This document provides information on fiberglass production including:

1) There are four main methods for producing fiberglass: hand lay-up, spray lay-up, pultrusion, and chopped strand mat.

2) Fiberglass was accidentally discovered in the 1930s and was used as a replacement for plywood in aircraft during World War II.

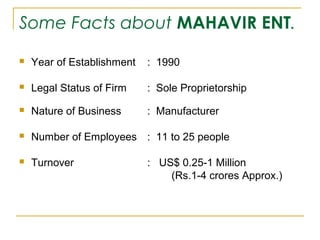

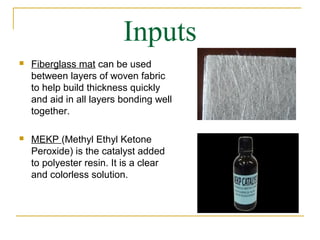

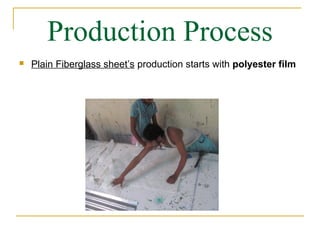

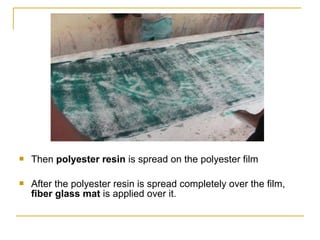

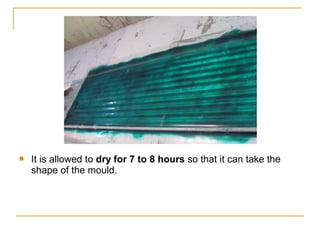

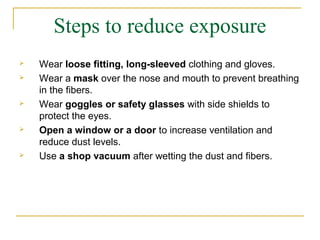

3) The document focuses on Mahavir Enterprise, a manufacturer of fiberglass sheets in India, and describes their production process, applications, and health and safety considerations.