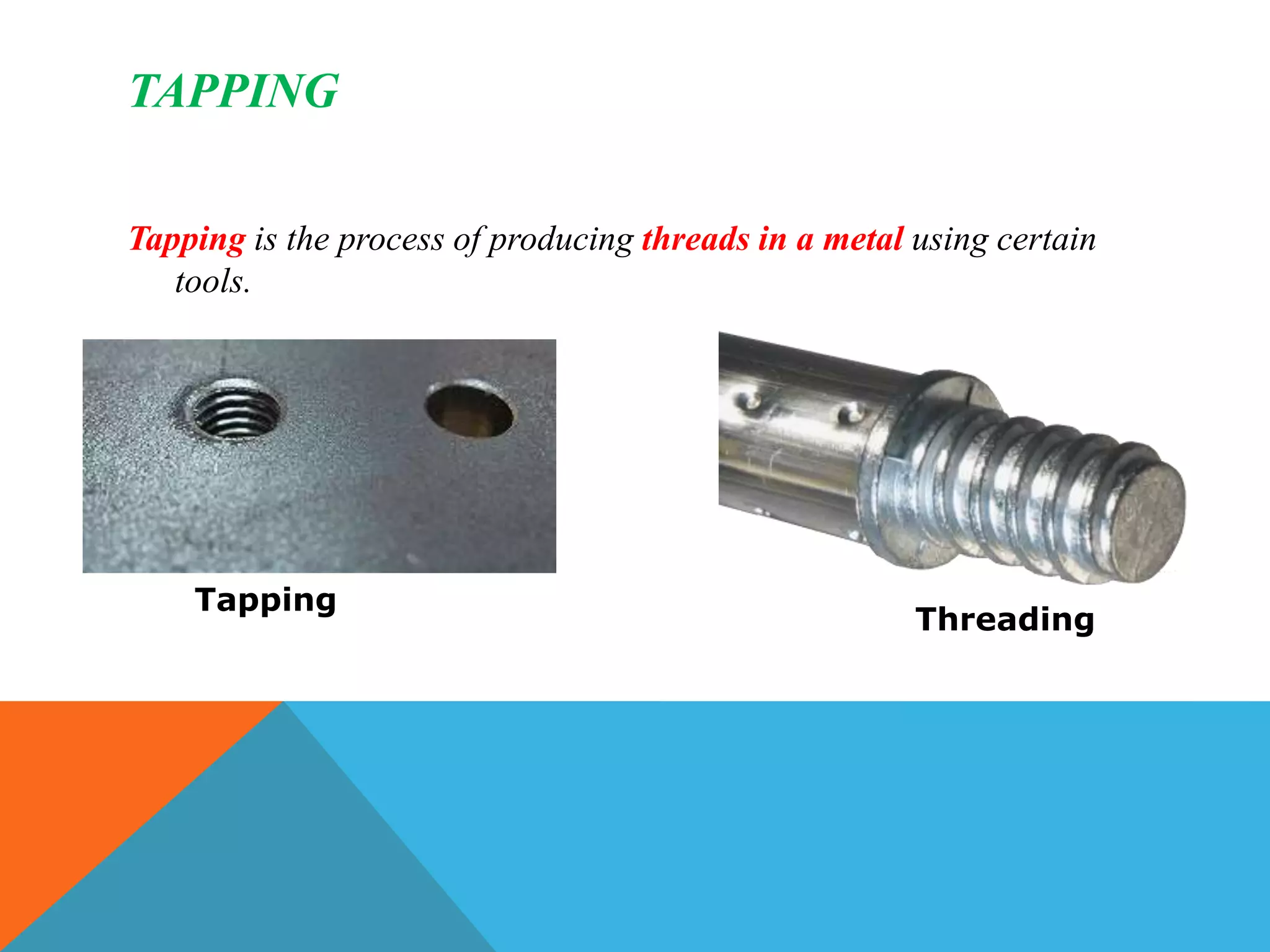

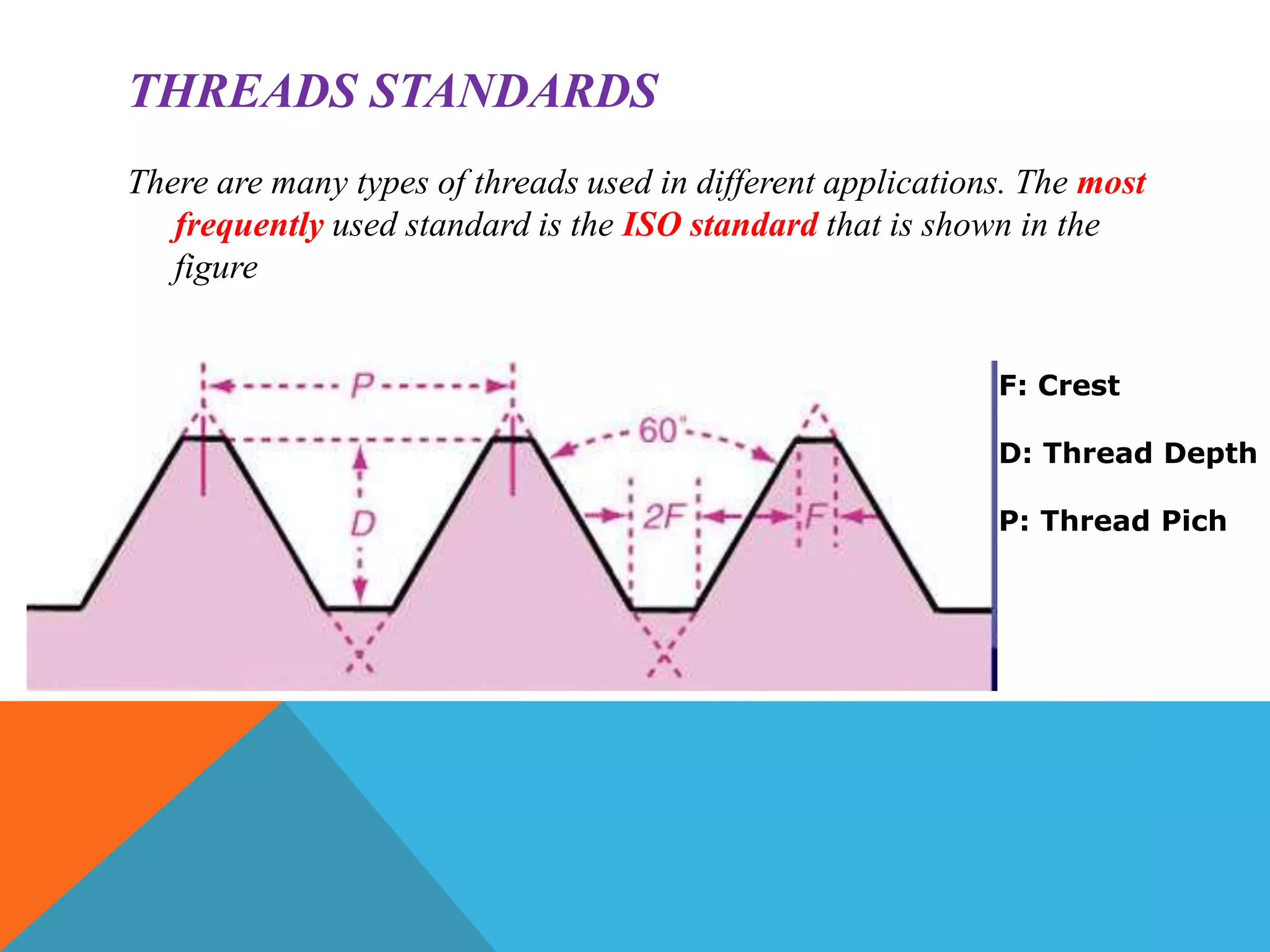

