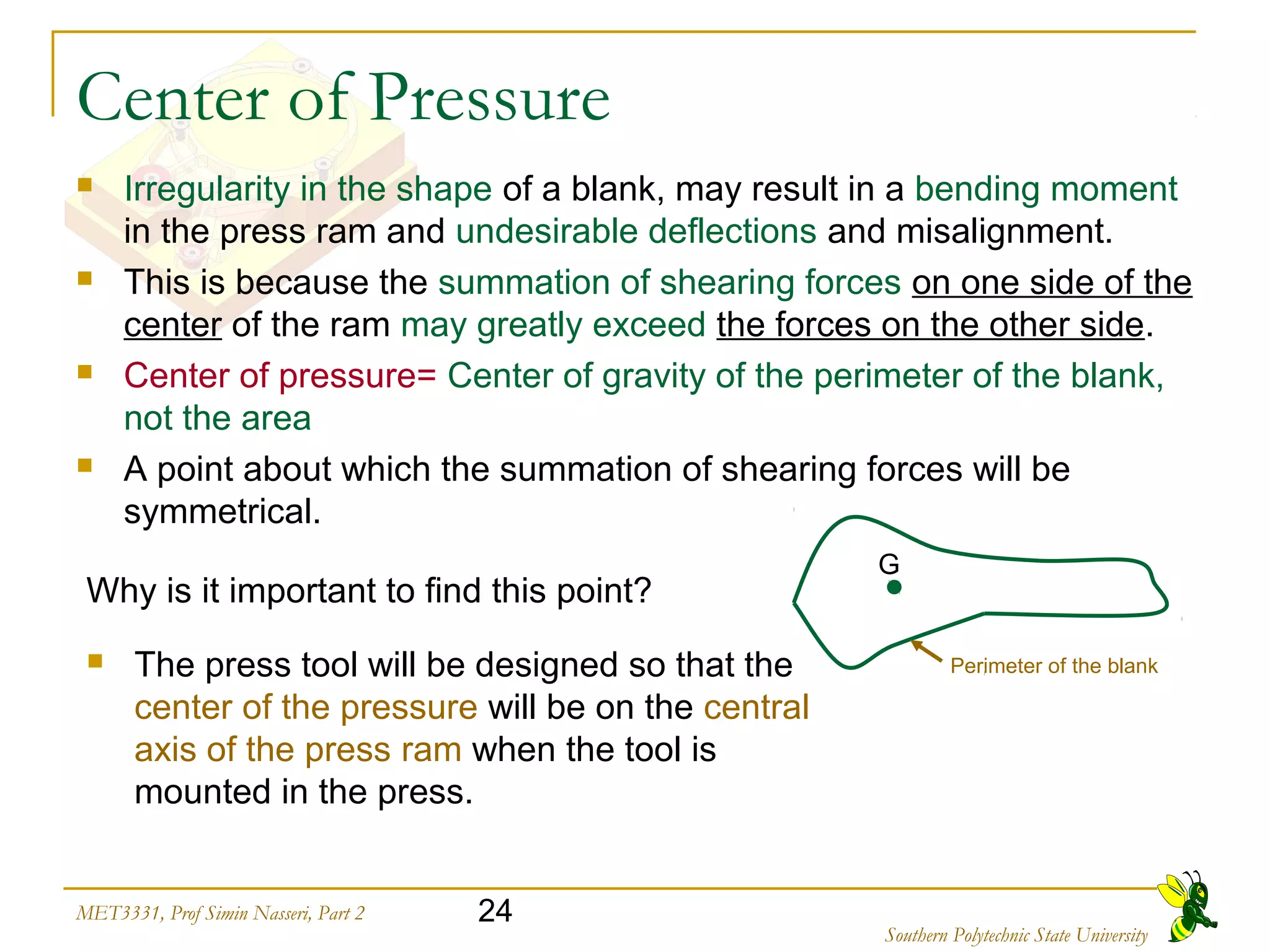

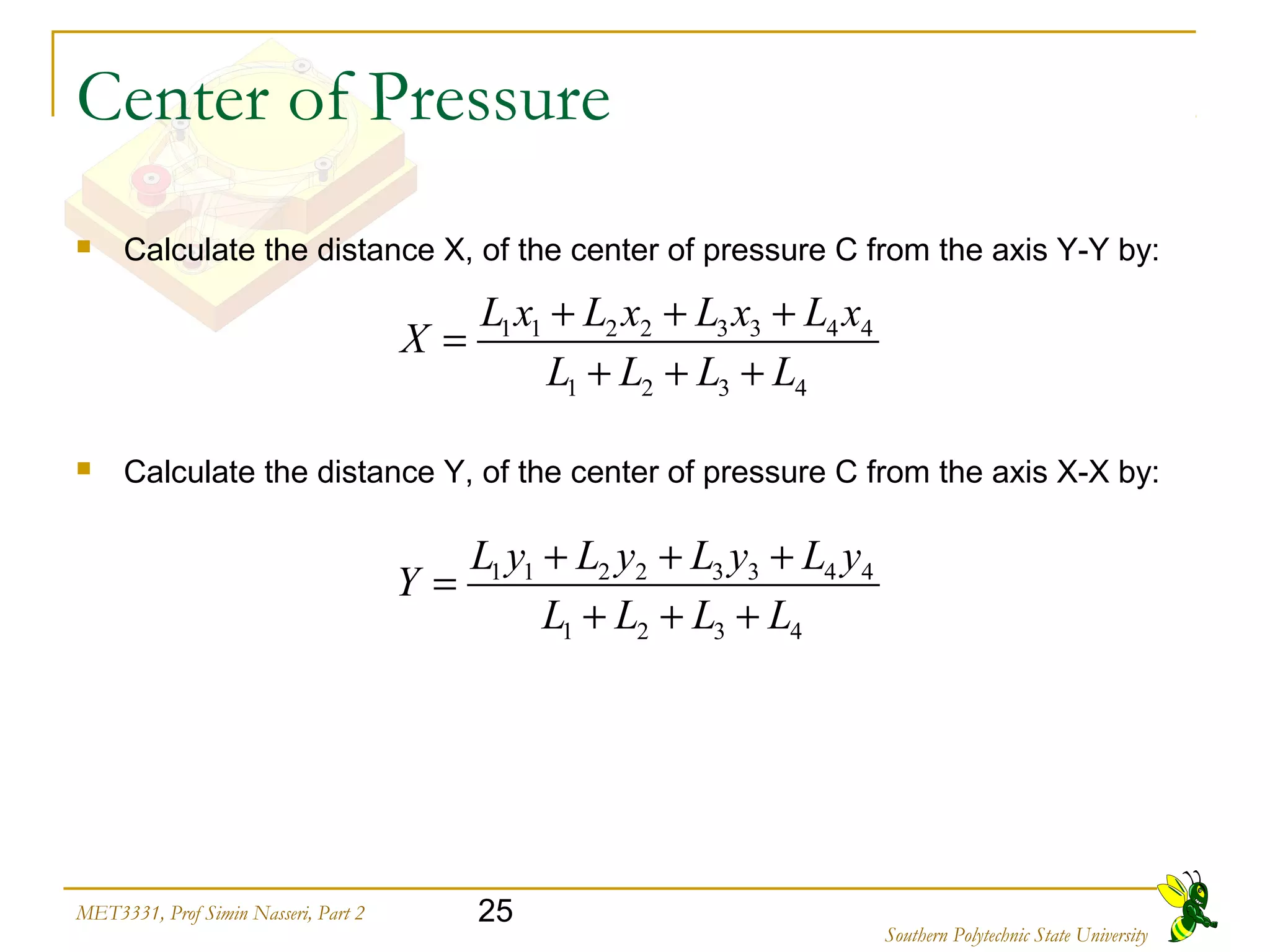

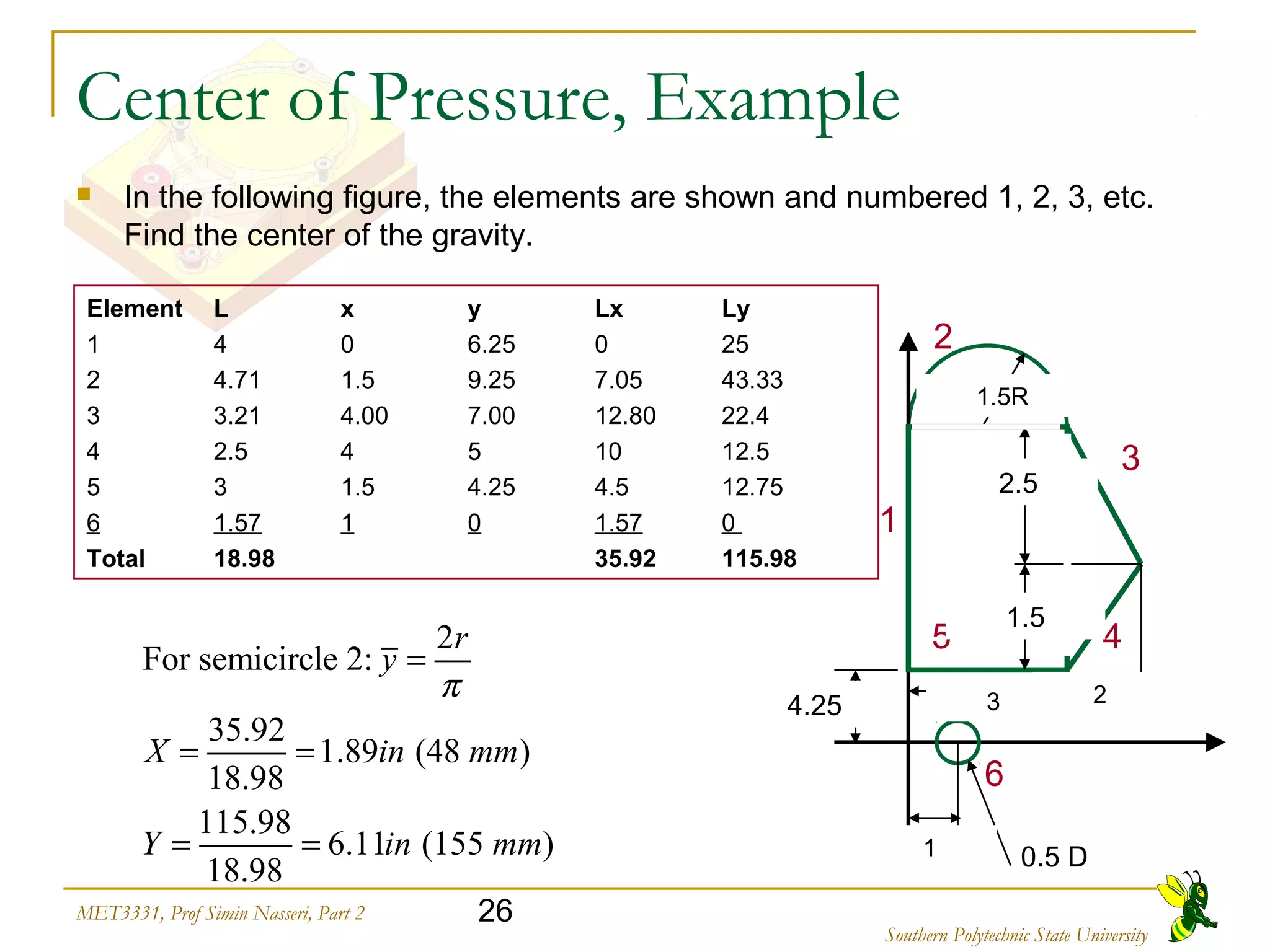

Okay, let's calculate the center of pressure step-by-step:

1) Calculate Lx, Ly for each element using the given dimensions

2) Sum Lx = 6.25 + 9.25 + 7 + 5 + 4.25 + 1 = 32.75

3) Sum Ly = 25 + 7.05 + 12.8 + 12.5 + 4.5 + 1.57 = 63.42

4) X (distance from axis YY) = Sum Lx / Sum L = 32.75 / 32.75 = 2.5

5) Y (distance from axis XX) = Sum Ly / Sum L = 63.42 / 32.75 = 1.94