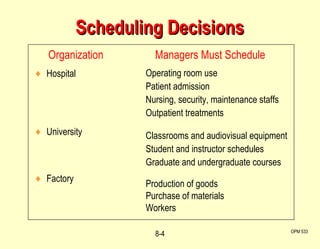

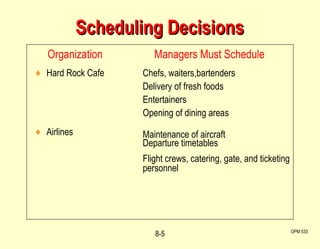

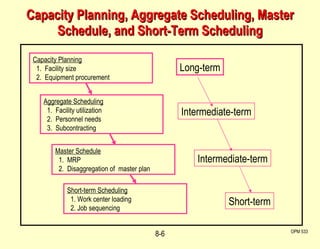

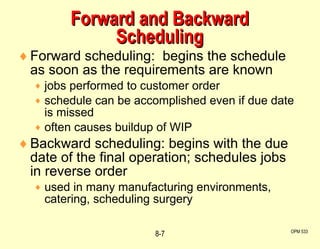

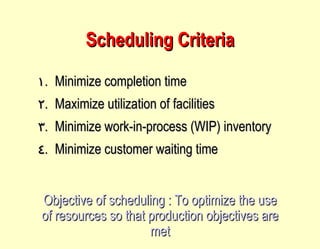

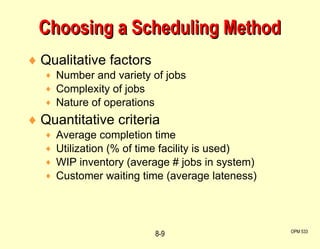

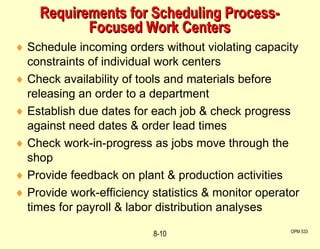

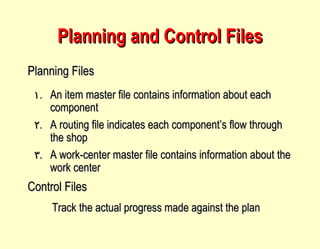

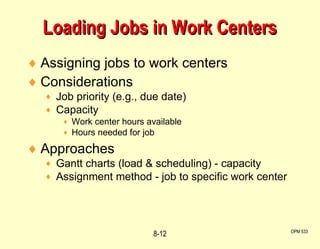

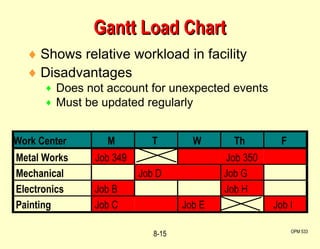

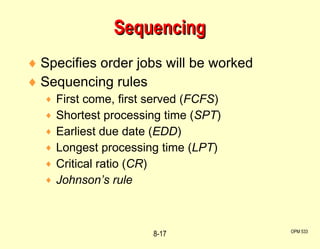

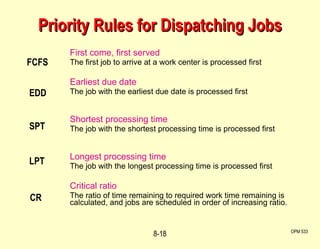

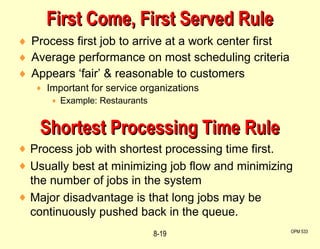

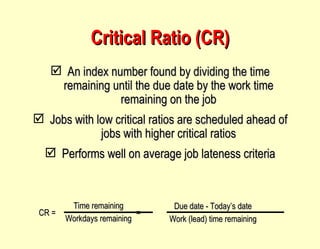

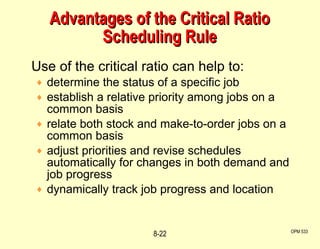

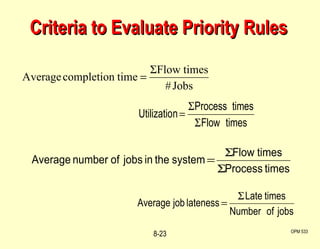

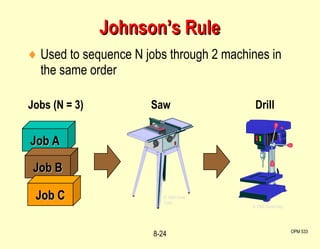

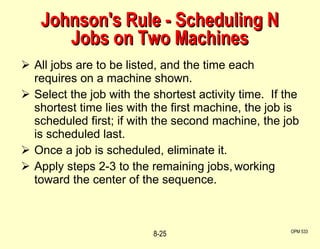

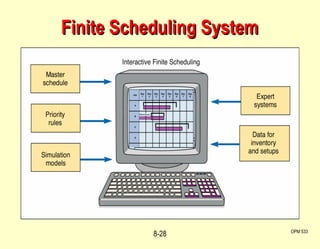

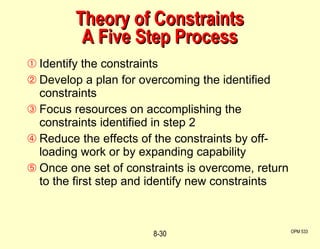

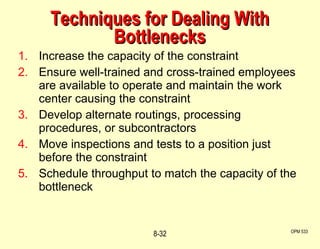

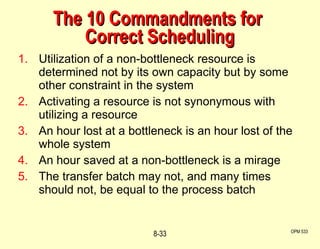

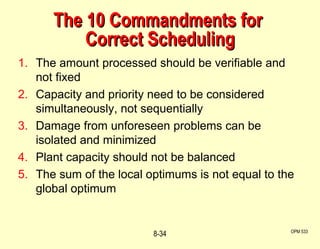

