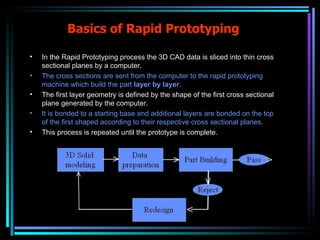

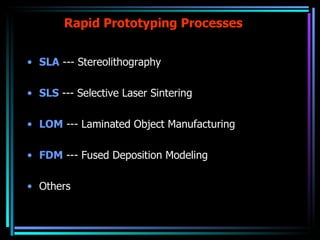

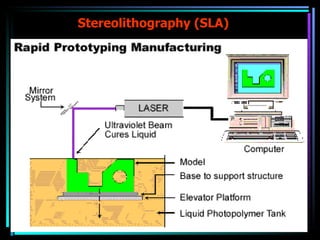

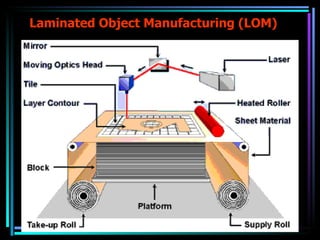

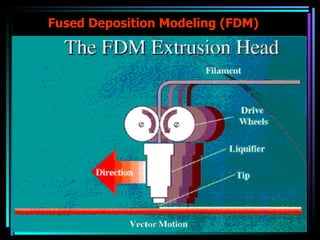

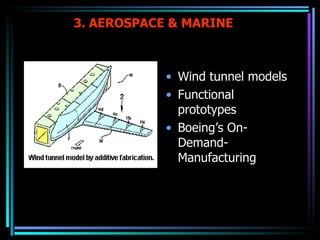

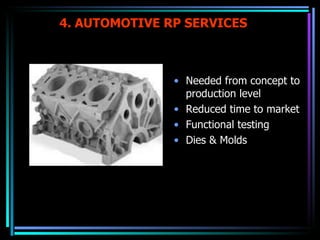

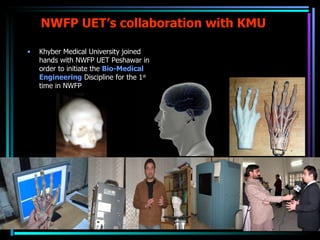

The document summarizes a presentation about rapid prototyping and its applications in the 21st century. It defines what a prototype is and discusses the need for prototyping. It then explains the basics of rapid prototyping, including the main processes of stereolithography, selective laser sintering, laminated object manufacturing, and fused deposition modeling. The document outlines common materials used and applications of rapid prototyping in various fields like aerospace, automotive, biomedical, architecture, fashion and more. It concludes by discussing NWFP UET's collaboration with Khyber Medical University to initiate bio-medical engineering.