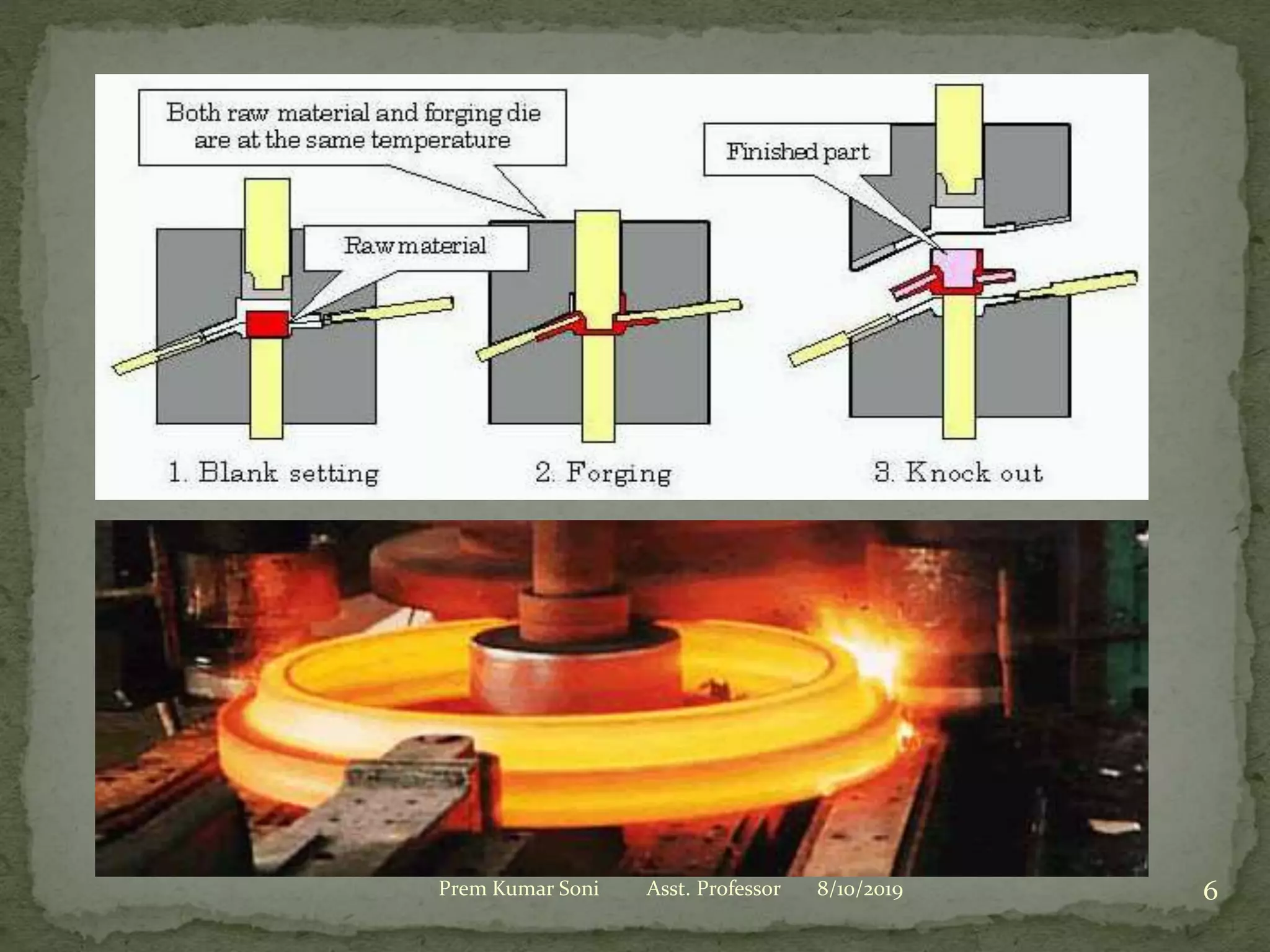

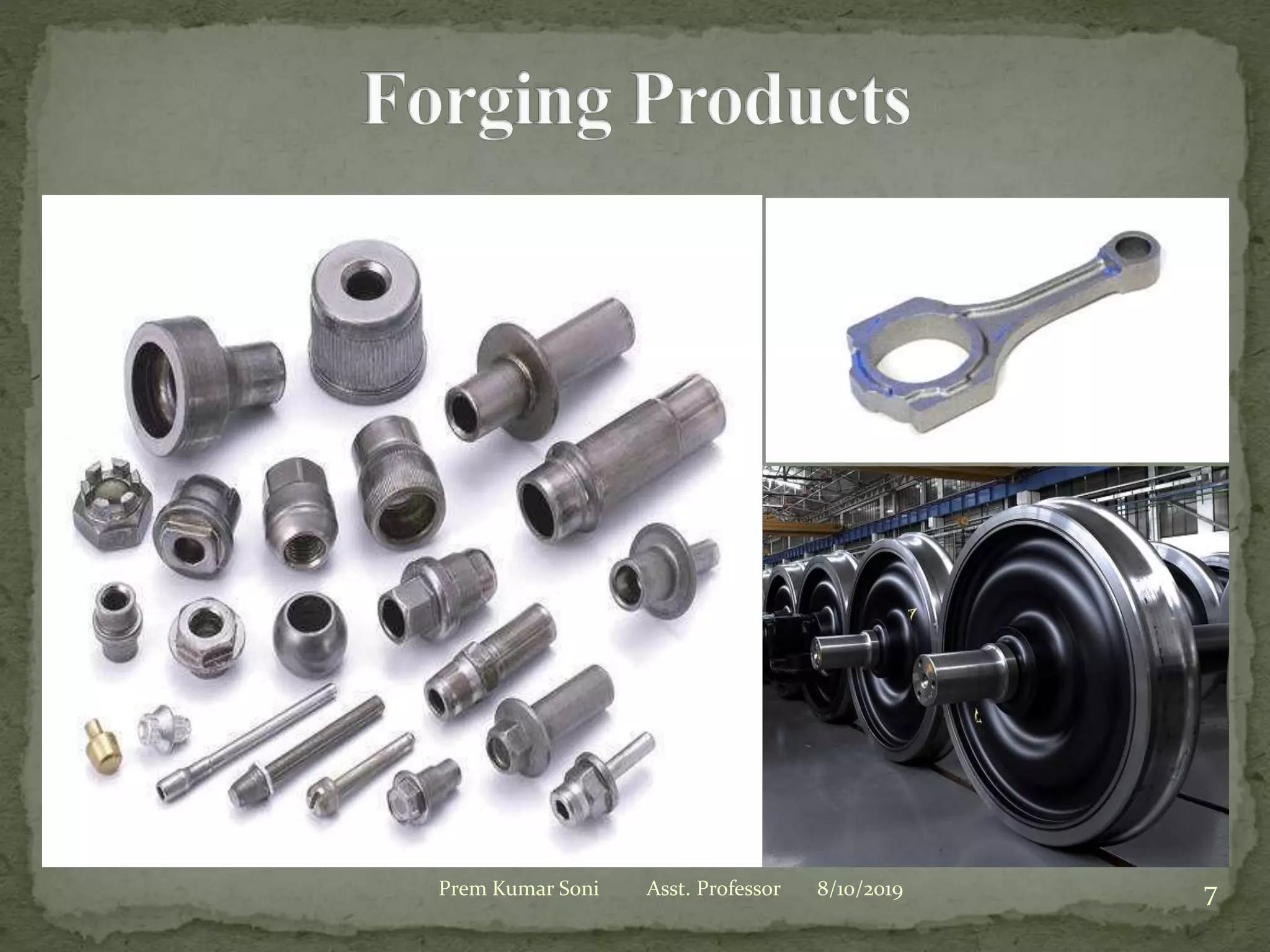

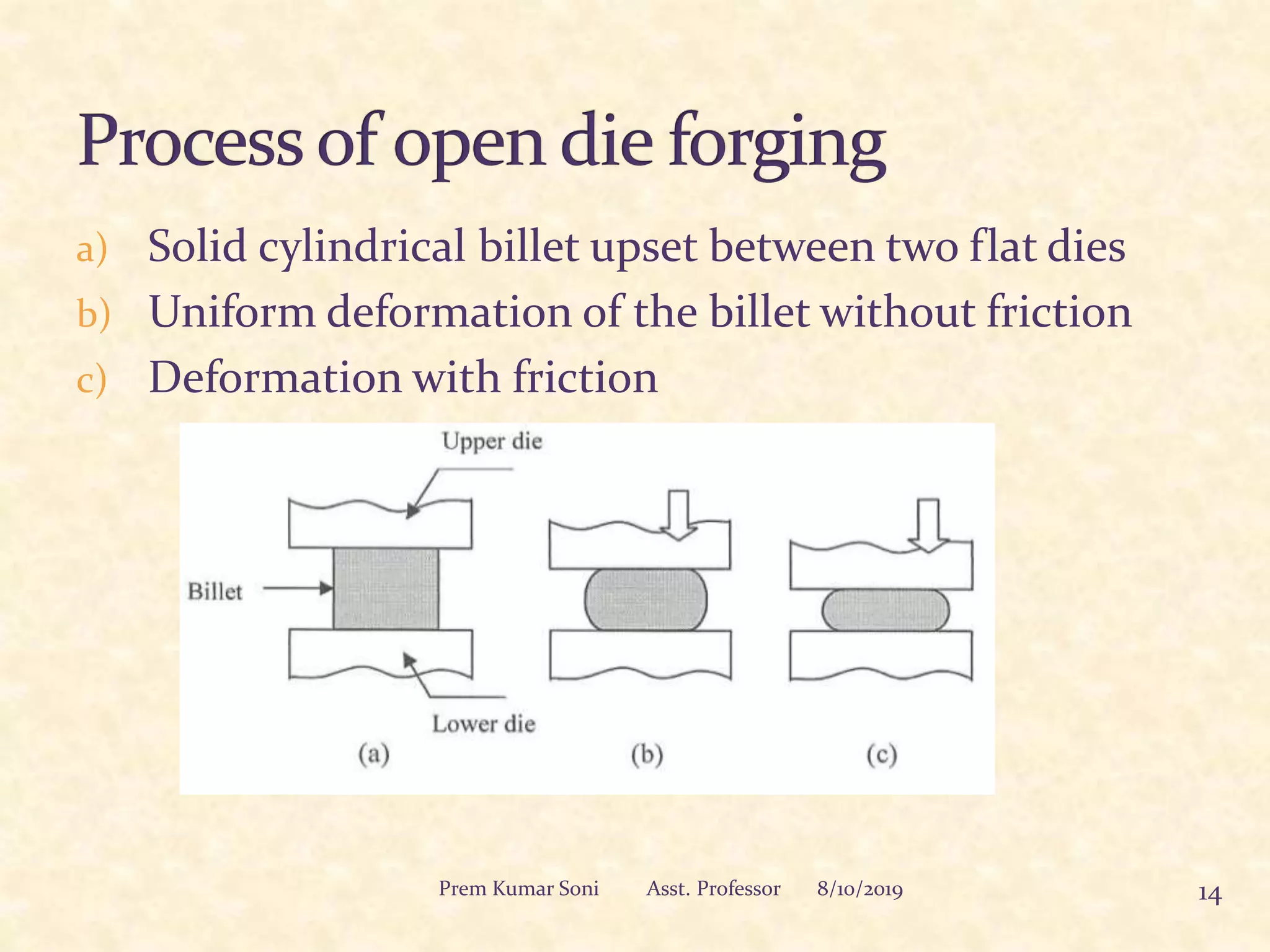

