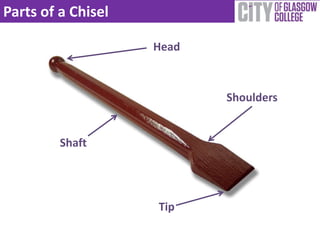

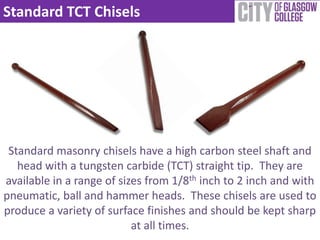

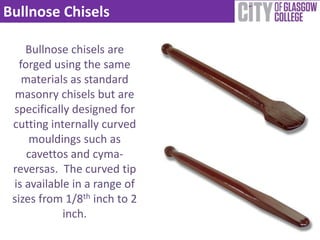

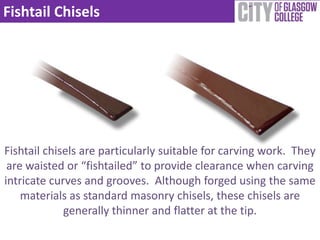

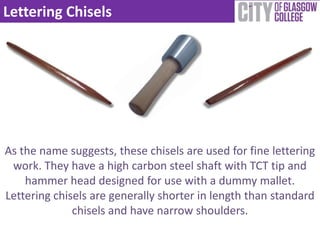

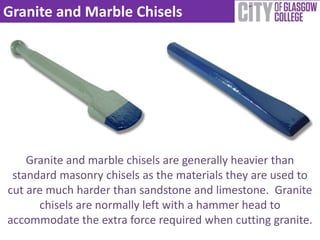

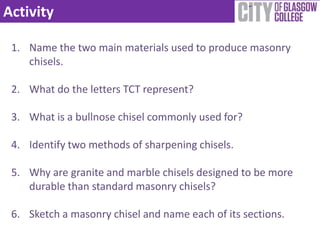

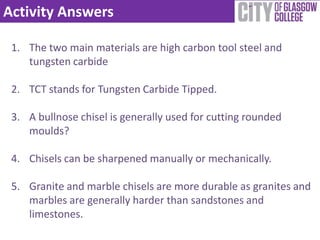

This document provides information about masonry chisels. It describes the parts of a chisel including the head, shoulders, and shaft. Chisels are typically made of high carbon tool steel with a tungsten carbide tip. Different types of chisel heads and uses are outlined, including standard, bullnose, fishtail, and lettering chisels. Granite and marble chisels are designed to be more durable due to the hardness of those materials. Chisels can be sharpened manually or mechanically using grinding wheels or diamond sharpening blocks.