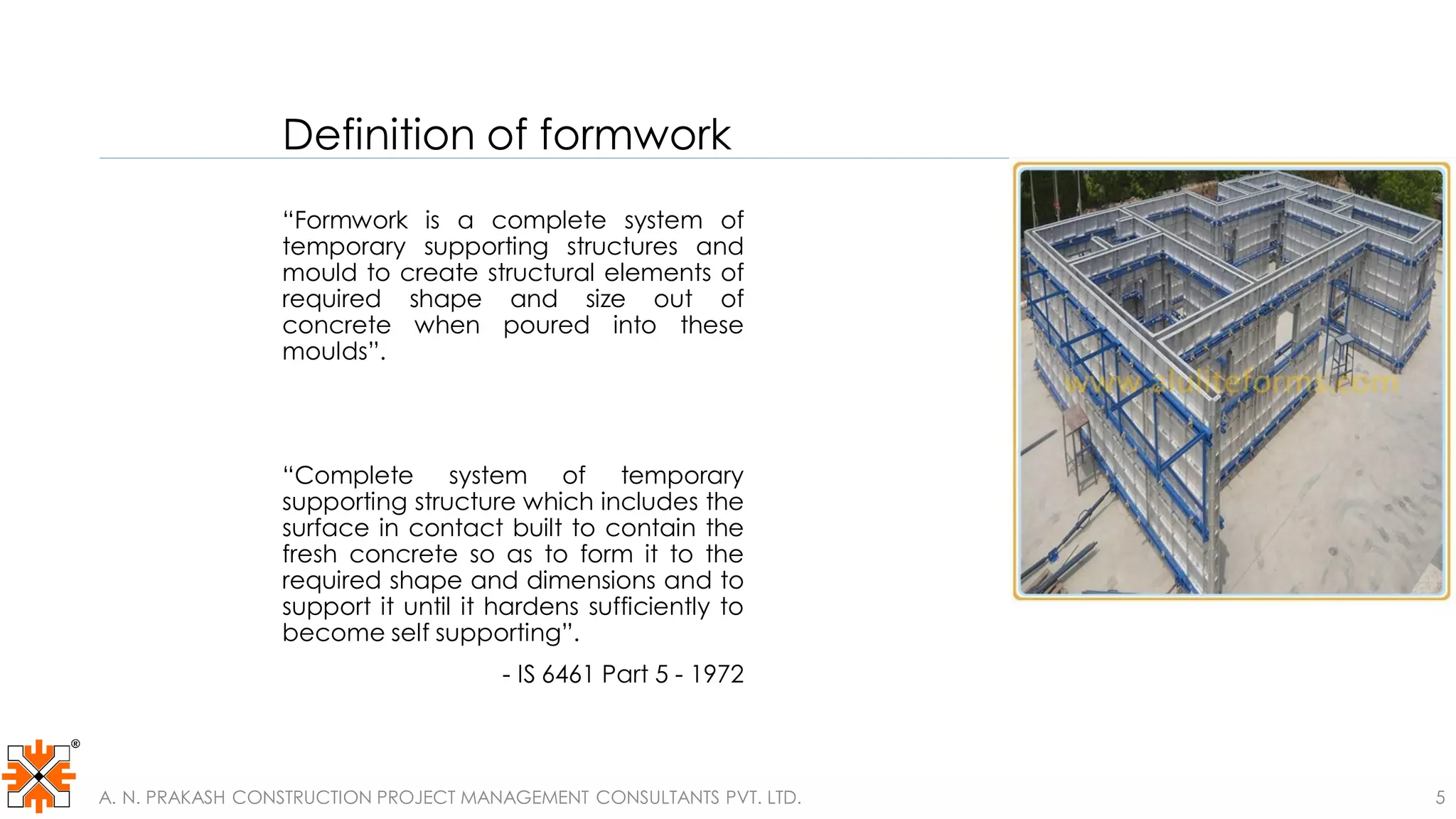

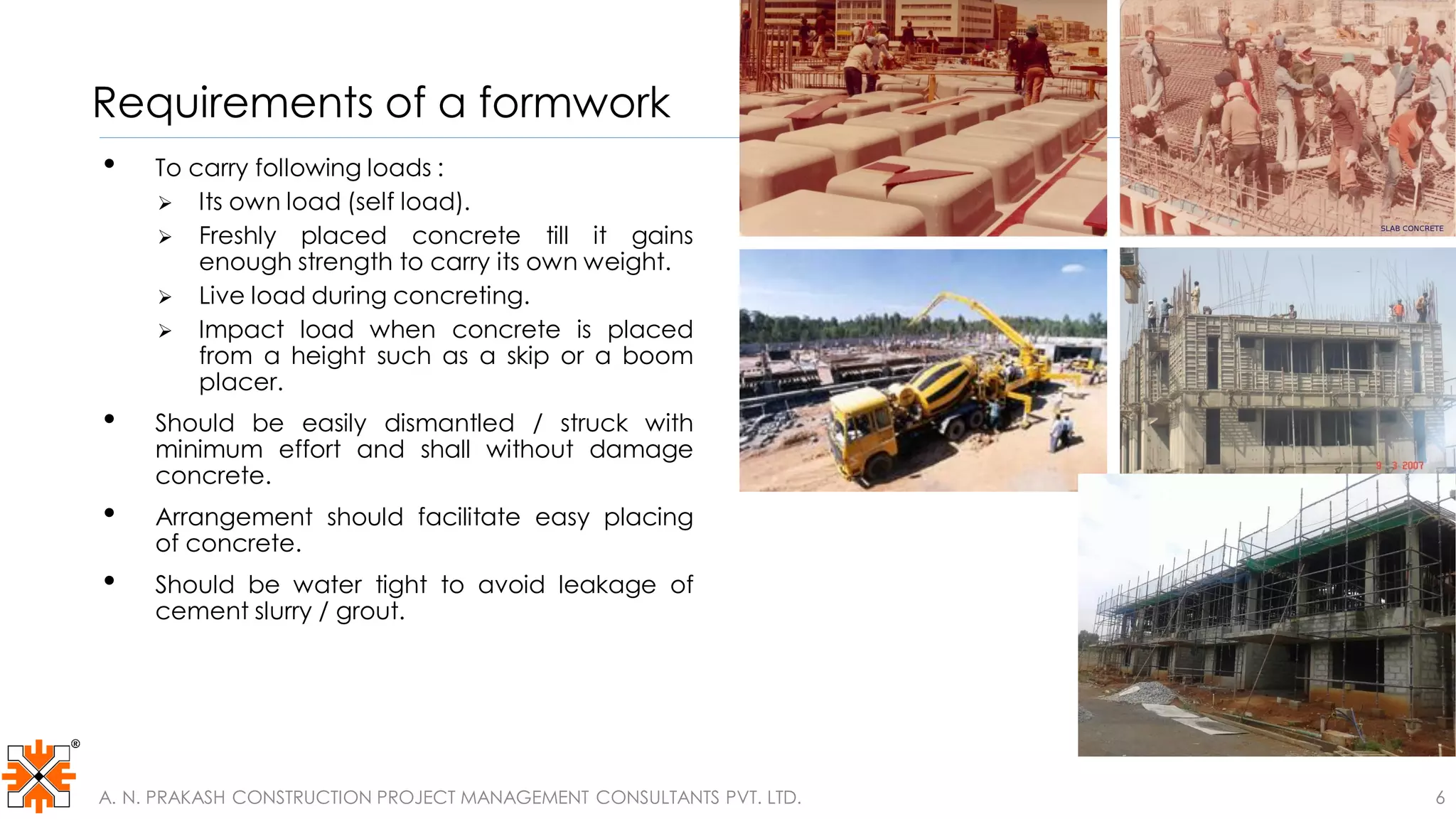

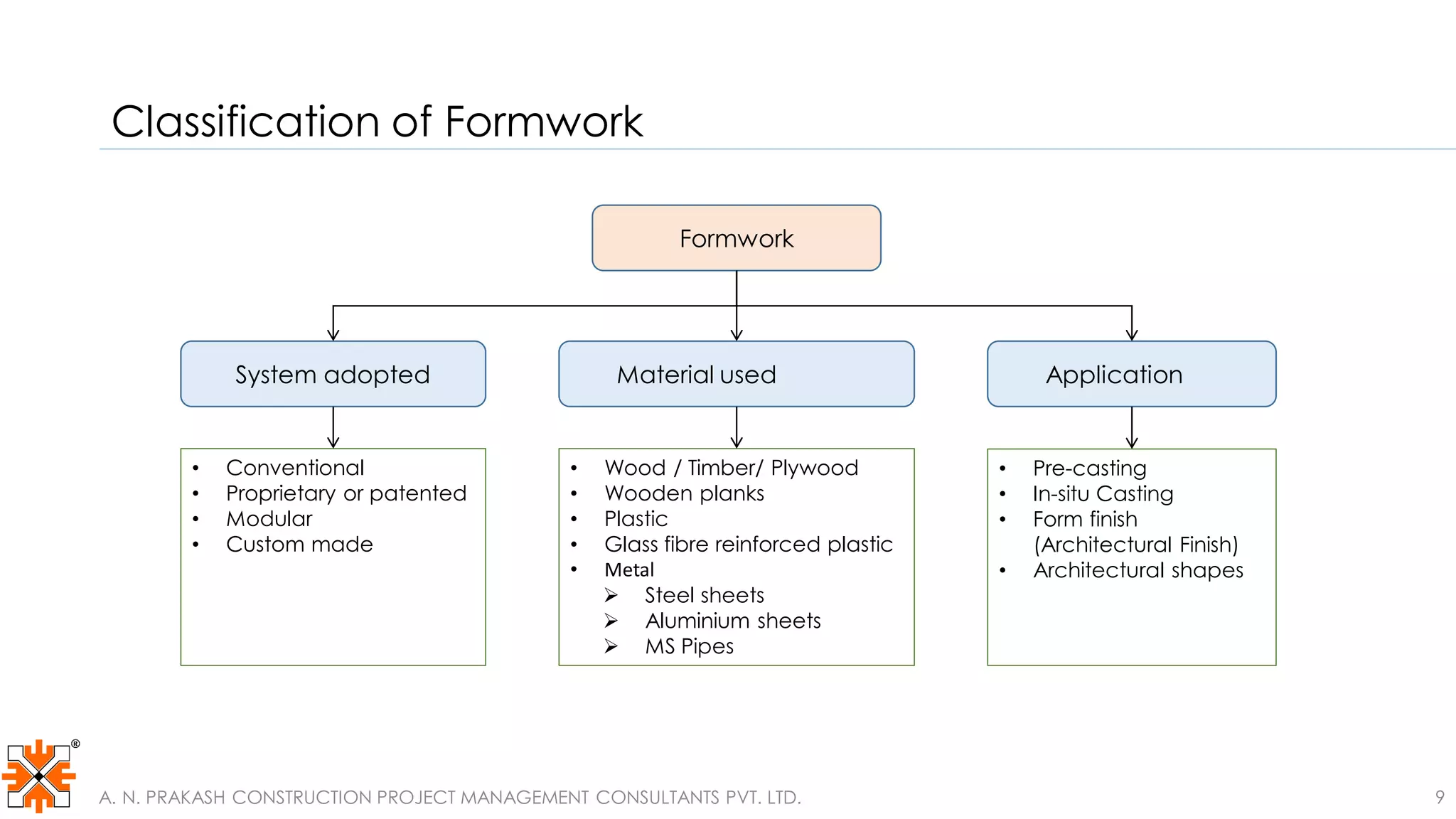

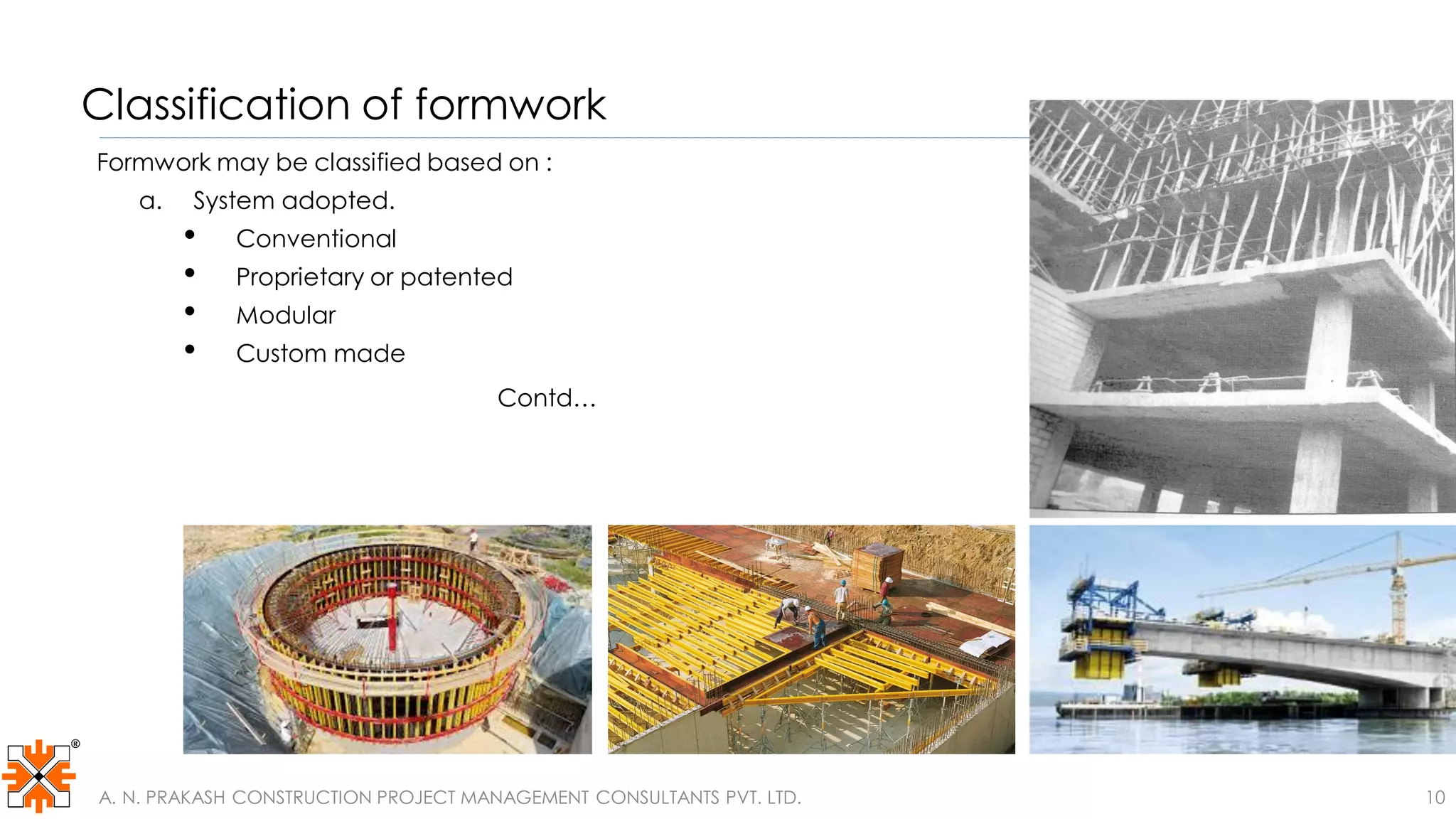

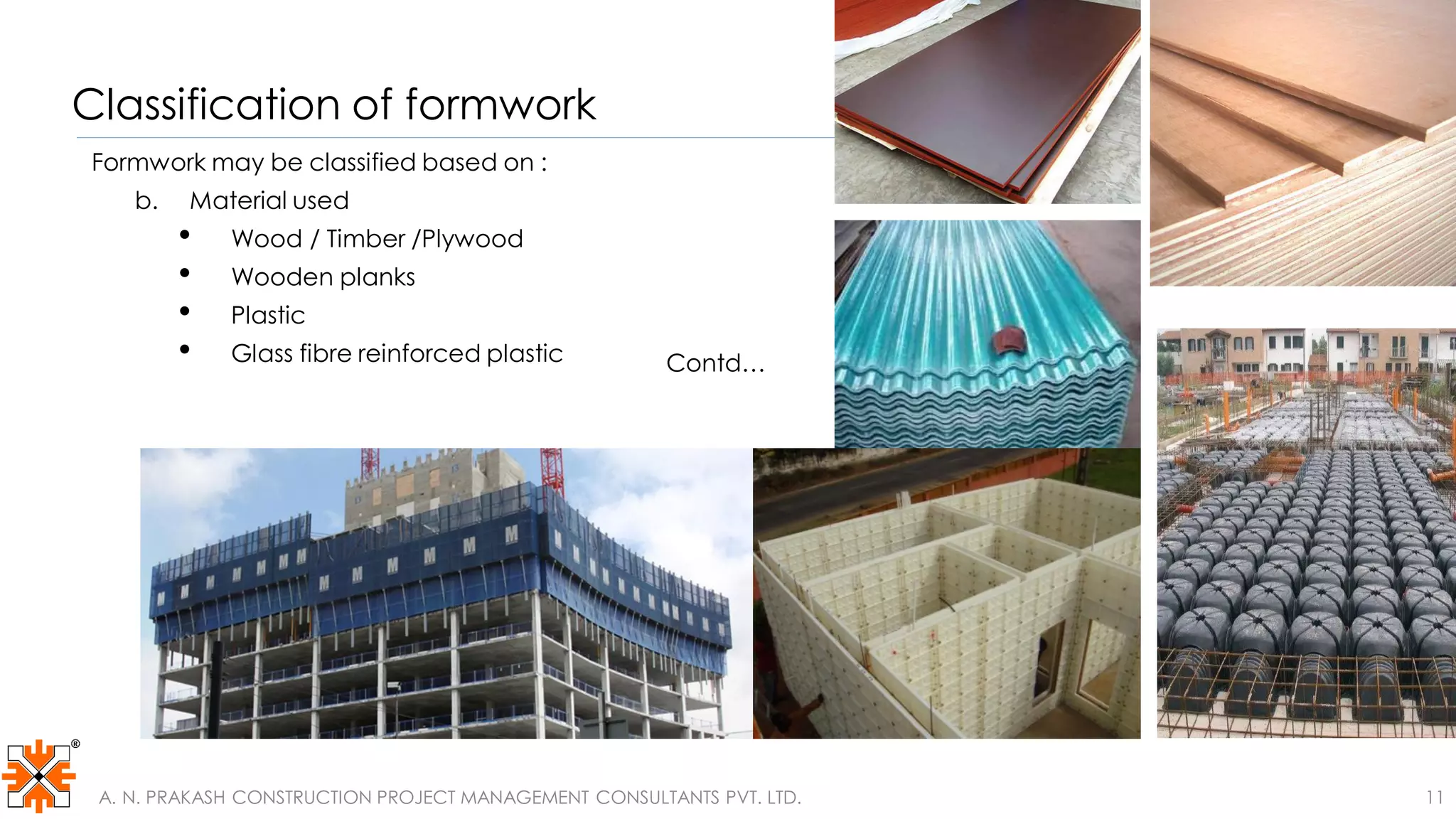

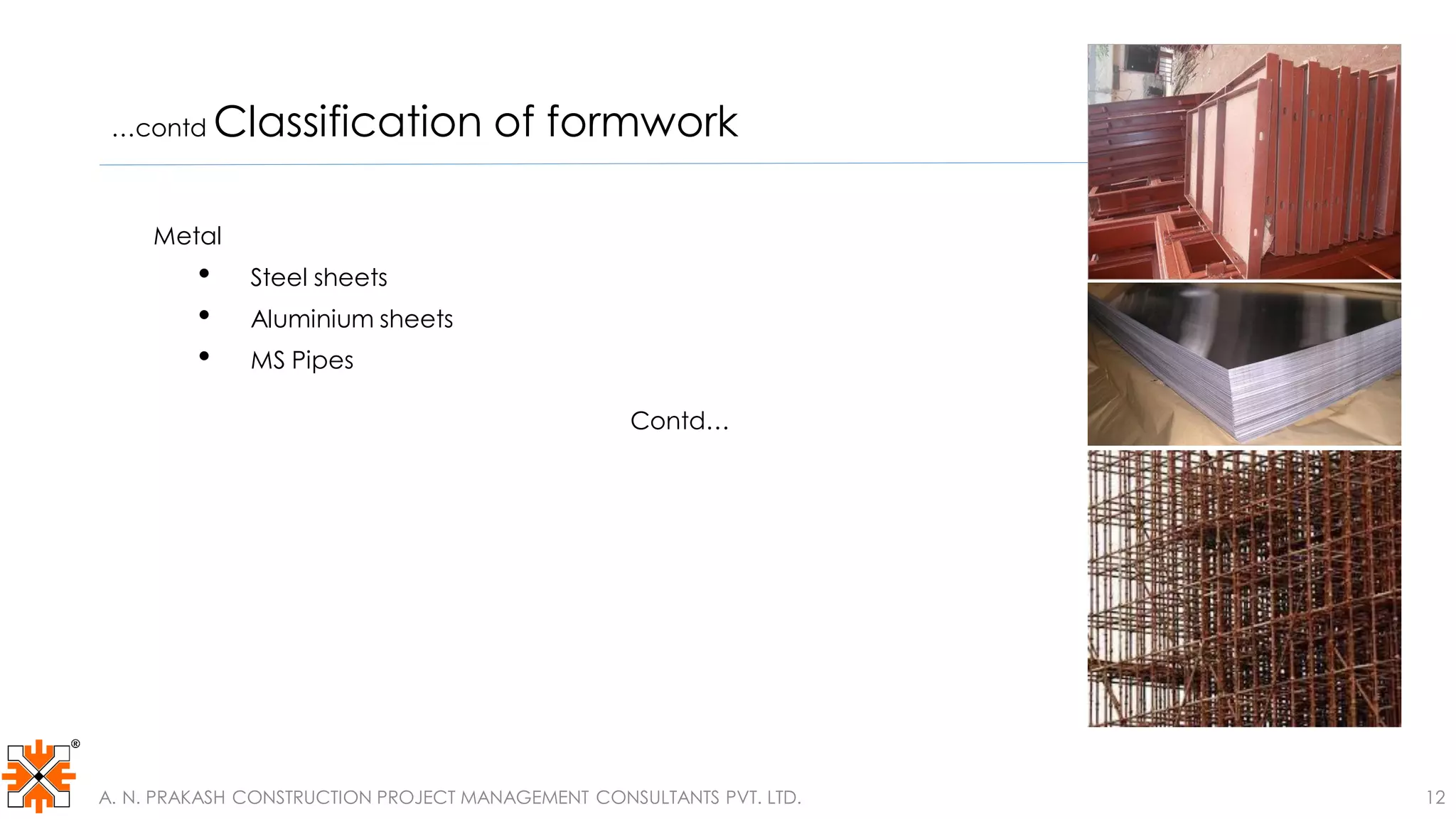

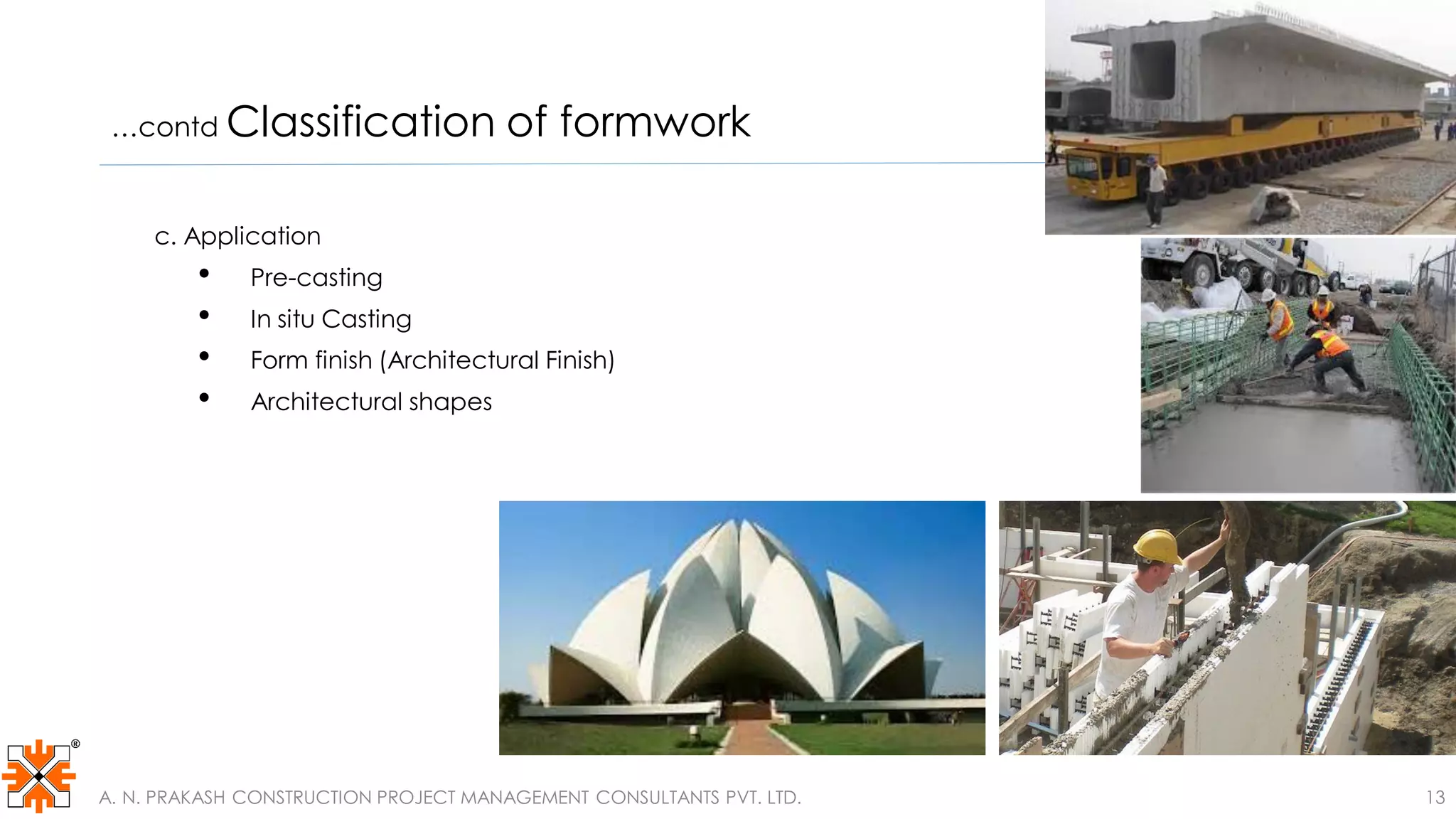

