloon control ring : - The balloon control ring should be 2 – 3 mm larger than the ring diameter. If the balloon control ring is too big, it will not fulfill its job of the releasing the yarn balloon. 5.Yarn Count & twist rate : - The spinning geometry is determined by the yarn count and twist rate. Coarser count & low twist yarn run with lower delivery rate, followed with lower spindle speed, hence large ring diameter, 2 flange rings with long spinning tube is suitable for it. While fine counts & high twist yarn produces at high delivery rate & spindle speed followed with high traveller speed, which can be obtained only at small size ring diameter, single flange & with short tube length. If you selected a higher ring diameter against recommended ring diameter for a particular count, then to get the desire production level your traveller speed will be very high at same spindle speed and resultant end breaks rate & yarn hairiness will be very high, which ultimately causes the reduction in production with worse quality yarn. Hence to get the desire production rate with quality an optimum ring diameter to be selected for a particular count range. Fig.1, demonstrate the selection of ring diameter according to count pattern & traveller speed. Table .1 : Shows the spinning data w.r.t. spinning geometry. Table .1 : - Spinning data independence on the spinning geometry. Sr. No. Description

- 4. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 4 1 Count (Ne) 30sCH 30sCH 30sCH 30sCH 2 Twist per inch 19.5 20.5 21.5 22.5 3 Ring Diameter (mm) 38 42 45 50 4 Bobbin Length 180 210 230 250 5 Spindle Speed (RPM) 20000 17500 16000 13500 6 Traveller Speed (m/s) 39.8 38.5 37.7 35.3 7 Delivery Speed (M/Min.) 26 22.8 20.8 17.6 8 Cop weight (Gms.) 45 65 85 125 Conclusion : - The selection of Ring flange is mainly depend upon the yarn diameter or yarn count. 2 flange rings to be selected for count range below 20sNE for heavy and bigger size traveller raceway, while single flange rings to be selected for count range above 20sNE for getting higher productivity, better Quality and ring & traveller life. Following factors to be taken into consideration at the time of selecting ring diameter : - 1. Ring diameter can be chosen 25 mm smaller at a maximum with regard to the spindle to spindle gauge. 2. Ring diameter should be 1.8 to 2.1 times with top of spinning tube diameter. 3. Ring diameter should be 1/5th of the spinning tube length. 4. Ring diameter should be 2 – 3 mm less as compared to balloon control ring. 5. Finally count pattern & require traveller speed to be considered for selecting Ring diameter. Following table - 2 may be helpful for selecting the ring diameter according to expected traveller speed & count range : - Table -2 : Recommended Ring diameter according to count range & traveller speed. Ring Diameter (mm) Expected Maximum Traveller Speed (m/s) Suitable Count Range (Ne) 51 / 48 mm 25 to 32 6s to 20s 45 / 42 mm 30 to 40 16s to 40s 40 / 38 mm 35 to 42 24s to 80s 36 mm 30 to 42 70s & above Question – 2 : How Ring travellers affect the yarn Quality & downstream processes?

- 5. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 5 Ans. : A ring traveller plays very important role in ring spinning system. It is not only important for yarn production while it is also important for yarn Quality. Following Quality parameters directly affects with ring traveller : - 1. Yarn Hairiness : - Yarn hairiness is directly influenced by ring traveller. Following are the reasons to increase yarn hairiness due to ring traveller : - a. Low bow Ring traveller causes high hairiness; hence to reduce the yarn hairiness higher bow height travellers should be selected. b. Lighter weight ring traveller : - Usually to get the higher spindle speeds spinners selects lighter weight ring traveller which causes high hairiness, hence to overcome the hairiness problem in yarn heavier ring travellers to be selected. c. Burn out Ring traveller : - Burn out ring traveller also causes hairiness problem, hence traveller changing schedule should be followed strictly and exact cause of ring traveller burn out to be analyzed and rectified. 2. Neppy yarn : - Problem of neppy yarn observed with burn out ring travellers, which may be overcome by either replacing the defective rings or by reducing the ring traveller life. 3. Low Elongation : - Heavier ring traveller causes low yarn elongation, which may be avoided by selecting right weight ring traveller. 4. Higher breaks in downstream processes : - Lighter weight ring traveller allow to pass weak yarn to next processes where it occurs breaks and causes low efficiency, hence for a good quality yarn, weight of ring traveller to be selected in such a manner where weak yarn should break at ring frame stage itself. Burn out travellers also causes thin & weak places in yarn. 5. Higher classimat faults & Winding cuts : - High hairiness, neppy yarn, low elongation, weak yarn, higher end breaks either due to defective ring traveller or due to wrong selection of ring travellers resultant into higher classimat faults &