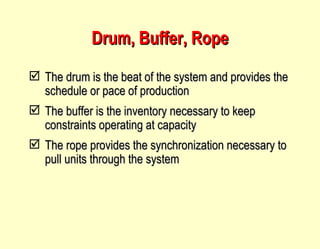

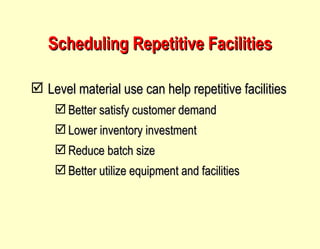

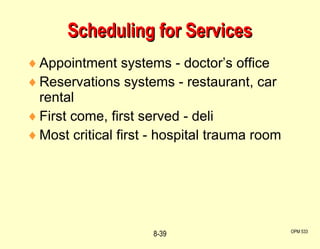

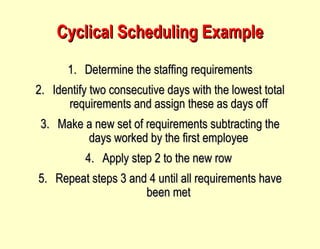

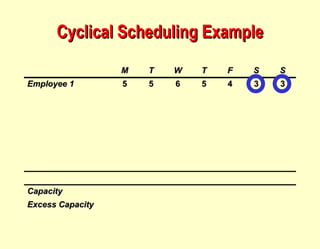

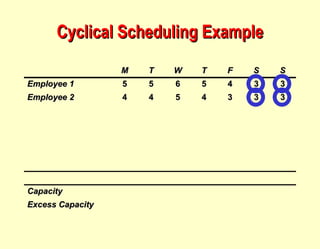

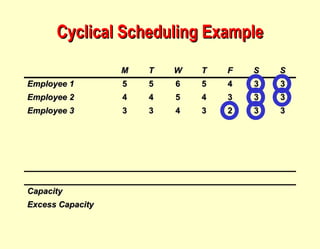

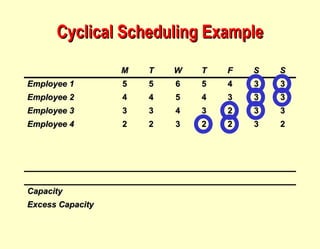

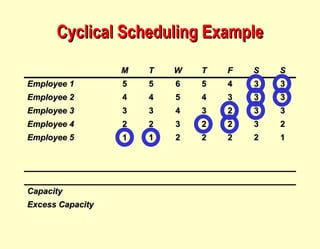

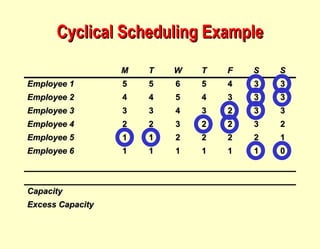

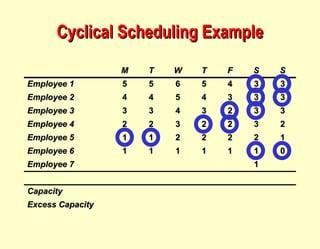

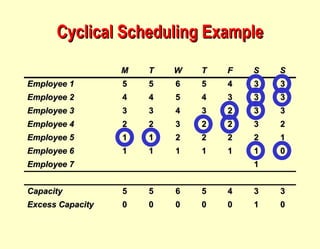

The document discusses various concepts and techniques related to short-term scheduling operations management. It covers topics like capacity planning, aggregate scheduling, master scheduling, forward and backward scheduling, scheduling criteria, sequencing rules, priority dispatching, bottleneck identification and management, and finite capacity scheduling. The goal of scheduling is to optimize resource use so that production objectives are met.