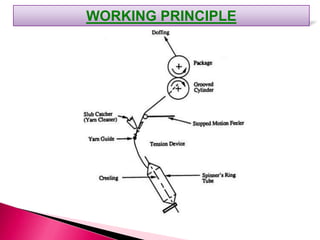

This document discusses winding, which is an important operation in the spinning section that creates large yarn packages. It describes the three zones of winding and the two types of winding: spindle drive and friction drive. It also provides details on the components of an autoconer winding machine, including the cradle, drum, magazine, tension assembly, yarn clearer, and others. The working principle and requirements of the winding process are explained.