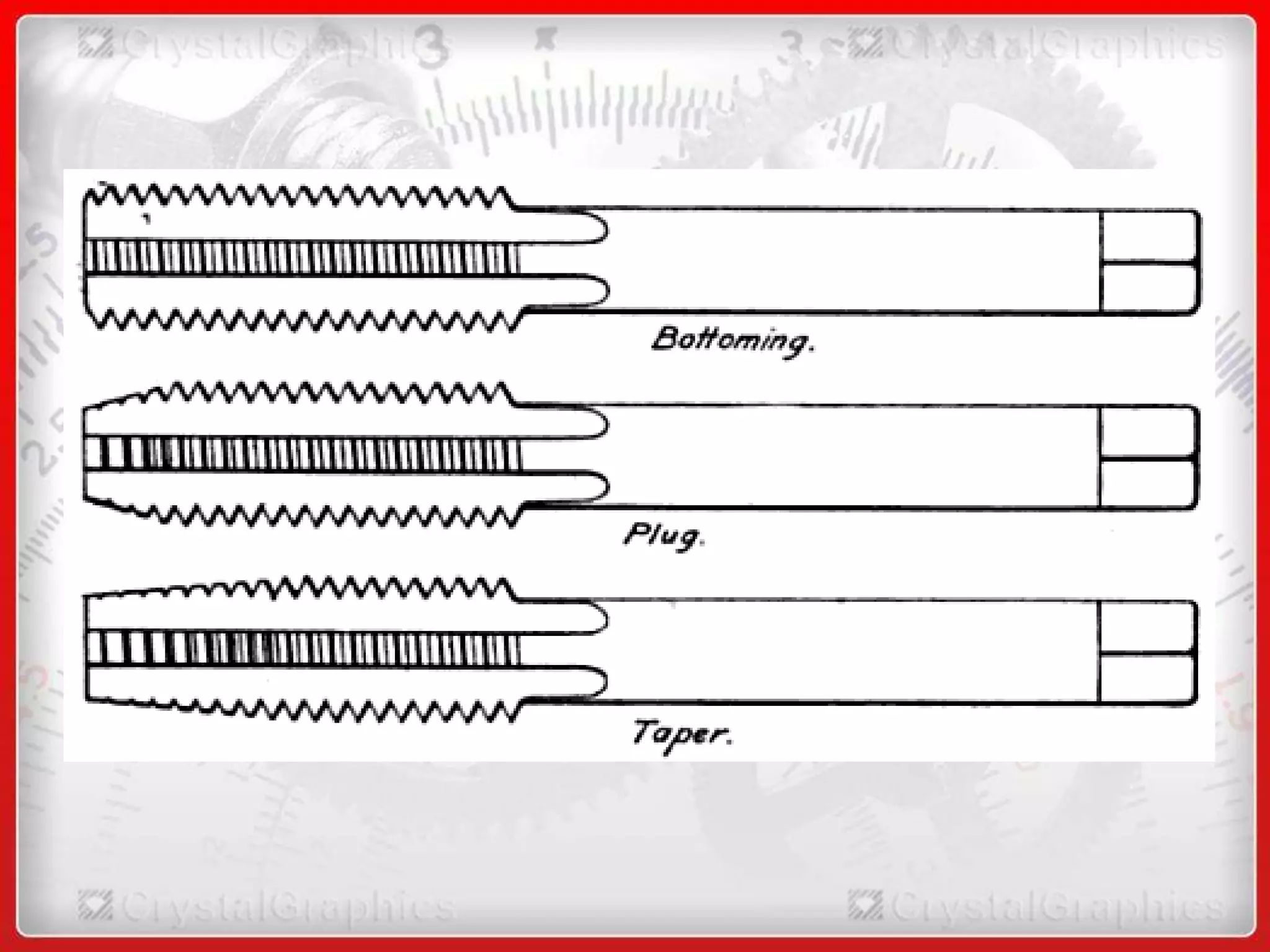

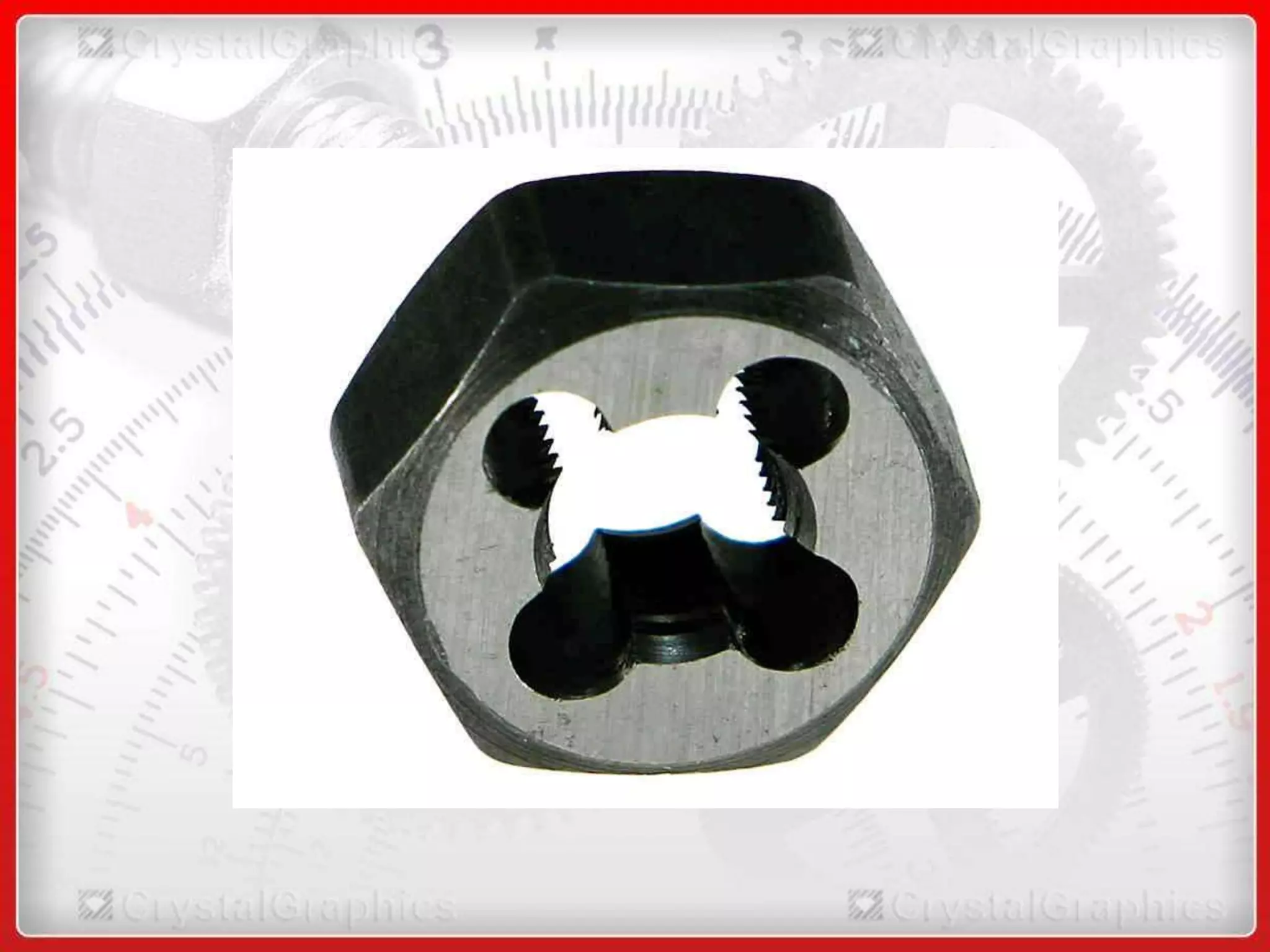

Taps and dies are cutting tools used to create screw threads, known as threading. Taps are used to cut female threads in nuts, while dies are used to form male threads in bolts. There are three main types of taps - bottoming taps clean up existing threads, taper and intermediate taps start threads in untapped holes with tapered cutting edges, and spiral point plug taps are most common for power tapping. Dies are used to form threads on bolts and rethreading dies can clean up damaged threads. The process of using taps is called tapping while using dies is called threading, and both can be used to clean up threads through chasing.