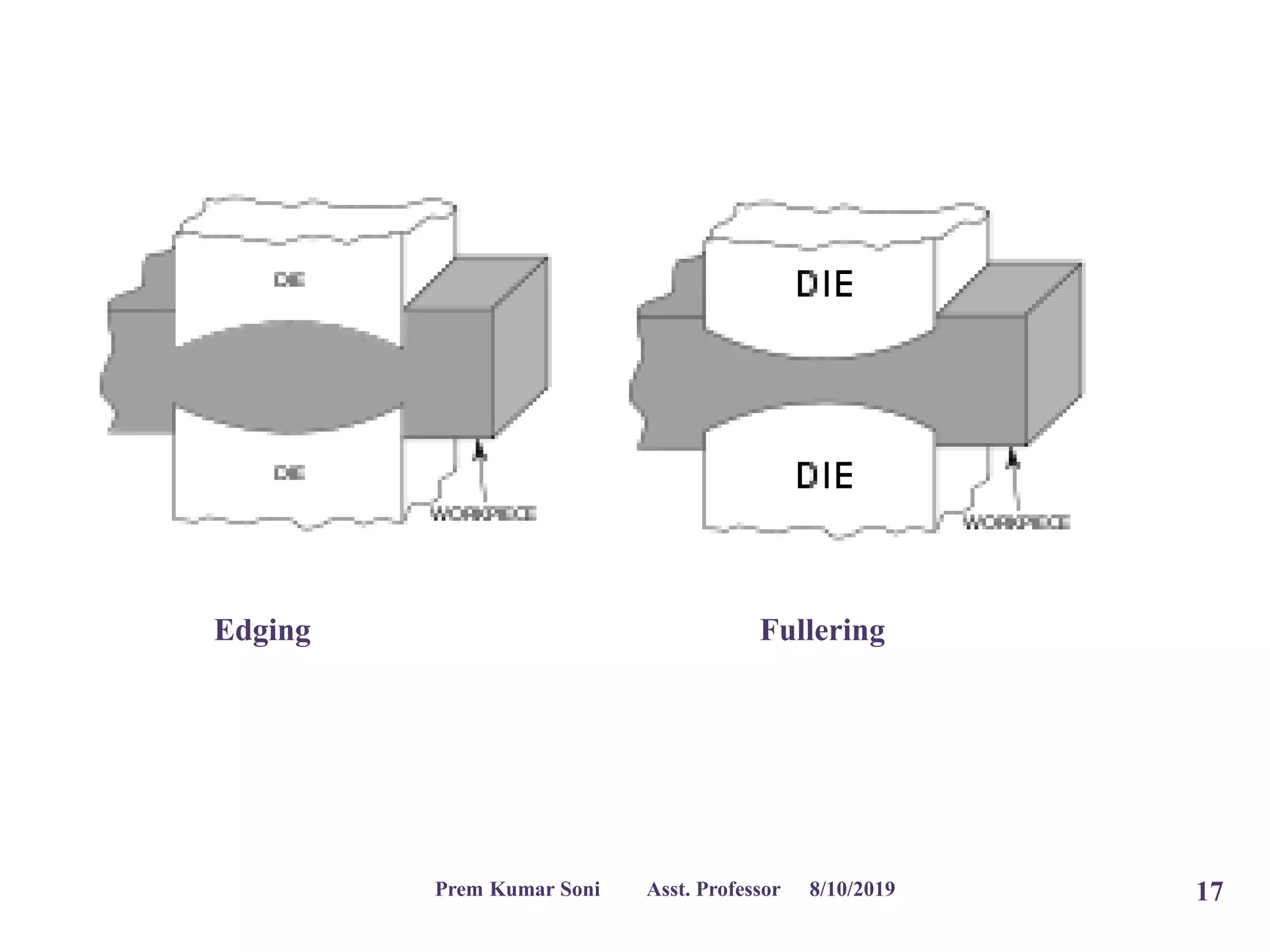

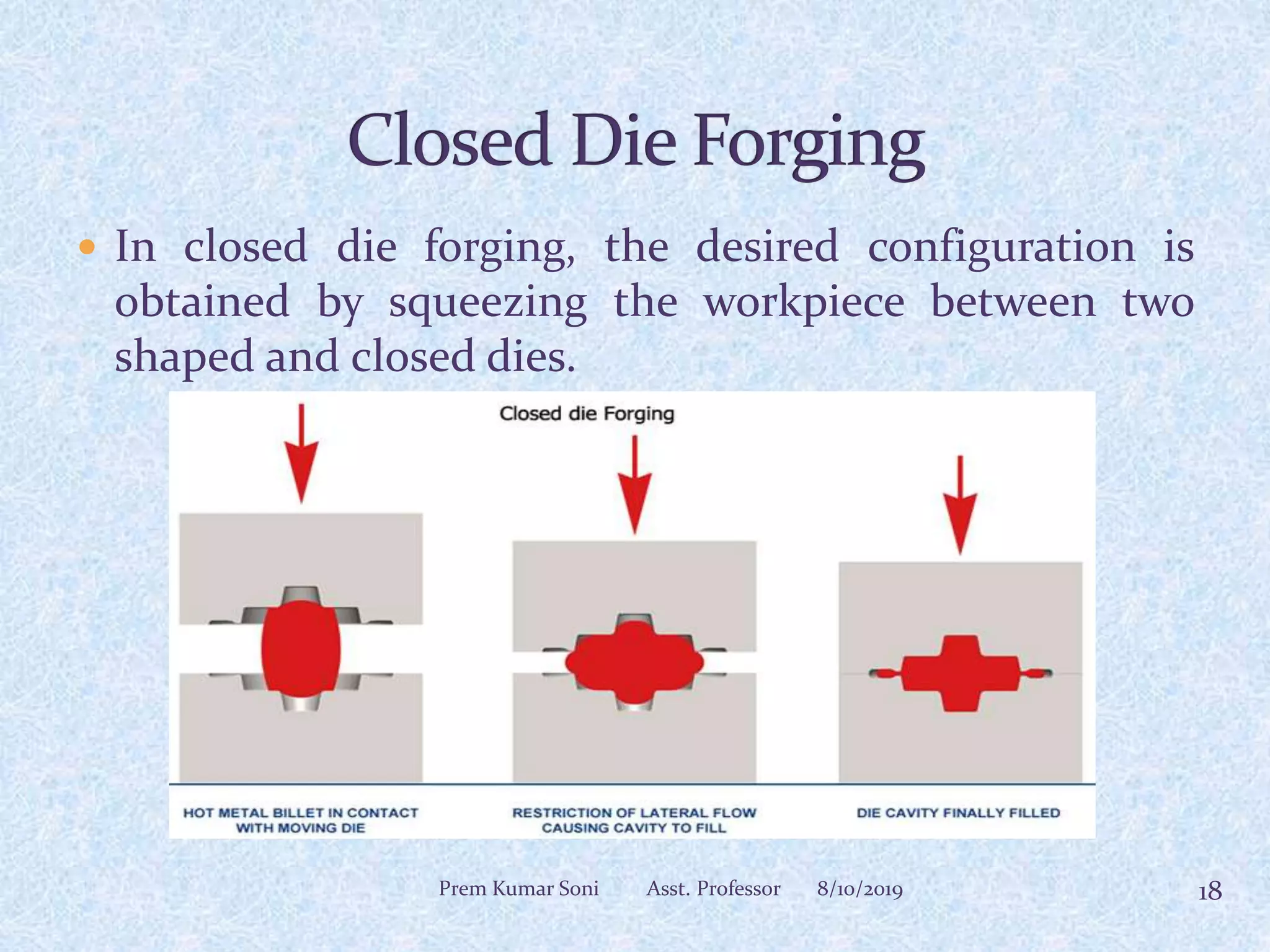

