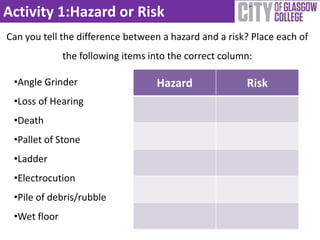

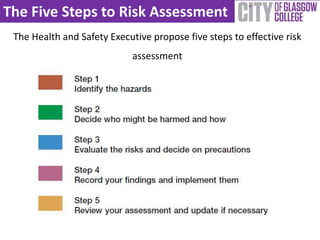

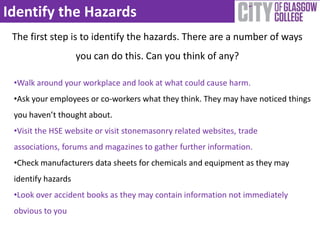

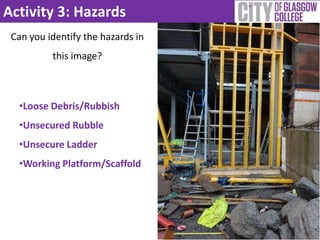

This document provides an introduction to risk assessment for stonemasons. It explains that a risk is the likelihood of harm from a hazard together with the severity of the harm. Common hazards in stonemasonry like angle grinders and ladders are identified. It outlines the five steps to conducting a risk assessment: identifying hazards, identifying those affected, evaluating risks and controls, recording the assessment, and reviewing it. Workers are asked to identify hazards in an image and discuss hazards from their own experience. The document instructs trainees to complete a risk assessment for cutting stone.