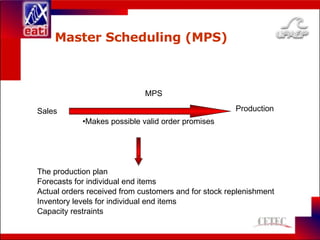

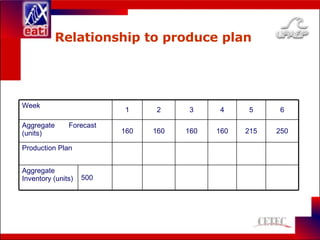

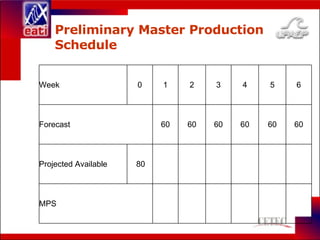

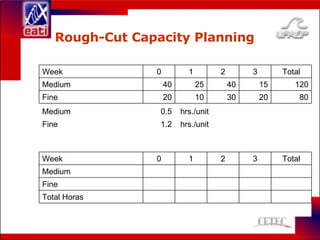

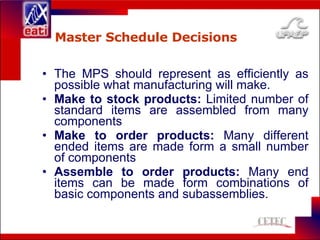

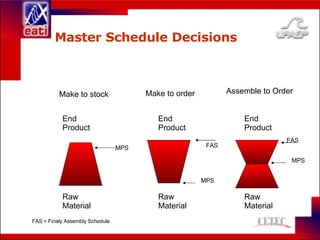

The document discusses master scheduling (MPS), which forms a link between production planning and manufacturing. The MPS drives material requirements planning and keeps production priorities valid. It is a priority plan for manufacturing that reflects marketplace needs and manufacturing capacity. The MPS allows for valid order promises and production planning based on forecasts, orders, inventory levels, and capacity constraints. Developing an effective MPS involves maintaining customer service levels, optimizing resource use, and keeping inventory investment at required levels.