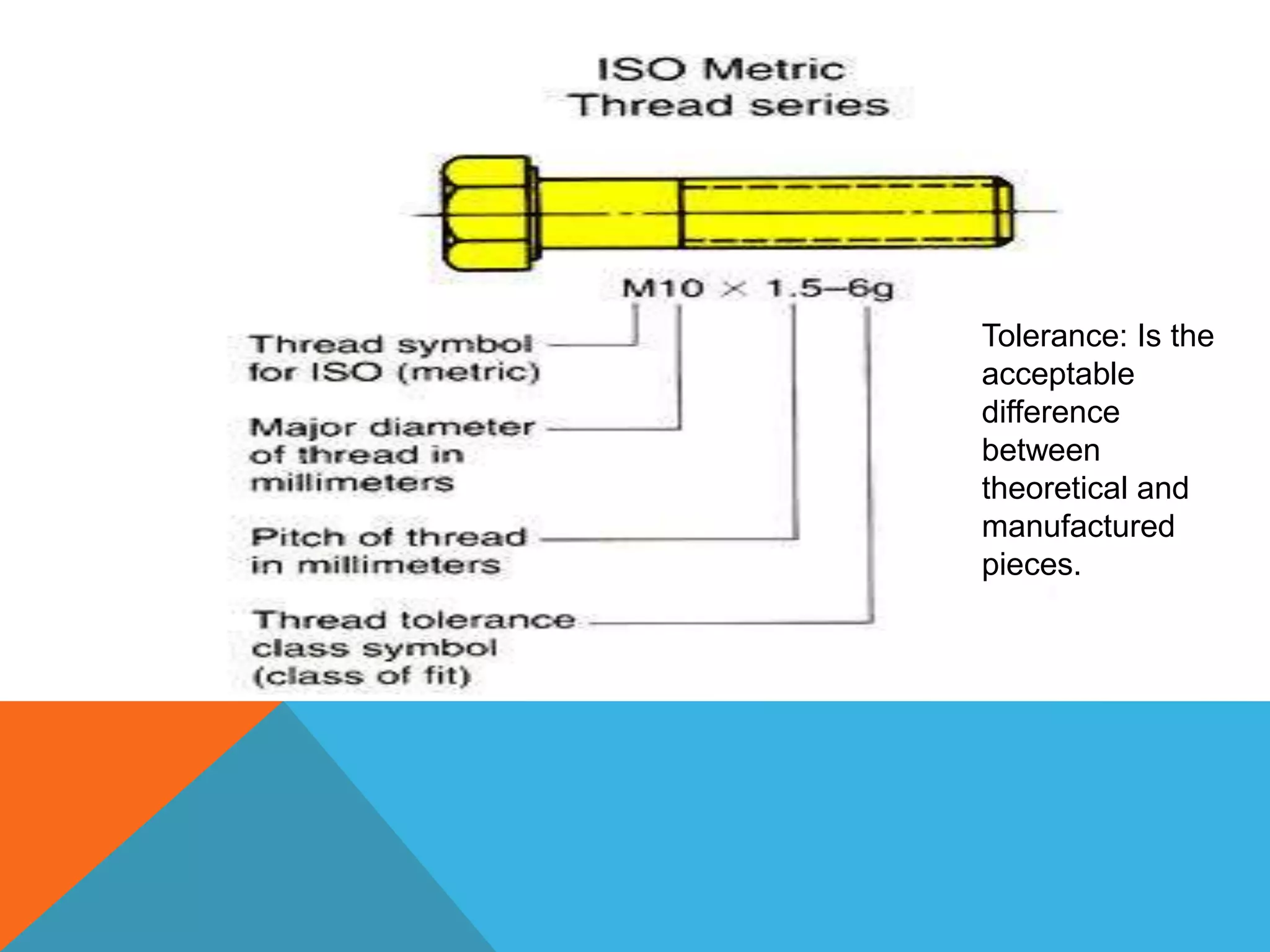

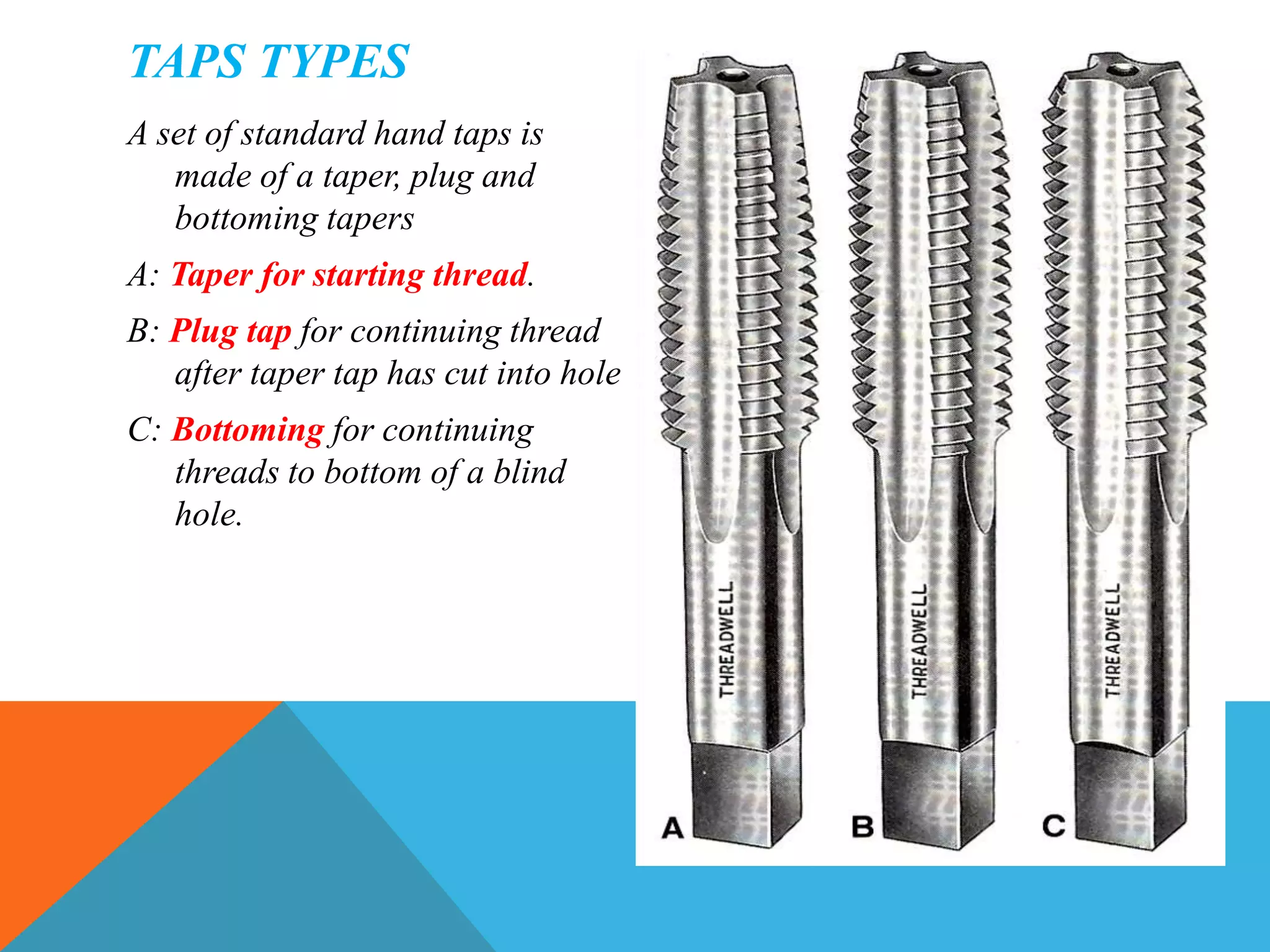

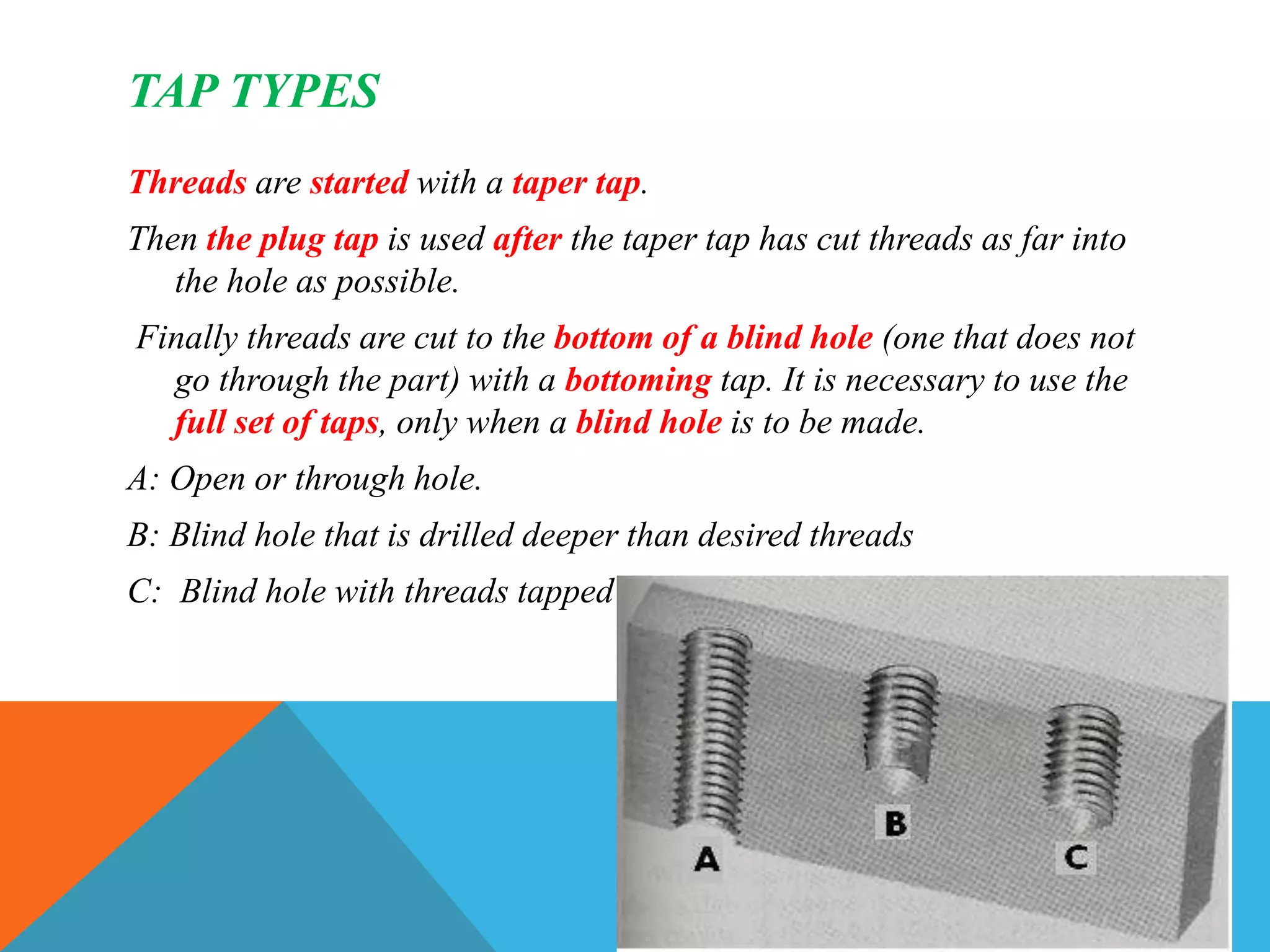