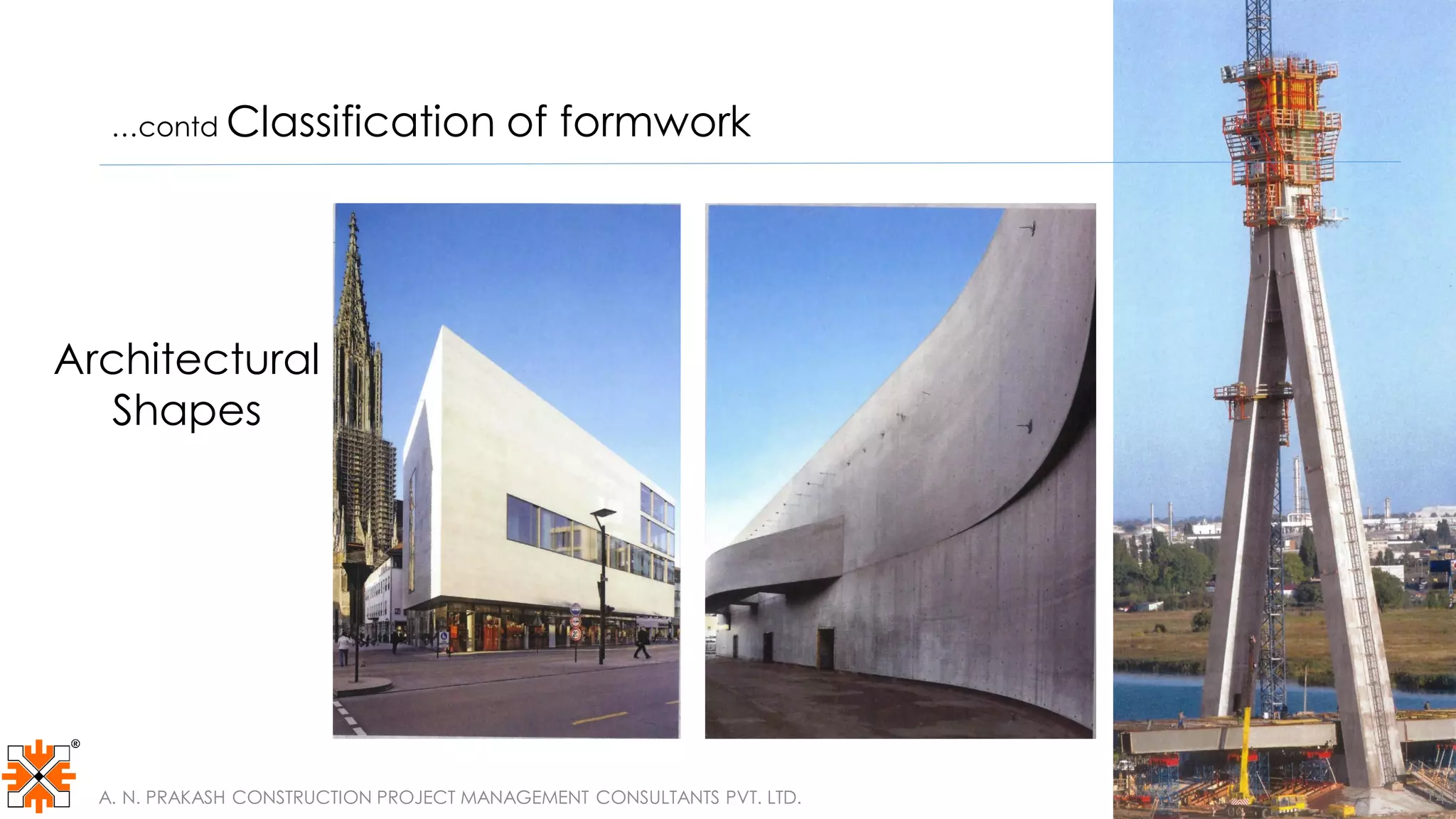

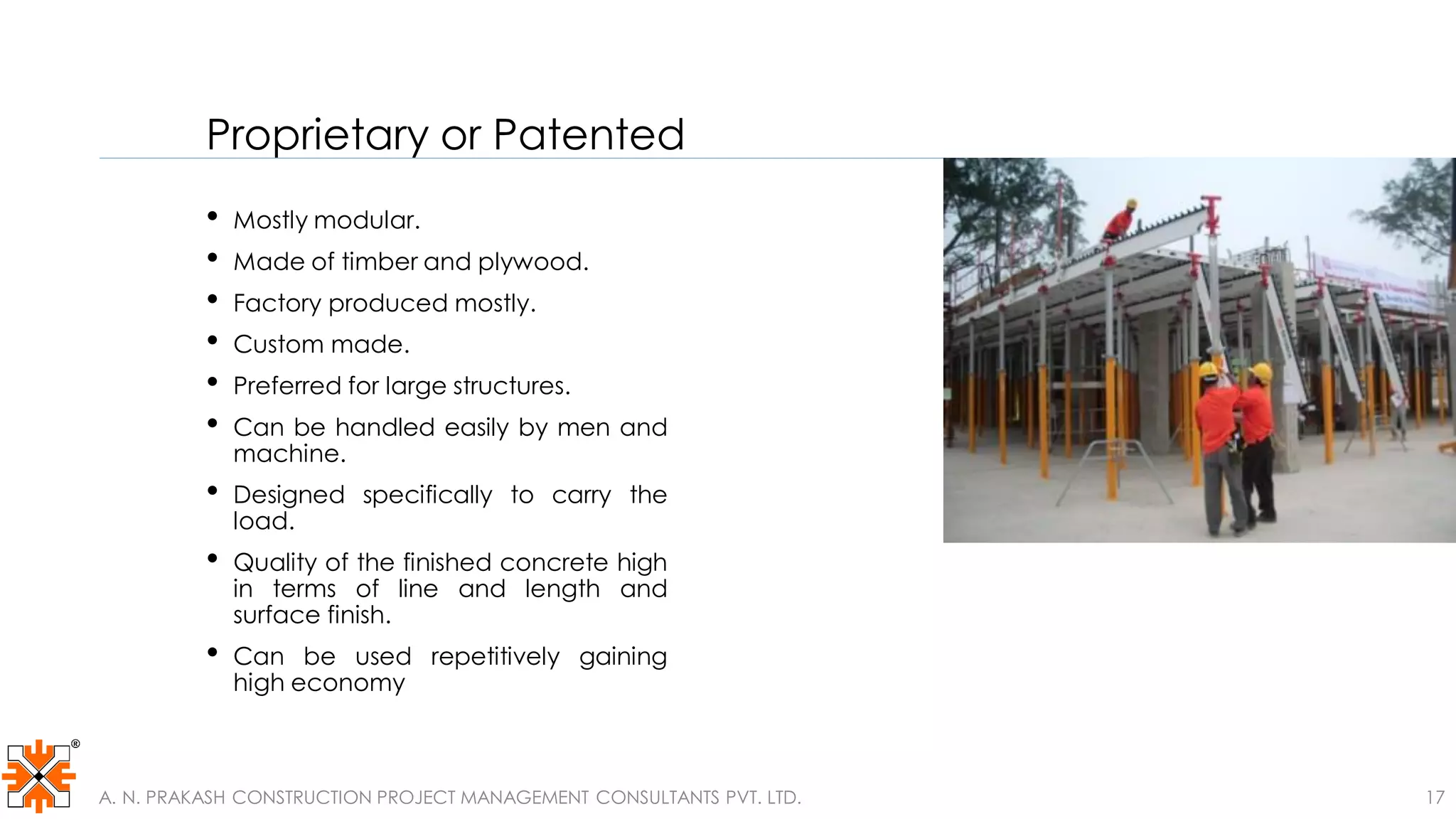

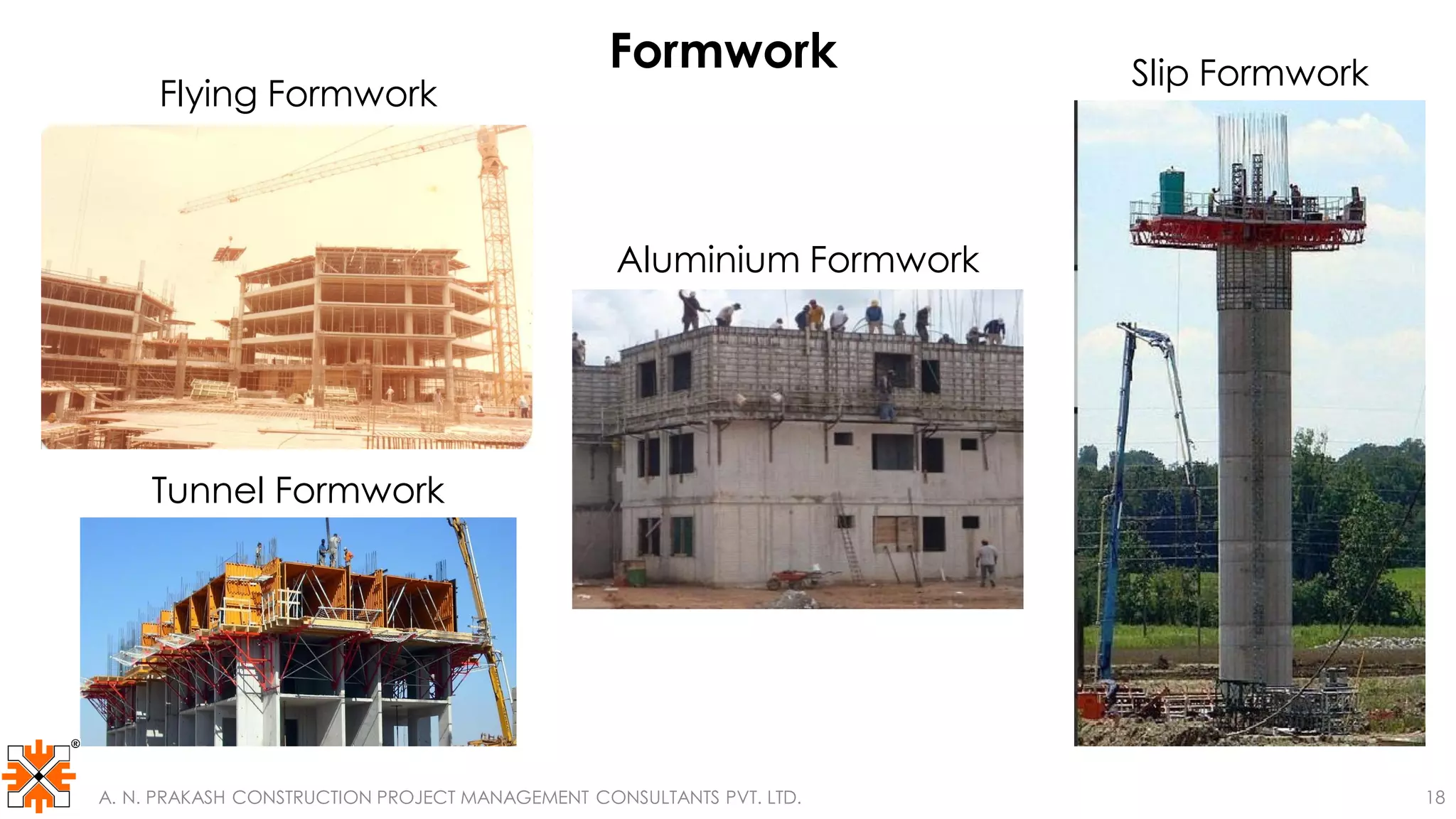

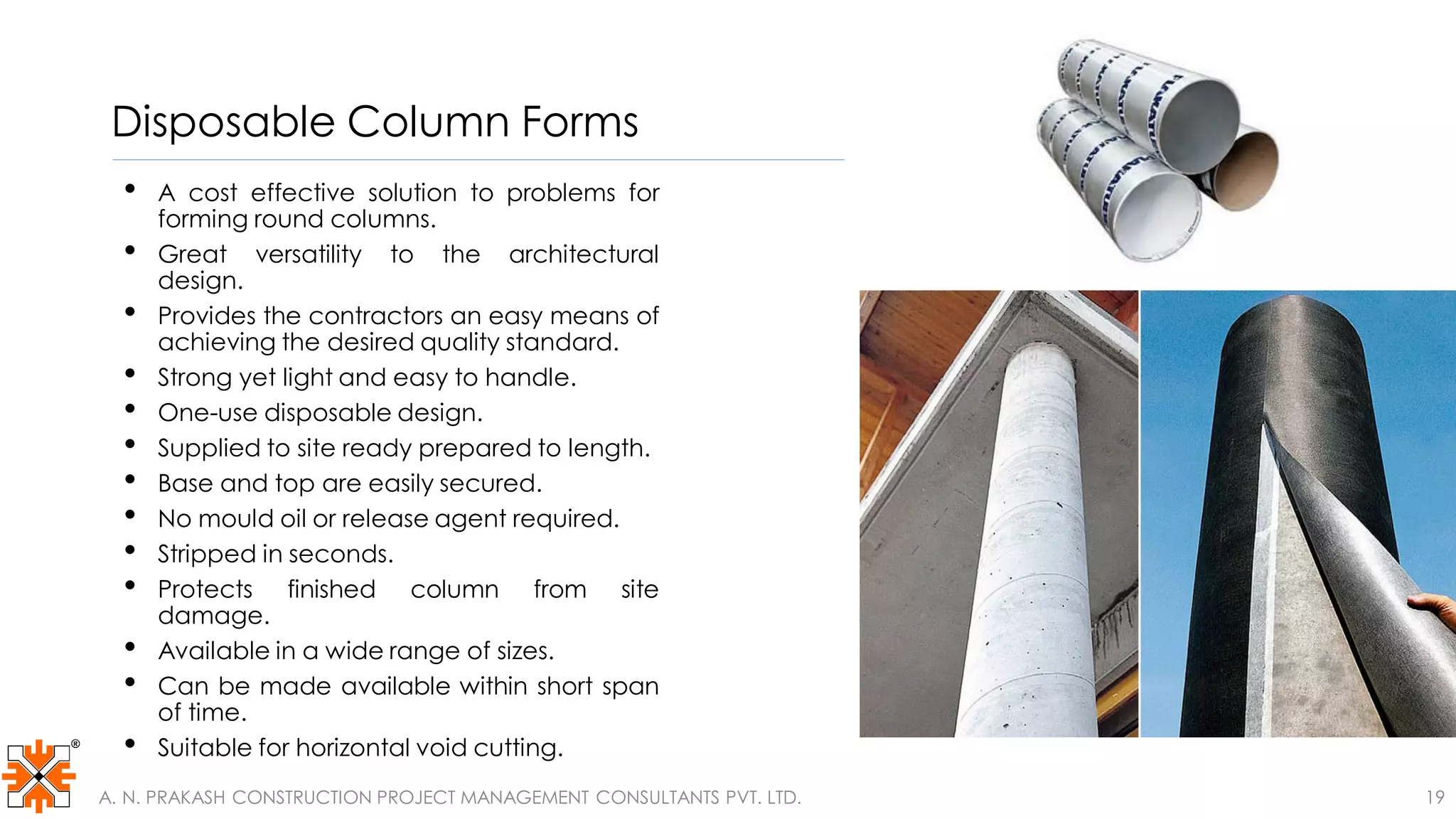

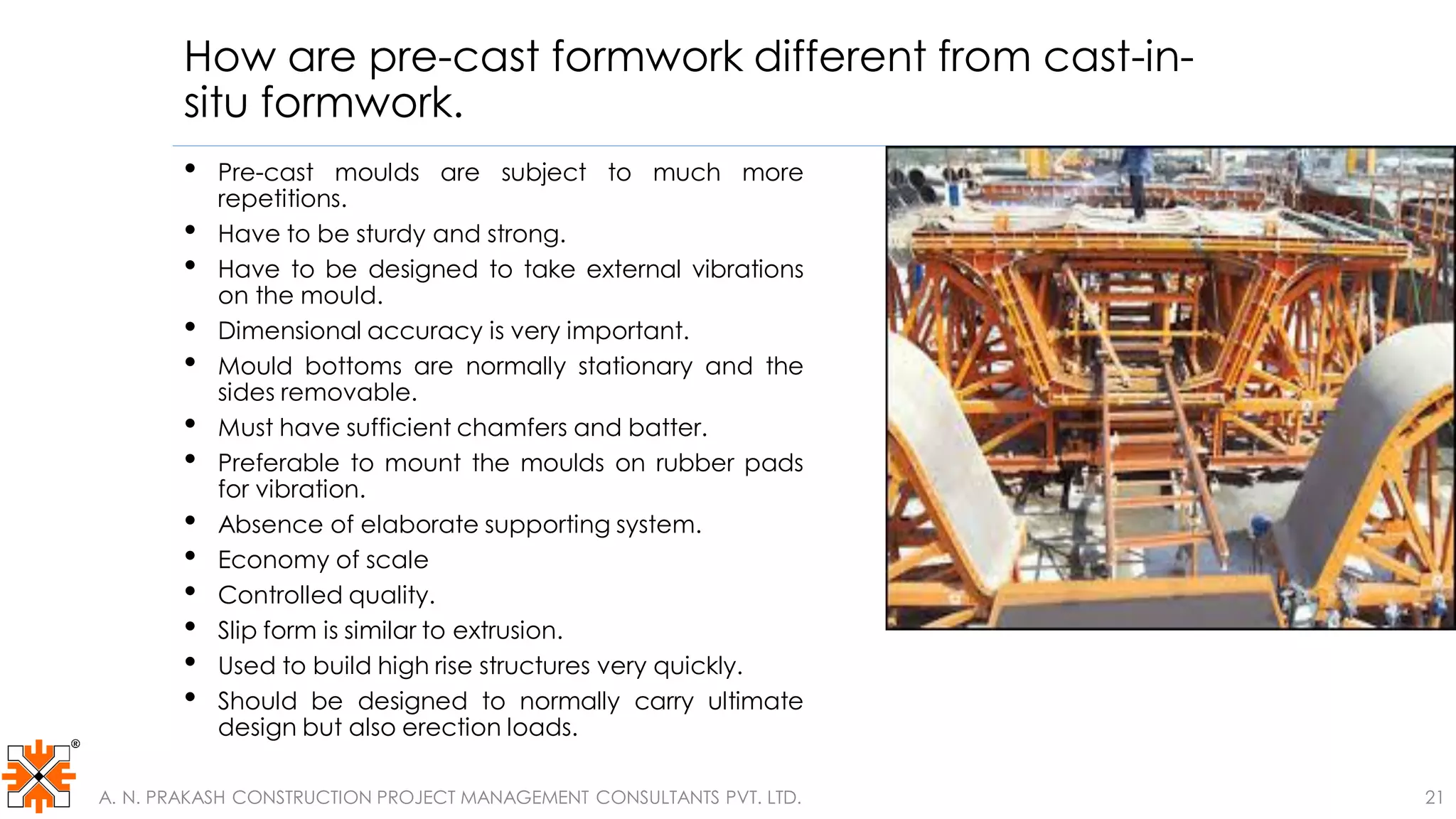

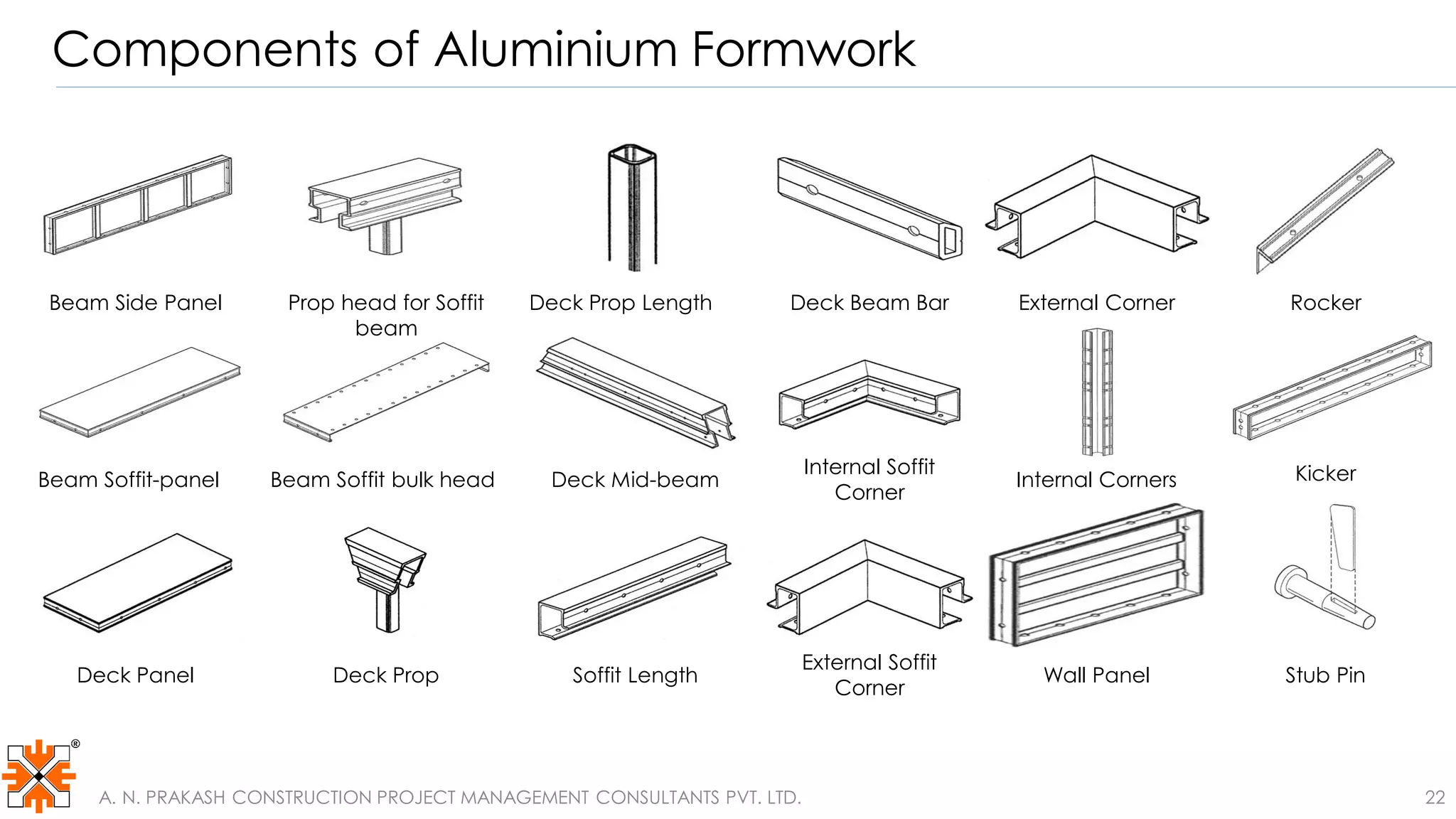

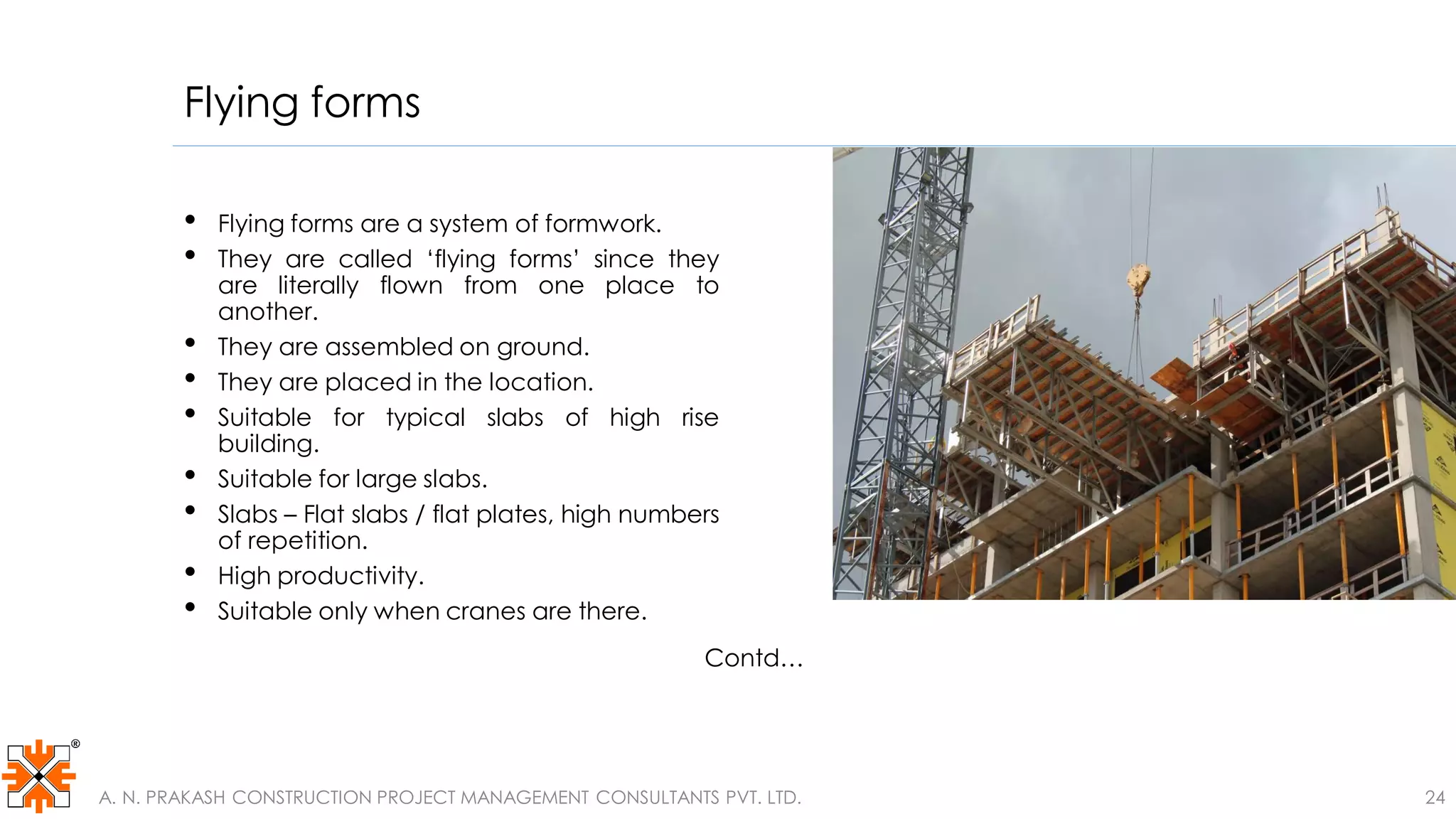

