The document discusses various interfacing examples with the ARM 7 LPC2148 microcontroller, including connections for LEDs, relays, stepper motors, DACs, ADCs, seven-segment displays, and LCDs. Each section includes a brief explanation of the components used, their configuration, and sample code for implementing functionality. These examples serve as practical applications for controlling and displaying data using the LPC2148 microcontroller.

![Dr.Y.NARASIMHA MURTHY Ph.D

yayavaram@yahoo.com

PROGRAM

#include <LPC2148.H> // 2148 Header

#include "SPIsw.h"

unsigned long DACval, DACreg;

int main (void) // Main program

{

PINSEL0 = 0 ; // Port 0 as GPIO

PINSEL1 = 0x0000 ; // Port 0 as Outport

PINSEL2 & = 0x0000000C;

SPI_ init (&IOPIN0,29/*CS*/, 5/*MISO*/, 6/*MOSI*/, 4/*SCK*/, 0/*CPOL*/, 0/*CPHA*/) ;

// Set output voltage

DAC val = 2047 ; // Range [0..4095]

DAC reg = DACval | 0x7000 ;

SPI_enable () ; // Enable SPI port

SPI_char ((DACreg >> 8) & 0x00FF);

SPI_char (DACreg & 0x00FF) ;

SPI_disable () ; // Disable SPI port

while (1) ; // Infinite Loop

}

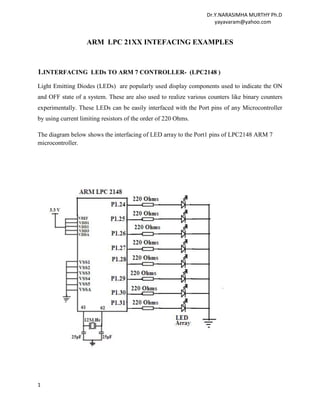

5. INTERFACING ADC –LPC2148

LPC2148 controller has two on n-chip ADCs. In the present program the ADC0 with channel 3

is used and configured to convert the analog input signal into its equivalent digital output.The

configuring of on chip ADC is shown below.

9](https://image.slidesharecdn.com/arm7-examplesfinal-130415124707-phpapp02/85/Arm7-Interfacing-examples-9-320.jpg)

![Dr.Y.NARASIMHA MURTHY Ph.D

yayavaram@yahoo.com

PROGRAM

#include<lpc21xx.h>

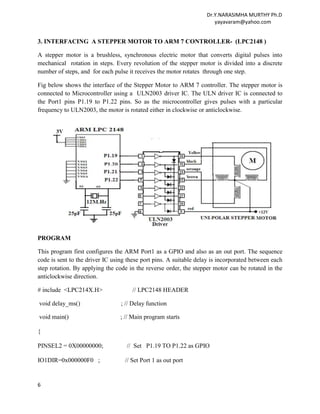

unsigned char seg[16] ={0x40,0x79,0x24,0x30,0x19,0x12,0x02,0x78,0x00,0x10,0x08,

0x03,0x46,0x21,0x06,0x0e};

unsigned char seg_val,seg_val1;

unsigned char count,count1;

unsigned long int var,var1;

void main(void)

{ unsigned long int k;

PINSEL0=0X00000000; // Select Port 0 pins as GPIO lines

12](https://image.slidesharecdn.com/arm7-examplesfinal-130415124707-phpapp02/85/Arm7-Interfacing-examples-12-320.jpg)

![Dr.Y.NARASIMHA MURTHY Ph.D

yayavaram@yahoo.com

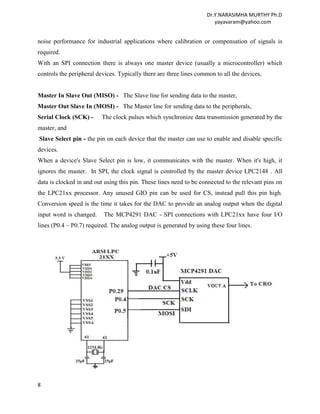

PINSEL1=0X00000000; // Select Port 1 pins as GPIO lines

IODIR0 = 0X00FF0000; // Configure the required pins of Port 0 as output pins

IODIR1 = 0X00FF0000; // Configure the required pins of Port 1 as output pins

for (count=0;count<=15;count++) // COUNT FOR MSB

{ IOCLR1 = var;

seg_val = seg[count];

var = seg_val;

var = var<<16;

IOSET1 = var;

for(count1=0;count1<=15;count1++) // COUNT FOR LSB

{ IOCLR0=var1;

seg_val1=seg[count1];

var1=seg_val1;

var1=var1<<16;

IOSET0=var1;

for(k=0;k<50000;k++);

} // End for loop

} // End for loop

} // End main.

