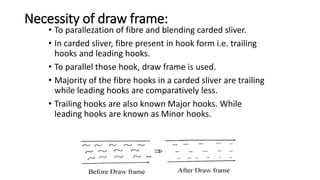

This document discusses the draw frame process for manufacturing yarn. The draw frame passes sliver through pairs of rollers to elongate and combine multiple slivers. This straightens and aligns fibers while improving uniformity. The draw frame doubles slivers, drafts them to increase length and reduce weight, and removes dust. Modern draw frames have higher speeds, better drafting systems, automatic functions, and monitoring systems to improve quality and efficiency in the yarn manufacturing process.