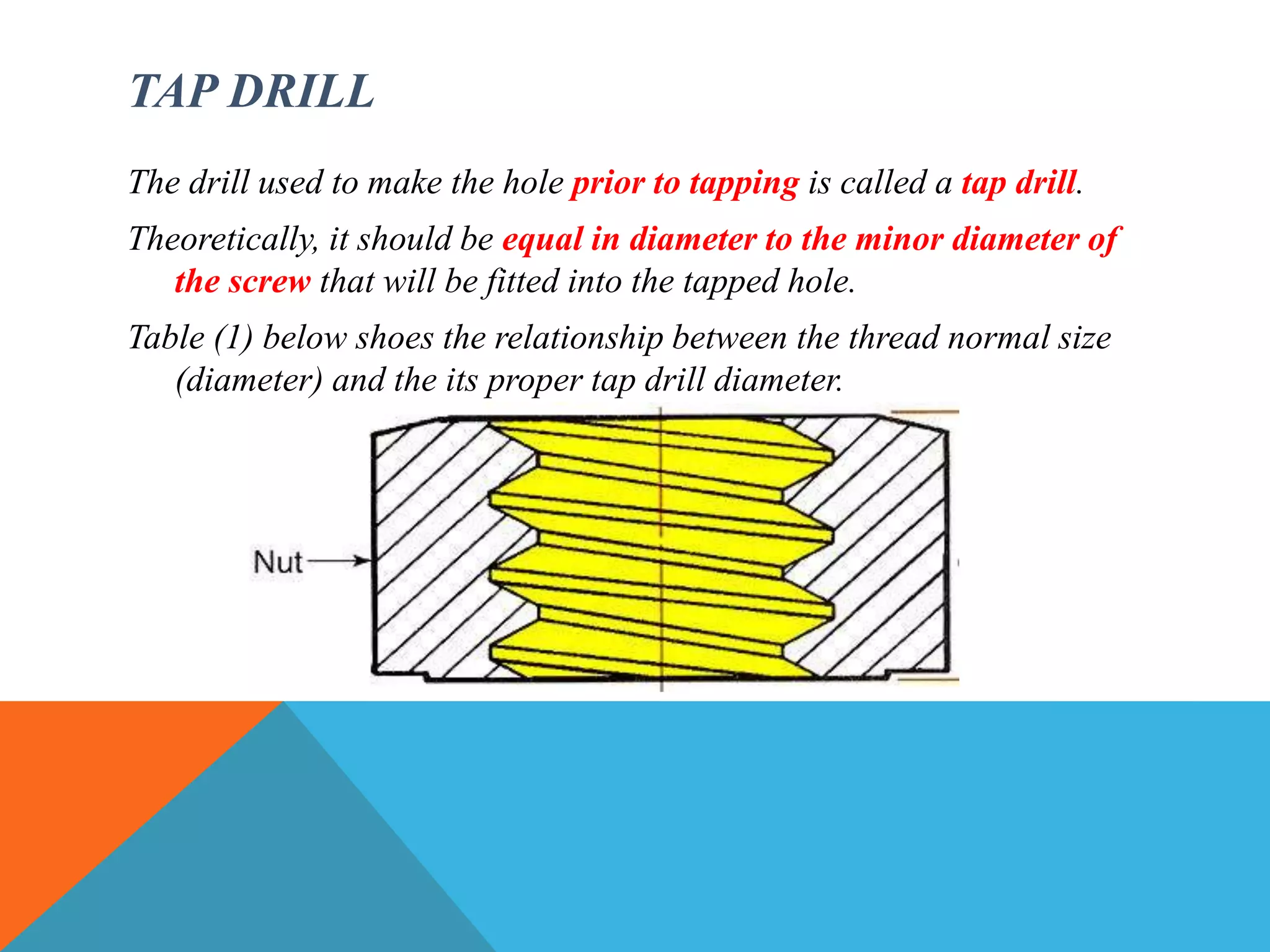

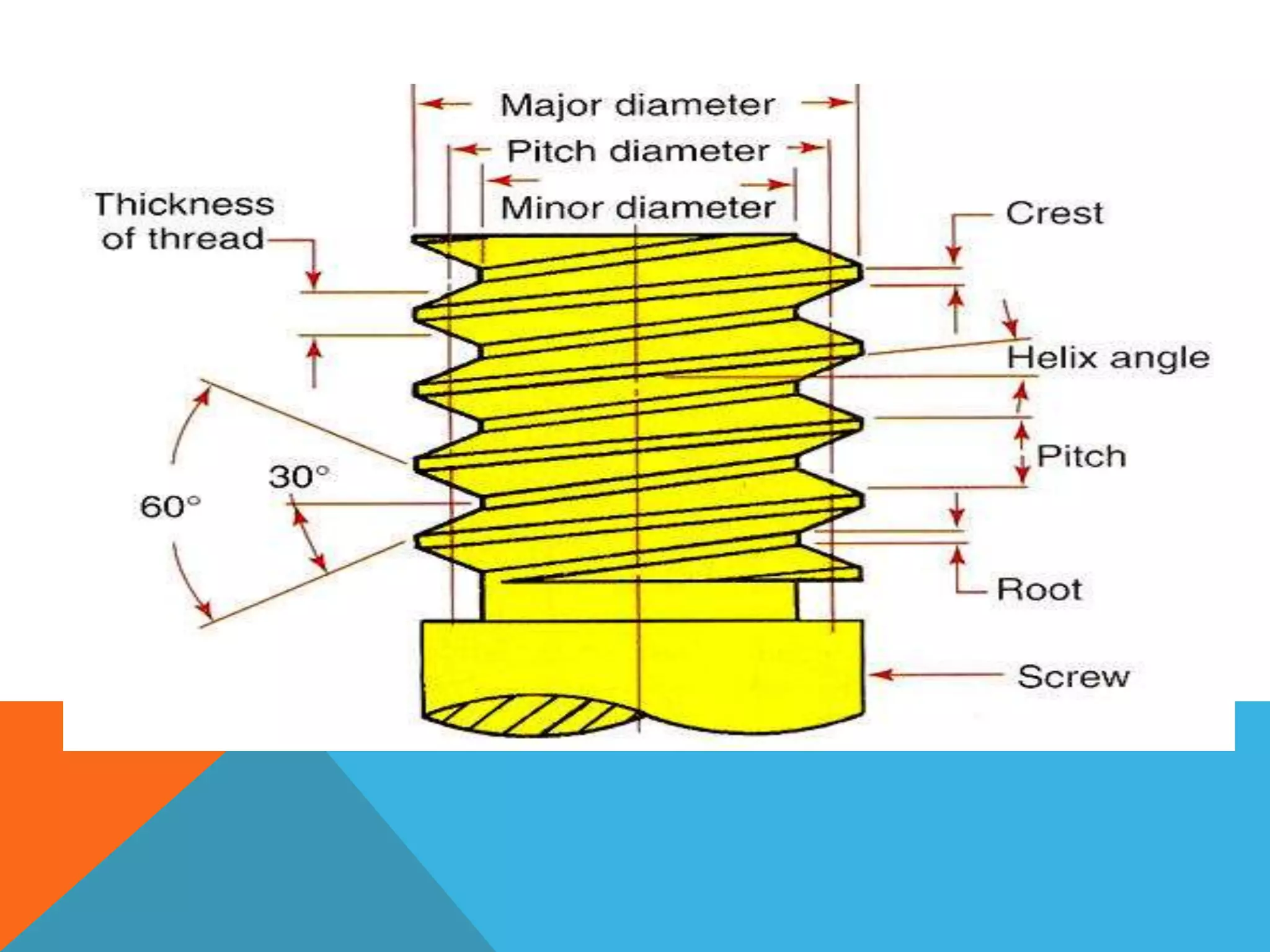

