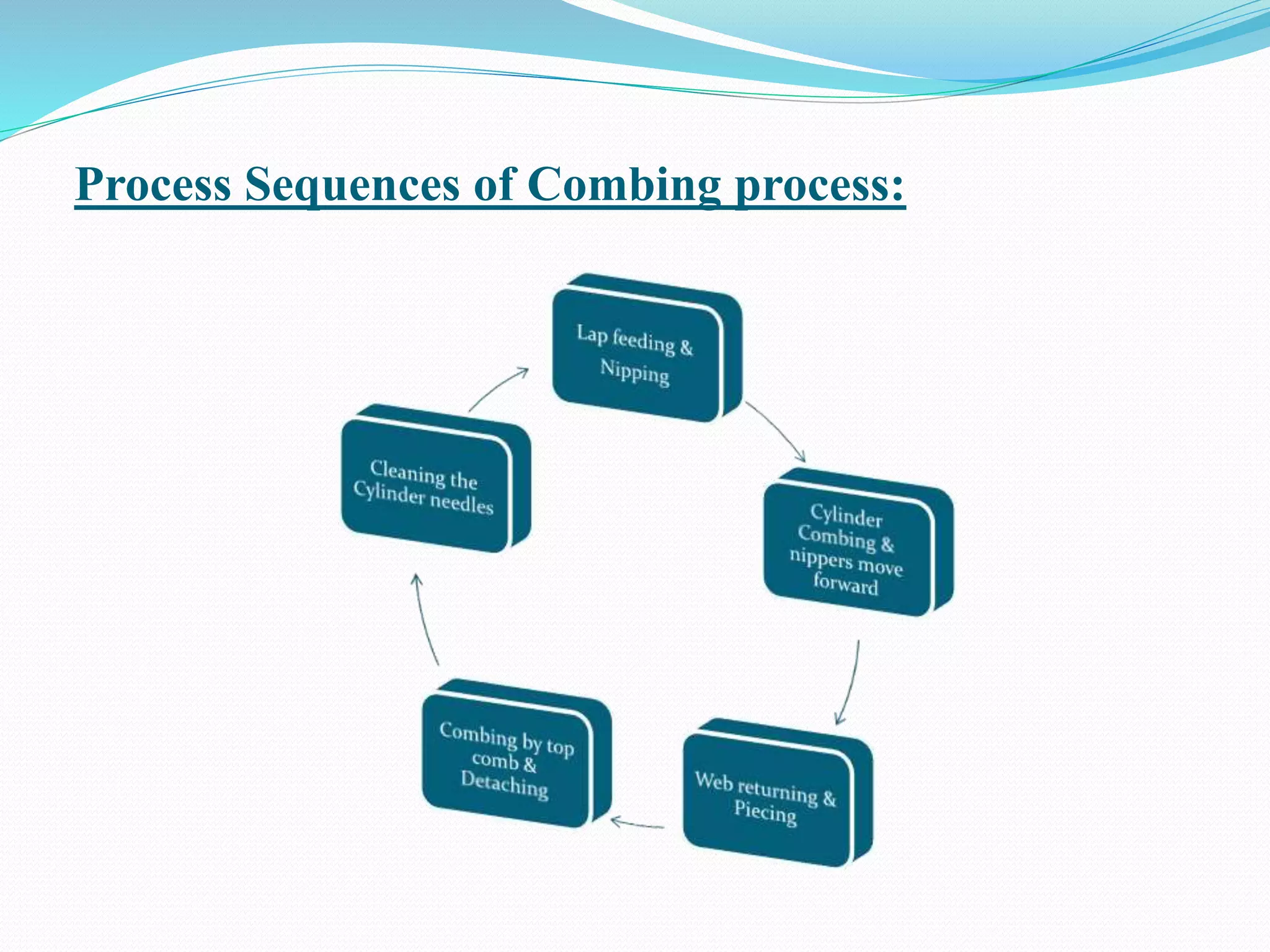

Combing is a process that improves fiber quality by removing short fibers and impurities. It produces a clean, parallel sliver. There are two types of combing feeds: forward (concurrent) and backward (counter). Forward feed has a higher production rate but lower quality, while backward feed has a lower production rate but higher quality. The document discusses combing process sequences, important terms, noil elimination theories for both feed types, and how feed length and detaching length impact noil percentage. Backward feed results in more combing action and higher quality sliver and noil than forward feed.

