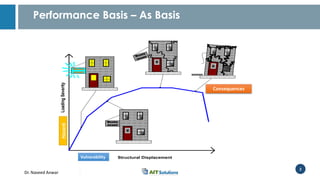

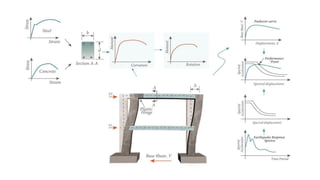

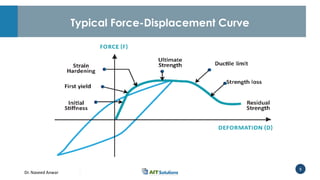

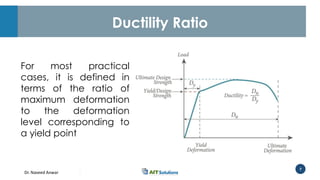

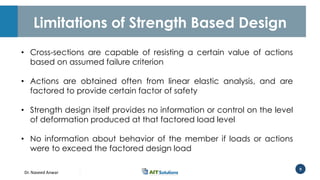

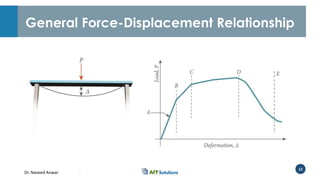

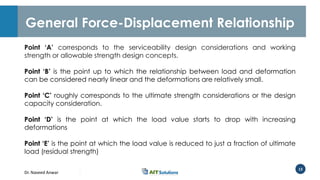

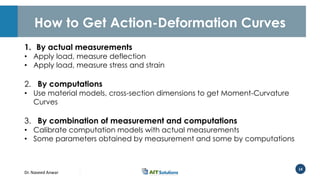

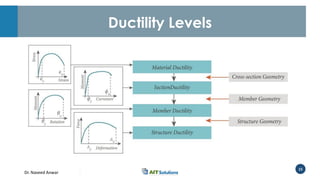

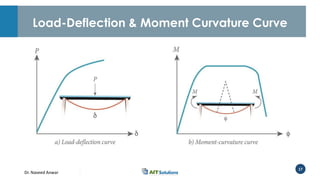

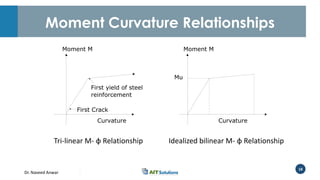

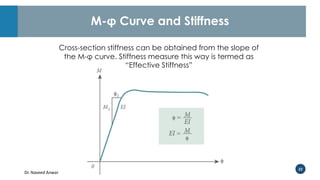

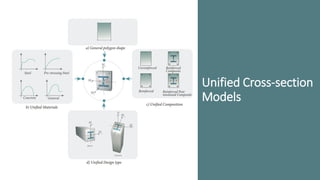

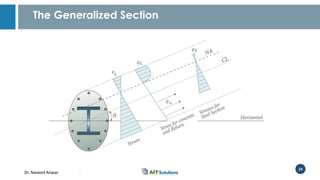

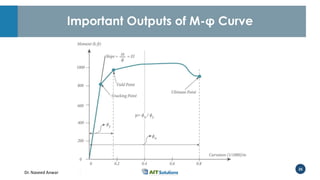

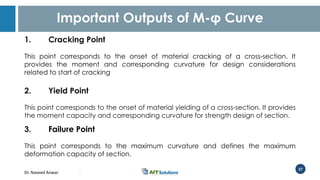

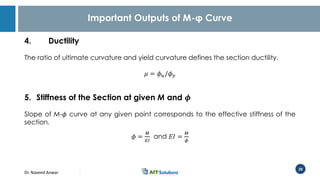

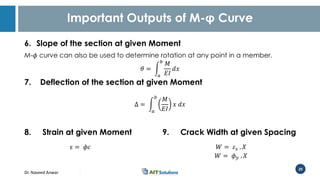

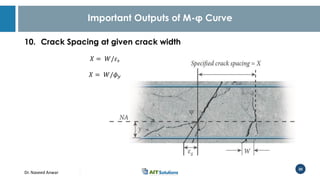

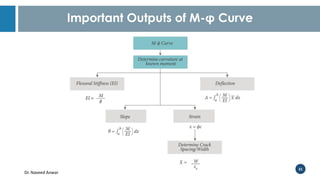

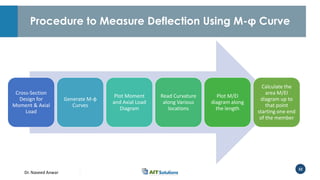

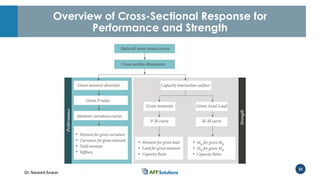

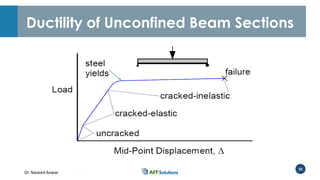

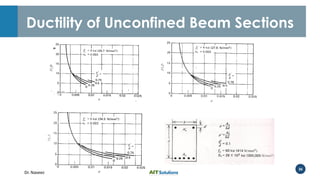

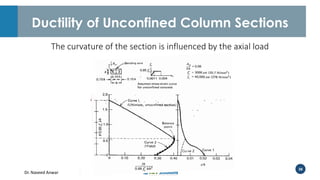

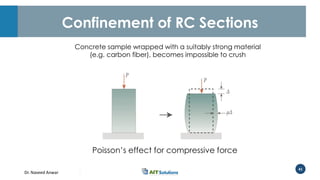

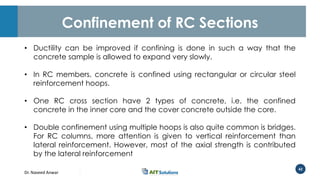

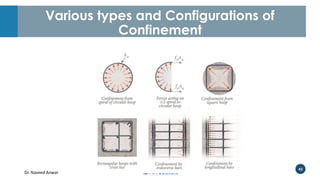