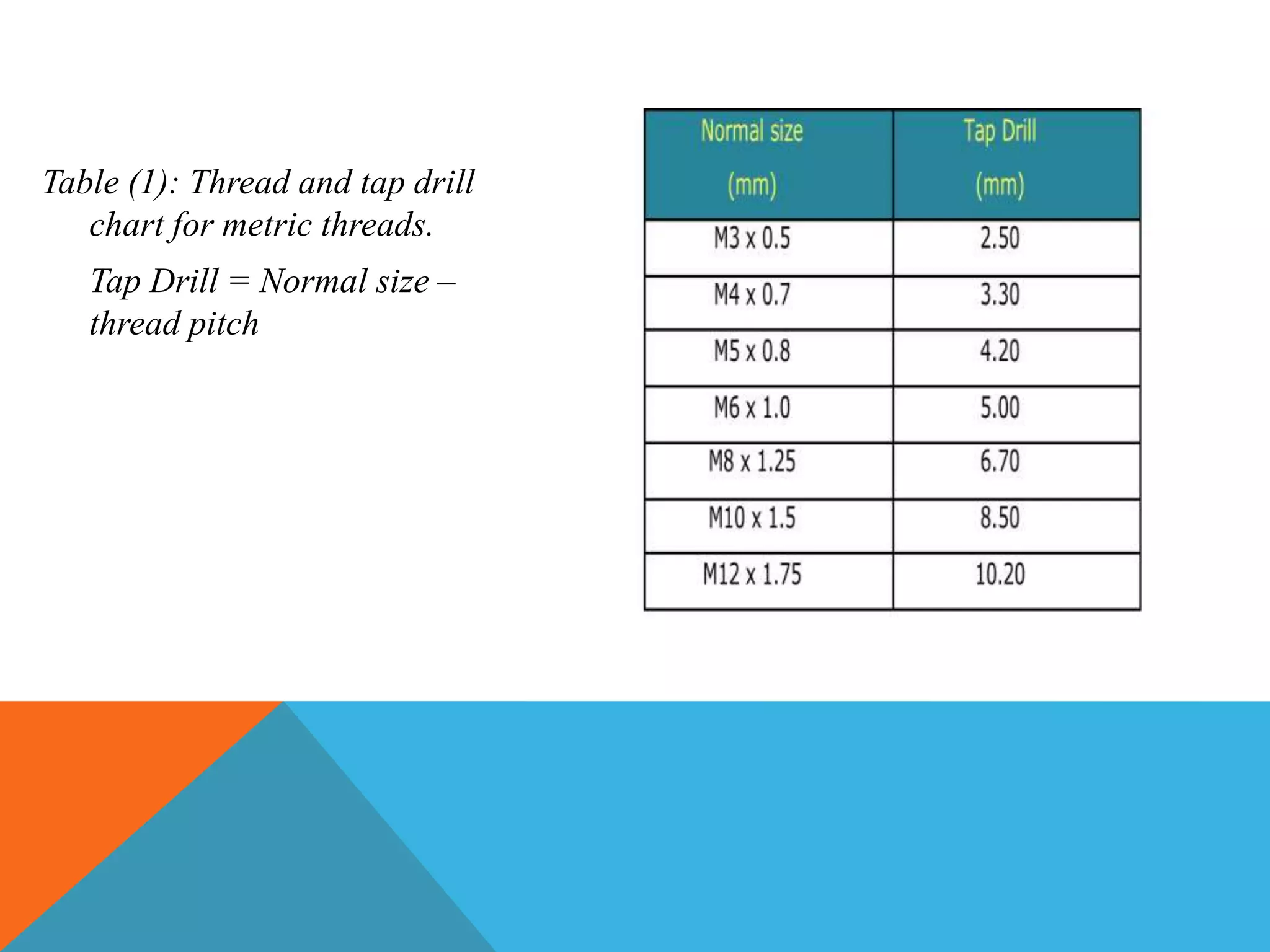

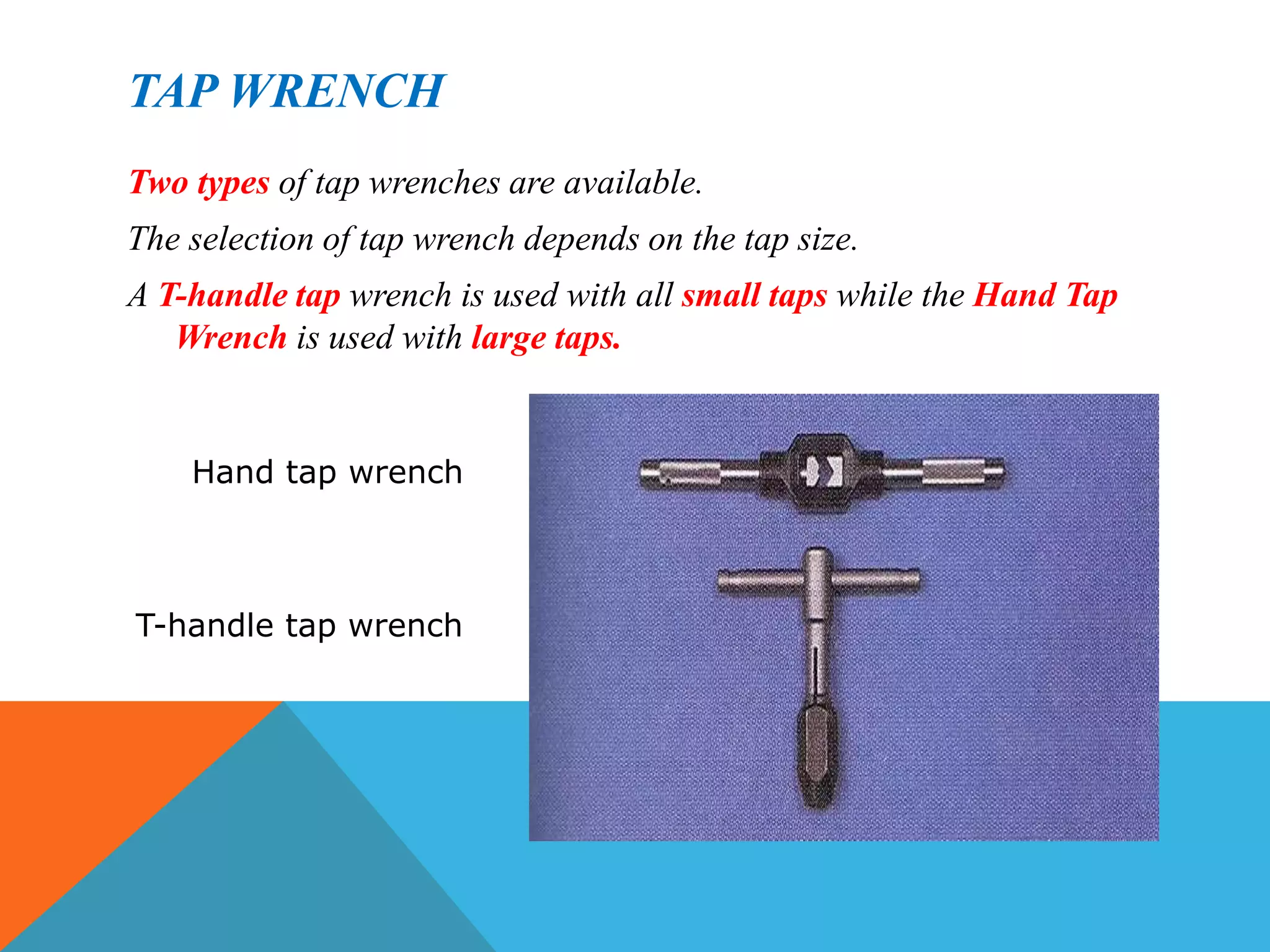

This document discusses tapping and threading. It begins by explaining the objectives of learning about tapping processes and tools. It then defines tapping as the process of cutting threads using specific tools. It discusses taper, plug, and bottoming taps for starting and finishing threads. It also covers tap types, drill sizes, wrenches, and best practices for safe and effective tapping.