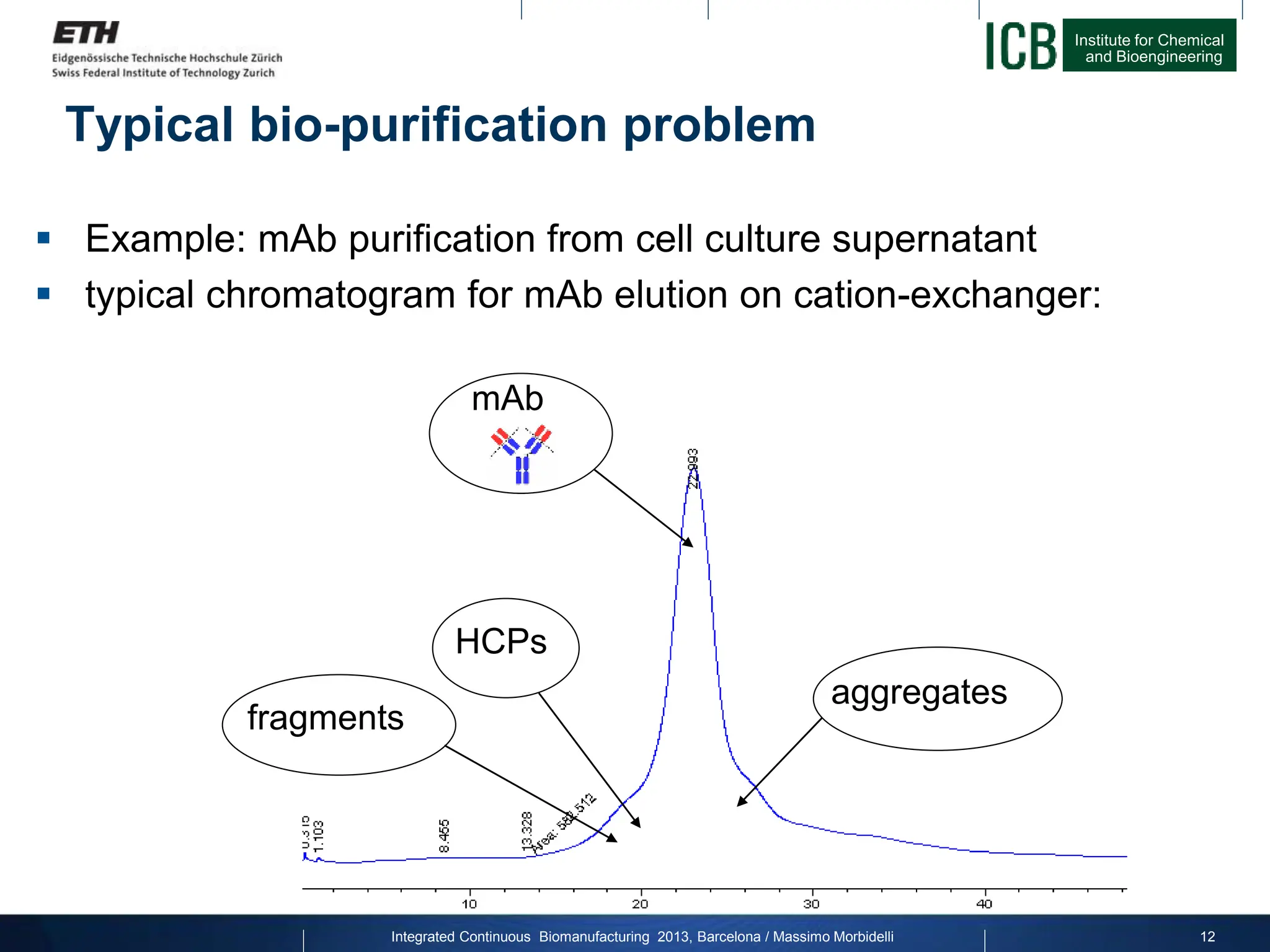

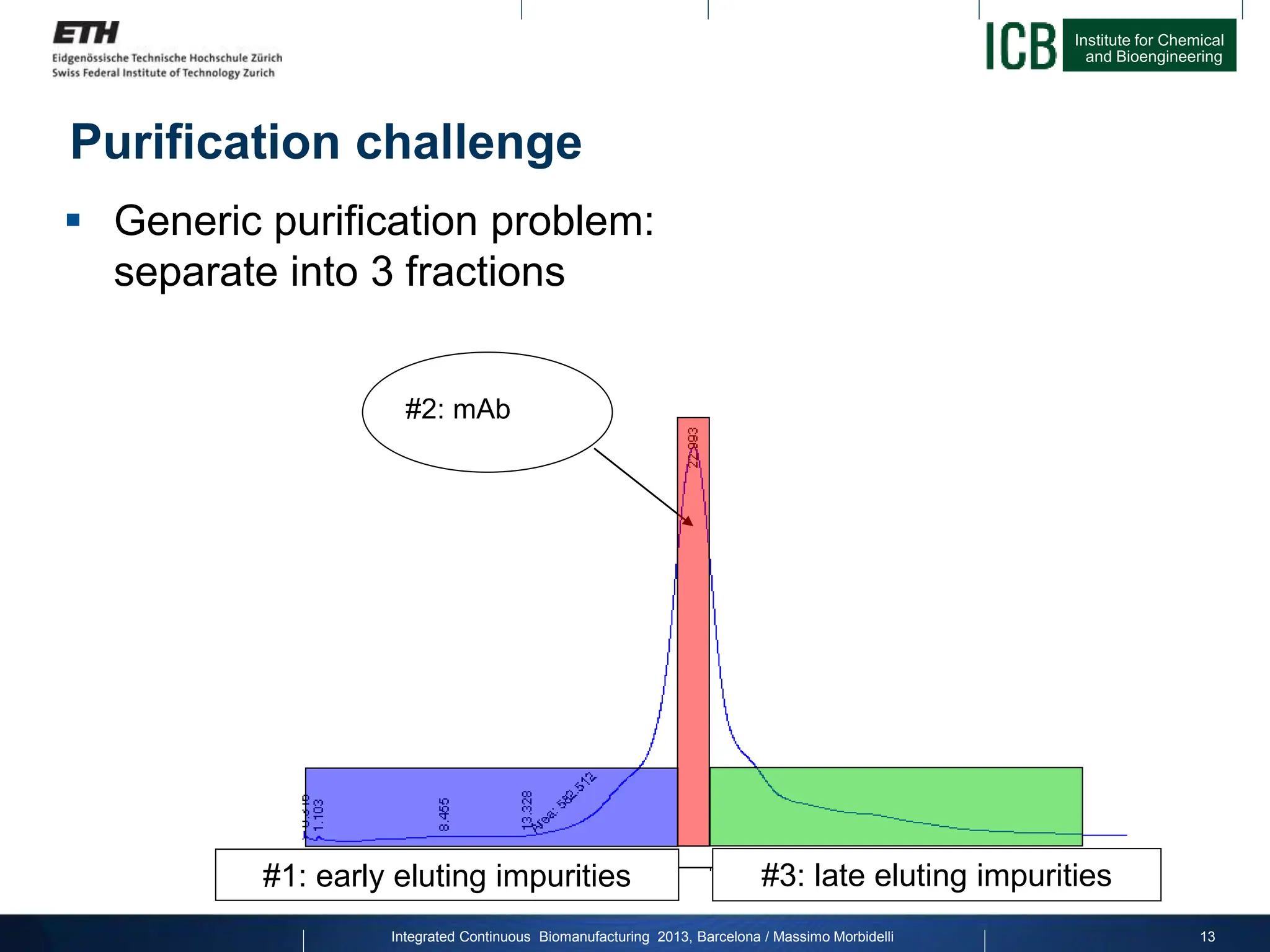

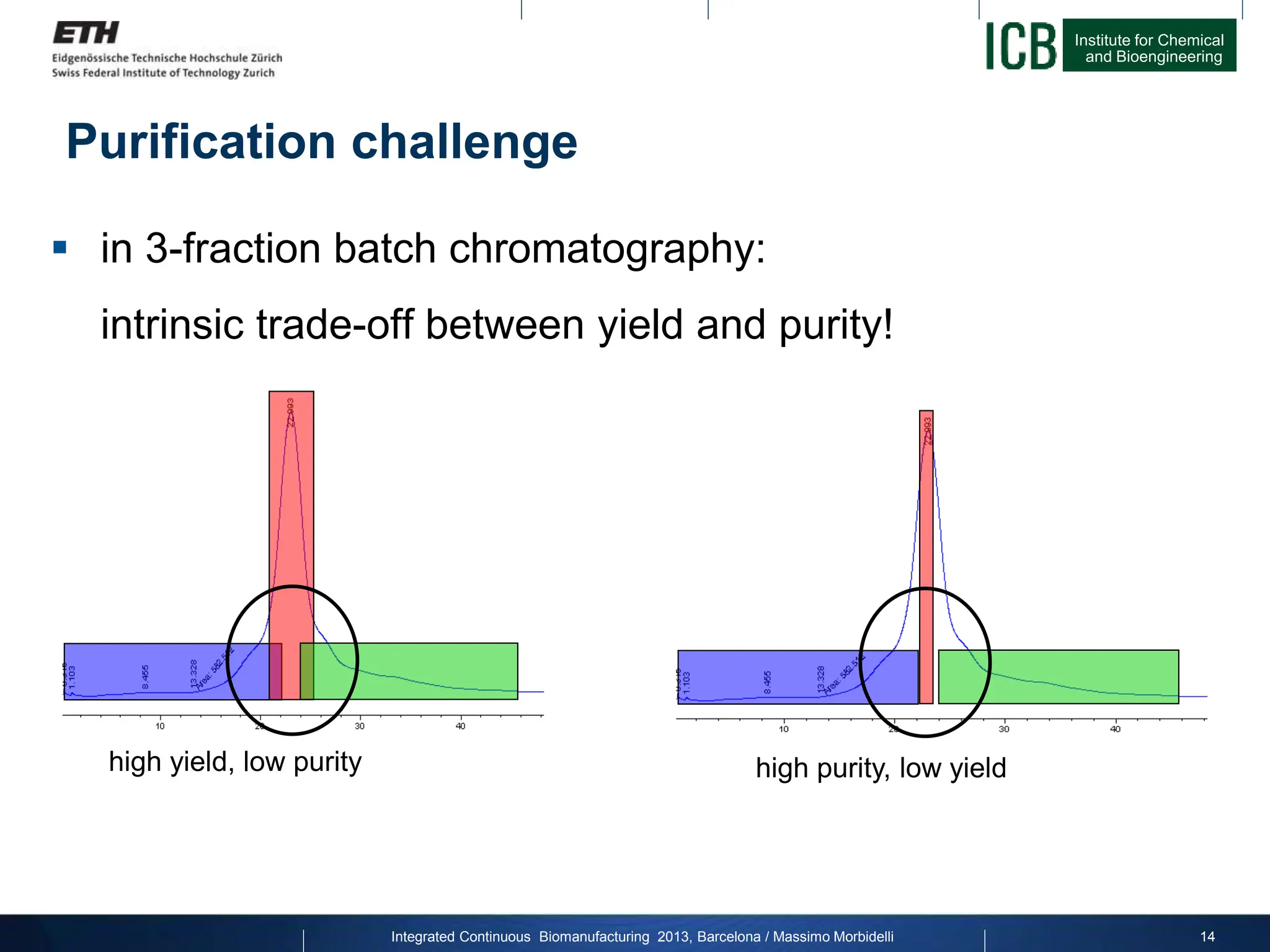

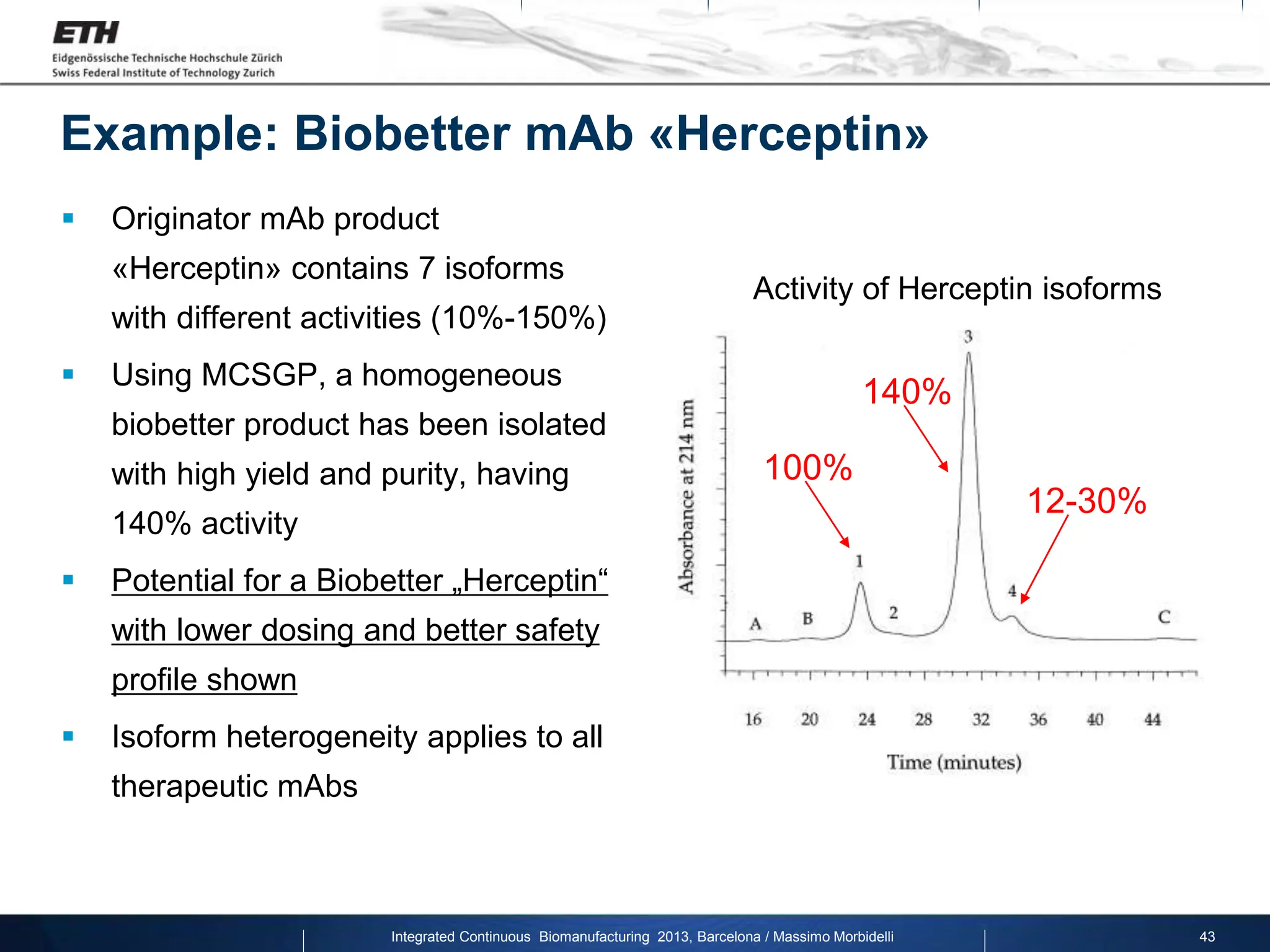

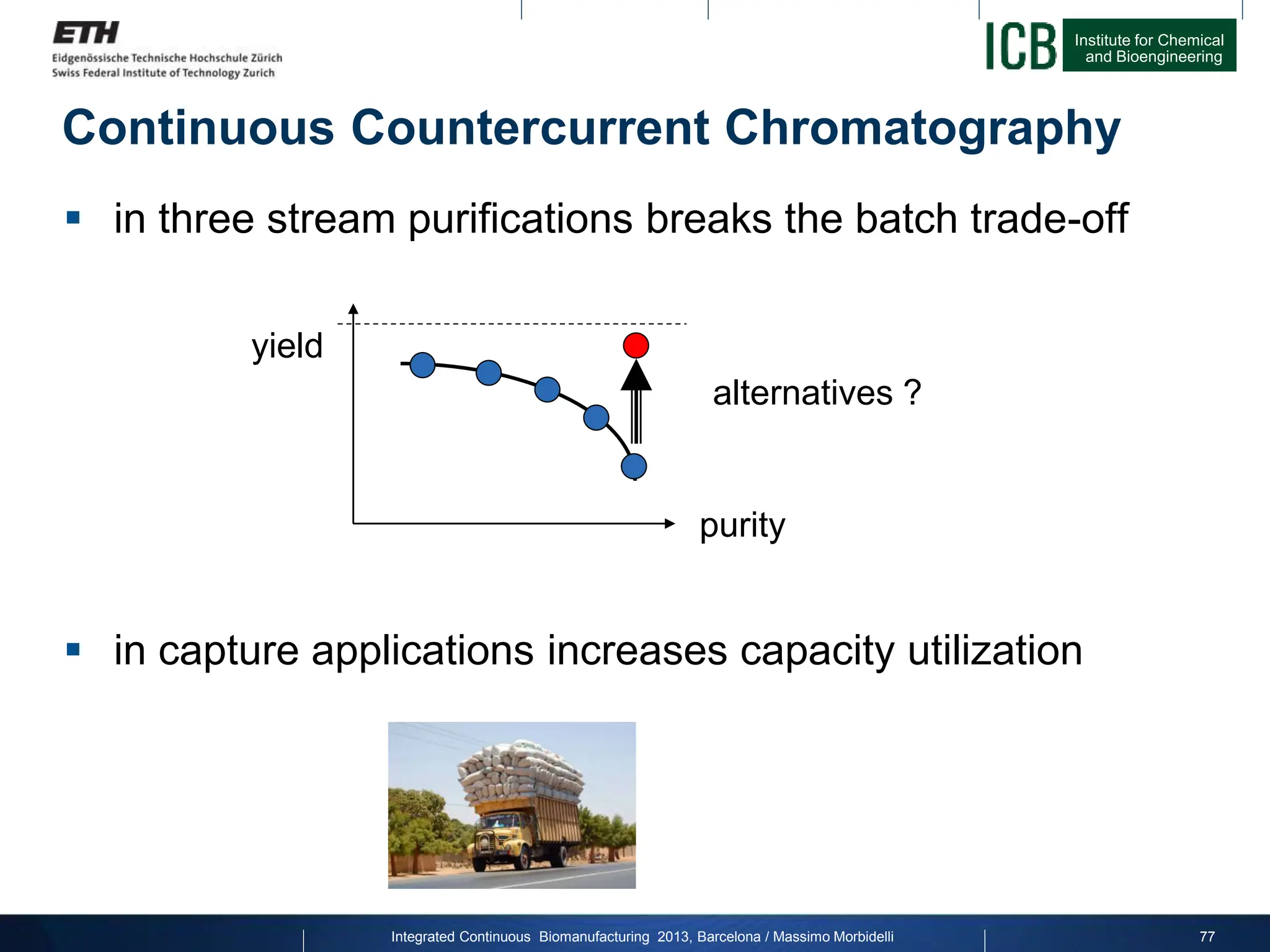

The document discusses multicolumn continuous countercurrent chromatography (MCSGP) as an alternative to batch chromatography for purifying biomolecules like monoclonal antibodies and peptides. MCSGP uses multiple chromatography columns connected in a continuous process to achieve high purity and yield for multi-component separations. It provides examples showing MCSGP can increase productivity 5-25x over batch and improve yield-purity tradeoffs. MCSGP is presented as enabling the production of biobetters and separation of complex molecules like antibody isoforms and bispecific antibodies.

![Institute for Chemical

and Bioengineering

10

Batch versus SMB performance

Separation of a pharmaceutical intermediate racemate

mixture on a chiral stationary phase (CSP)1

1 J.Chrom A 1006 (1-2): 267-280, 2003

0

0.5

1

1.5

2

2.5

3

Solvent requirement Productivity

HPLC Batch

SMB

Eluent need [L/g]

-80%

8x

Productivity [g/ kg/min]

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-6-2048.jpg)