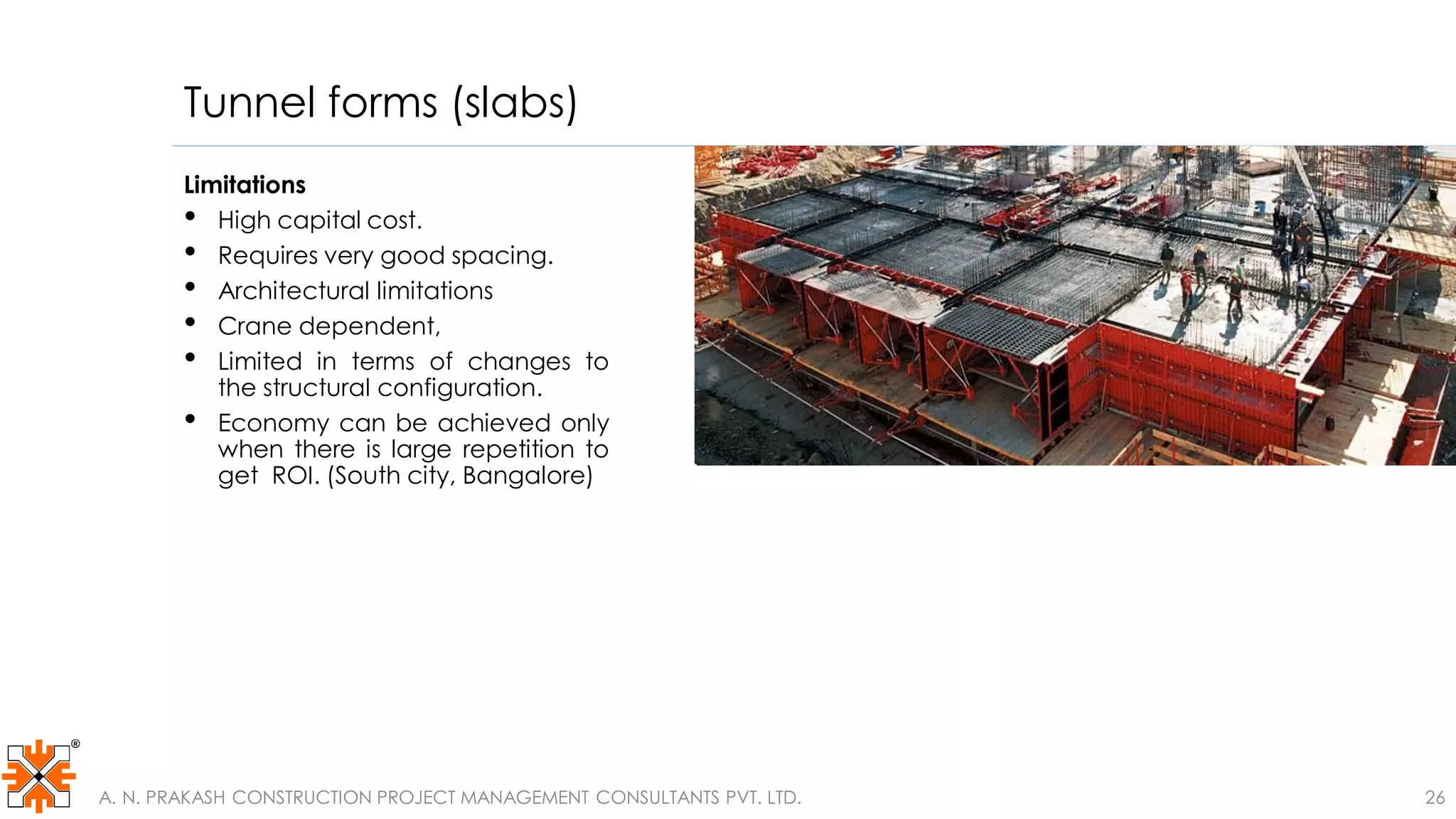

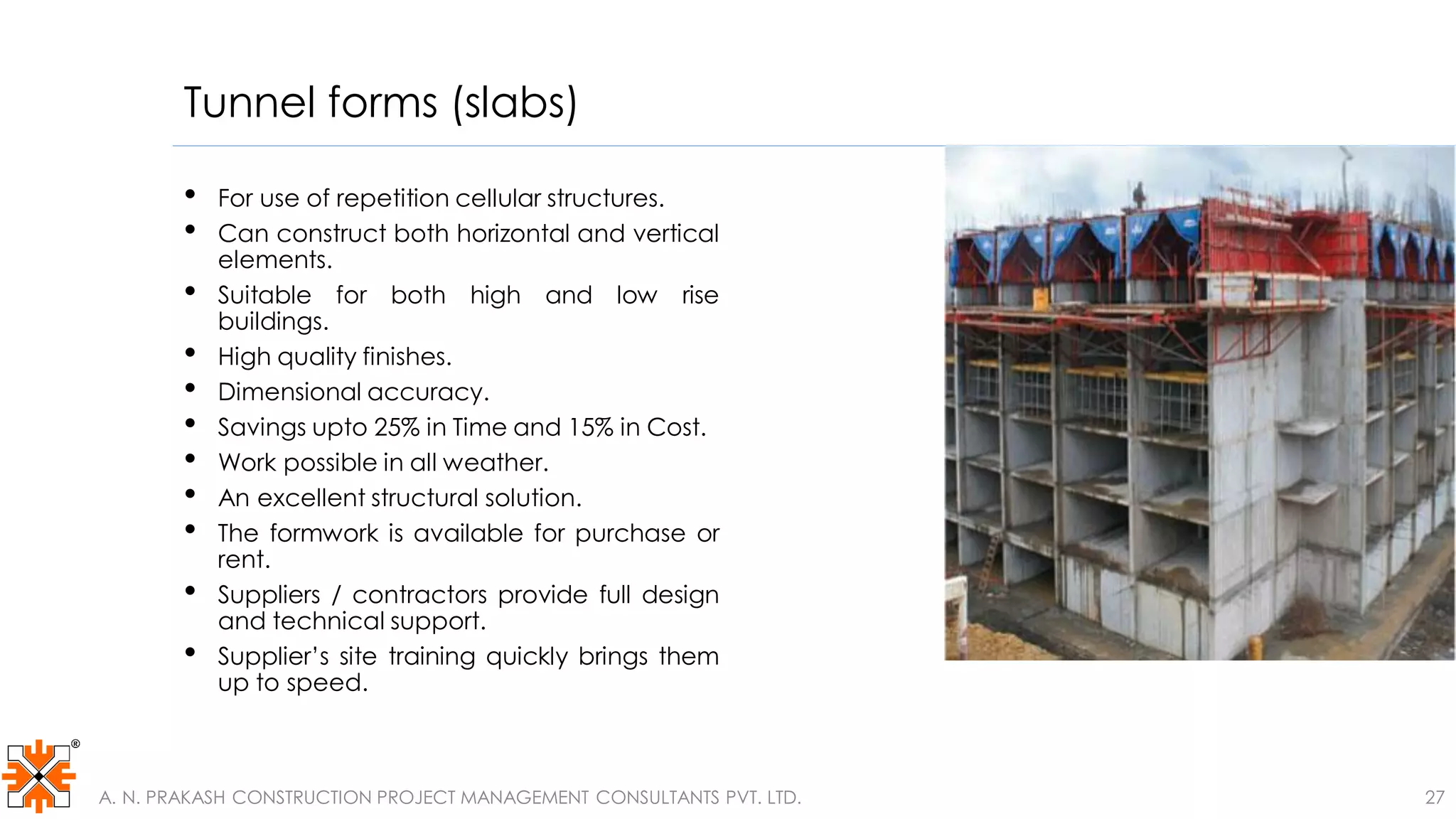

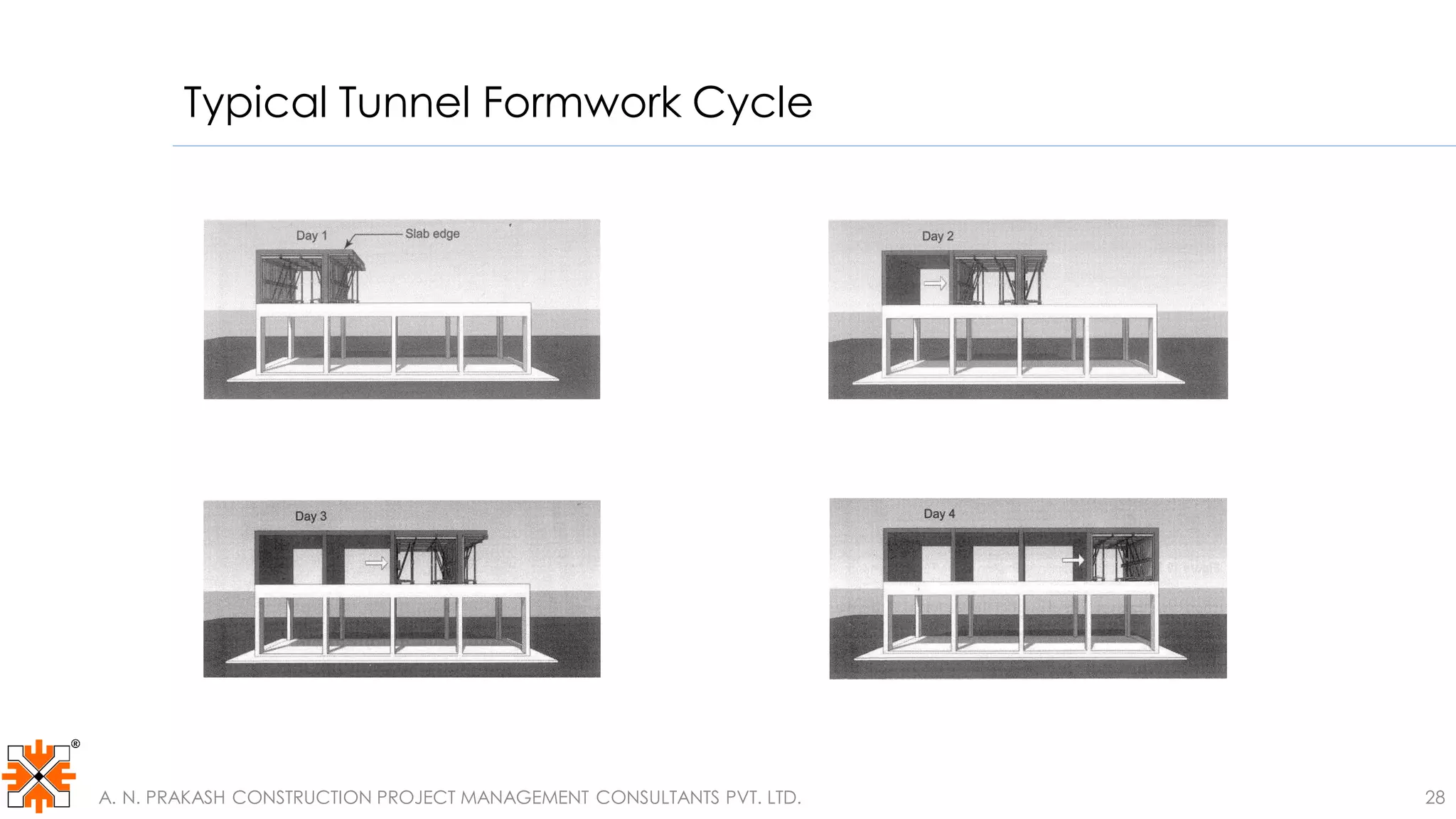

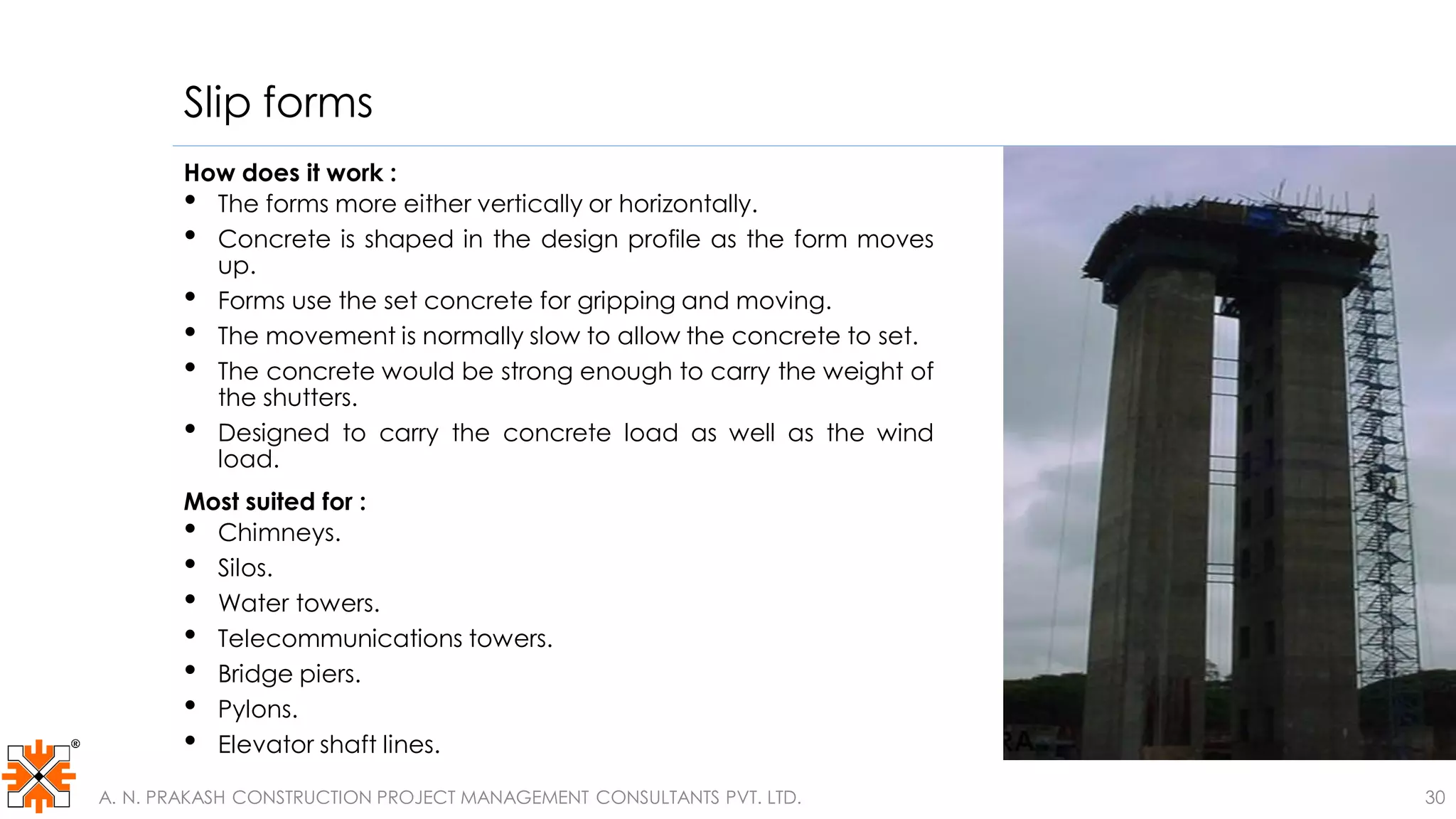

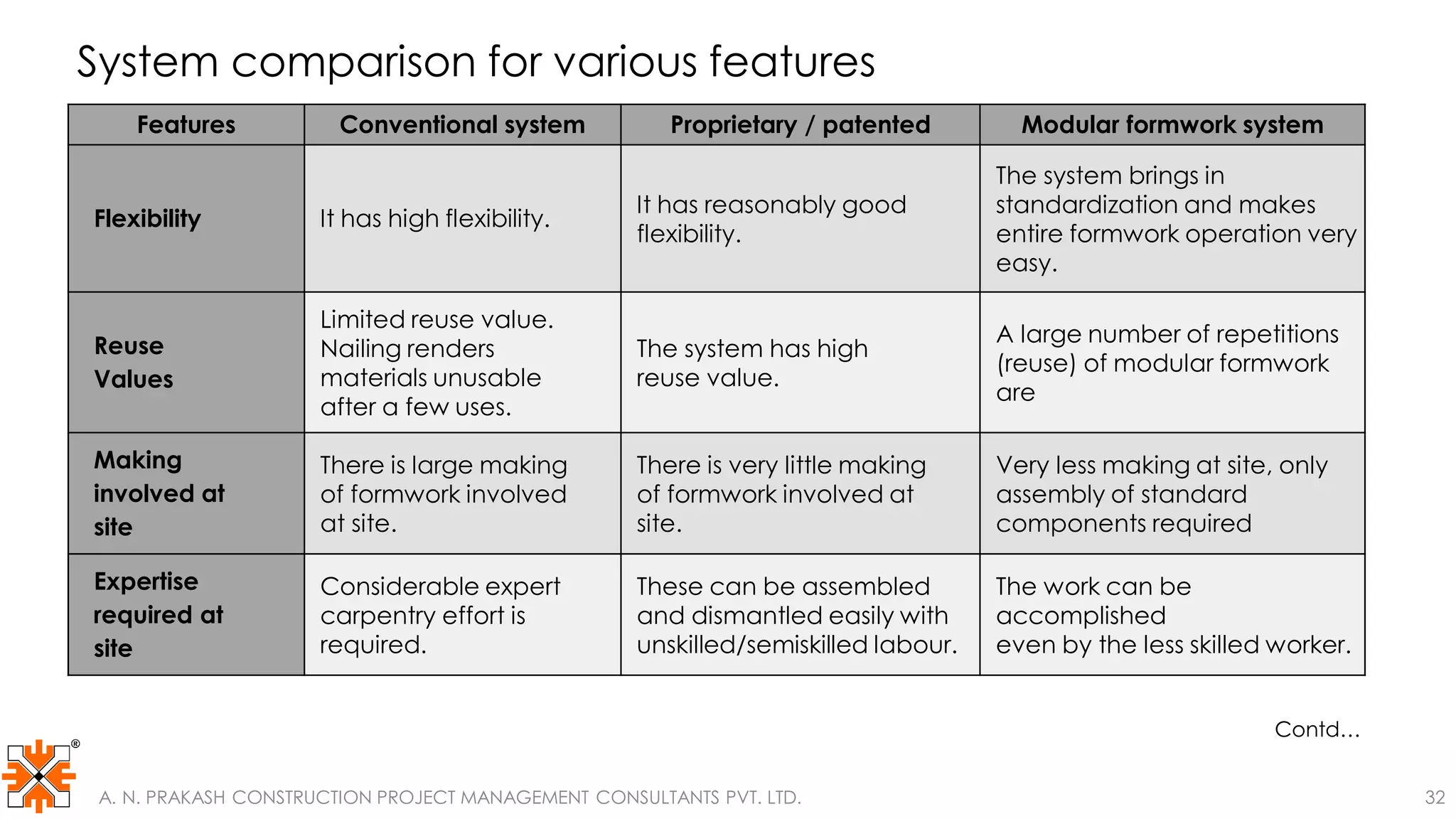

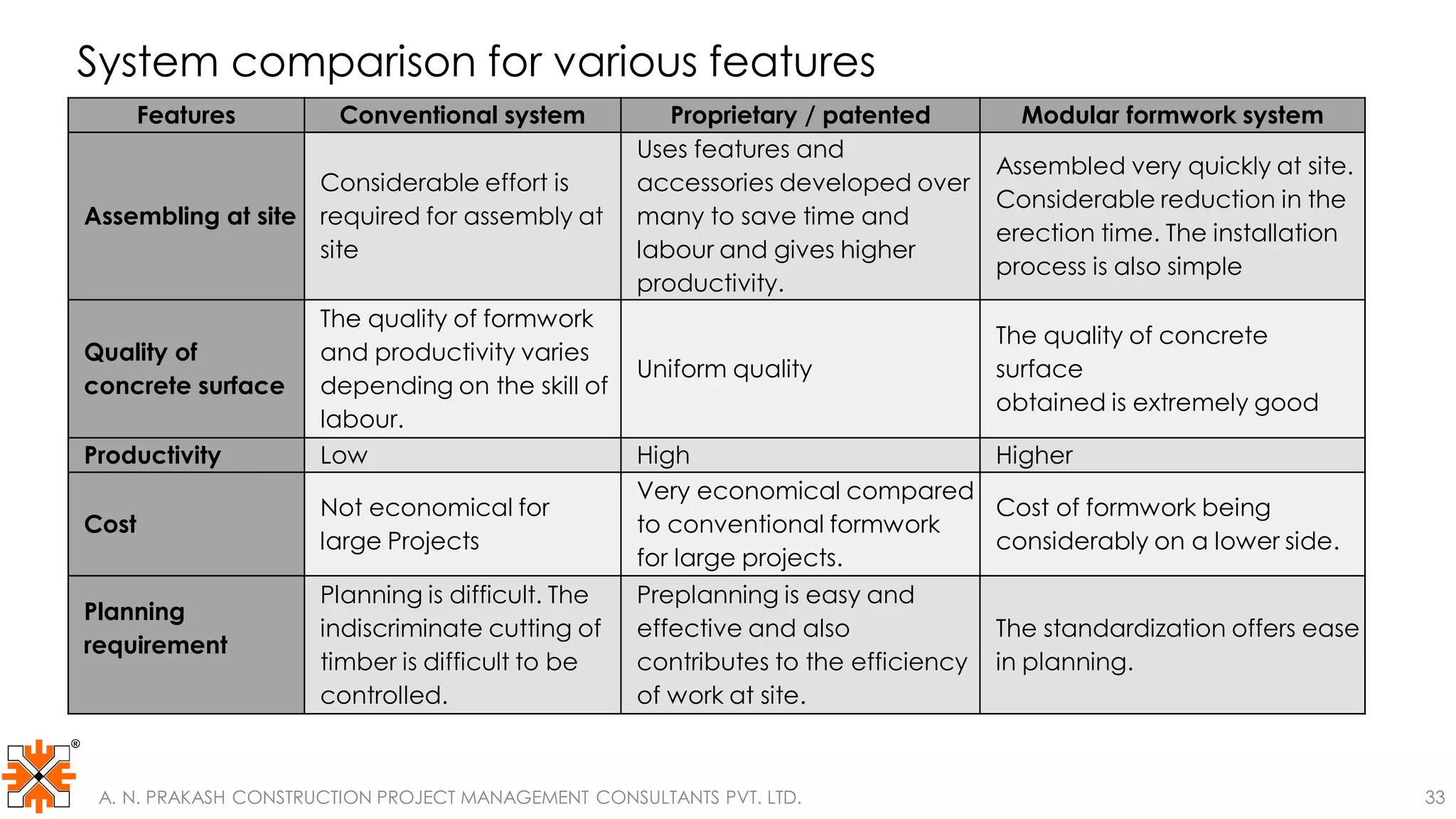

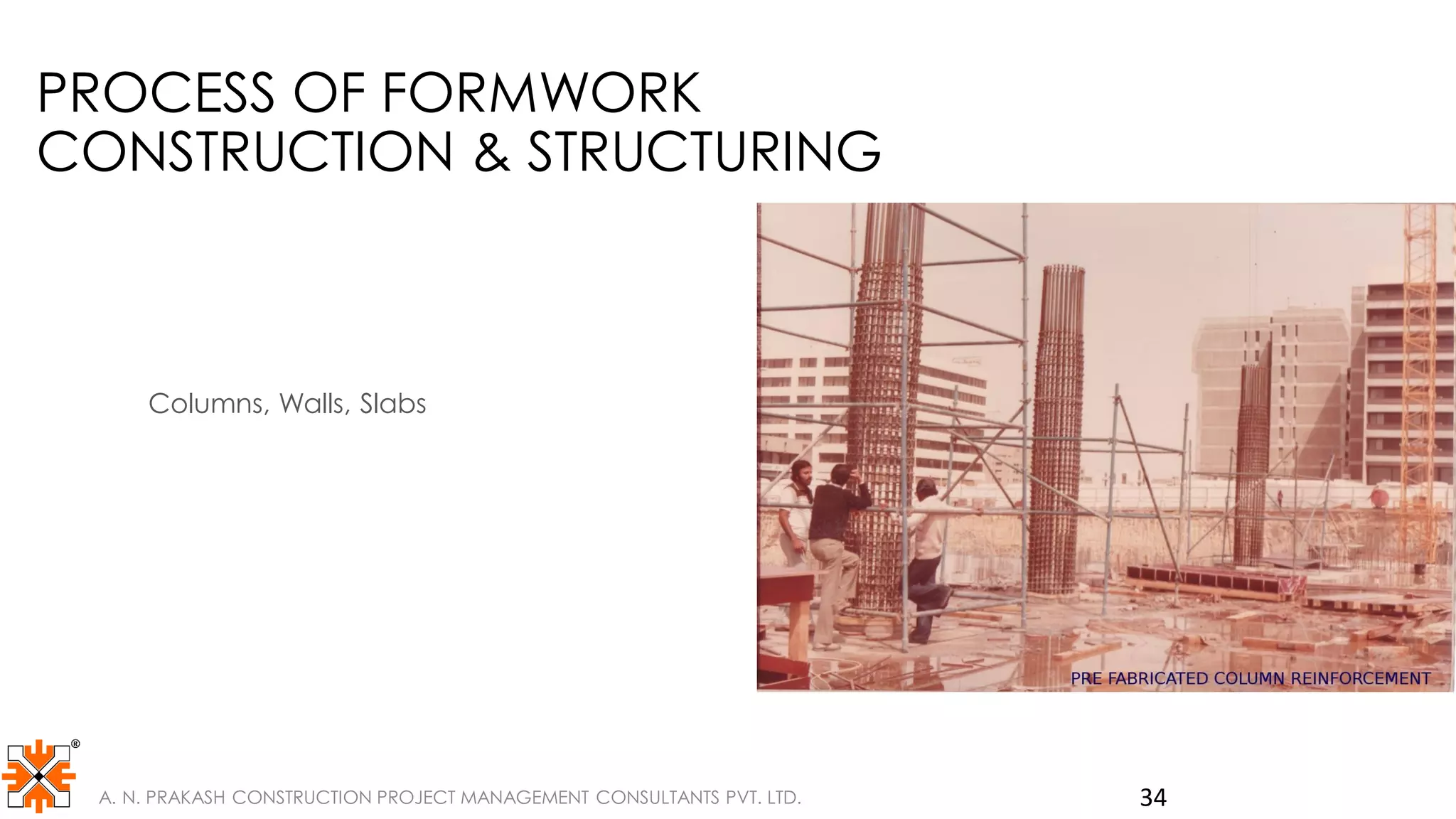

