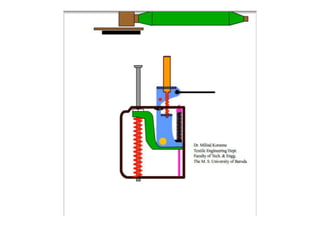

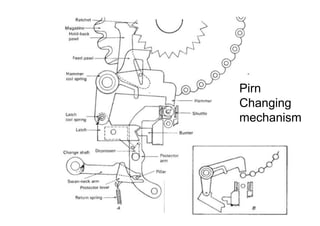

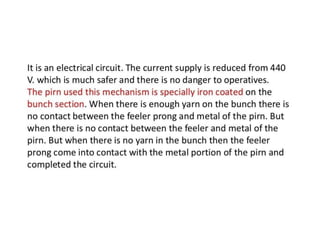

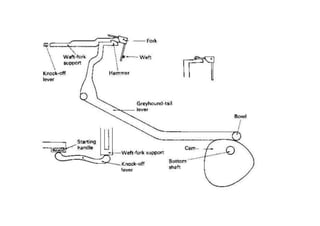

The document summarizes the working principle of the changing mechanism on an automatic conventional weaving loom. It describes that when the feeler detects there is no yarn left on the pirn, it causes a slight rotation of the changing shaft. This engages the bunter, which pushes the bunter lever and presses the pirn with a hammer to change it. The new full pirn is then positioned in the shuttle from the circular magazine mounted on the right side of the loom, which can hold 24-30 pirns.