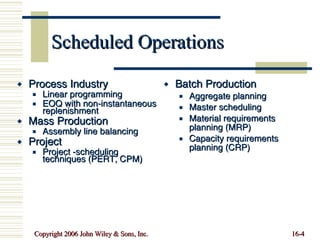

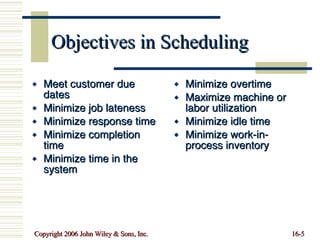

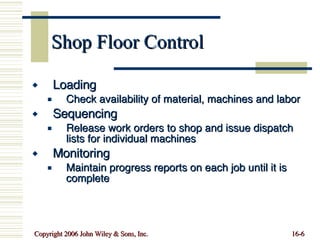

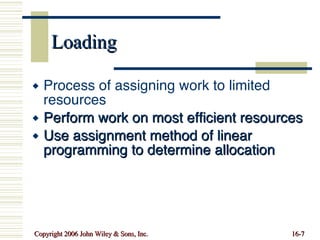

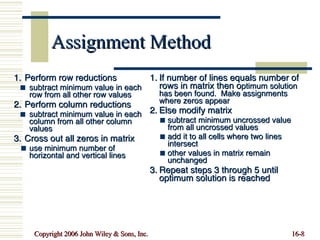

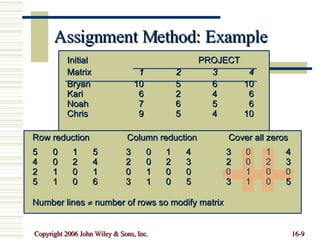

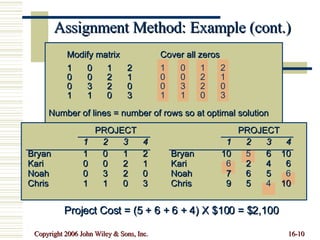

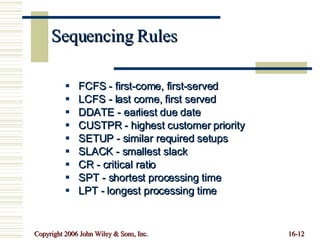

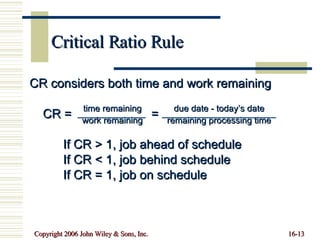

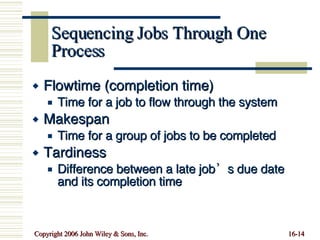

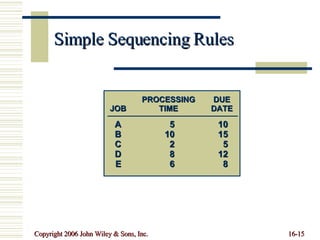

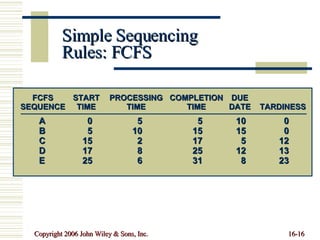

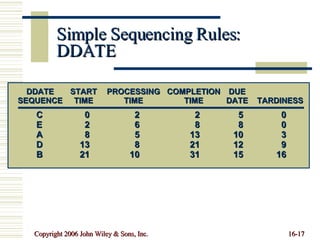

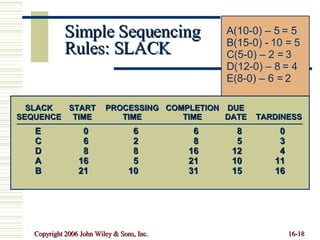

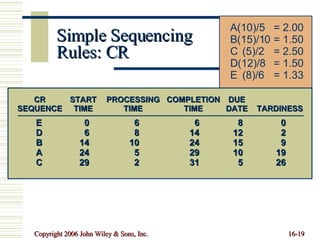

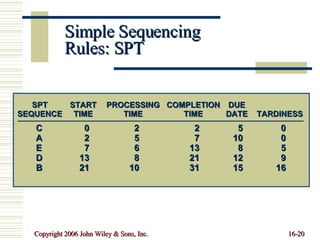

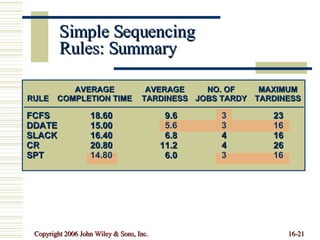

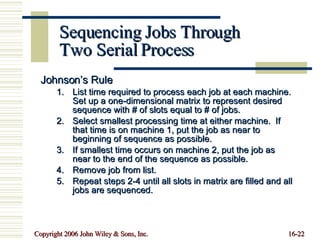

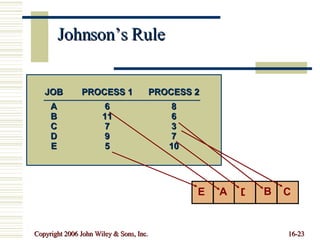

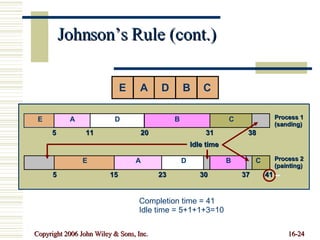