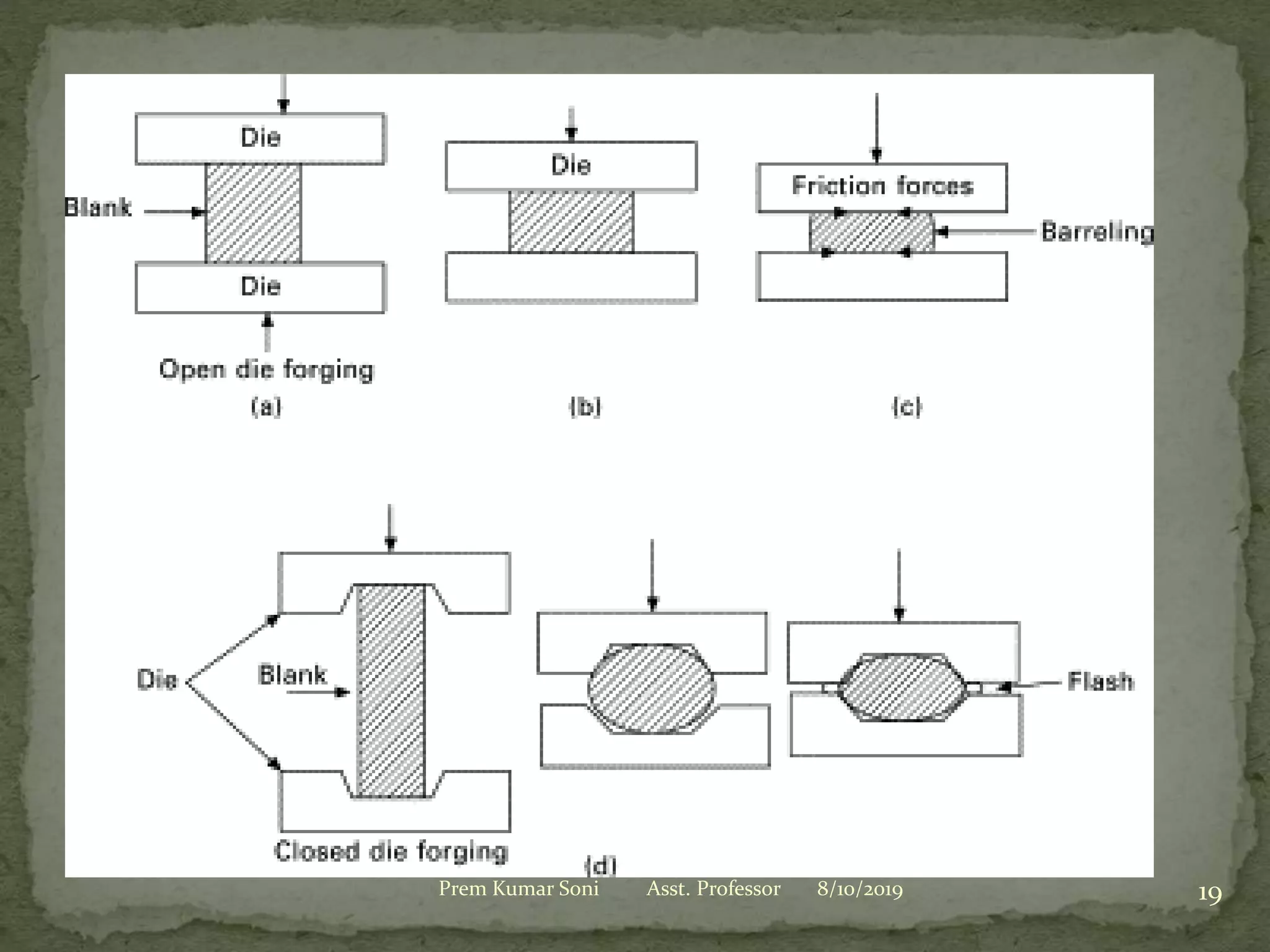

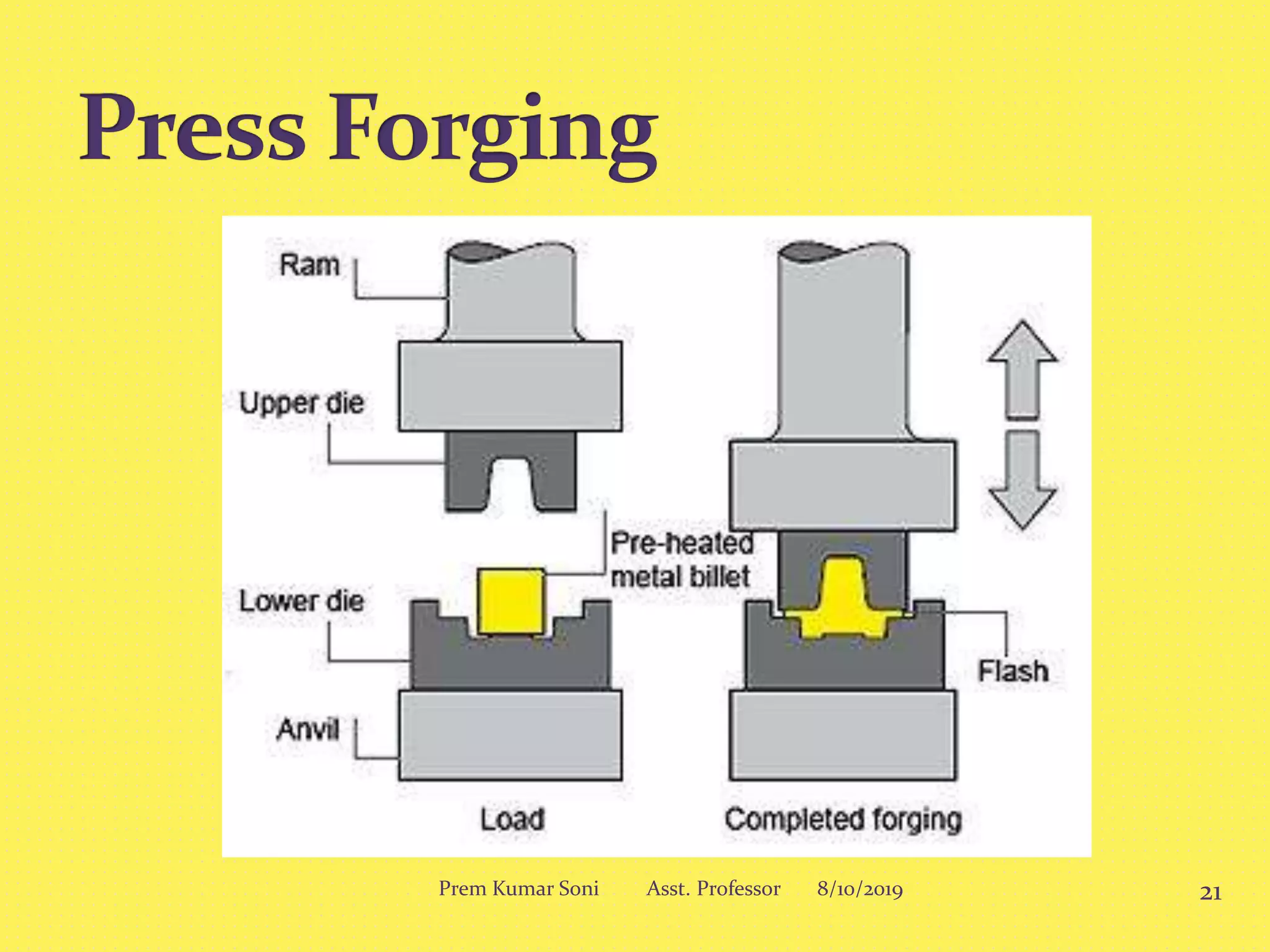

The document discusses the forging process, which involves shaping heated metal through techniques like hammer and press forging, and emphasizes the importance of plasticity in metal deformation. It details types of forging such as cold, hot, and press forging, along with their advantages, disadvantages, and various applications. Additionally, the document covers equipment used, classification of forging methods, common defects encountered, and guidelines for proper forging techniques.