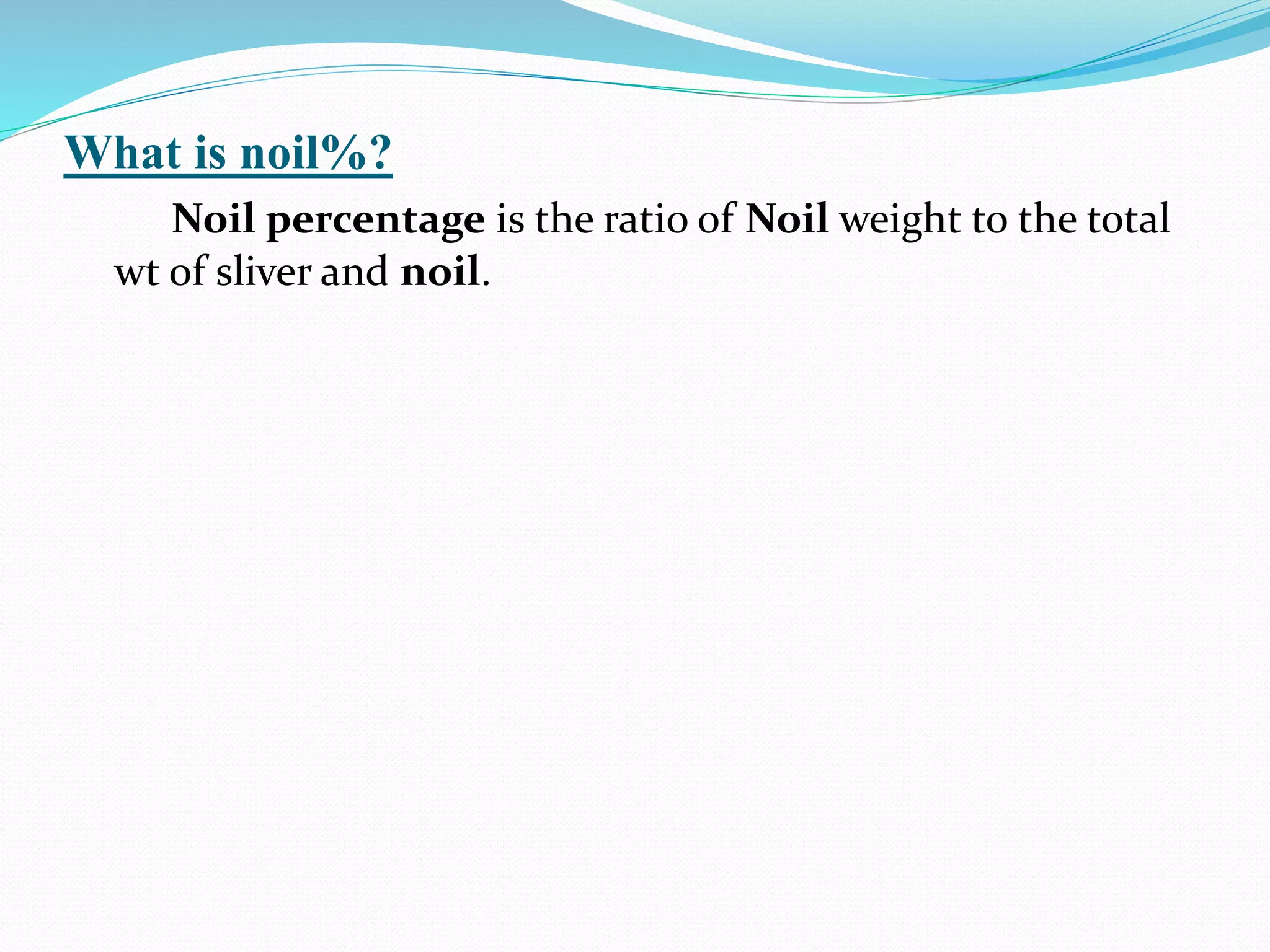

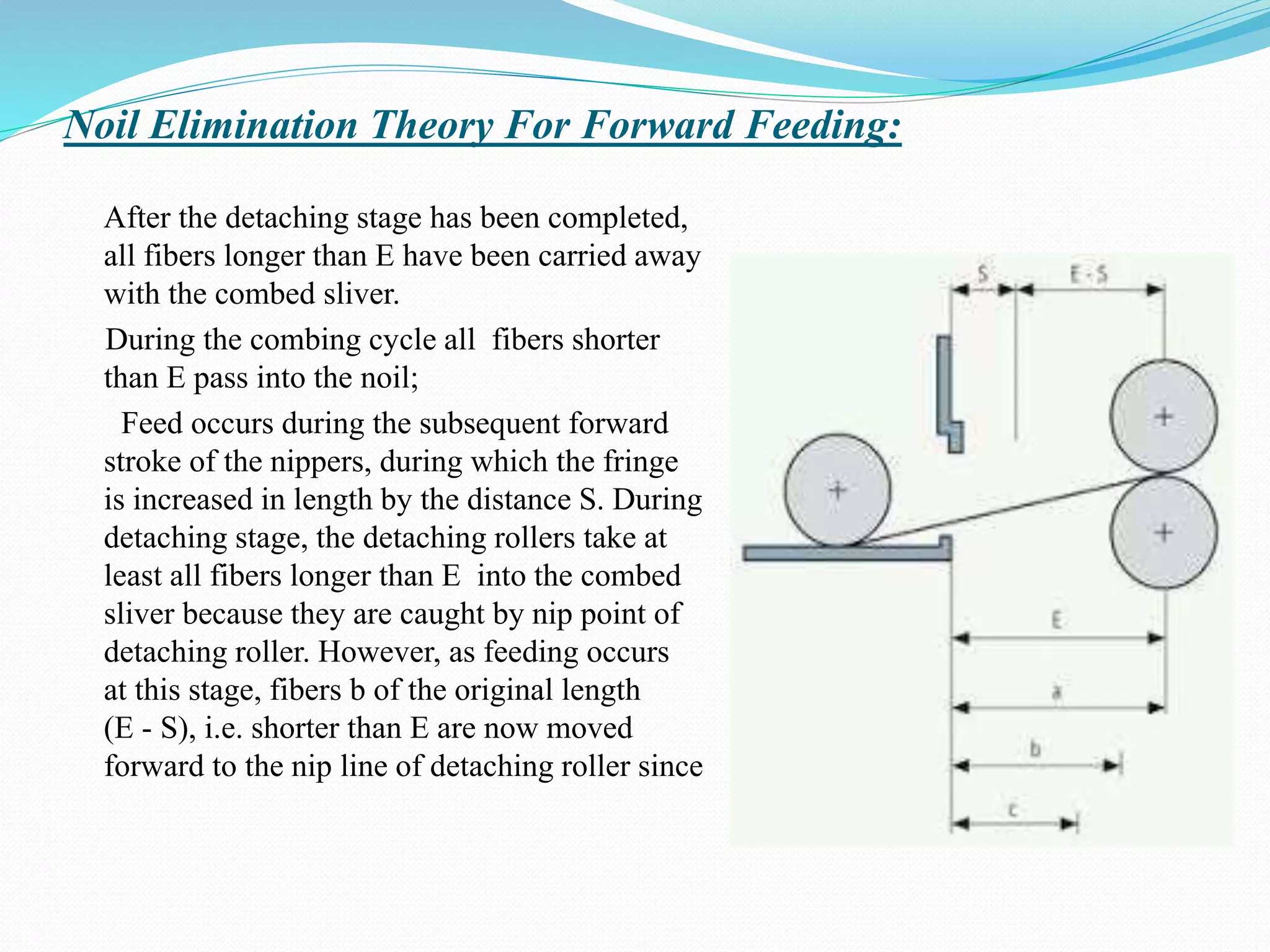

![Noil Elimination Theory For Forward Feeding:

