This document provides information about roving frames, including:

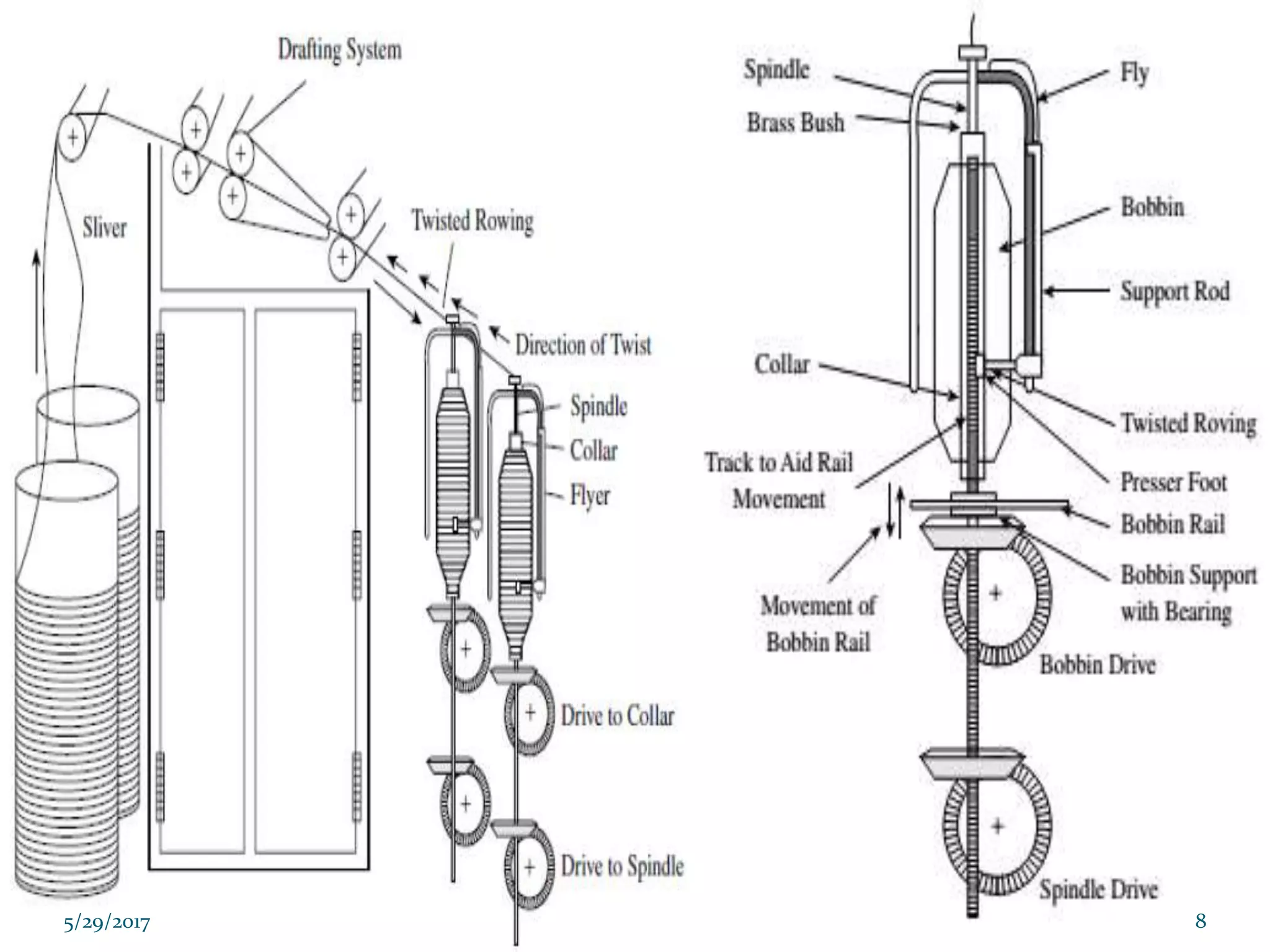

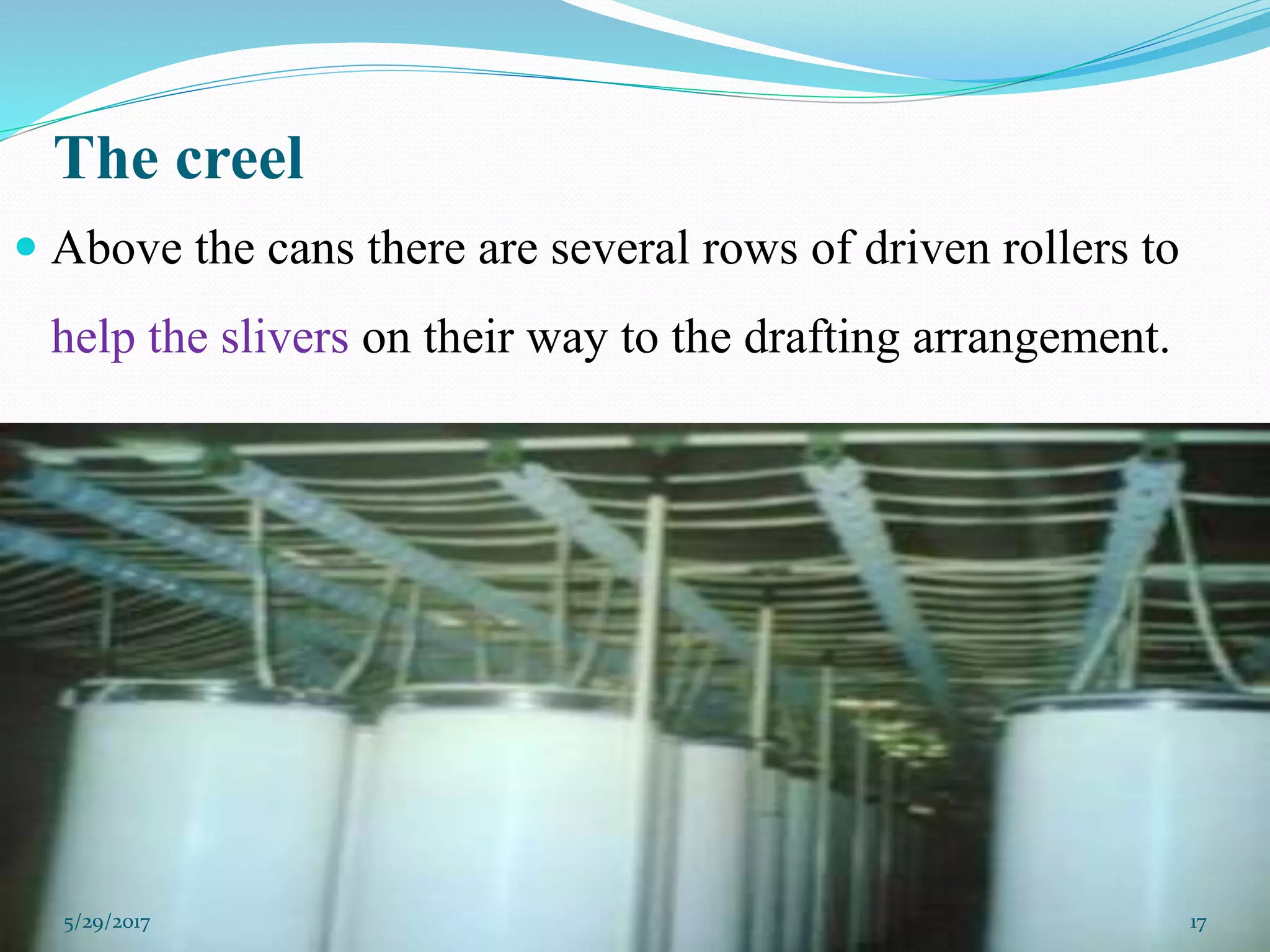

- Roving frames take sliver from draw frames and produce roved which is wound onto packages.

- They draft the sliver to a thin strand, impart twist for protection, and wind the roving onto packages.

