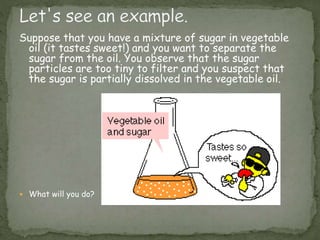

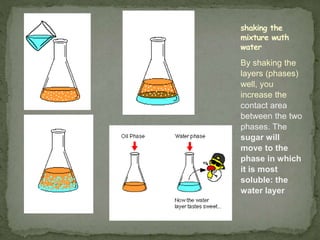

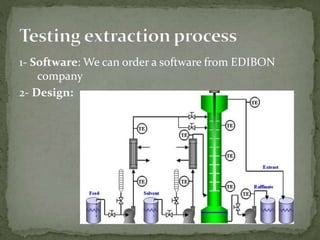

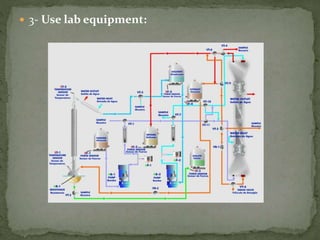

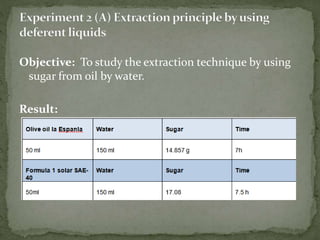

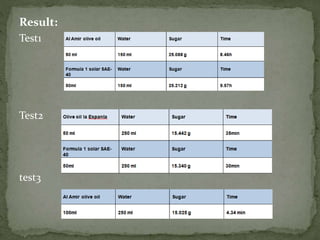

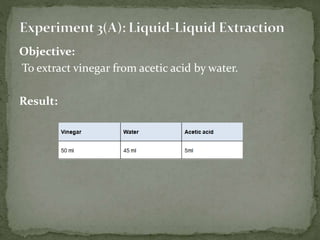

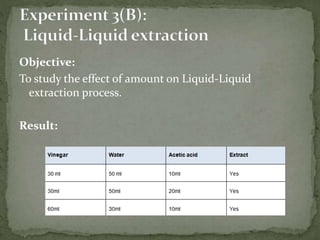

The objective was to study liquid-liquid extraction through maintaining the unit and manual experiments. For the unit, a diaphragm seal was found to be damaged, preventing its use. Manual experiments showed extraction of sugar from oil using water and vinegar from acetic acid using water. Further experiments are needed to fully understand the impact of variables like amount. A new diaphragm seal or pump is recommended to fix the unit.