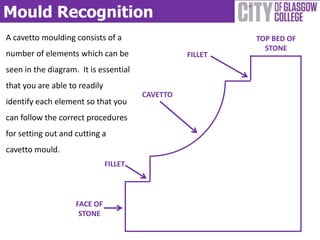

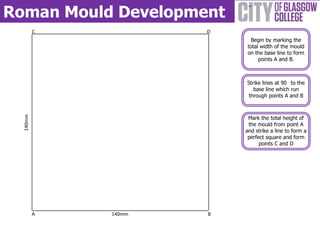

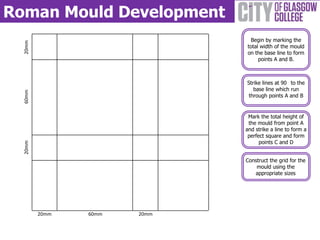

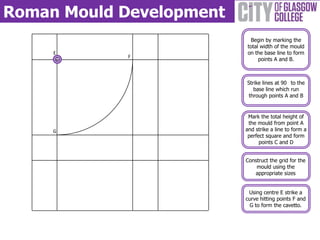

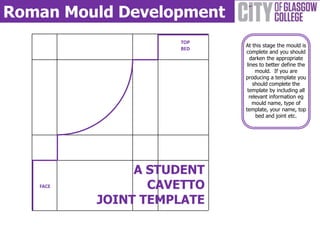

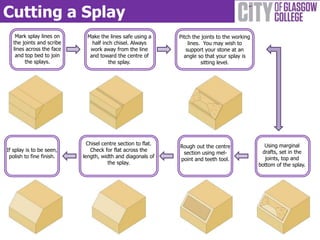

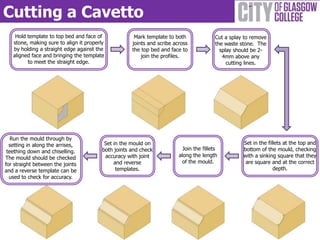

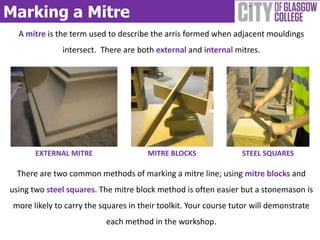

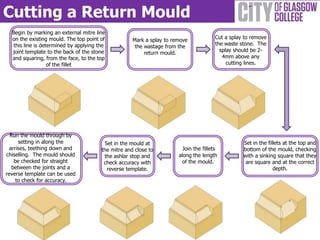

This document provides instructions for stonemasons on how to cut different types of mouldings, including cavetto mouldings and return moulds. It explains how to identify the elements of a cavetto moulding, set out a template to mark the moulding, and cut the moulding using chisels. It also describes how to mark and cut mitres, splays, and return moulds. The goal is to teach stonemasons the proper techniques for shaping stone to create decorative mouldings.