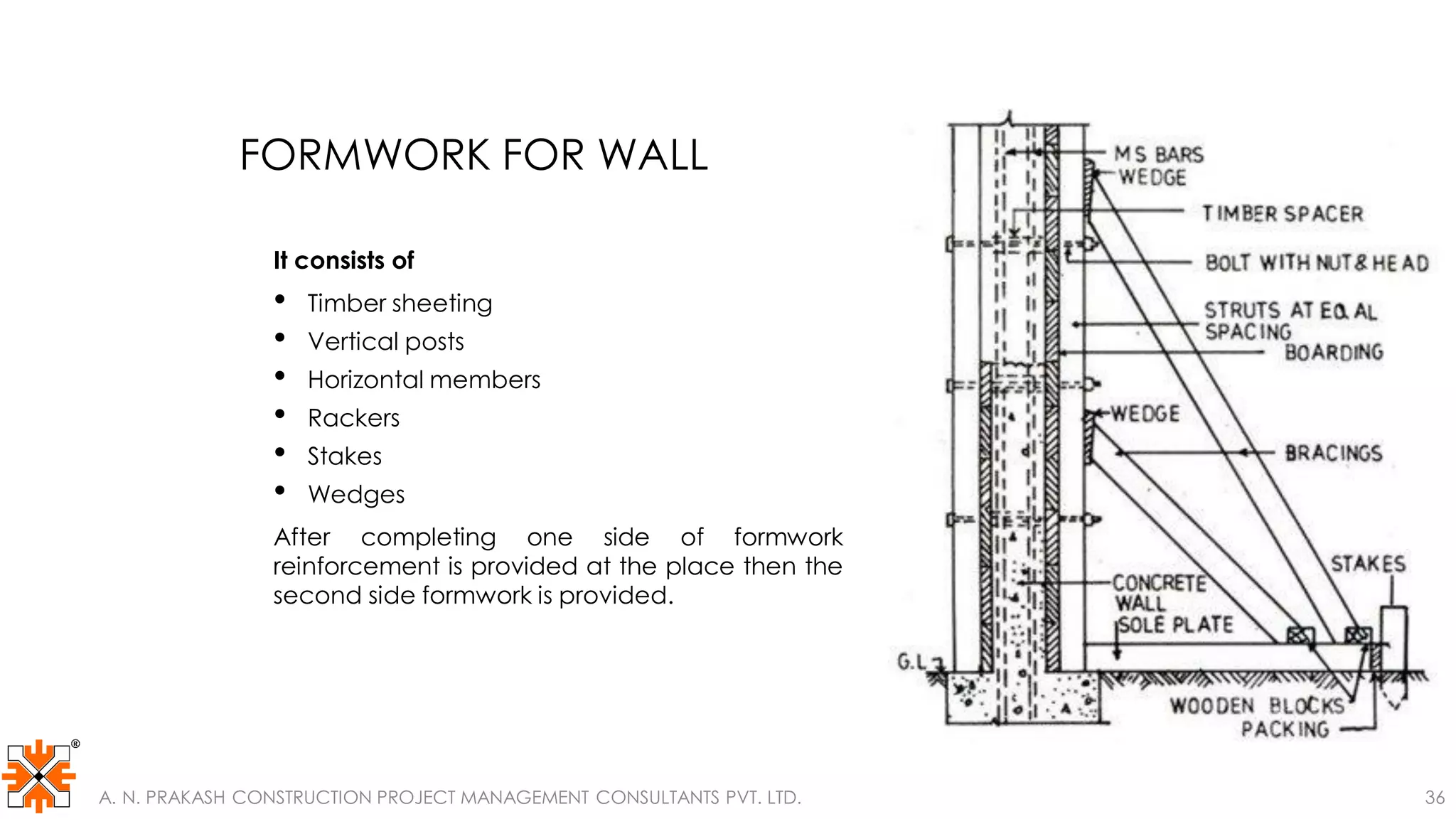

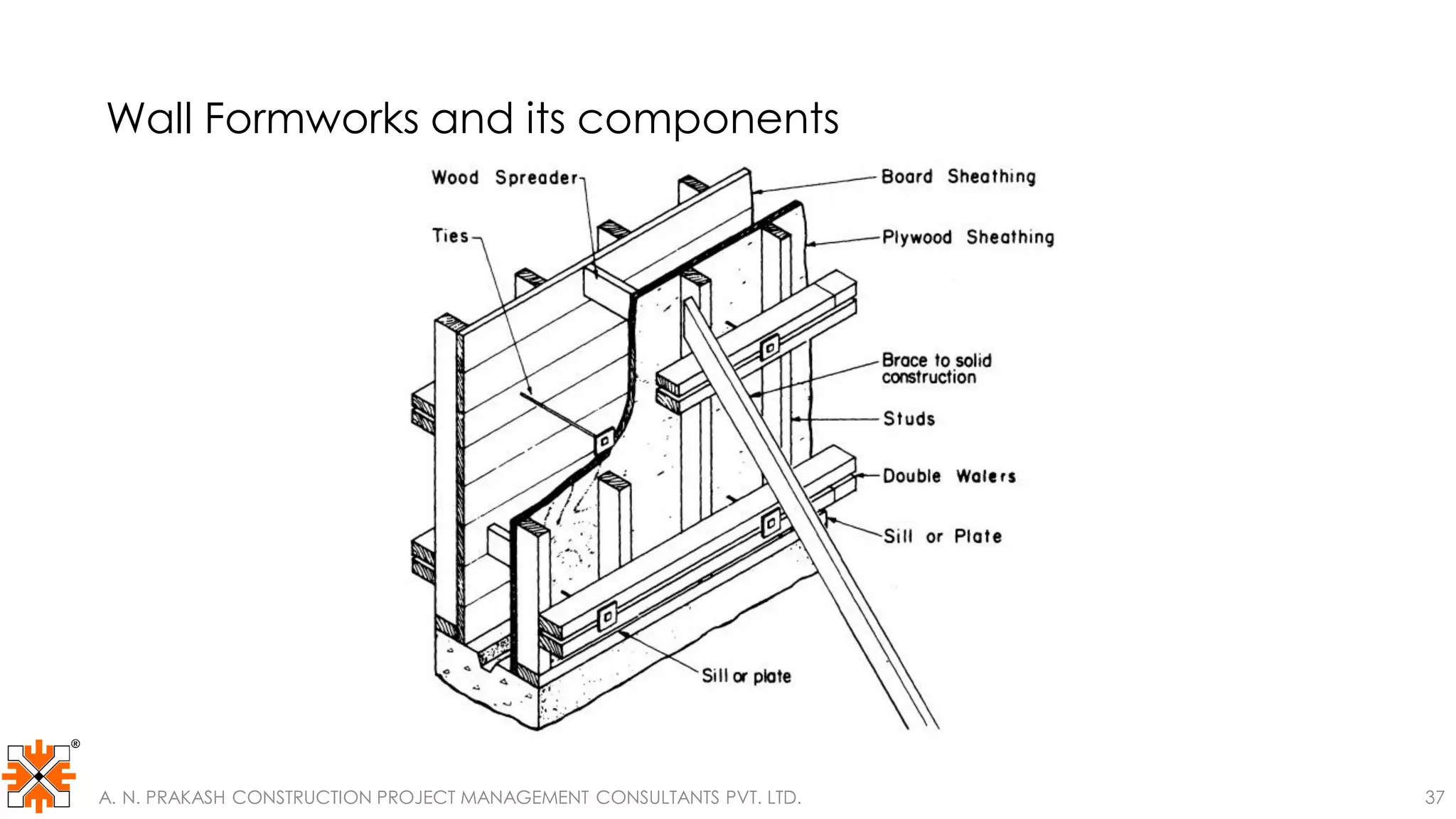

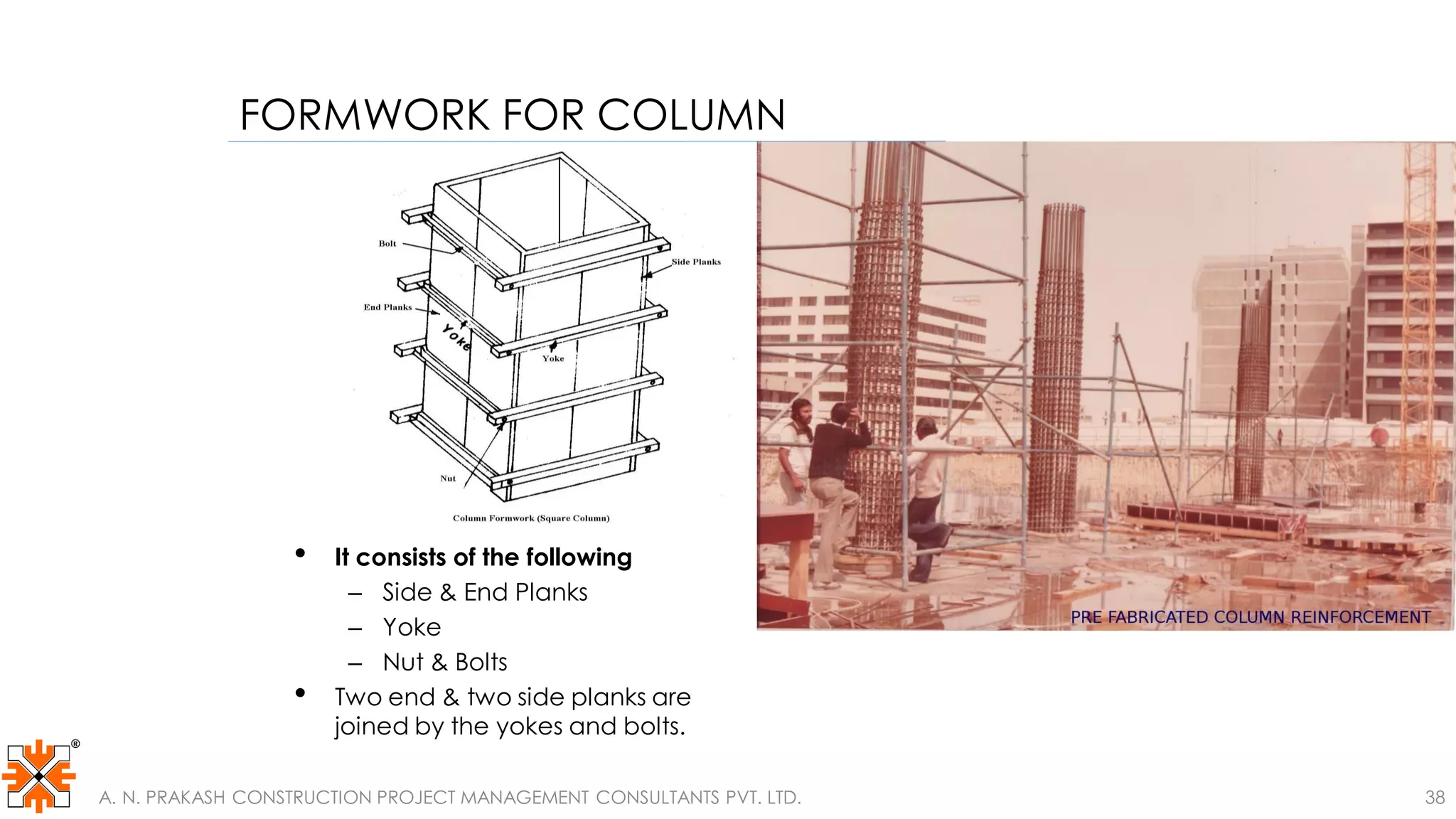

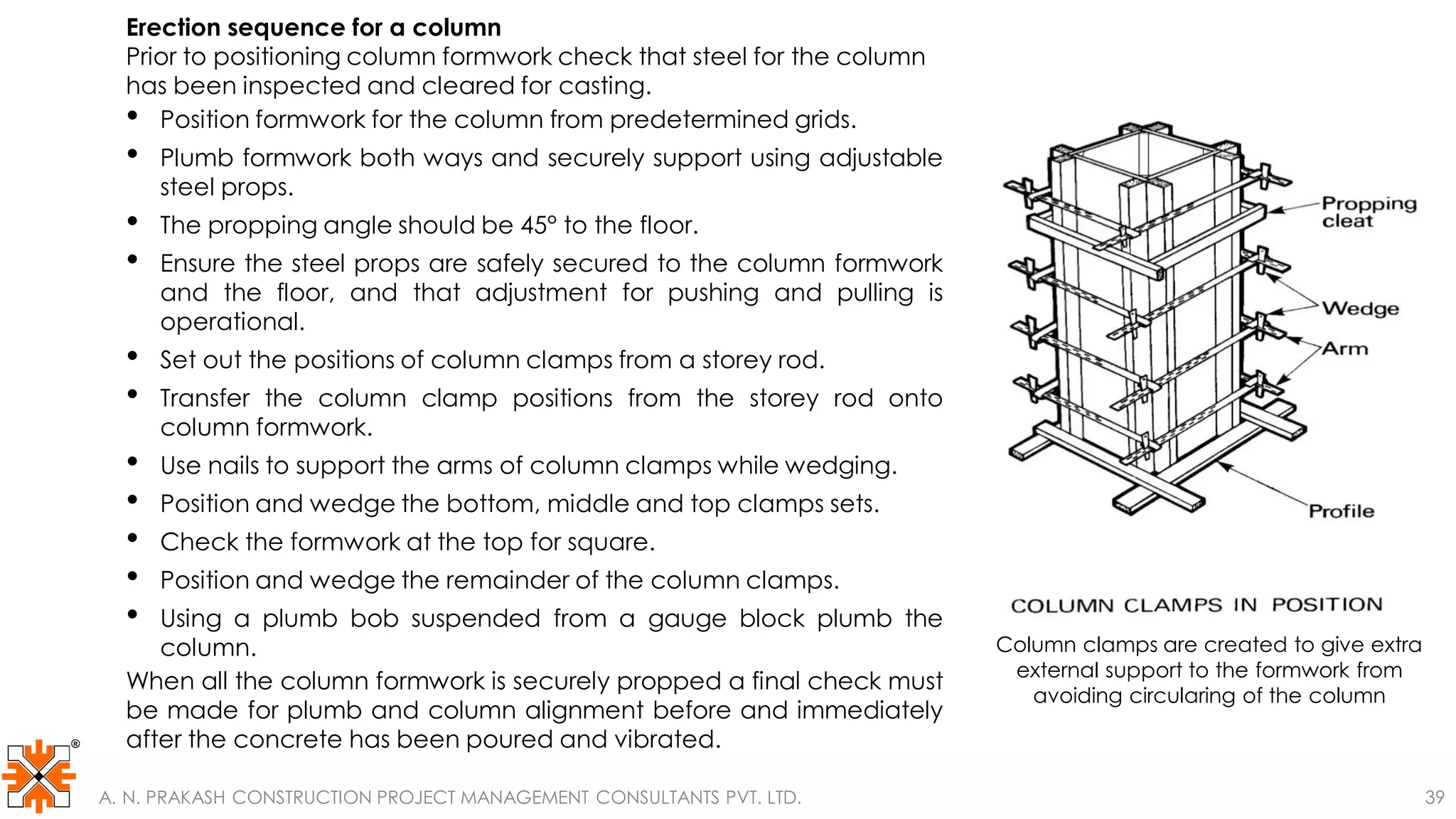

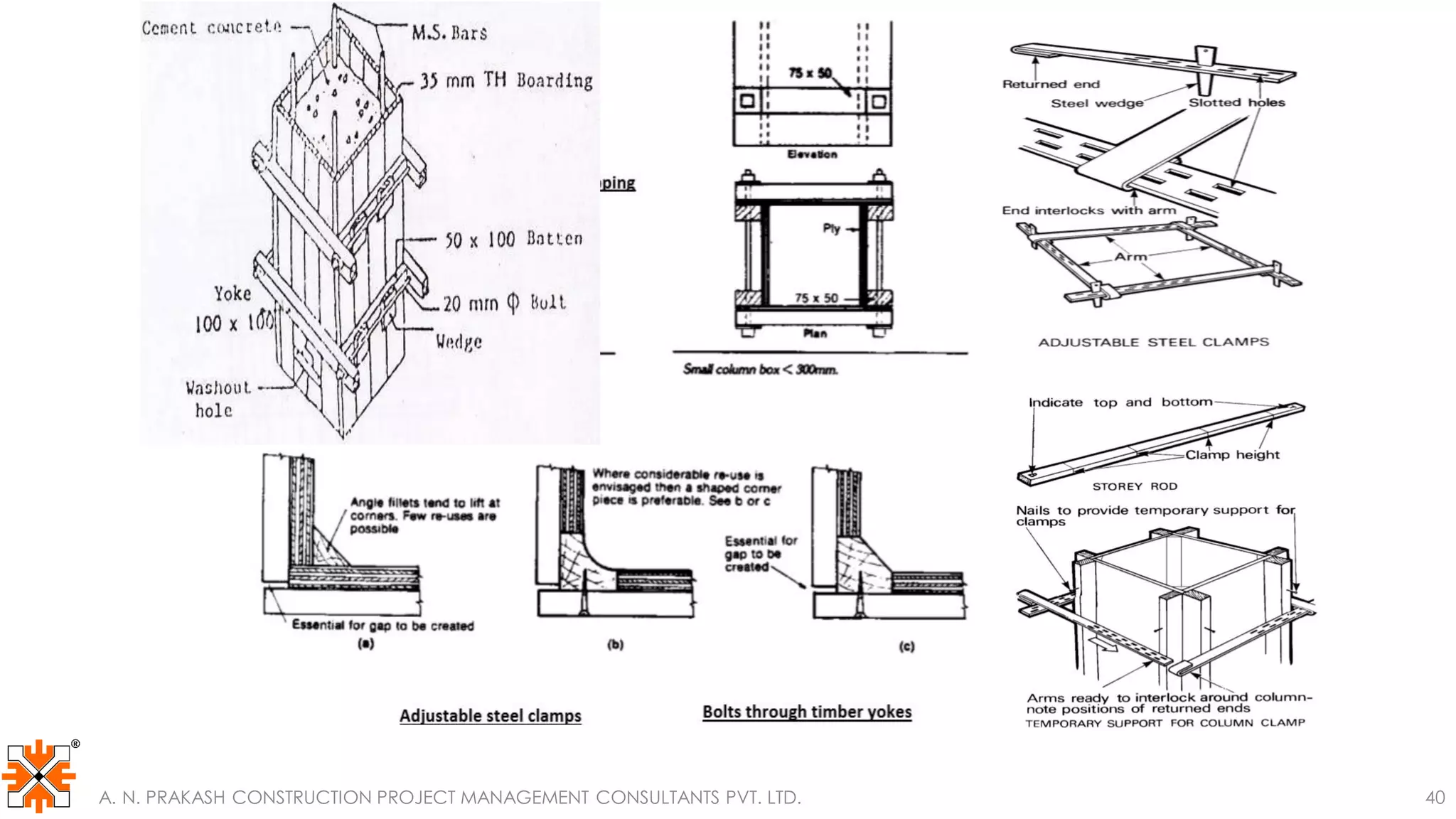

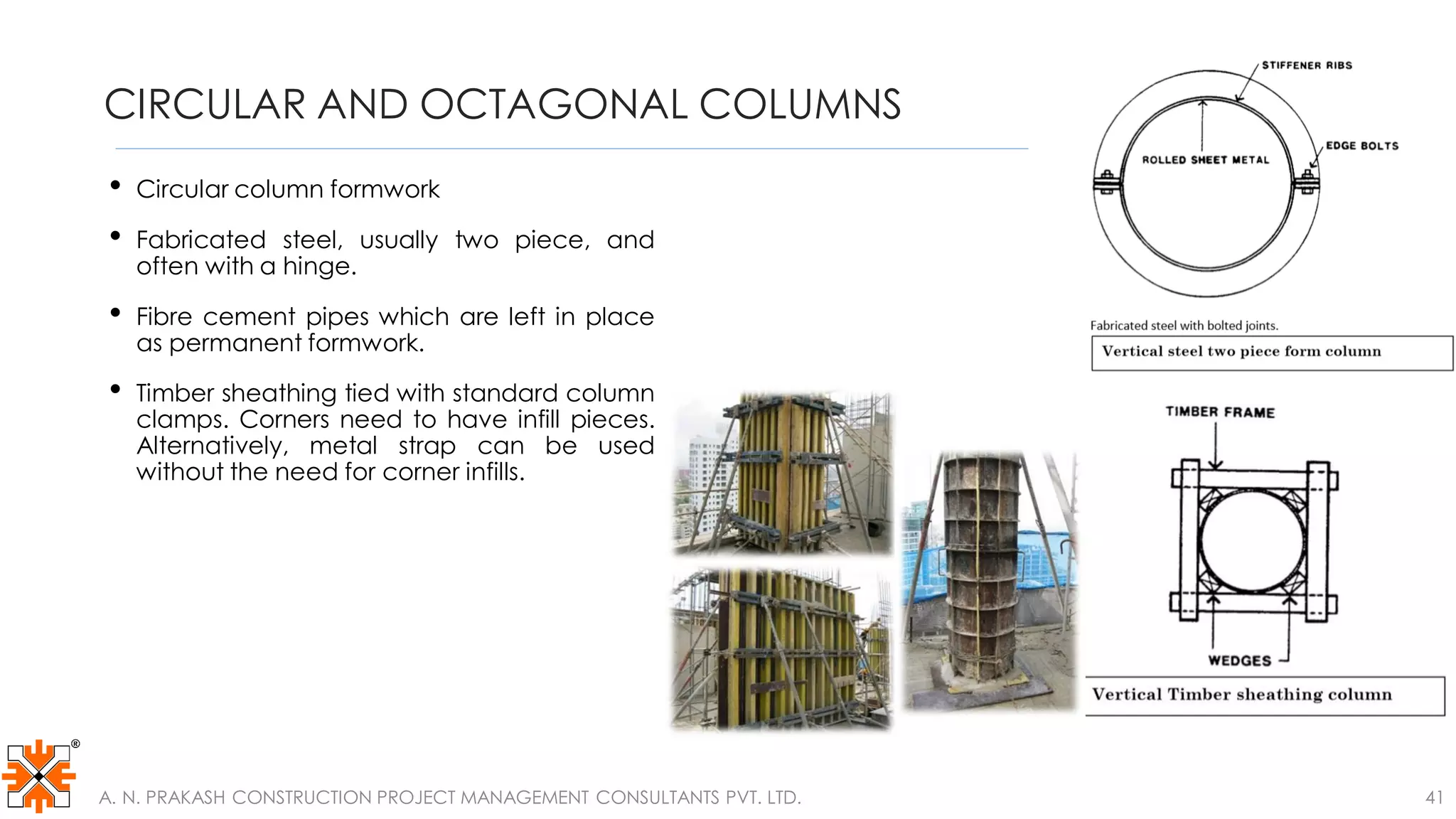

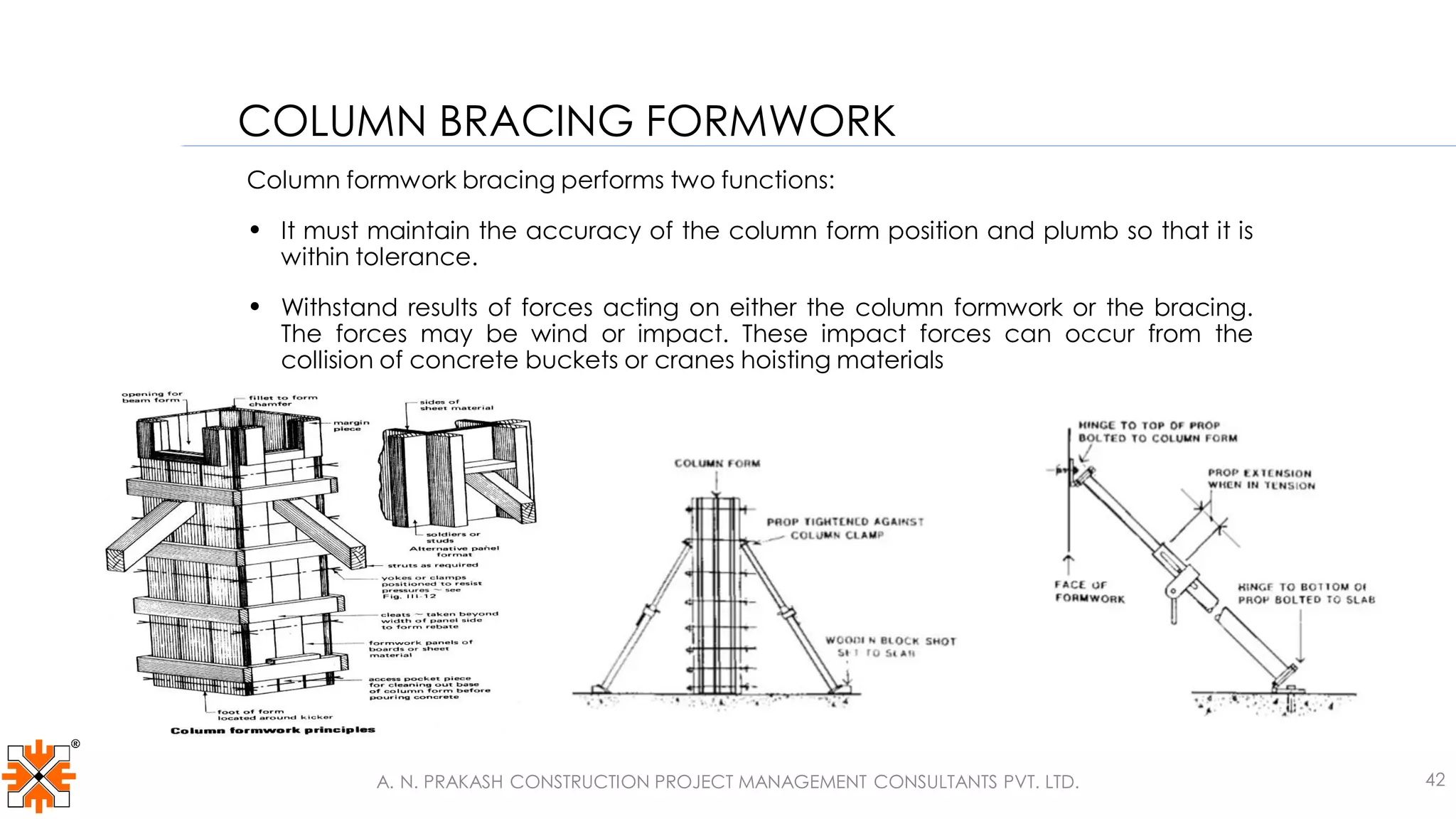