![Institute for Chemical

and Bioengineering

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli

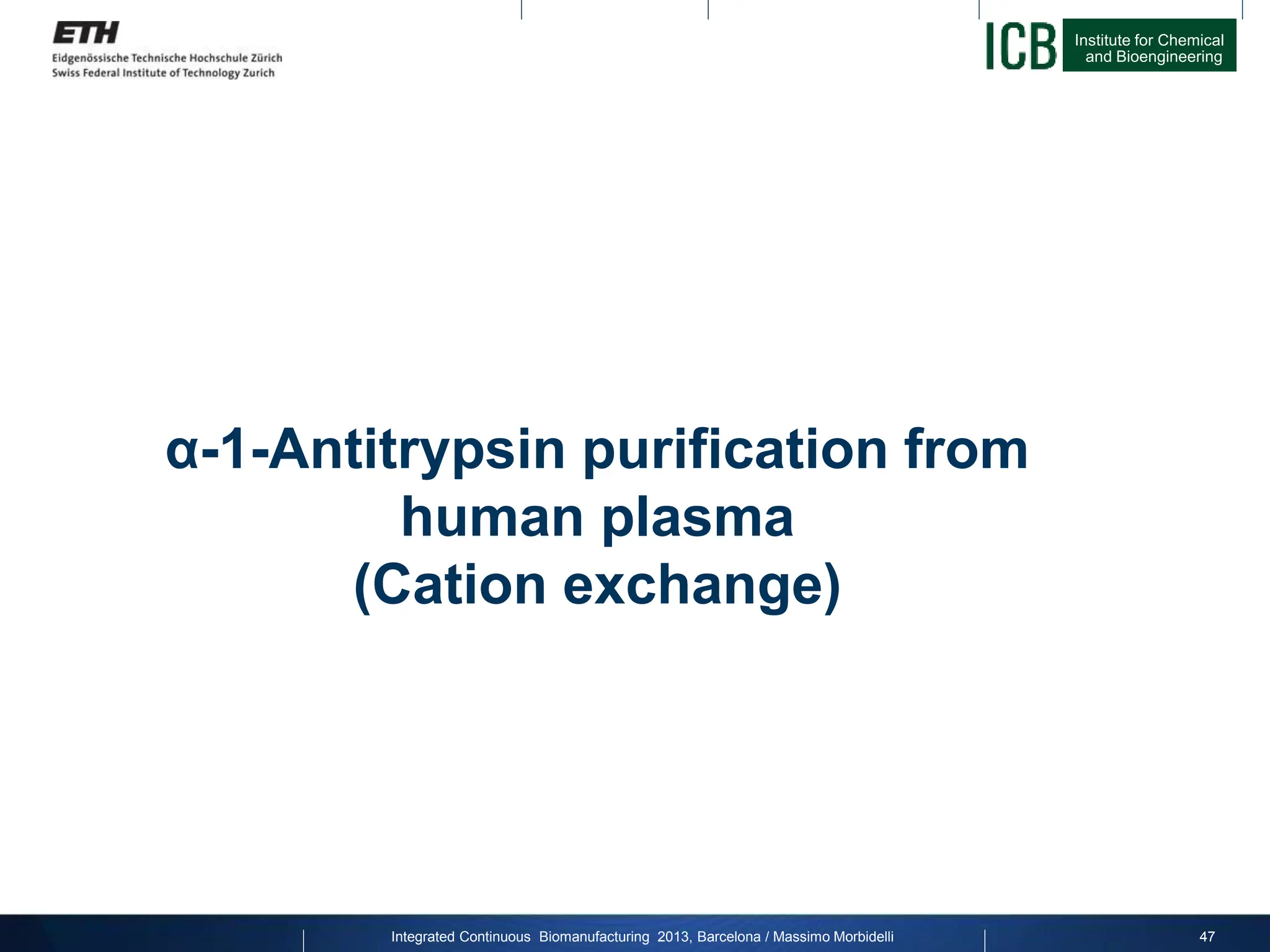

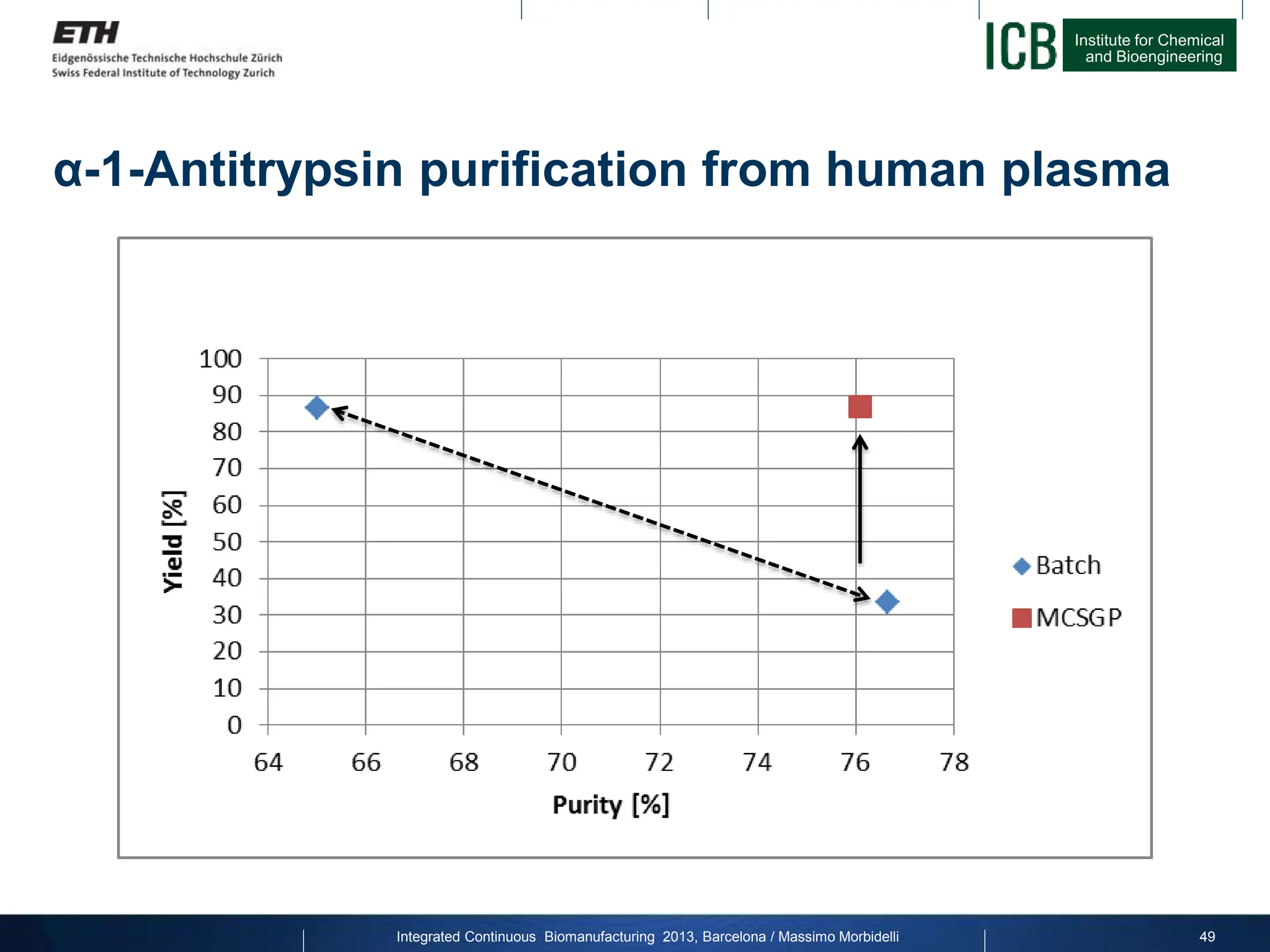

α-1-Antitrypsin purification from human plasma

50

MCSGP

Weak

(IgG, HSA)

Product

(AAT)

Strong

Impurities

Purity [%] Yield [%]

Batch (max. P) 76.66 33.35

Batch (max. Y) 65 86.47

MCSGP 76.08 86.74](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-28-2048.jpg)

![Institute for Chemical

and Bioengineering

Purification Result - Productivity

factor 25

Joint project with Novartis Pharma on Calcitonin:

Productivity

[g/L/h]

Yield for constant purity [%]

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli 59](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-37-2048.jpg)

