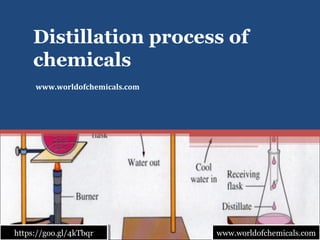

The document discusses the distillation process used to separate chemical mixtures. Distillation works by heating a liquid mixture until it evaporates, then condensing the vapors to separate components by differences in their boiling points. There are several types of distillation processes including simple, fractional, batch, continuous, and steam distillation. Distillation has many industrial uses such as purifying water and chemicals and separating components of crude oil.