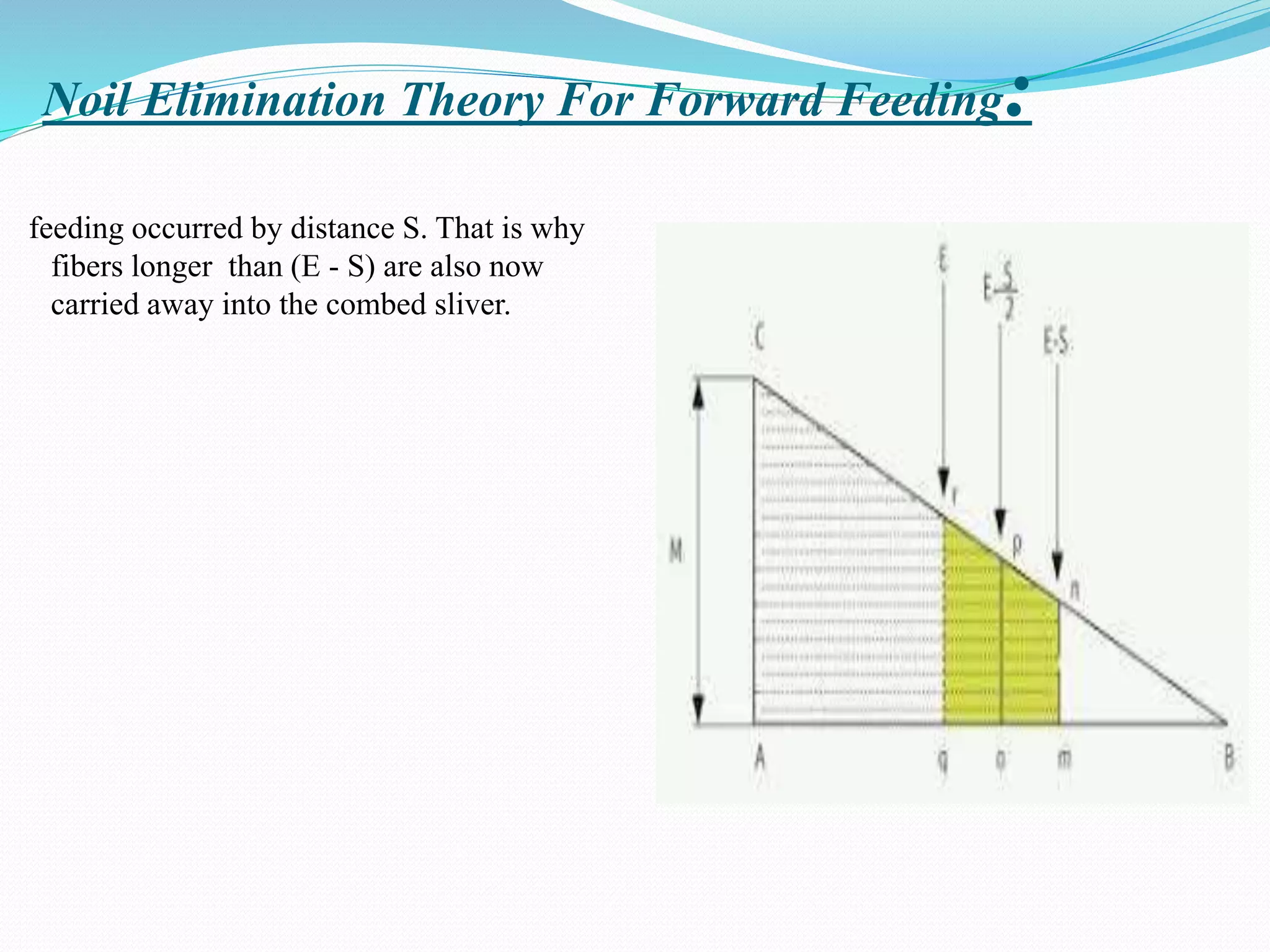

Since in similar triangles the

areas are in the same ratio as

the squares of the sides, and

since the noil percentage is

based on the ratio of weight

of waste to weight of

feedstock.

The following relationship

can be assumed:

p%=(oBp/ABC)×100

=(op²/AC²)×100

=[(E-S/2)²/M²]×100

p = noil percentage](https://image.slidesharecdn.com/presentationonforwardfeedbackwardfeedofcombing-200605181341/75/Presentation-on-forward-feed-amp-backward-feed-of-combing-18-2048.jpg)