![Institute for Chemical

and Bioengineering

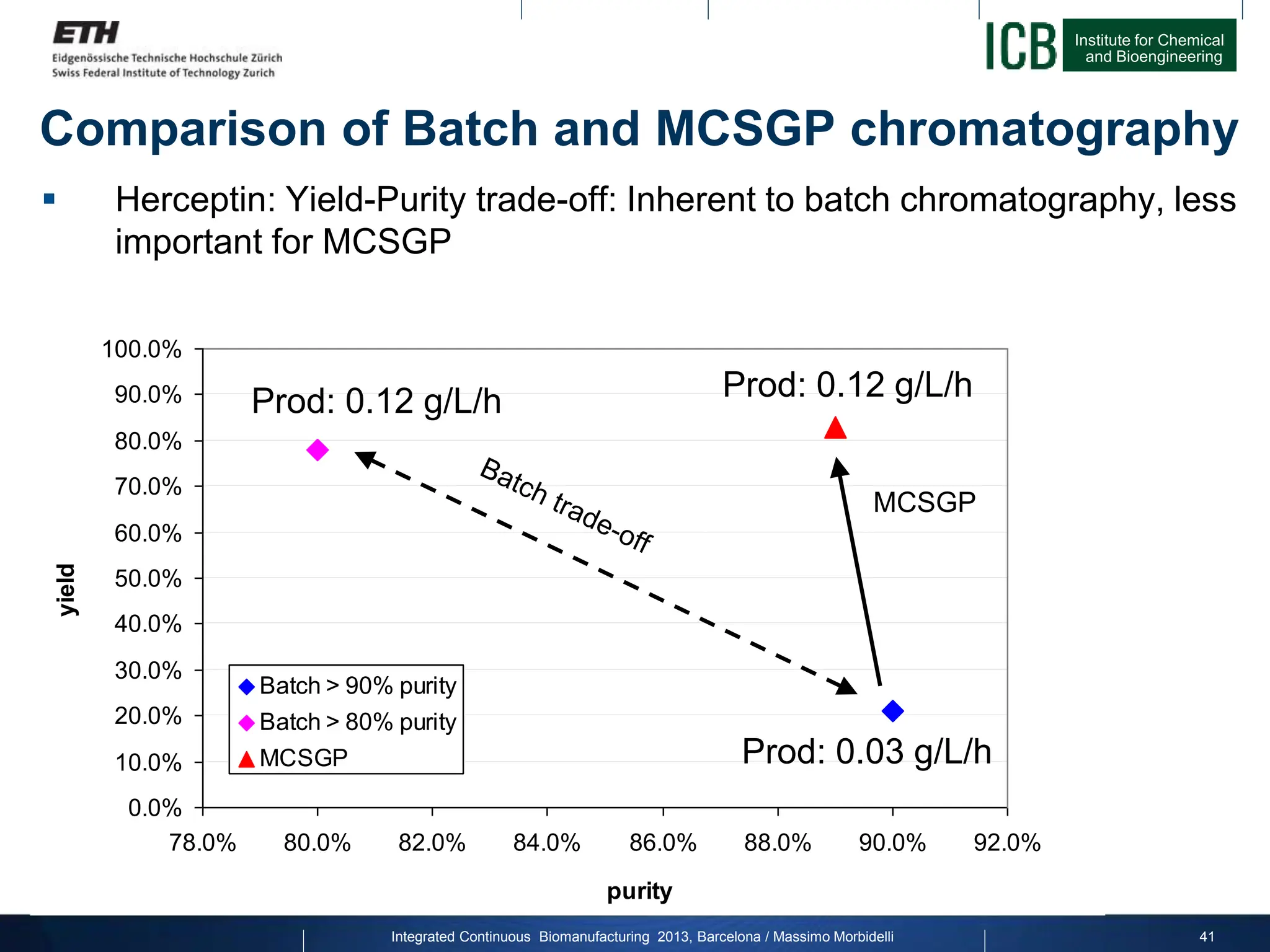

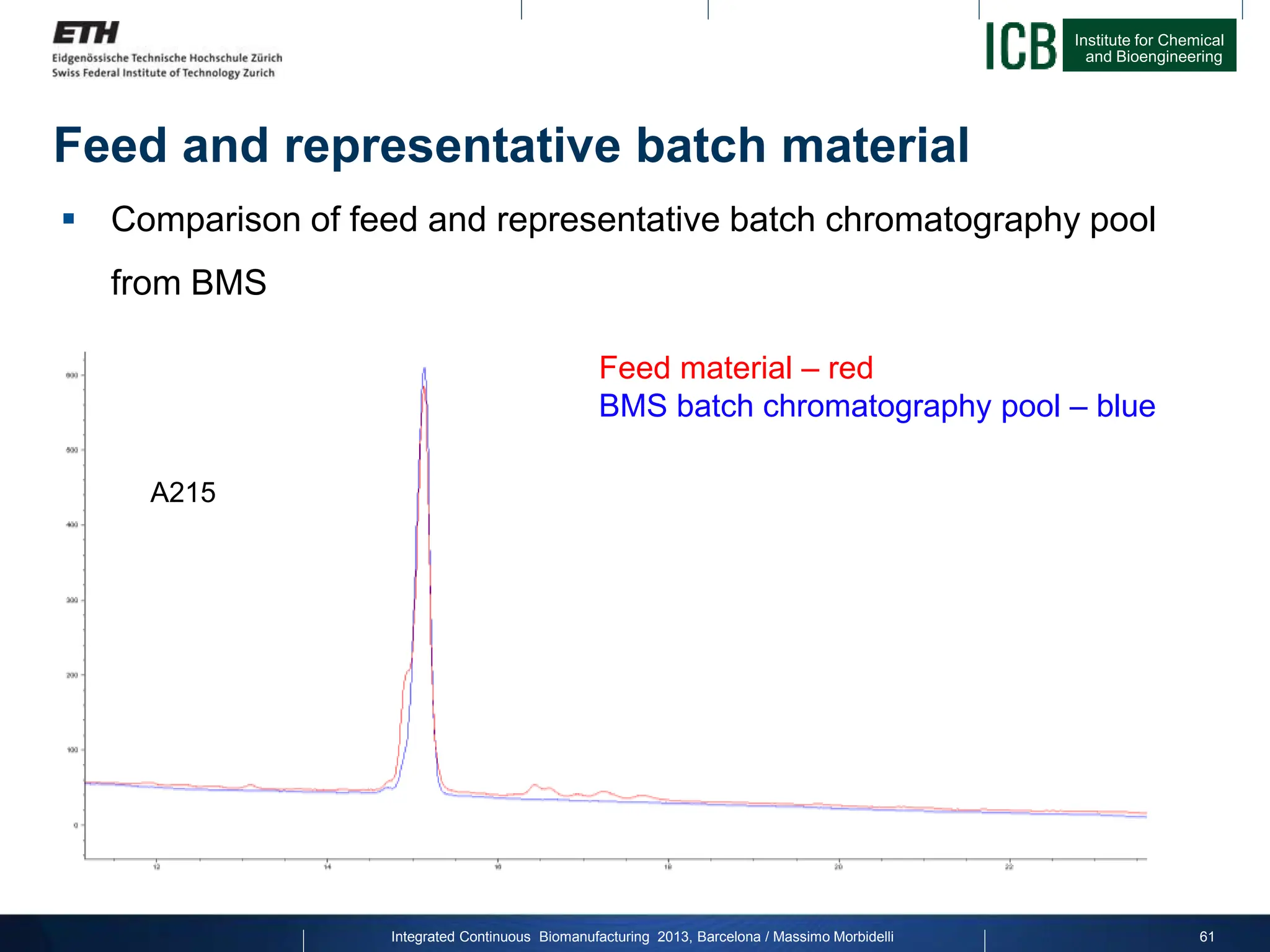

Comparison of Batch and MCSGP

Overview of results:

96.0

96.5

97.0

97.5

98.0

98.5

99.0

0 10 20 30 40 50 60 70 80 90 100

Purity

[%]

Yield [%]

A215

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli 63](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-41-2048.jpg)

