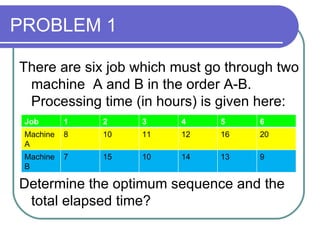

The document describes three problems involving determining the optimal sequence of jobs through multiple machines to minimize the total elapsed time.

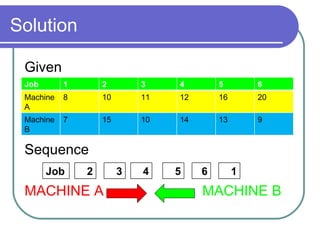

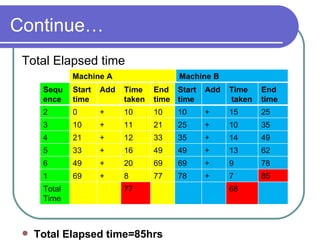

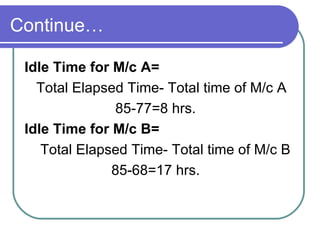

For the first problem involving two machines, the optimal sequence is job 2, 1, 6, 5, 4, 3 with a total elapsed time of 85 hours.

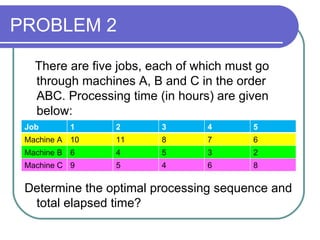

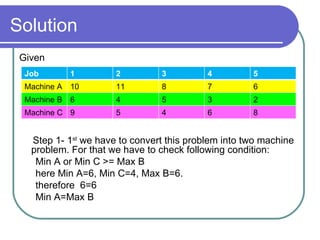

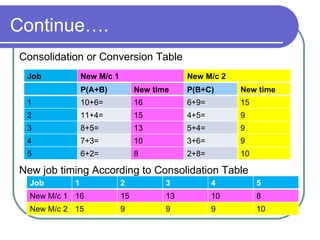

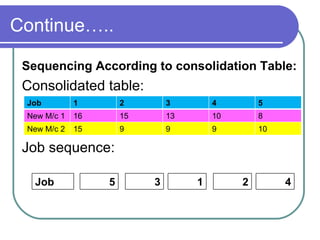

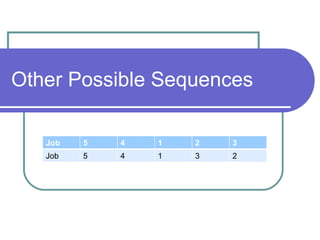

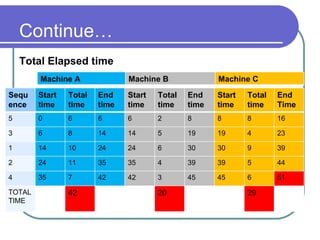

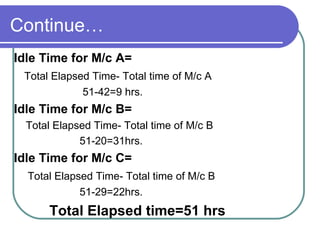

The second problem involving three machines is converted to two virtual machines, and the optimal sequence is job 3, 4, 2, 1, 5 with a total elapsed time of 51 hours.

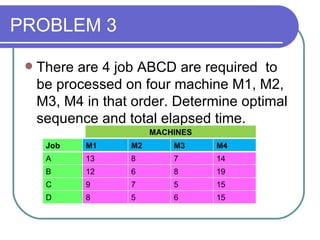

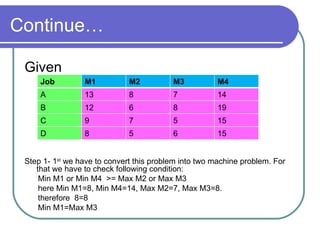

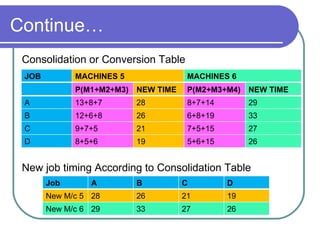

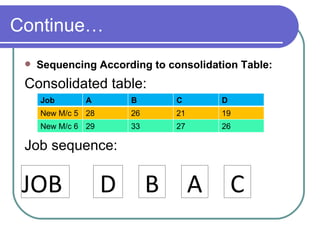

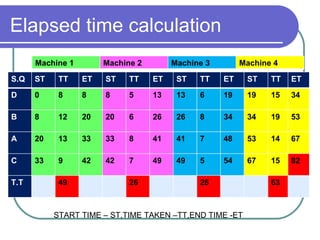

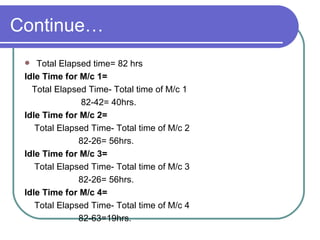

The third problem involving four machines is also converted to two virtual machines, and the optimal sequence is job C, A, B, D with a total elapsed time of 82 hours.