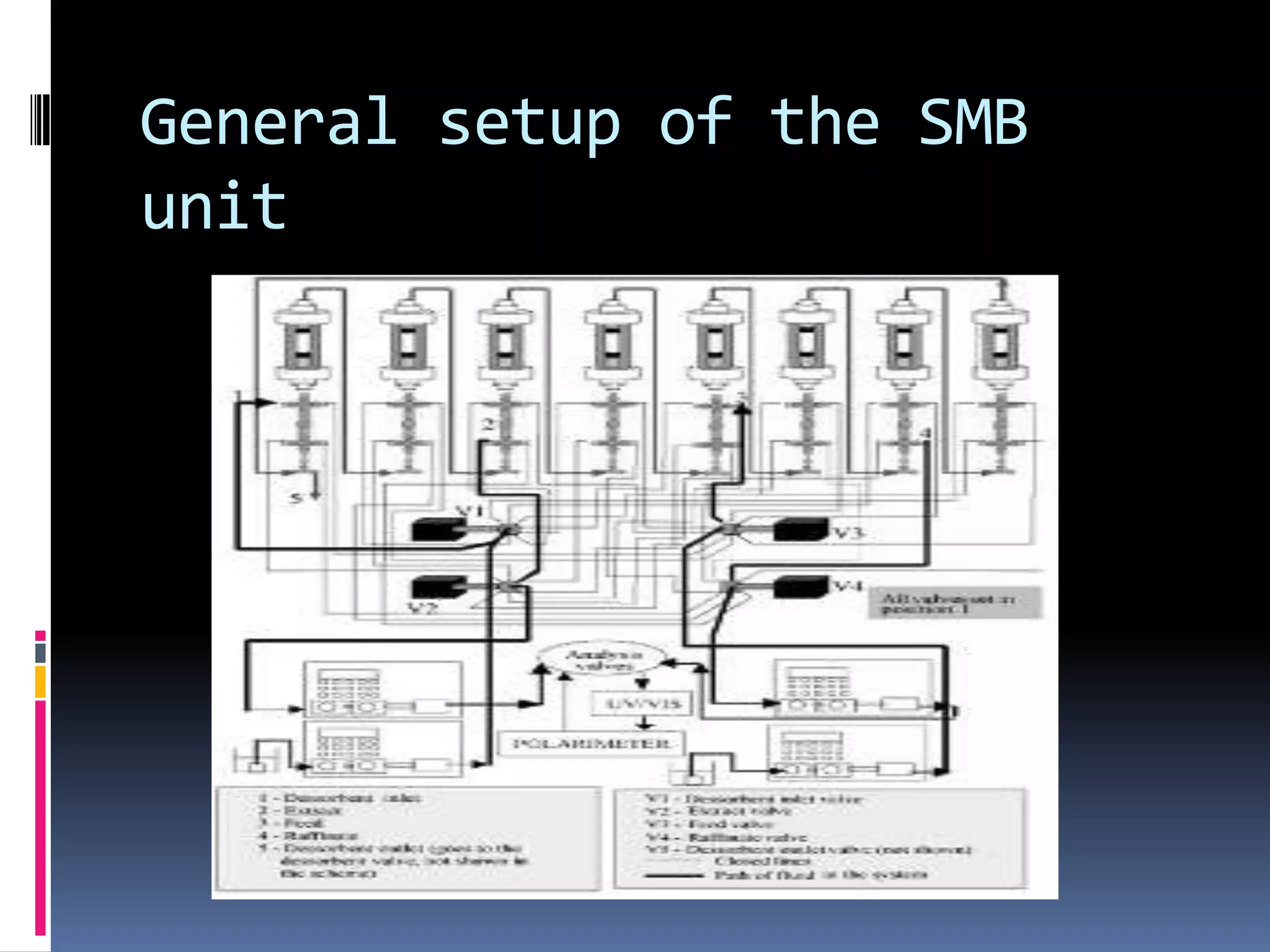

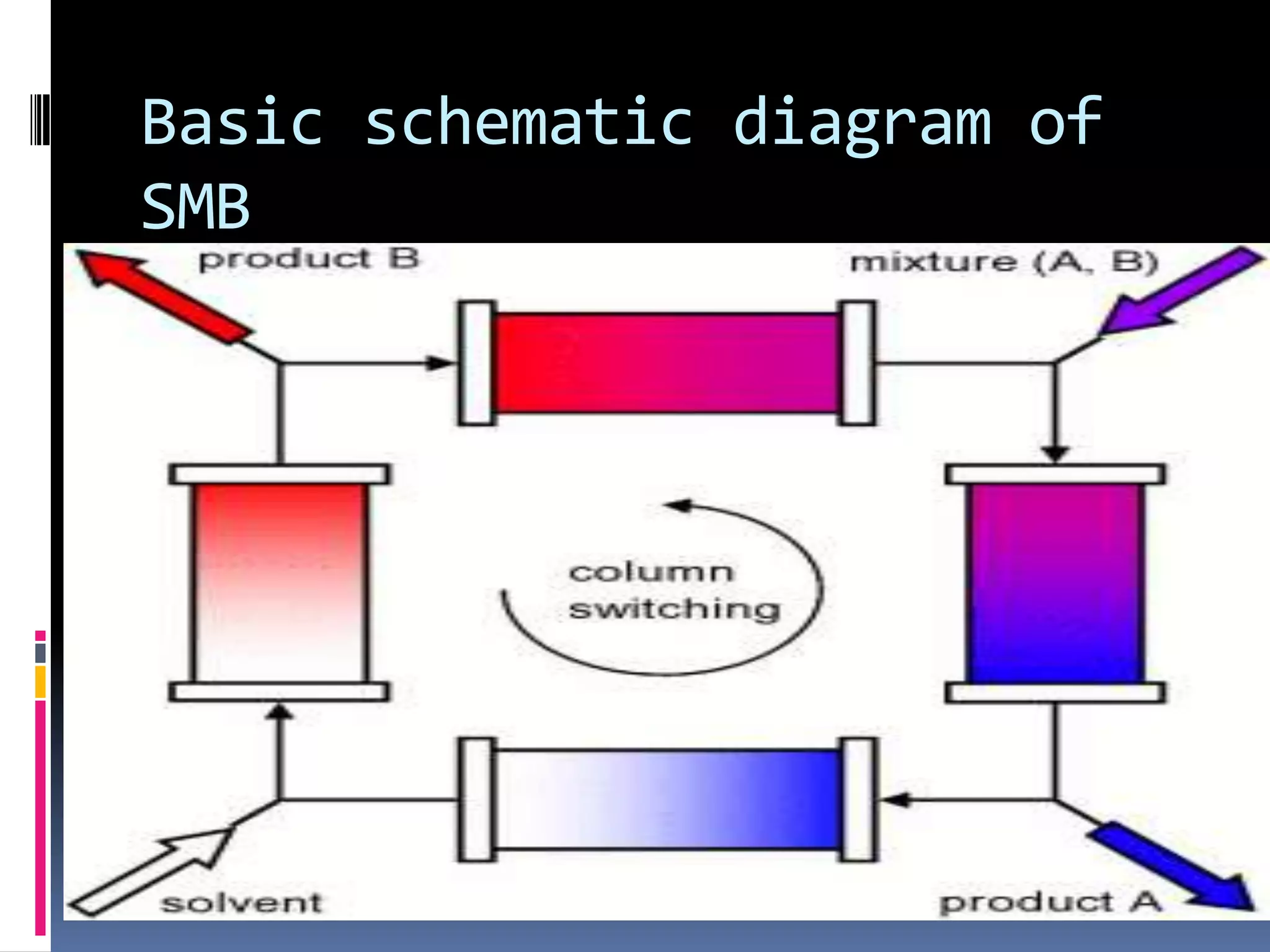

Simulated moving bed (SMB) chromatography is an advanced continuous purification technique widely applied in the pharmaceutical and petrochemical industries for separating complex mixtures into high-purity fractions. It enhances productivity while significantly reducing solvent consumption compared to traditional batch chromatography, making it preferred for large-scale operations. The technology has evolved to include various operational modes and is recognized for its effectiveness in the chiral separation of compounds and the purification of bio-pharmaceuticals.

![Reference

[1] Dr. Kathleen Mihlbachler, Ph.D., Eli Lilly and Company, Advances in

Large-Scale Biopharmaceutical Manufacturing and Scale-Up

Production, Available from -

http://www.bioplanassociates.com/asm/Abst21.html

[2]Yi Xie ,Yoon-Mo Koo,and Nien-Hwa LindaWang, Preparative

Chromatographic Separation: Simulated Moving Bed and Modified

Chromatography Methods, 2001, 6: 363-375, Available from -

http://www.bbe.or.kr/storage/journal/BBE/6_6/6726/articlefile/article.pd

f

[3]Arvind Rajendranb, Galatea Paredesa, Marco Mazzotti, Simulated

moving bed chromatography for the separation of enantiomers,Volume

1216, Issue 4, 23 January 2009, Pages 709-738, Available from

http://www.sciencedirect.com/science/article/pii/S0021967308018451

[4] Separations Analytical Instruments

bv website,http://www.separations.nl/docs/SMB%20Knauer%20SMB.pd

f](https://image.slidesharecdn.com/advancedchromatographytechnique-130720024906-phpapp01/75/Industrial-Applications-Of-Chromatography-Technique-14-2048.jpg)