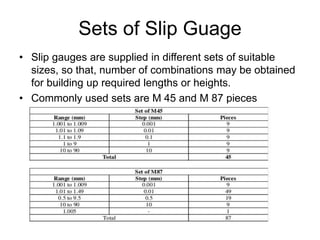

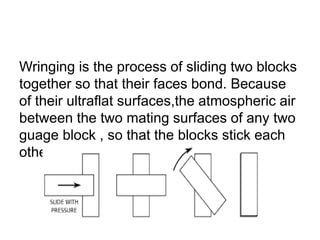

Slip gauges are rectangular blocks made of alloy steel that are used as standards to check the accuracy of measuring instruments. They are hardened, quenched, and superfinished to achieve a very high level of flatness and parallelism on their contact surfaces. Slip gauges are supplied in sets of different sizes so that various length combinations can be obtained through stacking.