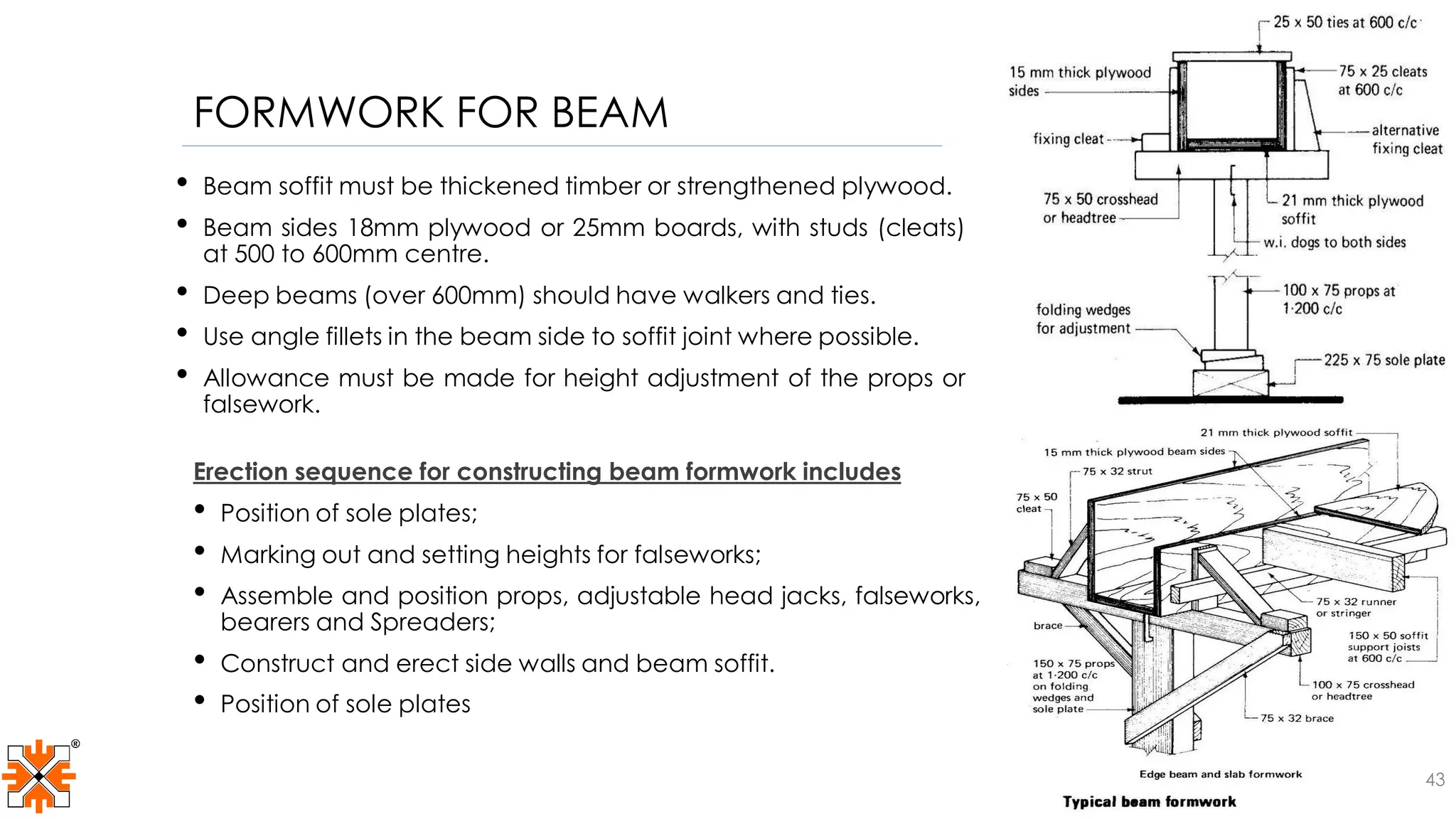

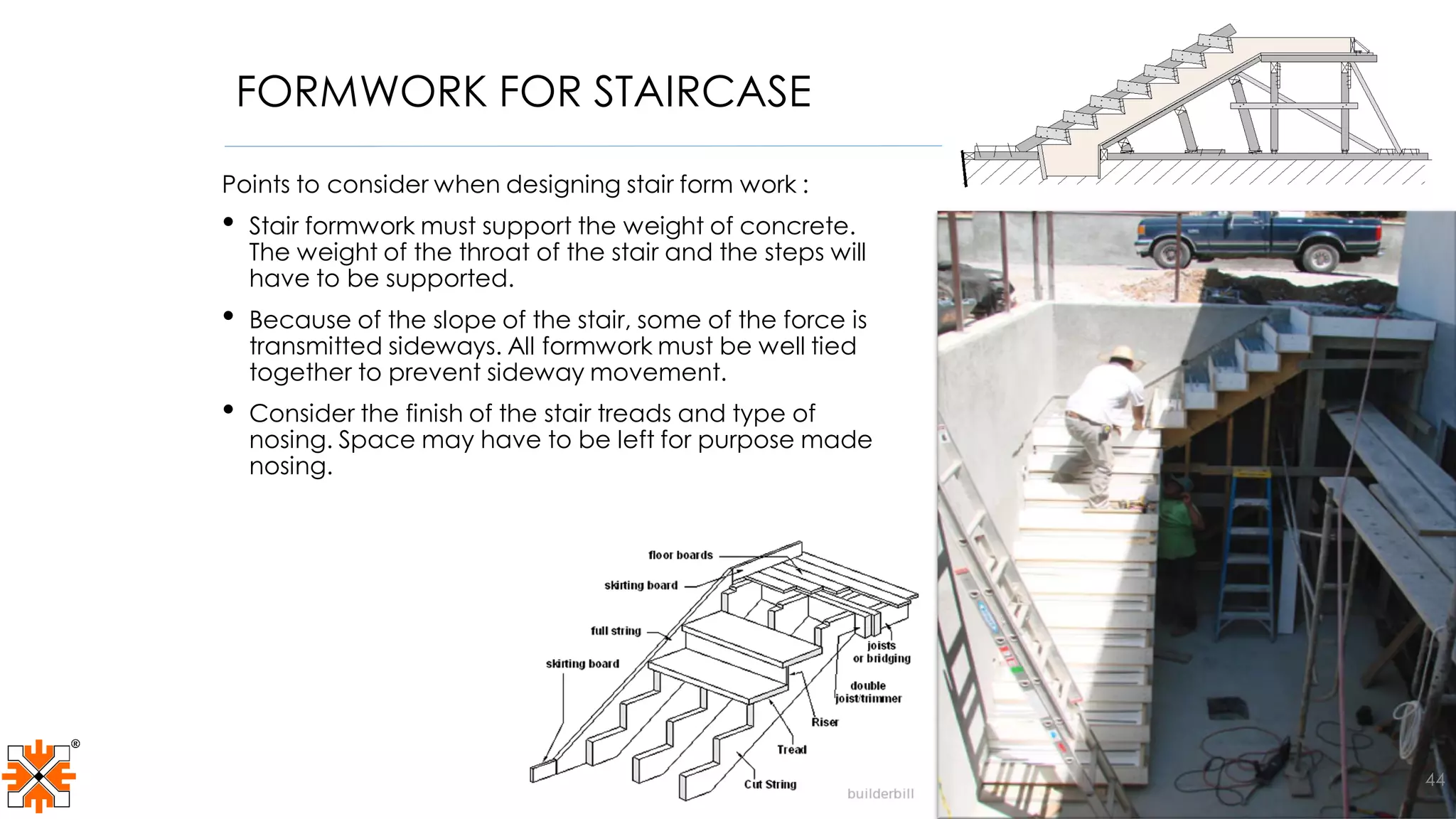

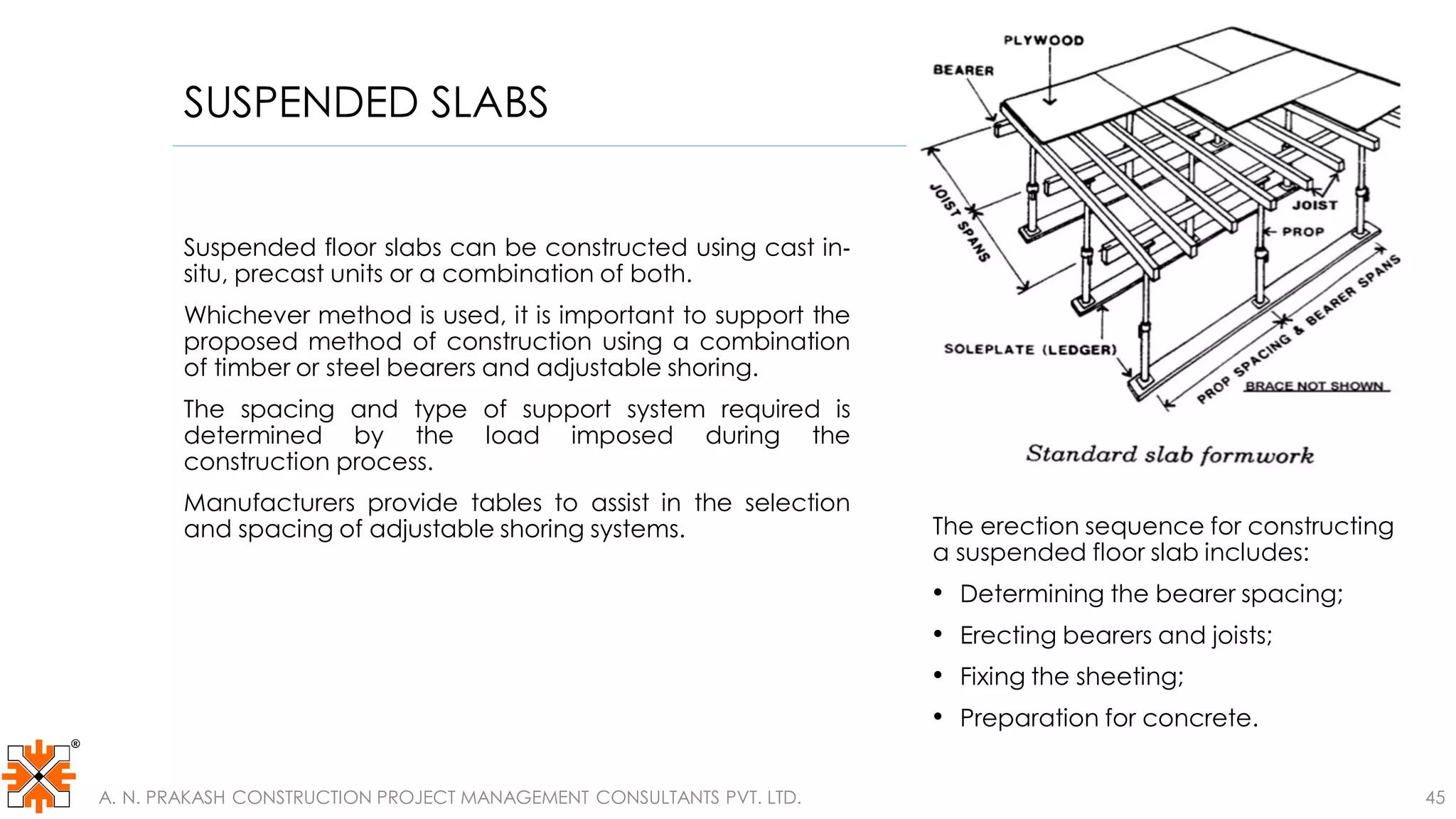

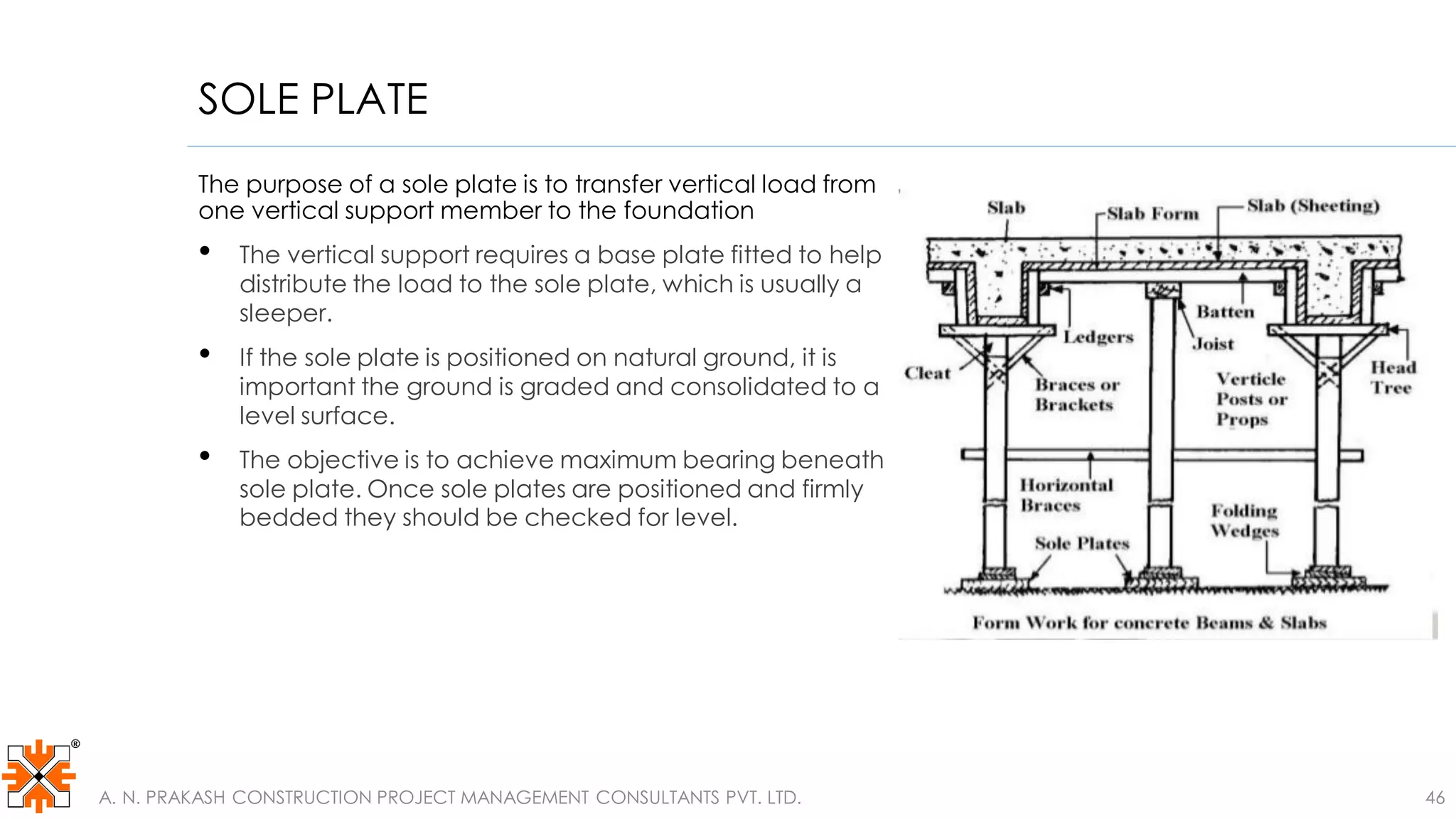

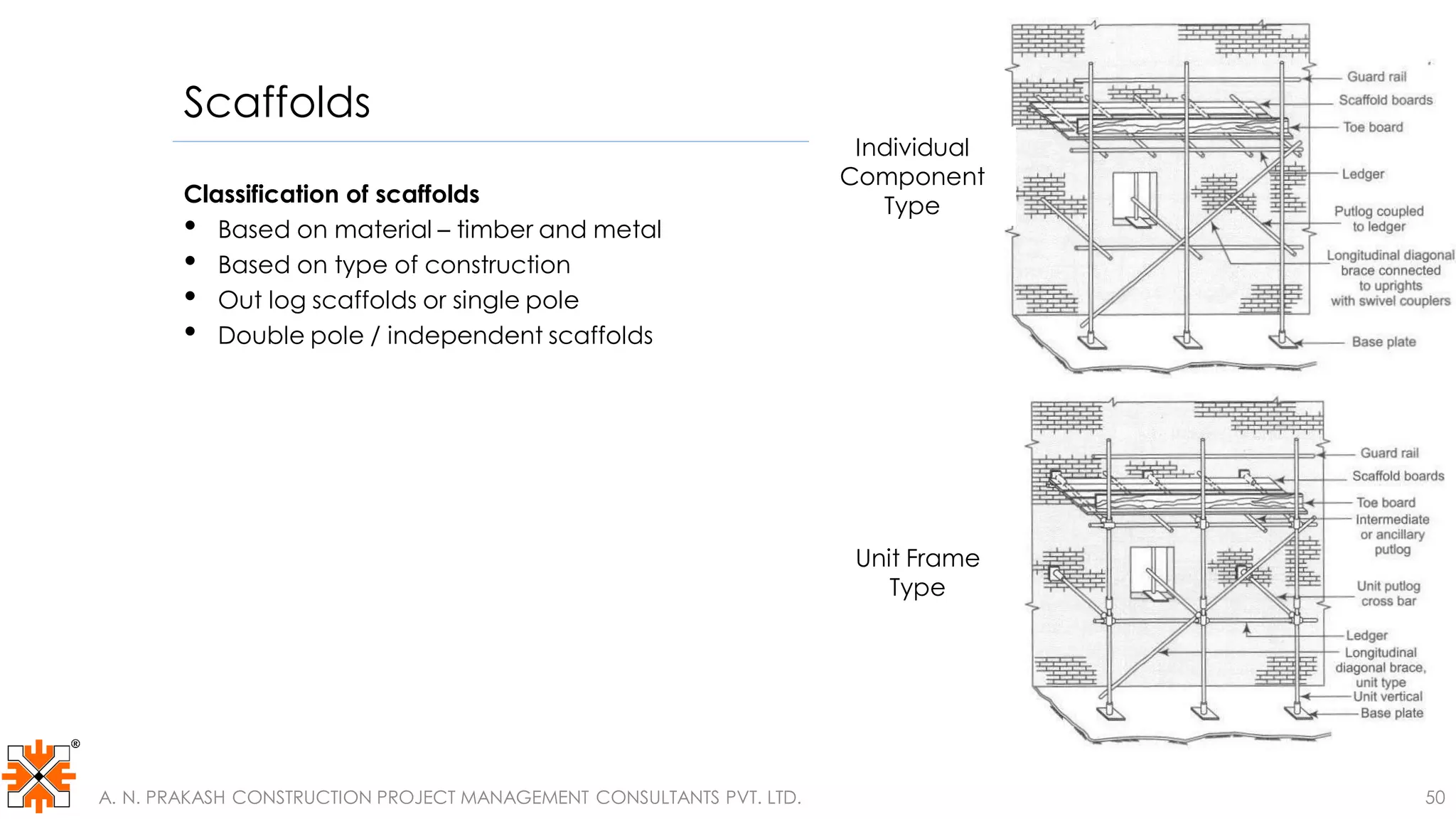

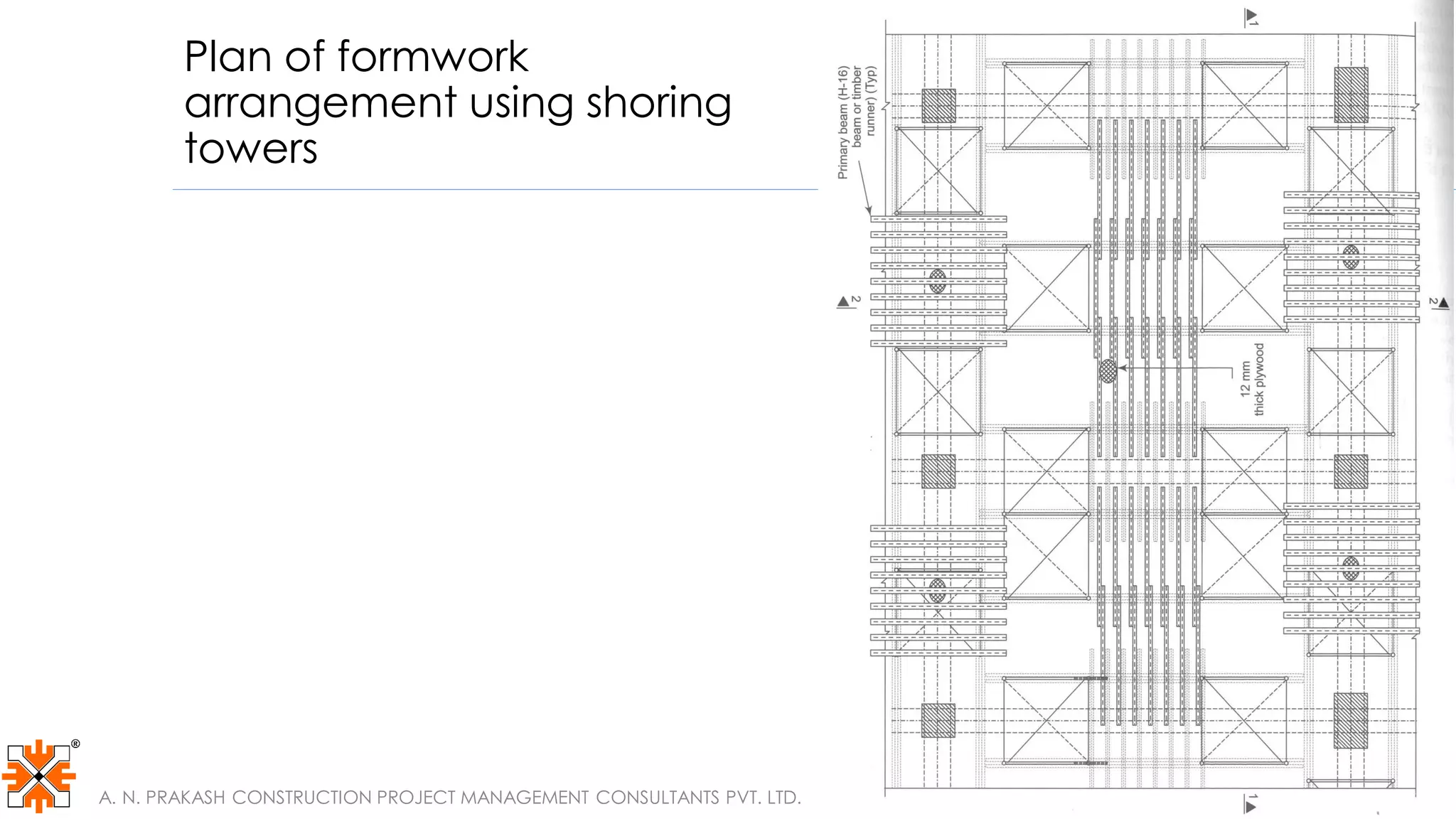

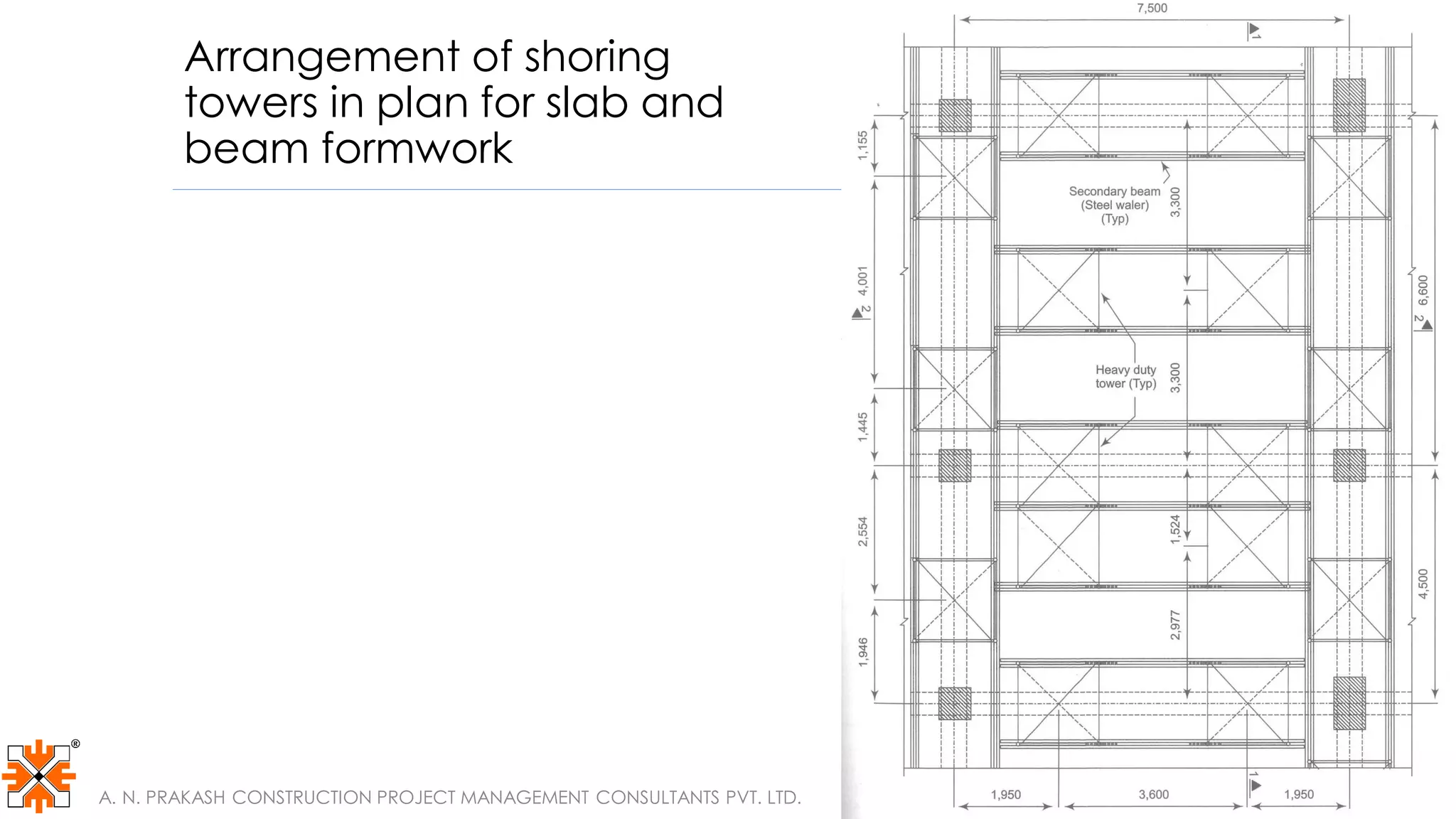