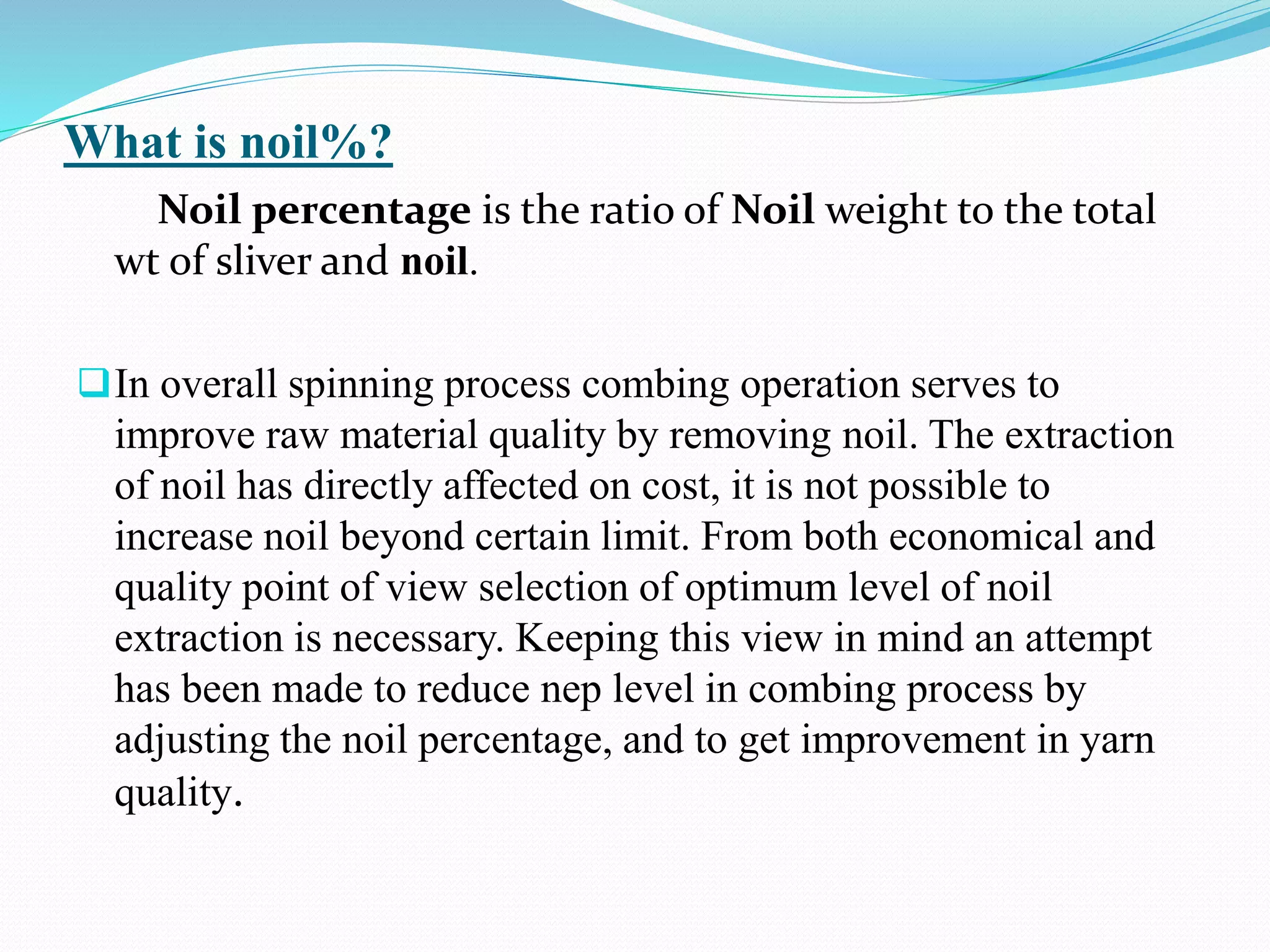

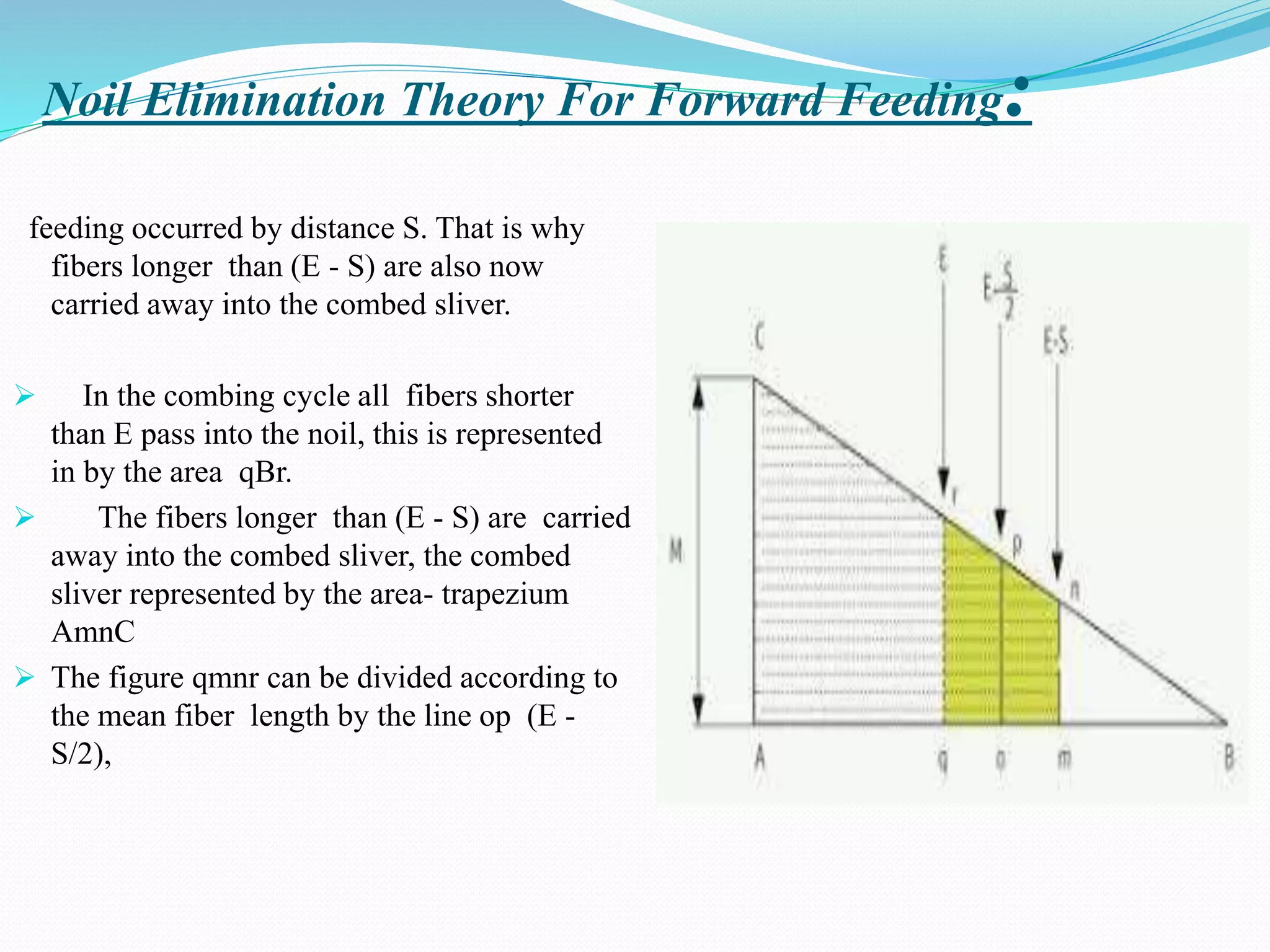

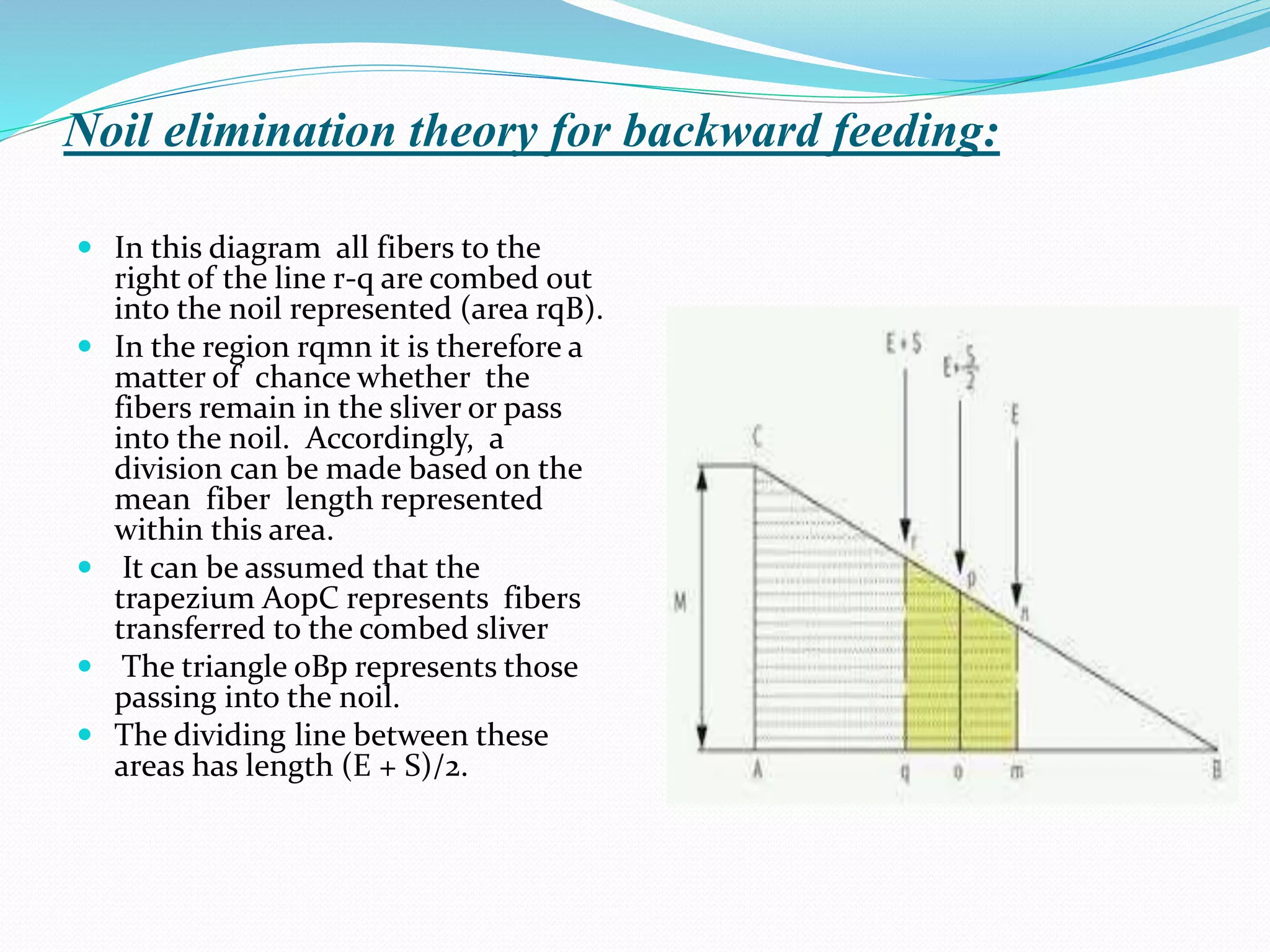

![Noil elimination theory for backward feeding:

The dividing line between these areas

has length E + S/2. Since in similar

triangles the areas are in the same ratio

as the squares of the sides, and since

the noil percentage is based on the

ratio of weight of waste to weight of

feedstock.

