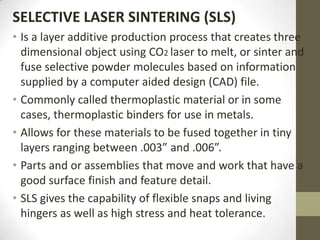

Rapid prototyping is a process that builds 3D objects from a digital CAD file layer by layer. It allows designers to quickly test designs by creating physical prototypes. Various techniques were developed in the 1960s-1980s including selective laser sintering which uses a laser to fuse powdered material. Rapid prototyping is now commonly used to build prototypes from 3D CAD models in hours rather than weeks. It offers advantages over traditional modeling like faster production and ability to modify designs easily.