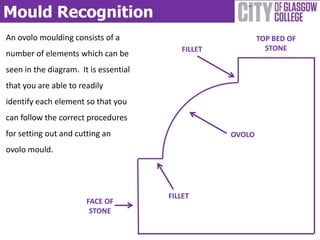

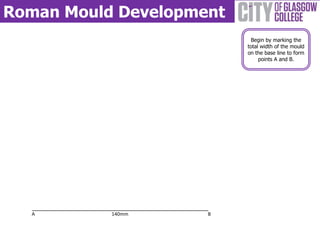

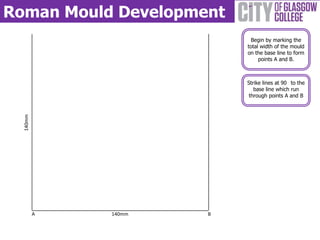

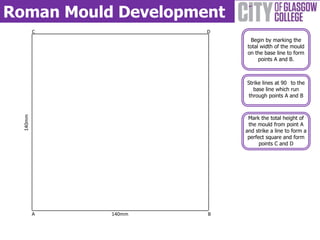

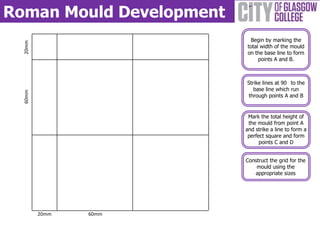

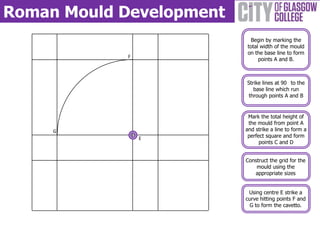

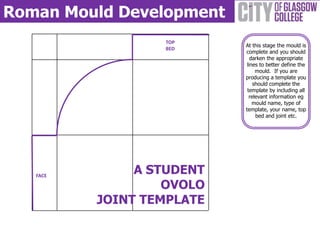

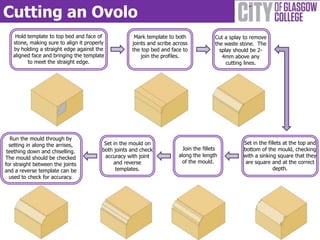

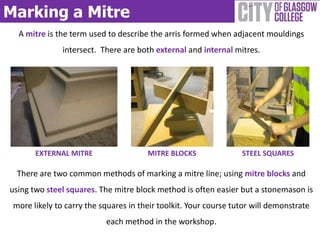

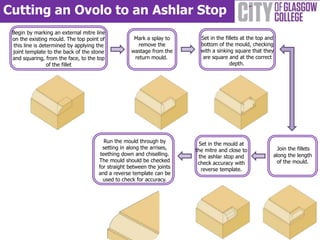

This document provides a detailed guide for stonemasons on how to cut an ovolo mould, including specific measurements and techniques for proper marking and shaping. It covers the necessary steps for creating templates, checking accuracy, and understanding mitres, both external and internal. The instructions are intended to ensure precise construction of stone moulds for masonry work.