- 6. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 6 winding cuts which again increases yarn joints and ultimately lowering the production efficiency in downstream processes with poor quality. Question – 3 : How to decide the life of ring traveller ? Ans. : The life cycle of ring traveller is important to keep the sustainable performance of ring spinning section and Quality of yarn. Following points influence on ring traveller life : - Kind of yarn (Cotton, Manmade fibre etc.) Yarn Count ( coarse – fine) Spindle Speed (RPM) & its variation. Surface condition of ring. Spinning settings i.e. lift, ABC ring & Lappet hook setting & clearance gauge etc.) Atmospheric condition (i.e. Humidity & Temperature). To decide the life of ring traveller control study should be conducted with following parameters : - Check the traveller fly out % on daily basis. Check the Ring frame breaks rate on daily basis. Check the yarn Quality parameters such as Yarn Hairiness, Elongation % & Elongation CV %, Yarn imperfection specially Neps on daily basis. Check physical condition of some ring travellers randomly selected (such as 1%) for burn travellers. These all parameters should be drawn in a control chart day wise and whenever there is any adverse deviation observed in trend that is to be marked. Study should be repeated at-least three times in different – different counts. Life of travellers should be selected just before two days from where trend of control chart deviated. Question – 4 : How to judge the burning of ring traveller ?

- 7. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 7 Ans. : The burning degree of traveller is classified by the discoloration of traveller foot part, which is caused by the friction heat. The following table gives the “burning degree” prepared from the burning colour : - Table – 3 : Traveller Discoloration & temperature at different stages of traveller burning. Burning Temperature Burning Degree Colour Traveller discoloration temperature Experiment value at traveller 0 No discoloration 1500 C 1500 C 1 Almost no discoloration 1700 C 1900 C 2 Slightly Yellow 2200 C 2550 C 3 Yellow or Gold 2250 C 2550 C 4 Red Brown 2450 C 2850 C 5 Reddish purple 2650 C 3100 C 6 Purple 2800 C 3350 C 7 Blue 3000 C 3600 C 8 Bright blue 3250 C 3800 C Source : Kanai Traveller standards. It will need considerable experience to classify the traveller burning into 9 degree as above. Therefore the burning degree is expressed by the ratio (%) of burned travellers to the total number of travellers. The burned traveller means the traveller with burning degree of 6 and more. Conclusion : - A small ring traveller is very important part of spinning mills, which may impact huge on yarn Quality & productivity of spinning mills as well as in downstream processes, hence it cannot be treated as a ignorant part and proper care to be taken while selecting ring traveller and ring traveller life. Scientific methods as explain above to be adopted to decide the ring traveller life. Judging of traveller burning is a considerable experience work and it may be judge by the discoloration of foot part of traveller. Produced by : Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC – Customer Care

- 8. Rings & Ring Travellers 2013 Produced By Mr. Sunil Kumar Sharma, Dy. General Manager – QA, PPC & Customer Care, Published in Spinning Textiles Magazine, Vol-8, Issue-3, May-June 2014 Page 8 Mobile No. : – 09552596742, 09921417107 E_mail : - sunil_ku67@yahoo.com Loknayak Jayprakash Narayan Shetkari Sahakari Soot Girni Ltd. Kamalnagar, Untawad – Hol, Shahada, Tal. : - Shahada, Dist. : - Nandurbar (MS) Pin : - 425409