![Institute for Chemical

and Bioengineering

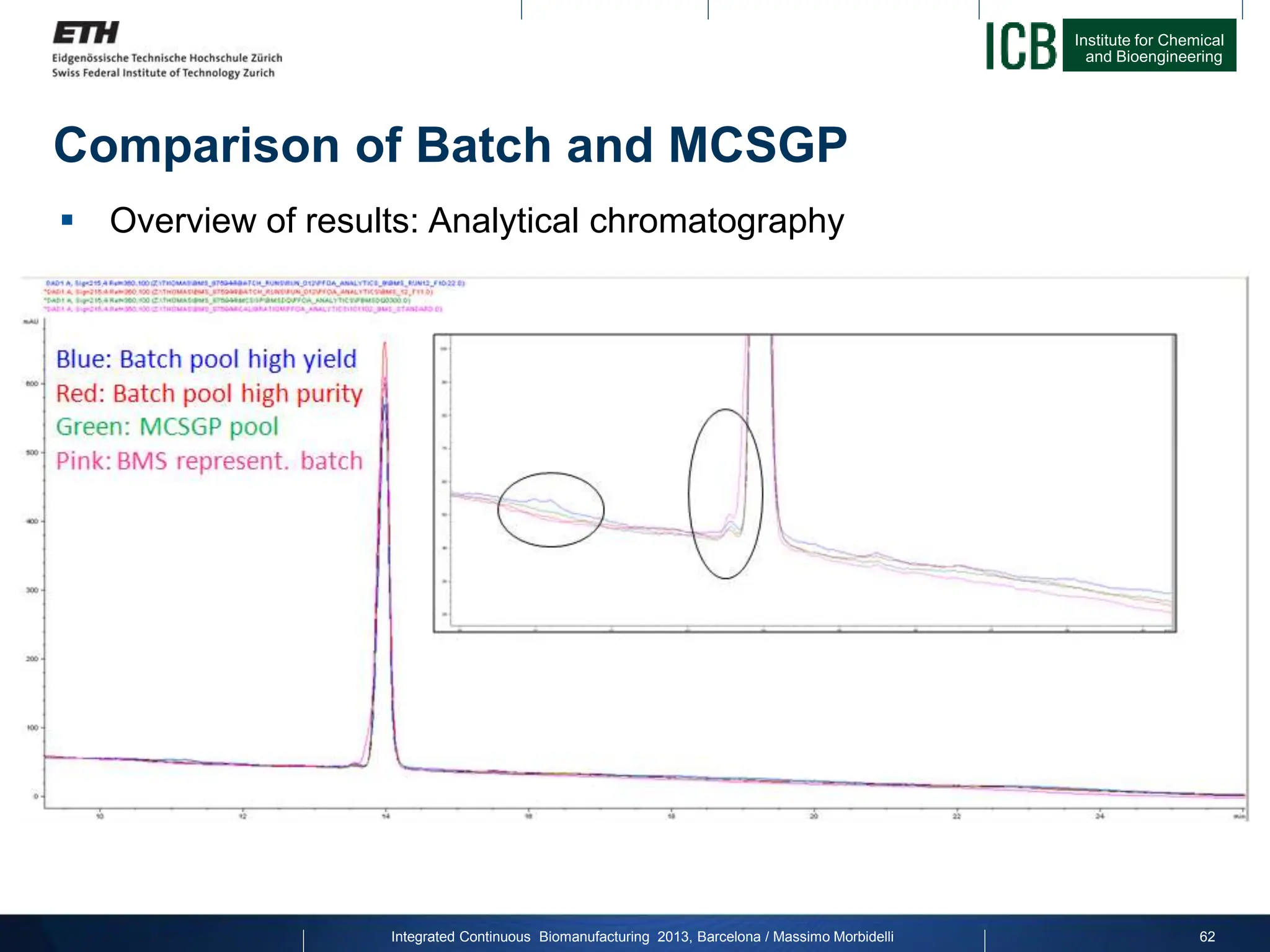

Comparison of Batch and MCSGP

Overview of results: Purity-Yield chart.

96.0

96.5

97.0

97.5

98.0

98.5

99.0

0 10 20 30 40 50 60 70 80 90 100

Purity

[%]

Yield [%]

Batch

MCSGP

Prod= 28-31 g/L/h

S.C. =0.9-1.0 L/g

conc.P = 8.4-9.3 g/L

Prod= 14 g/L/h

S.C.=0.7 L/g

conc. P = 3.3 g/L

Prod= 3 g/L/h

S.C.=3.5 L/g

conc. P = 8.2 g/L

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli 64](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-42-2048.jpg)

![Institute for Chemical

and Bioengineering

0

20

40

60

80

100

120

140

160

14 16 18 20 22 24

concentration

(normalized)

Time [min]

Feed

Product

W-fraction

S-fraction

EPA-EE (> 97% pure)

DHA-EE

Impurity

FA-EE

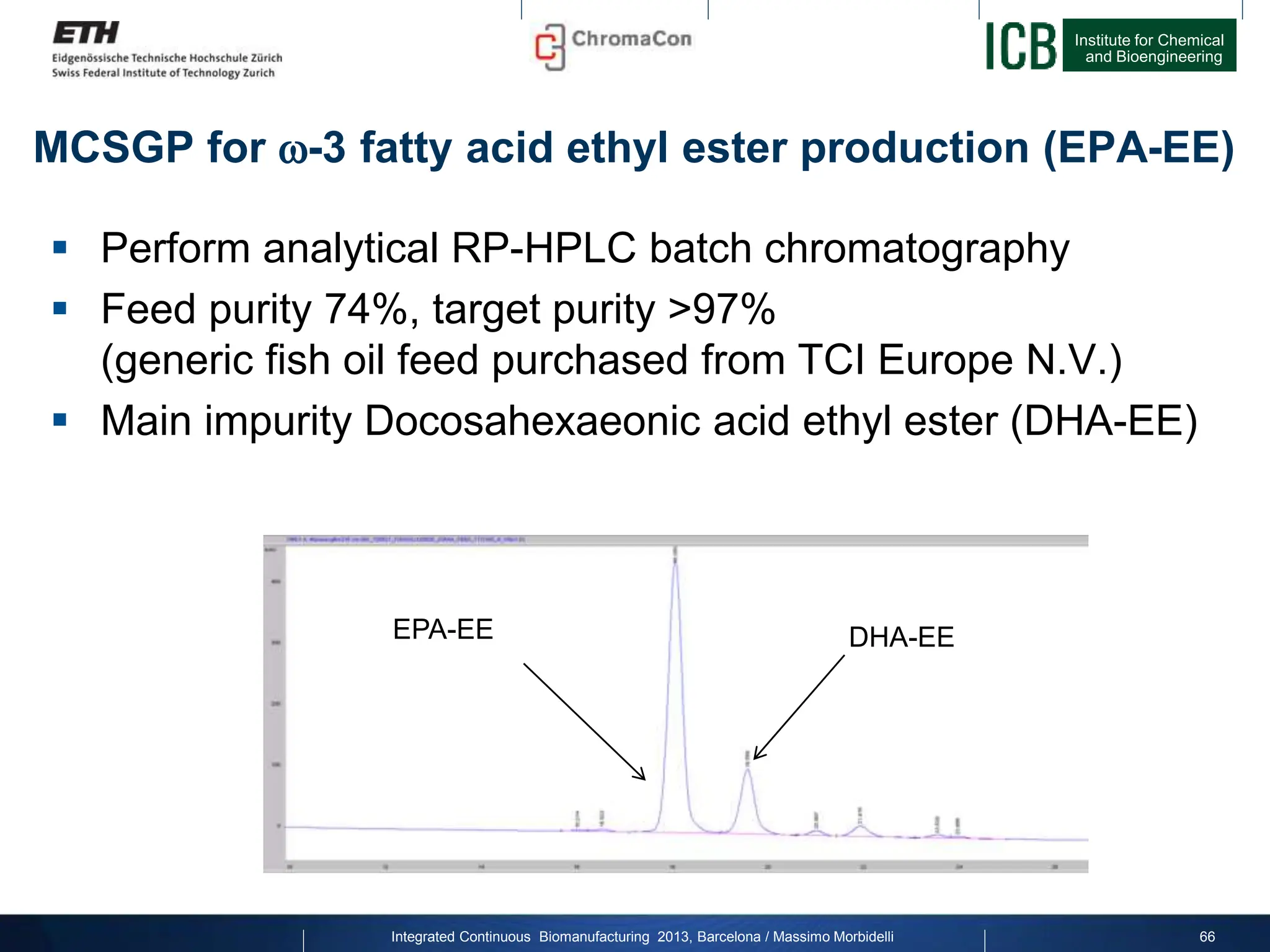

MCSGP for -3 fatty acid ethyl ester production (EPA-EE)