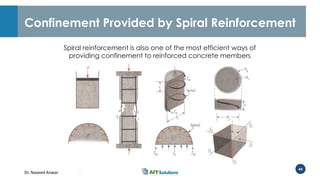

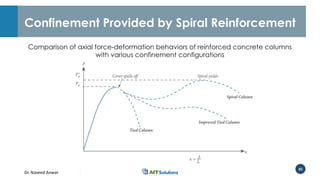

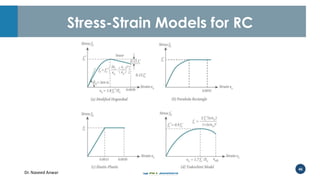

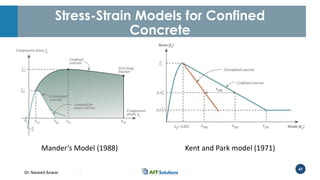

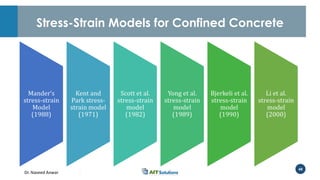

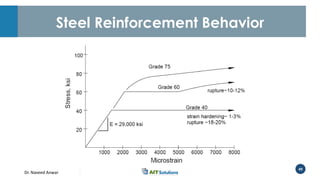

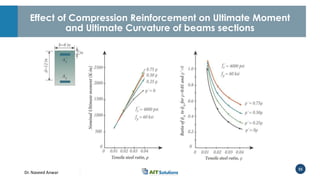

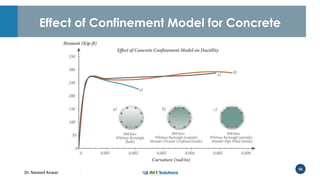

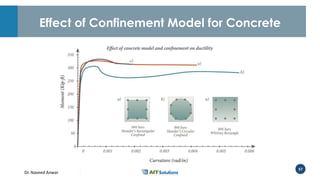

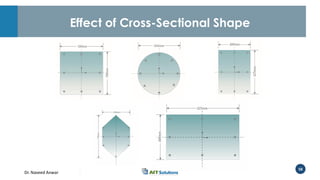

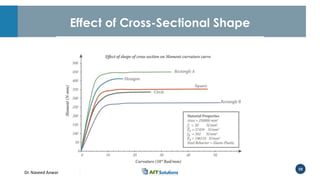

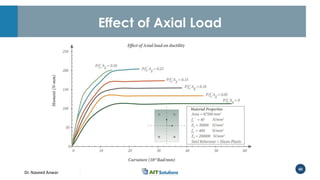

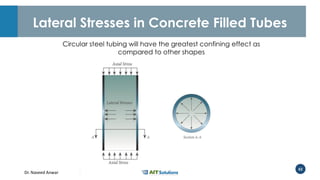

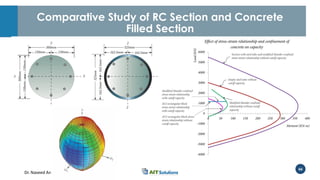

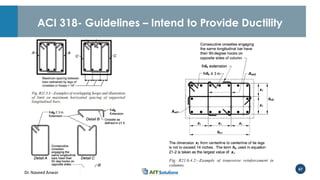

Dr. Naveed Anwar emphasizes the critical role of ductility in the structural performance and seismic design of tall buildings, highlighting its significance in performance-based design. The document discusses the relationship between various force-deformation curves, the importance of moment-curvature relationships, and the effects of confinement on ductility in reinforced concrete structures. It also reviews the limitations of strength-based design and outlines how ductility can be enhanced through appropriate design methodologies and detailing.