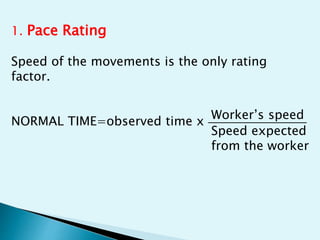

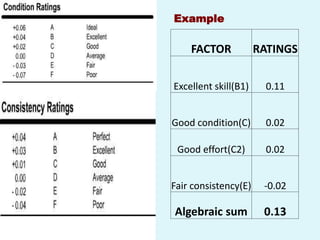

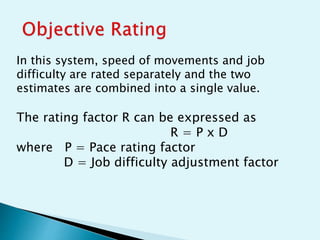

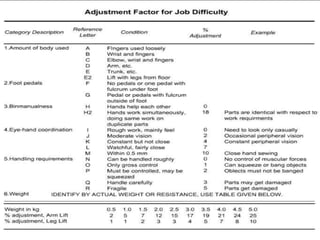

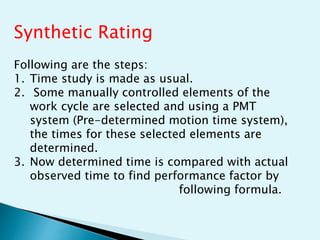

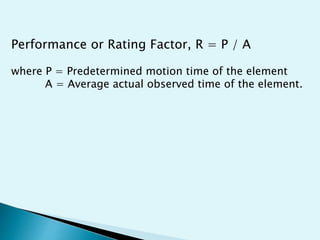

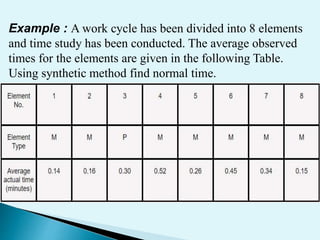

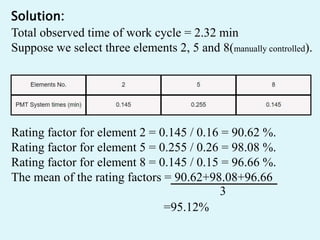

The document discusses various performance rating systems used in evaluating worker efficiency, including pace rating, Westinghouse system, and synthetic rating. It explains the methodology for calculating normal times based on observed performance and specific factors such as skill, effort, and conditions. Examples illustrate how to derive normal time and rating factors through different rating systems and their applications in work measurement.