Result chromatograms

69

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli

Overlay of analytical reversed

phase chromatograms of feed

and fractions from MCSGP

Feed: Ratio EPA/DHA= 4:1](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-45-2048.jpg)

![Institute for Chemical

and Bioengineering

MCSGP for -3 fatty acid ethyl ester production (EPA-EE)

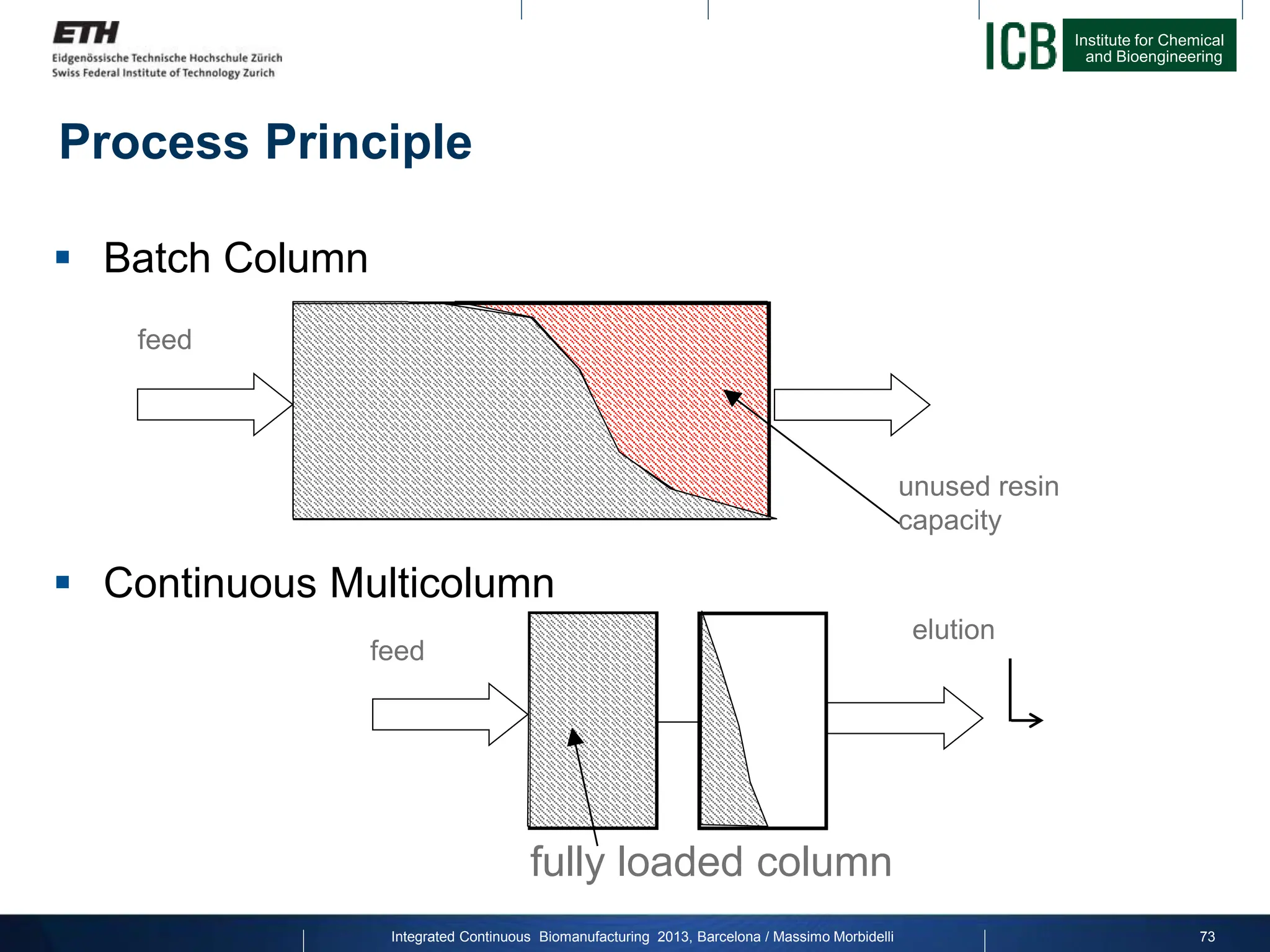

Process for production of > 97% purity EPA-EE developed based on

reverse phase chromatography with Ethanol as solvent

Resin & solvent cost reduction of 80% with respect to batch

chromatography

MCSGP

(20 m

resin)

Batch

(15 m

resin)

Improvement by

MCSGP

Purity [%] >97% >97%

Yield [%] 90% 36% + 250%

Productivity (Throughput)

[(g product)/(L resin)/(hr operation time)]

65 11 + 590%

Solvent Consumption

[L solvent/g product]

0.8 3.2 - 75%

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli 70](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-46-2048.jpg)

![Institute for Chemical

and Bioengineering

Buffers:

Method:

Experimental conditions: Batch chromatography

Equilibration A 20 mM Phos, 150 mM NaCl, pH 7.5

Wash B 20 mM Phos, 1 M NaCl, pH 7.5

Elution C 50 mM Na-Cit, pH 3.2

CIP D 0.1 M NaOH

93

Step CV [ml]

Equilibration (A) 5

Load

Wash-1 (A) 5

Wash-2 (B) 5

Wash-3 (A) 5

Elution (C) 5

CIP (D) 7.5

Re-Equi-1 (C) 2

Re-Equi-2 (A) 3

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-64-2048.jpg)

![Institute for Chemical

and Bioengineering

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli

Internal concentration profiles: 3-Col process

95

2 4 6 8 10

0

1

2

c

[mg/ml]

Column 1: Regenerating

2 4 6 8 10

0

20

40

60

80

Column Position [cm]

q

[mg/ml]

2 4 6 8 10

0

1

2

Column 2: Loading

2 4 6 8 10

0

20

40

60

80

Column Position [cm]

2 4 6 8 10

0

1

2

Column 3: FT uptake

2 4 6 8 10

0

20

40

60

80

Column Position [cm]