The following relationship can be

assumed:

p%=(oBp/ABC)×100

=(op²/AC²)×100

=[(E+S/2)²/M²]×100

p = noil percentage](https://image.slidesharecdn.com/presentationonforwardfeedbackwardfeedofcombing-200605181341/75/Presentation-on-forward-feed-amp-backward-feed-of-combing-22-2048.jpg)

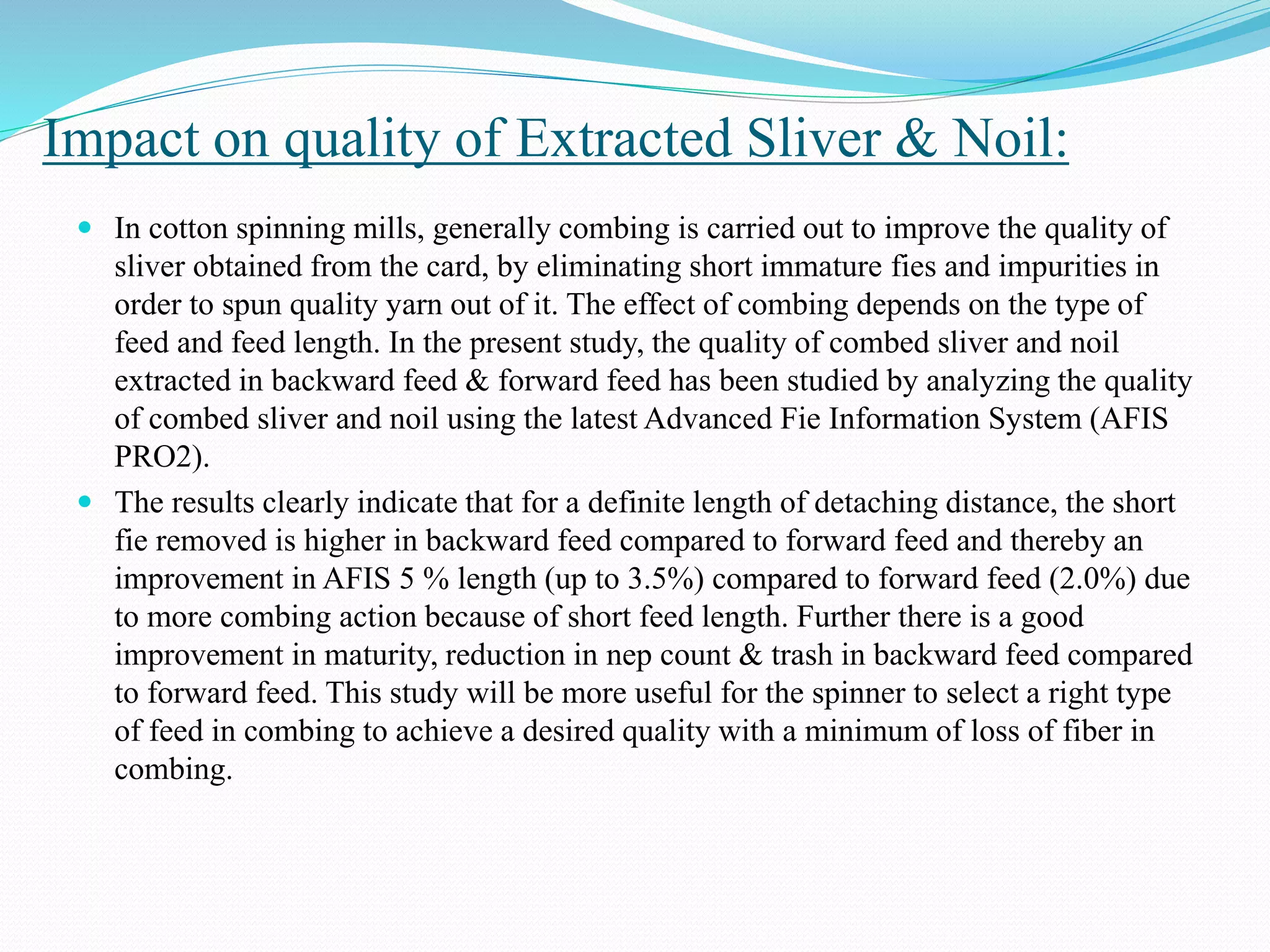

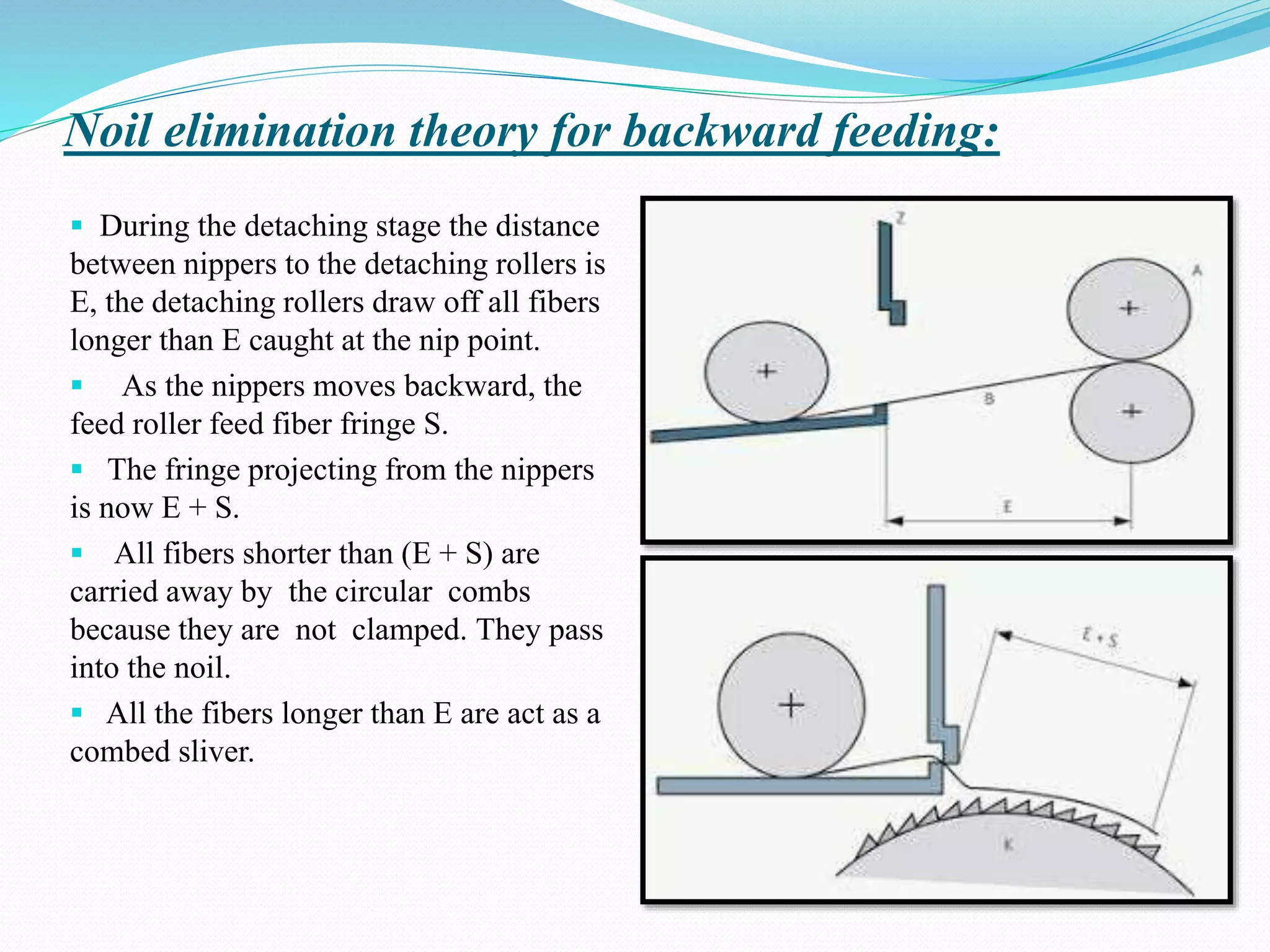

![Forward feed:-

Feeding should be completed during forward osscilation of nippers i.e. 0 to

24.

Nipper should remain in an opened state during feeding[i.e 10+2 to 34-2 or

12 to 32

Backward feed:-

Feeding should be completed during backward oscillation of nippers 24 to

40/0.

Nipper should remain in an opened state during feeding that is in between

12 to 32.

Feeding should end prior to commencement of cylinder combing process

[<35].](https://image.slidesharecdn.com/presentationonforwardfeedbackwardfeedofcombing-200605181341/75/Presentation-on-forward-feed-amp-backward-feed-of-combing-26-2048.jpg)