13](https://image.slidesharecdn.com/arm7-examplesfinal-130415124707-phpapp02/85/Arm7-Interfacing-examples-13-320.jpg)

![Dr.Y.NARASIMHA MURTHY Ph.D

yayavaram@yahoo.com

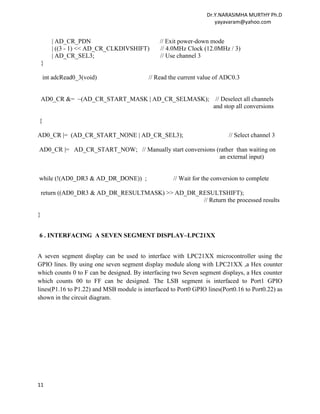

7 . INTERFACING OF 2X16 LCD MODULE - LPC21XX

The ARM7 LPC21xx processor is interfaced to the 2x16 LCD mpdule in 4-bit mode .The

interfcae diagram is shown below.The four data pins are connected with 4 data bits (P0.19 –

P0.22 pins to bits D4-D7), address bit (RS-P0.16), read/write bit (R/W-P0.17) and control

signal (E-P0.18) to make LCD display complete.The pins D0,D1,D2,D3 are left free with out

any connections.

16X 2 LCD is a 16 pin module . In which pins 1 &16 are grounded, 2 &15 are given to V CC

and 3rd pin is given to potentiometer in order adjust the contrast of LCD. Pins 4, 5 & 6

corresponds to RS, R/W & EN respectively. Pins 7 to 14 are data lines from D0 to D7

respectively. Here the LCD is used in 4 bit mode i.e. upper 4 bits are used to transfer the data

with MSB first and LSB next. Port 0 pins i.e. from P0.16 to P0.22 are used for both data and

control signals. The interfacing diagram of 16X2 LCD is shown below.

PROGRAM

#include <LPC21xx.H>

long unsigned int data,temp1,temp2;

unsigned char *ptr,data_array[] = "SSBN DEGREE & PG COLLEGE, ATP";

void main()

{

int i=0;

14](https://image.slidesharecdn.com/arm7-examplesfinal-130415124707-phpapp02/85/Arm7-Interfacing-examples-14-320.jpg)

![Dr.Y.NARASIMHA MURTHY Ph.D

yayavaram@yahoo.com

PINSEL0 = 0x00000000; // Select Port 0 pins as GPIO lines

IODIR0 = 0x00ff0000; // Configure the required pins of Port 0 as output pins

lcd_init(); // LCD initialization

delay(2500); // Delay

ret_home(); // Cursor to return home

delay(2500); // Delay

clr_disp(); // Clear display

delay(2500); // Delay

ptr = &data_array[0];

for(i=1;i<sizeof(data_array);i++)

{

if(i == 17)

{ temp1 = 0xc0; // Goto 2nd line in the LCD

lcd_com(); // Byte to nibble conversion of LCD command

delay(800);

} // End if

data = *ptr;

lcd_data(); // Byte to nibble conversion of LCD data

ptr++;

} // End for loop

} // End main

void lcd_init(void) // Initialization of LCD

{

temp2=0x30; // Assign command to temp2

temp2=temp2<<16; // Shift the data by 16 bits left

cmd_wrt(); // Command write subroutine

delay(800); // Delay

temp2=0x30; // Assign command to temp2

temp2=temp2<<16; // Shift the data by 16 bits left

cmd_wrt(); // Command write subroutine

delay(800); // Delay

temp2=0x30; // Assign command to temp2

temp2=temp2<<16; // Shift the data by 16 bits left

cmd_wrt(); // Command write subroutine

delay(800); // Delay

temp2=0x30; // Assign command to temp2

temp2=temp2<<16; // Shift the data by 16 bits left

cmd_wrt(); // Command write subroutine

delay(800); // Delay

temp2=0x20; // Assign command to temp2

temp2=temp2<<16; // Shift the data by 16 bits left

cmd_wrt(); // Command write subroutine

delay(800); // Delay

temp1 = 0x28; // Command for LCD to function in 4 bit mode

lcd_com();

delay(800);

15](https://image.slidesharecdn.com/arm7-examplesfinal-130415124707-phpapp02/85/Arm7-Interfacing-examples-15-320.jpg)