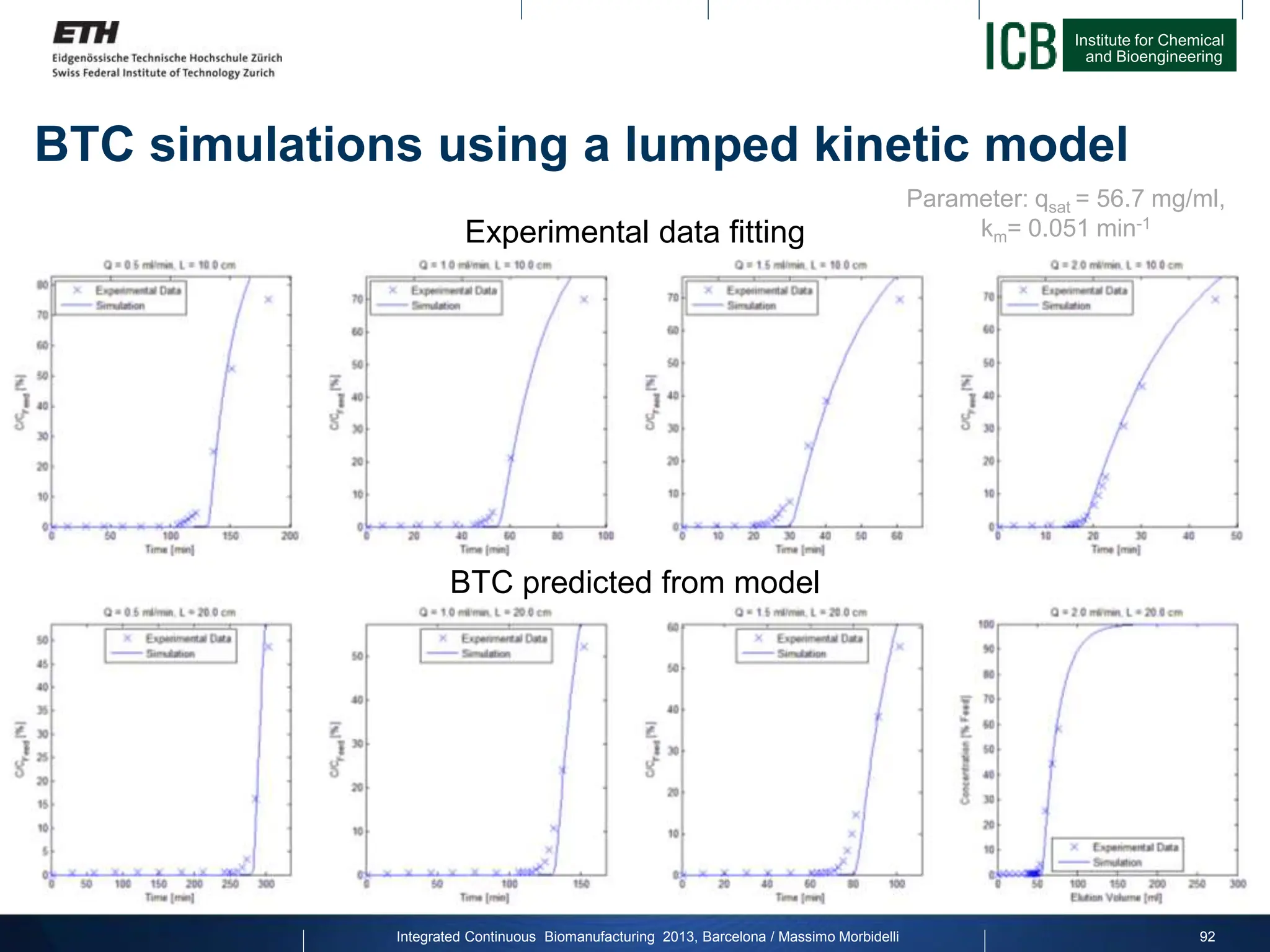

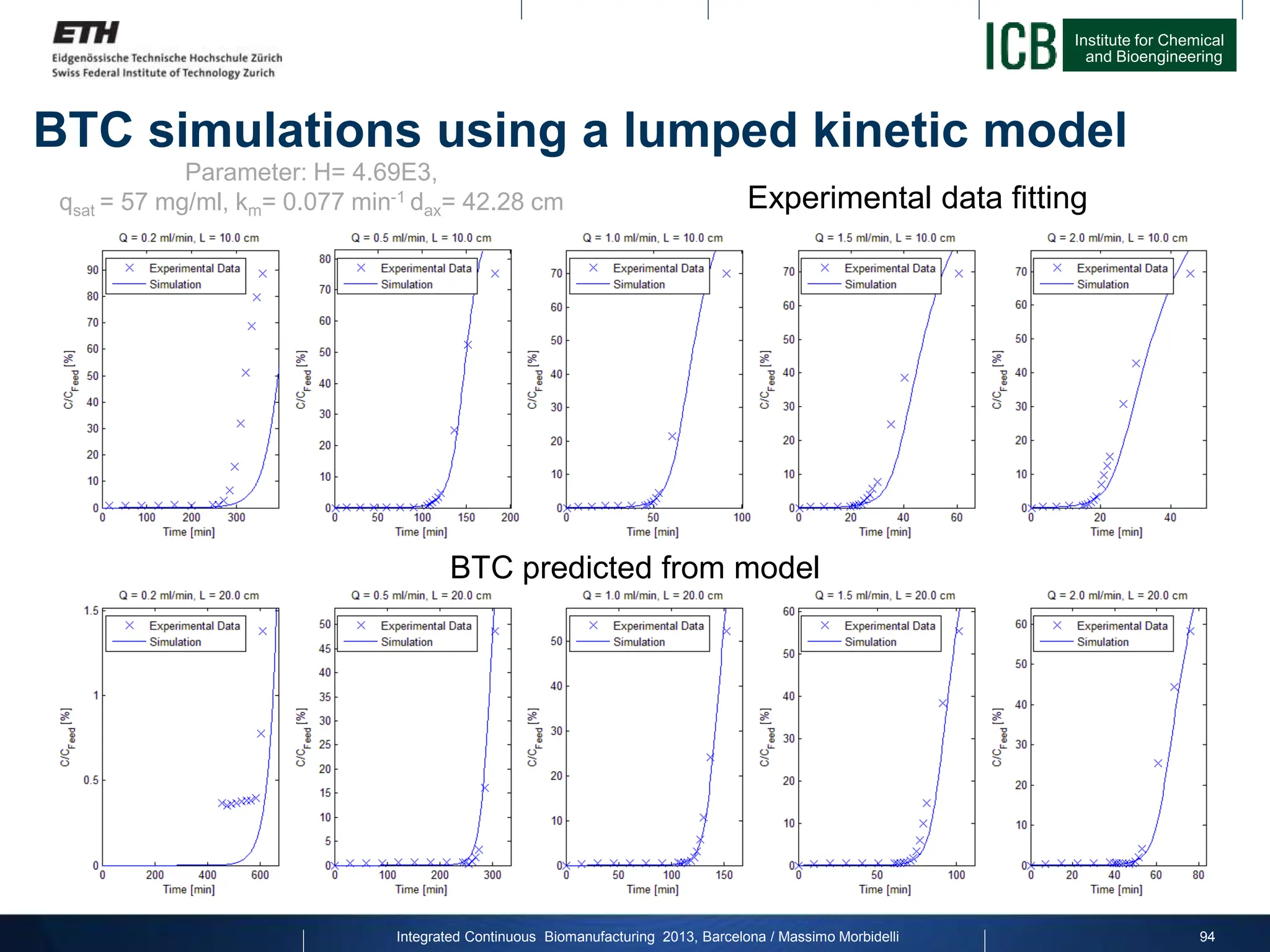

Simulation parameters: lumped kinetic model

Q= 0.84 ml/min, H= 4.69E3, qsat = 55 mg/ml, km= 0.077 min-1](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-66-2048.jpg)

![Institute for Chemical

and Bioengineering

Economic evaluation: buffer consumption per year

96

Significant buffer consumption

savings achieved using

Amsphere JWT 203 and

CaptureSMB

PoC Phase III Commercial

Product per harvest [kg] 4 10 24

Fermenter harvest size [L] 2000 5000 12000

Product concentration [g/L] 2 2 2

Harvests per year [-] 8 8 8

Effective production per year [Kg] 32 80 192

Harvest processing time [h] 24 24 24

Resin lifetime [-] 1 harvest 4 harvests 200 cycles

Resin exchange after max. [Year] n.a. n.a. 1

Resin costs AmsphereTM

[US$/L] 13000 13000 13000

Resin costs Agarose [US$/L] 17500 17500 17500

0

50

100

150

200

250

PoC Ph III Comm.

[1000

L]

Buffer consumption per year

(300 cm/h)

0

50

100

150

200

250

PoC Ph III Comm.

[1000

L]

Buffer consumption per year

(600 cm/h)

Integrated Continuous Biomanufacturing 2013, Barcelona / Massimo Morbidelli](https://image.slidesharecdn.com/1-morbidelli-131014presentationbarcelonamm-240202071600-e66e82ca/75/1-Morbidelli-131014_Presentation_Barcelona_MM-pptx-67-2048.jpg)