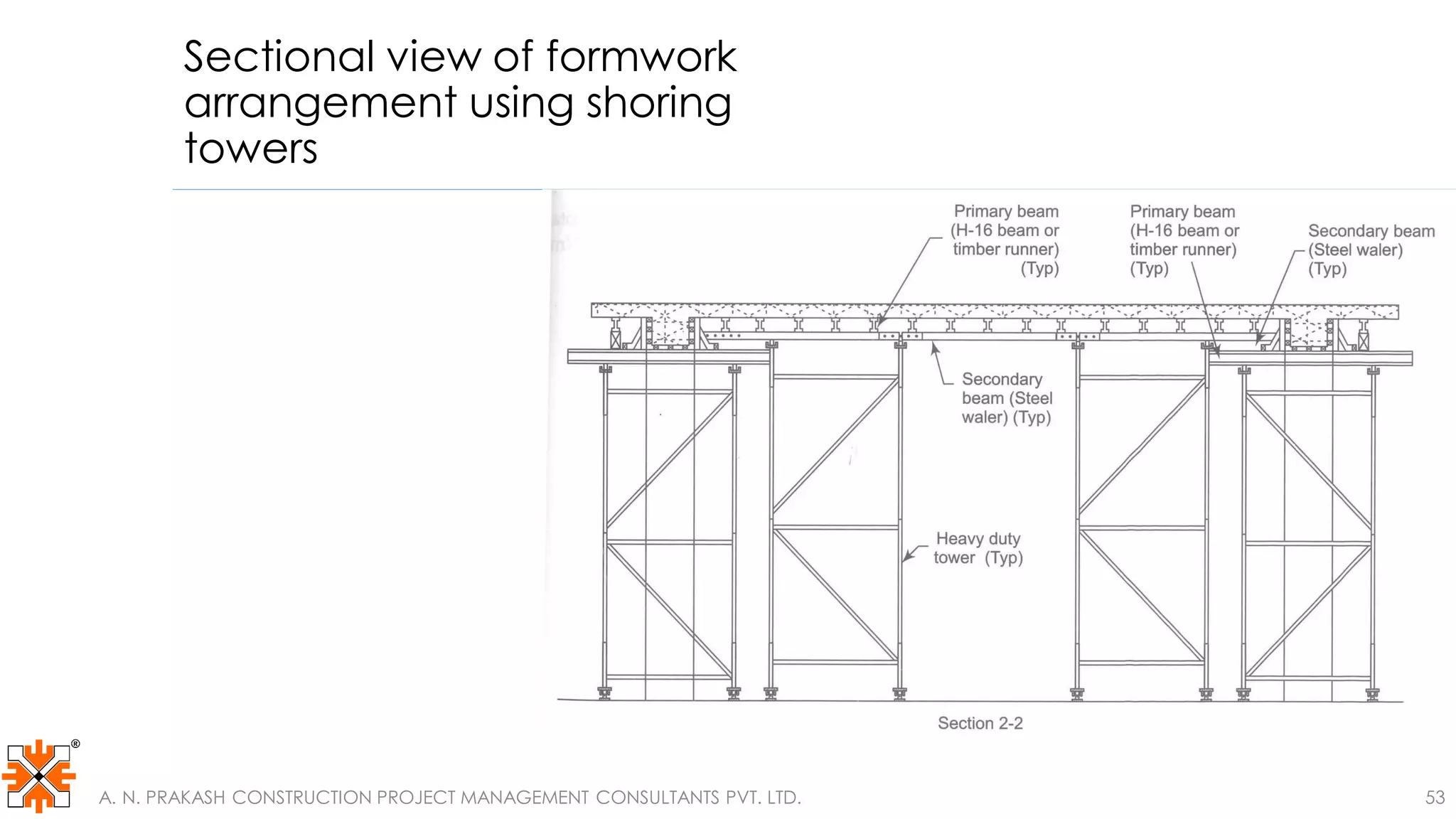

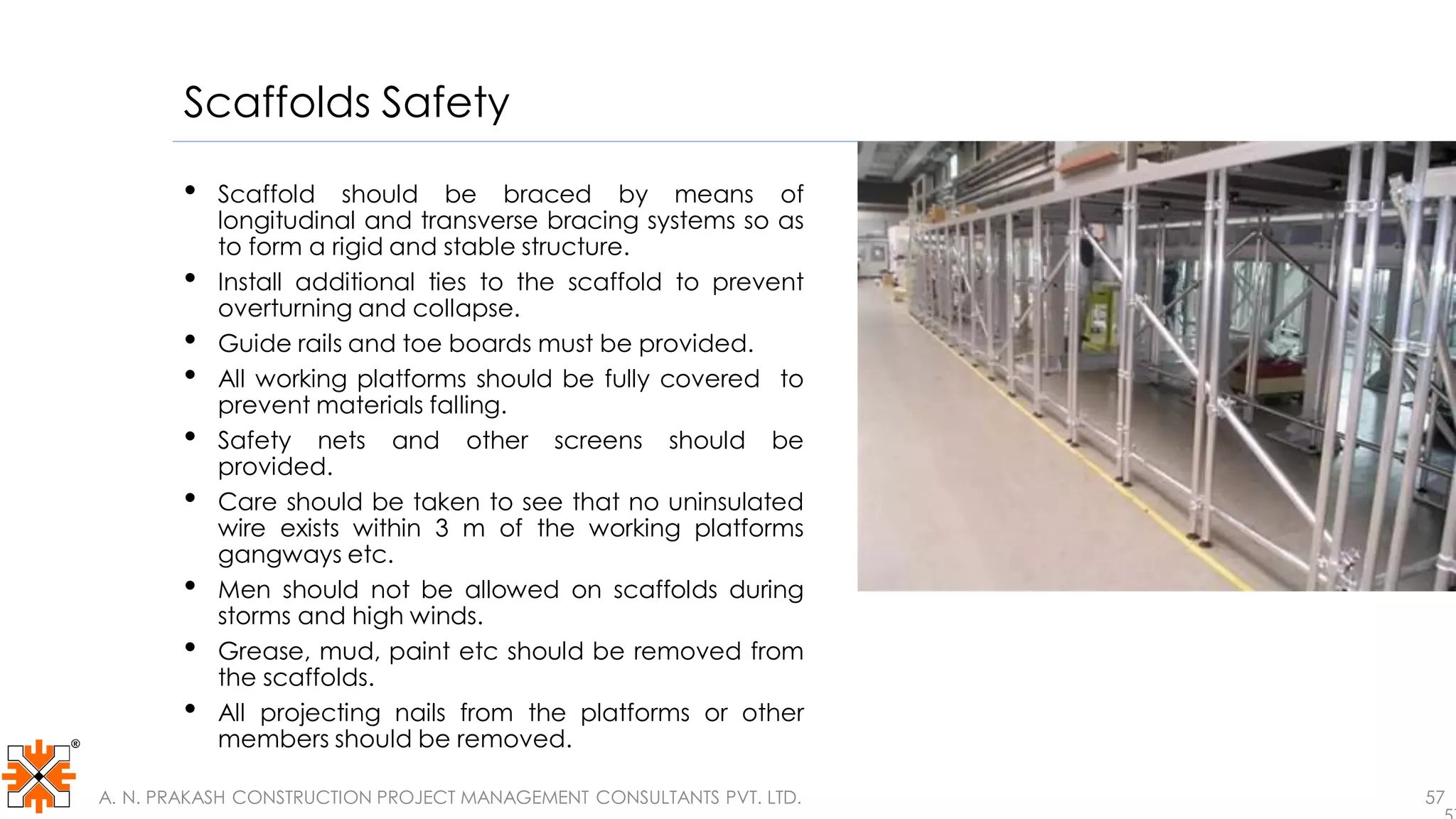

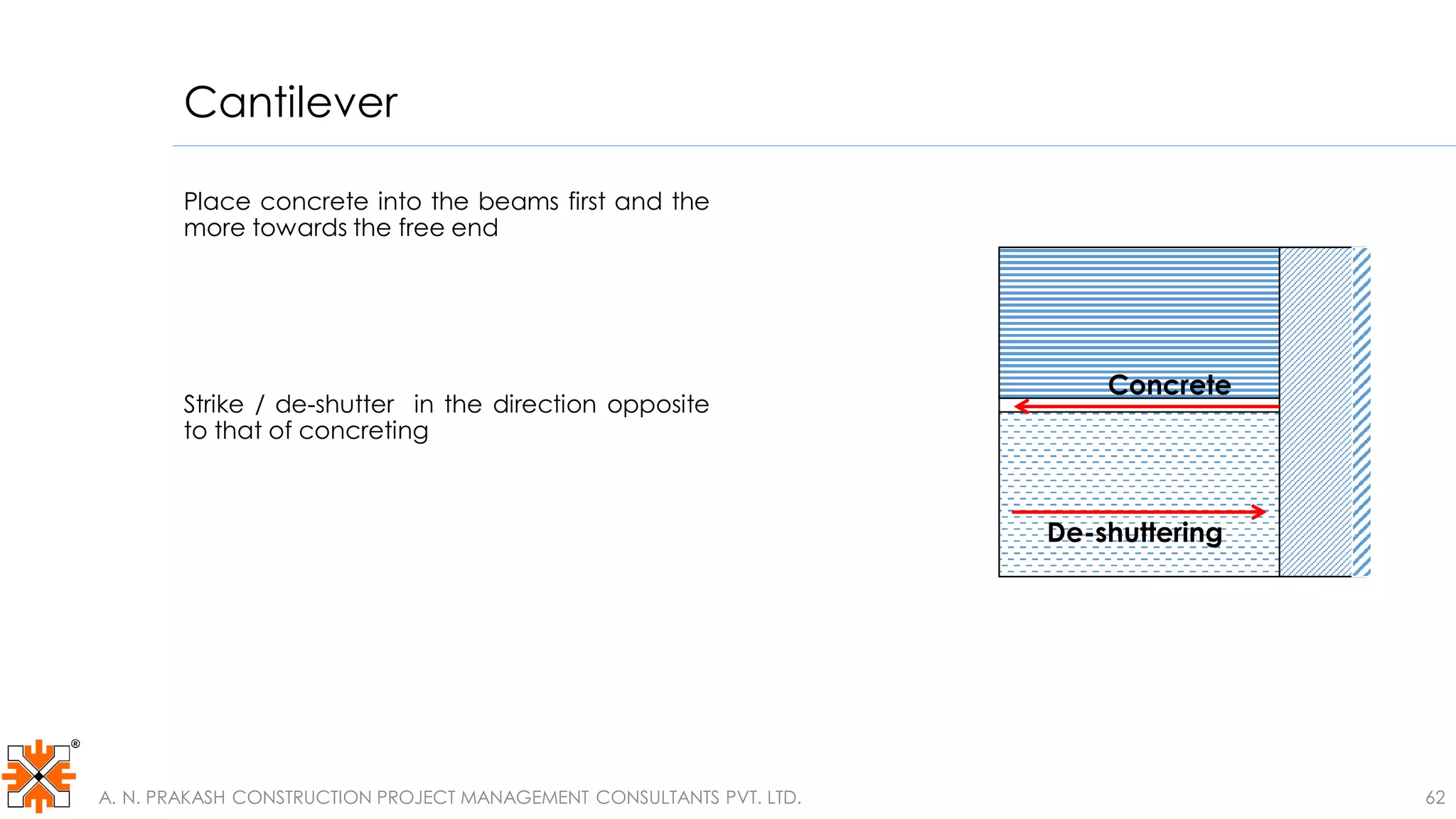

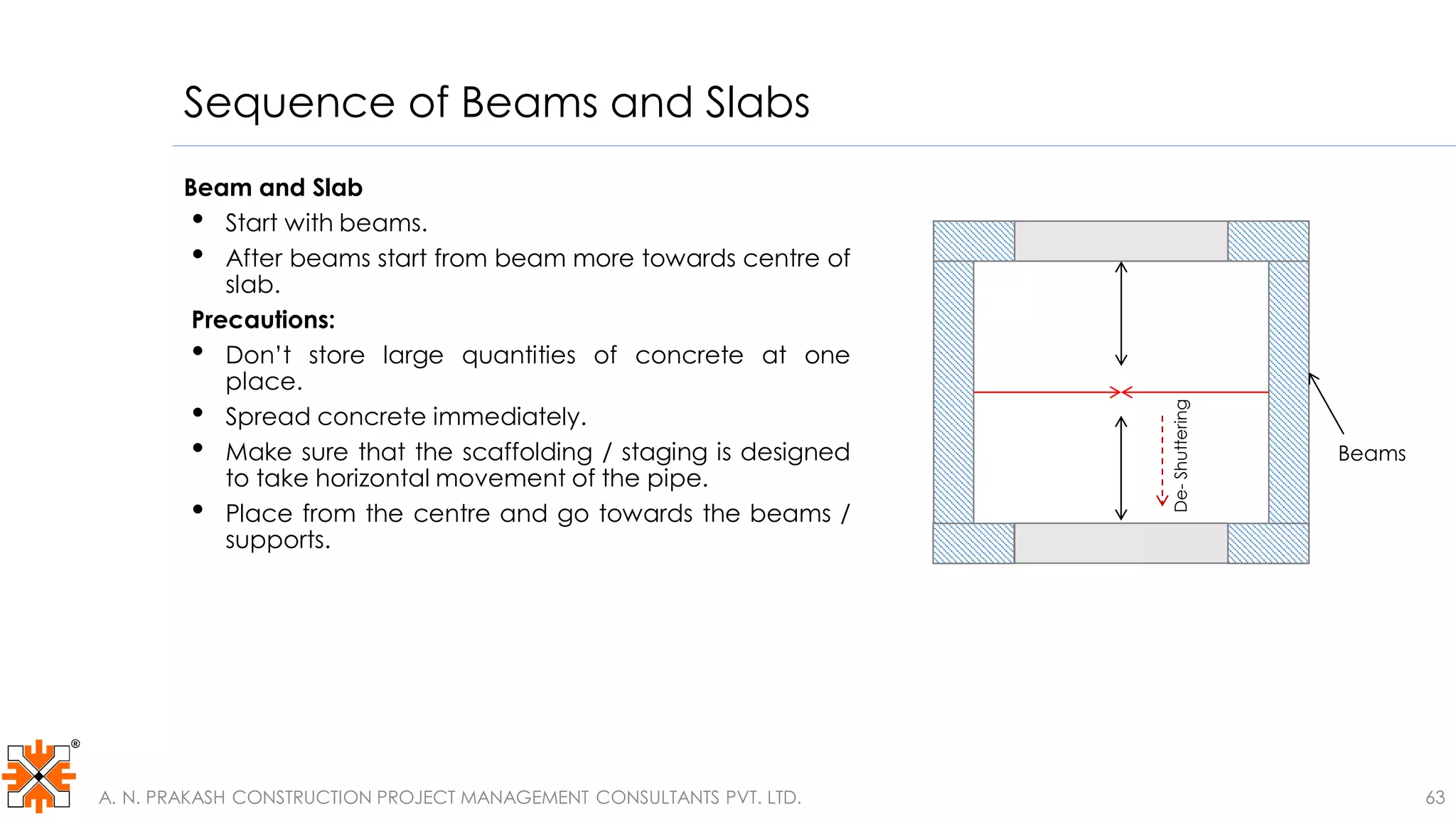

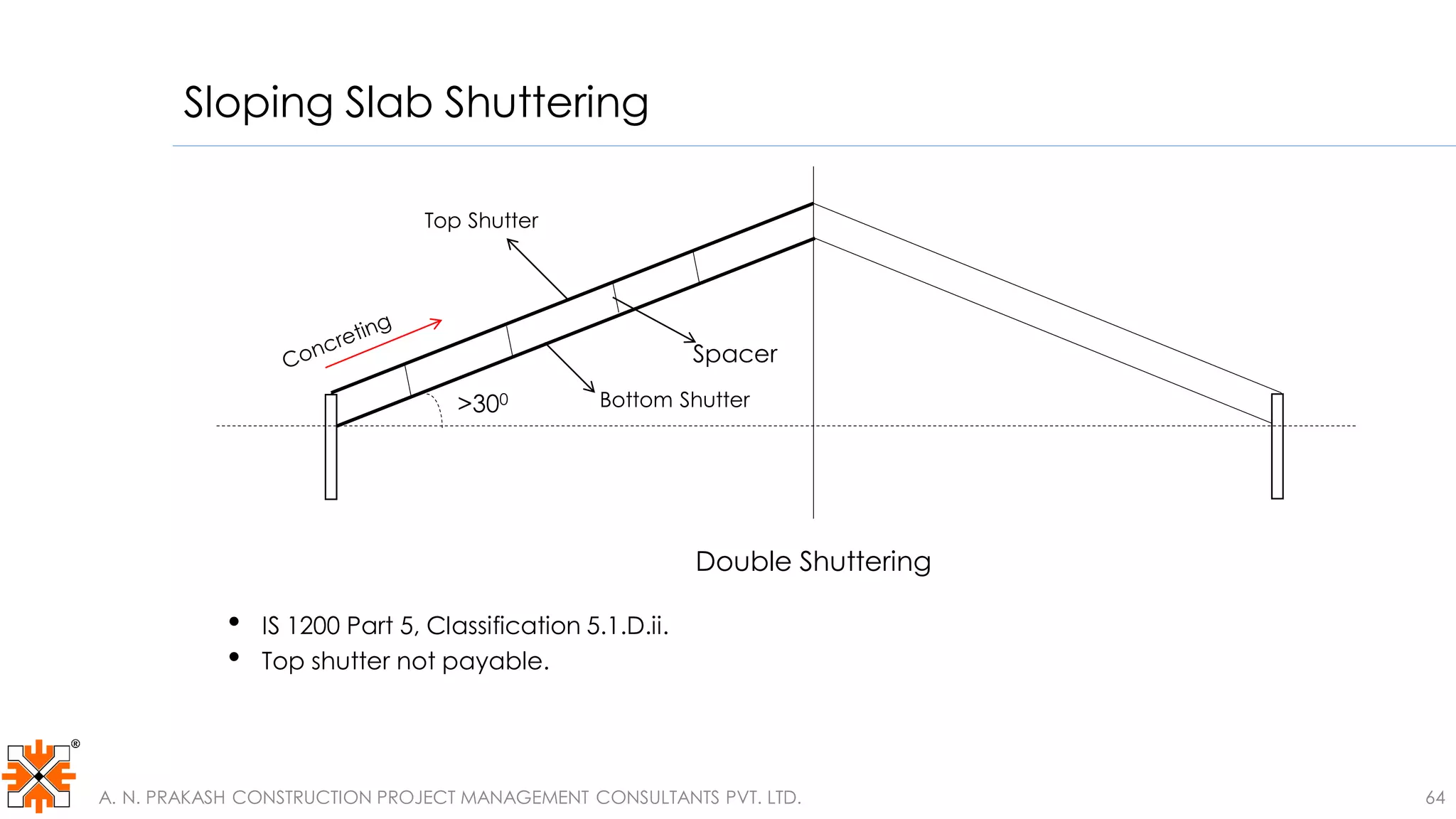

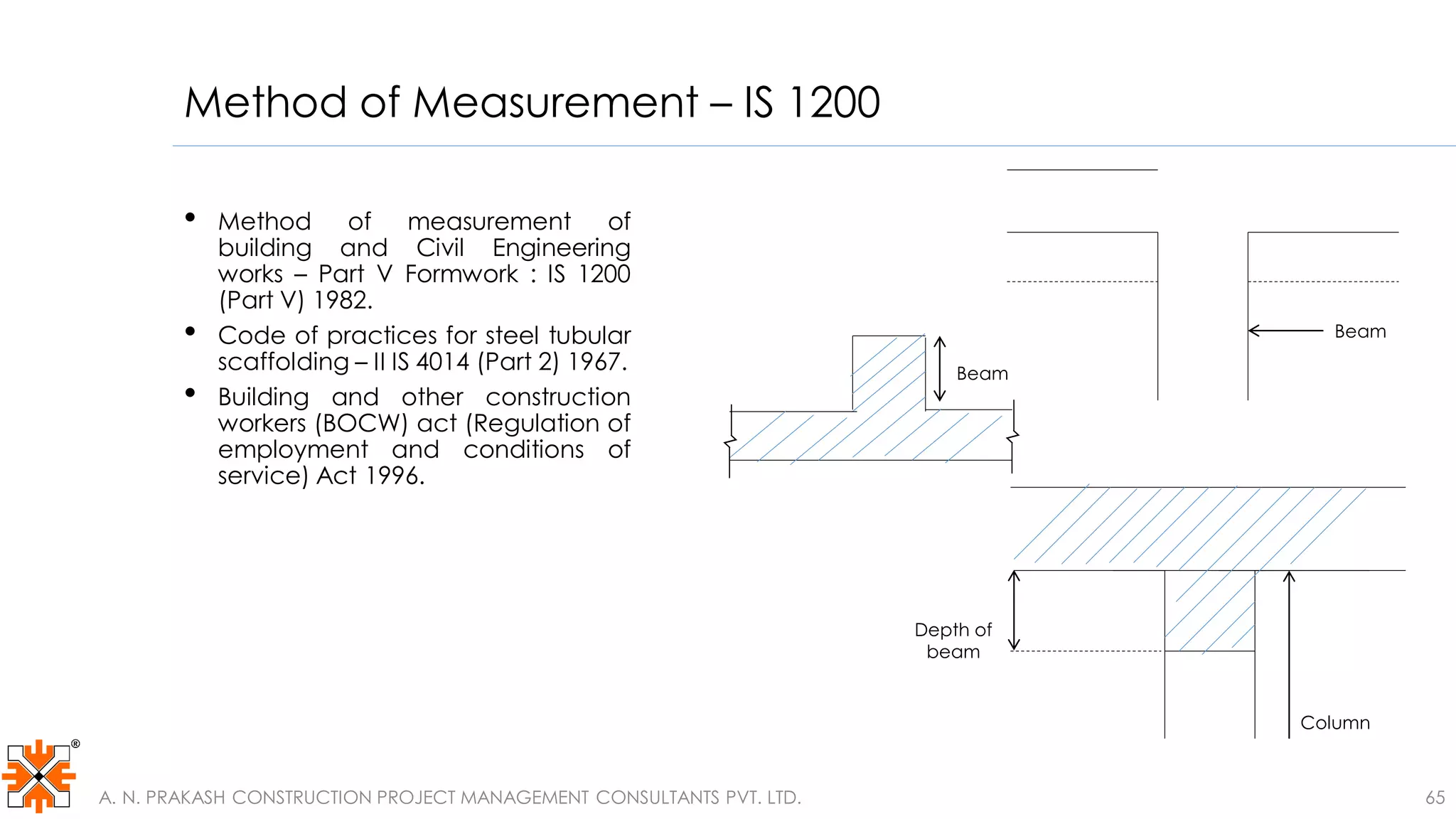

This document discusses formwork used for concrete structures. It begins with defining formwork as a temporary supporting structure used to form concrete into required shapes and sizes. Formwork is then classified based on the system used, materials, and application. Specific formwork types are described, including conventional timber formwork, proprietary modular systems, aluminum formwork, slip forming, and tunnel forming. Components, uses, and construction processes are outlined for walls, columns, beams, and other concrete elements. Considerations for precast versus cast-in-place formwork are also covered.