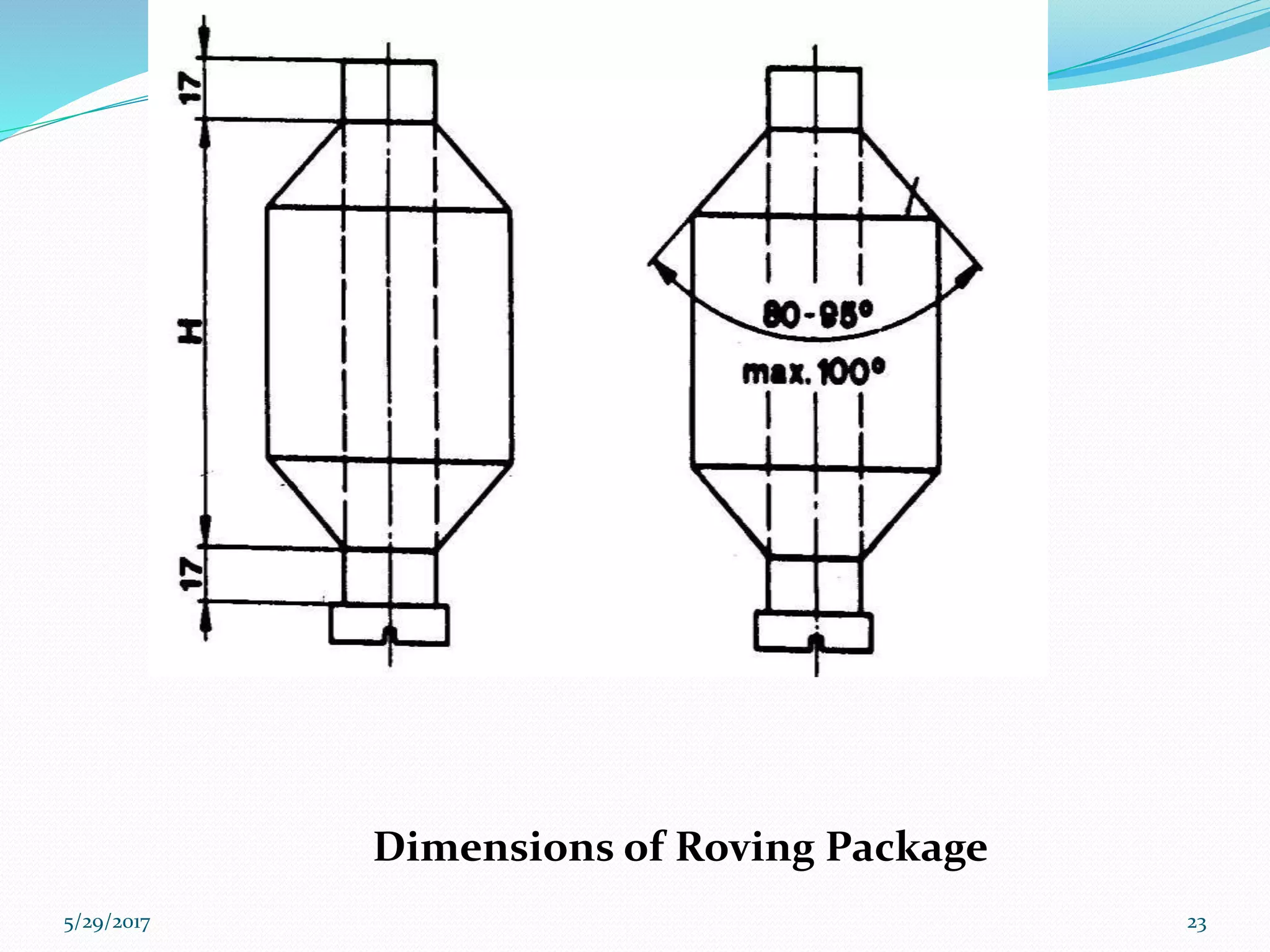

- The key components are the drafting system, flyer, and bobbin rail which winds the roving in layers onto packages.