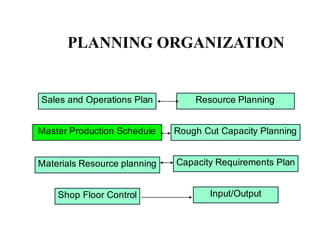

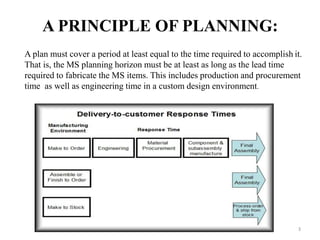

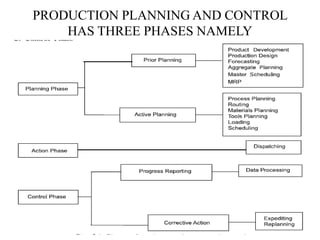

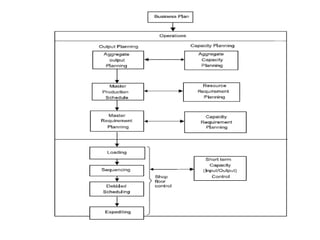

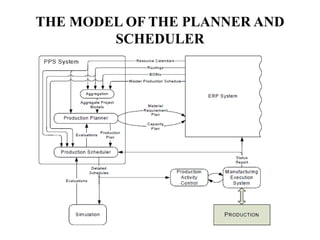

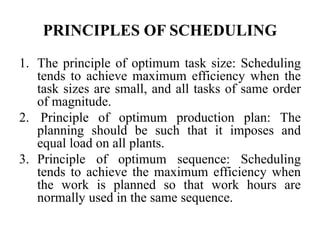

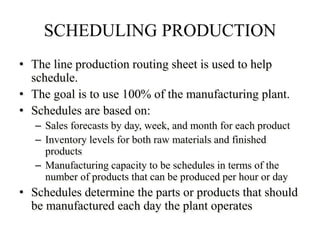

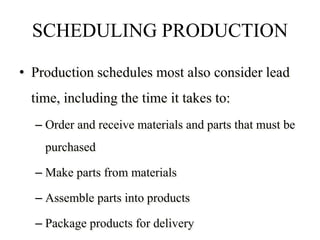

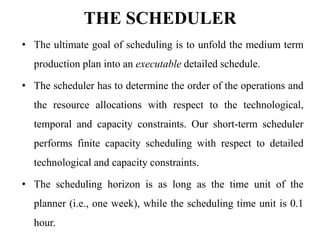

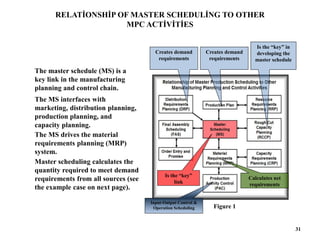

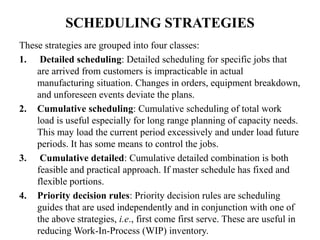

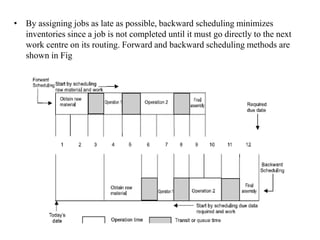

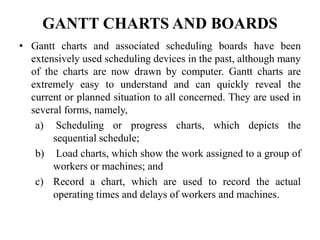

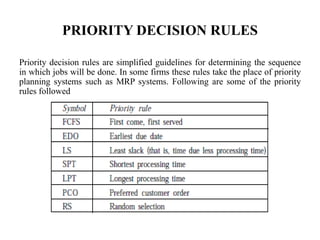

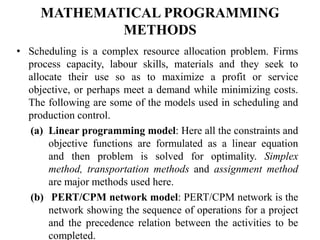

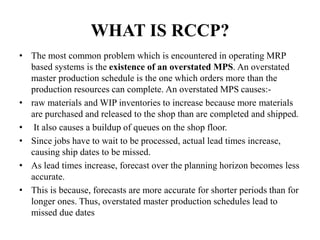

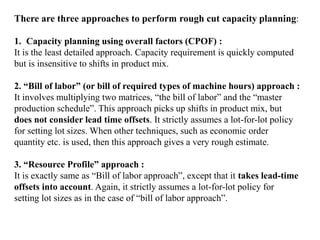

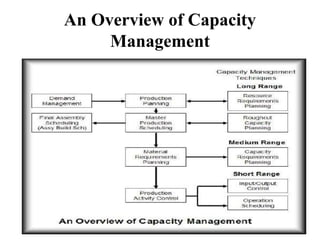

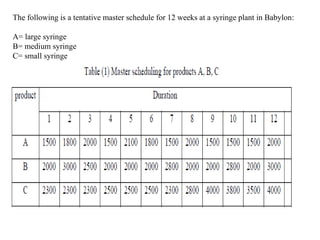

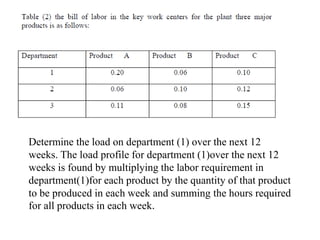

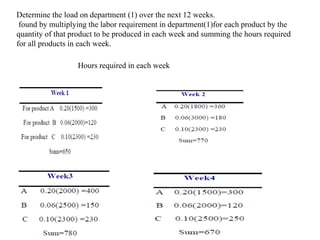

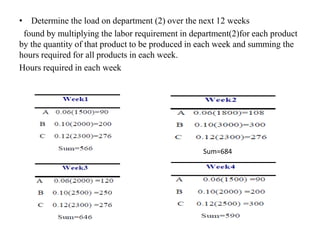

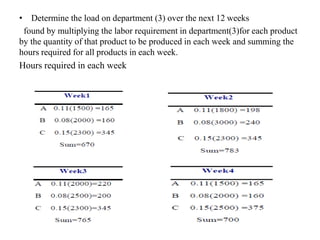

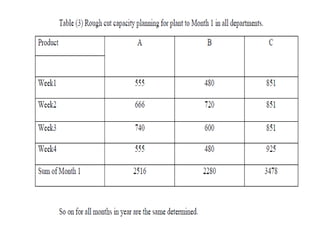

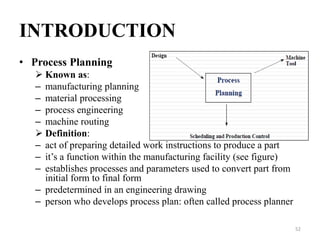

The document provides information on production management and planning. It discusses various production planning concepts like master production scheduling, rough cut capacity planning, resource planning, shop floor control, and materials resource planning. It also covers scheduling concepts like loading, sequencing, dispatching, and expediting. Furthermore, it describes the roles of a production planner and scheduler and discusses planning techniques like priority decision rules, Gantt charts, mathematical programming methods, and rough cut capacity planning.