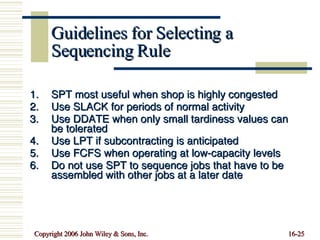

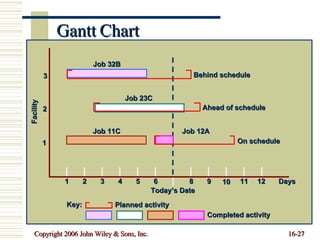

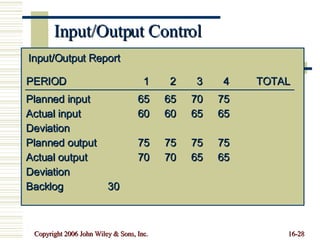

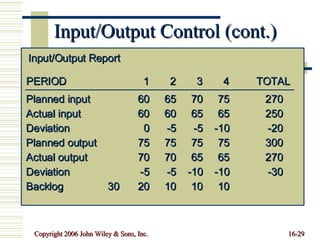

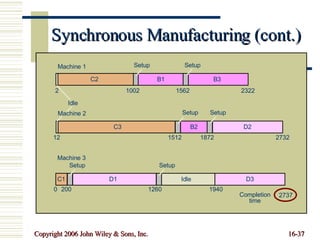

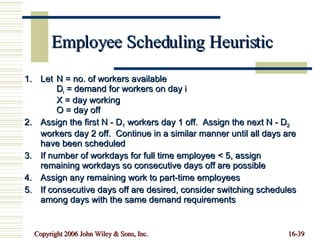

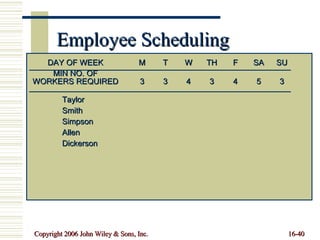

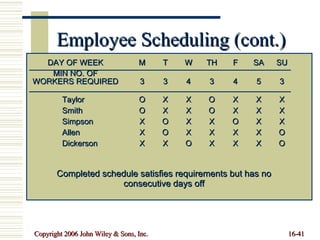

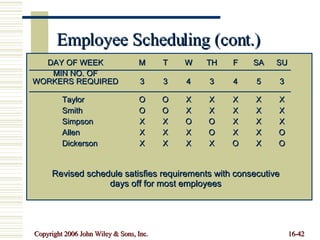

The document discusses various concepts related to scheduling operations management including objectives, loading, sequencing, monitoring, and advanced planning systems. It provides examples of sequencing rules like FCFS, DDATE, and SPT and compares their performance on a sample problem. Guidelines for selecting rules are outlined. Input/output control and Gantt charts are discussed as monitoring tools. Finally, it briefly covers employee scheduling heuristics.