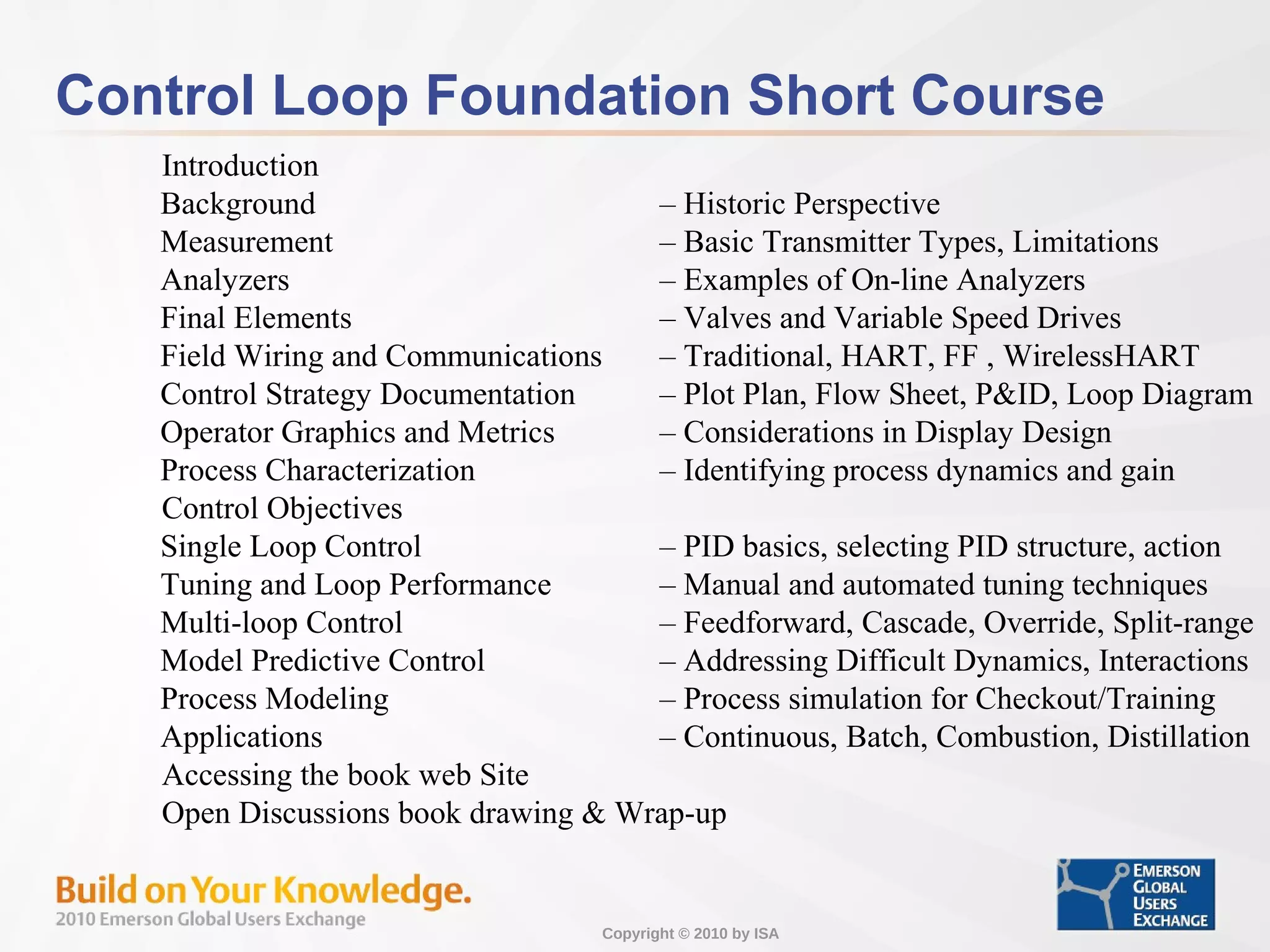

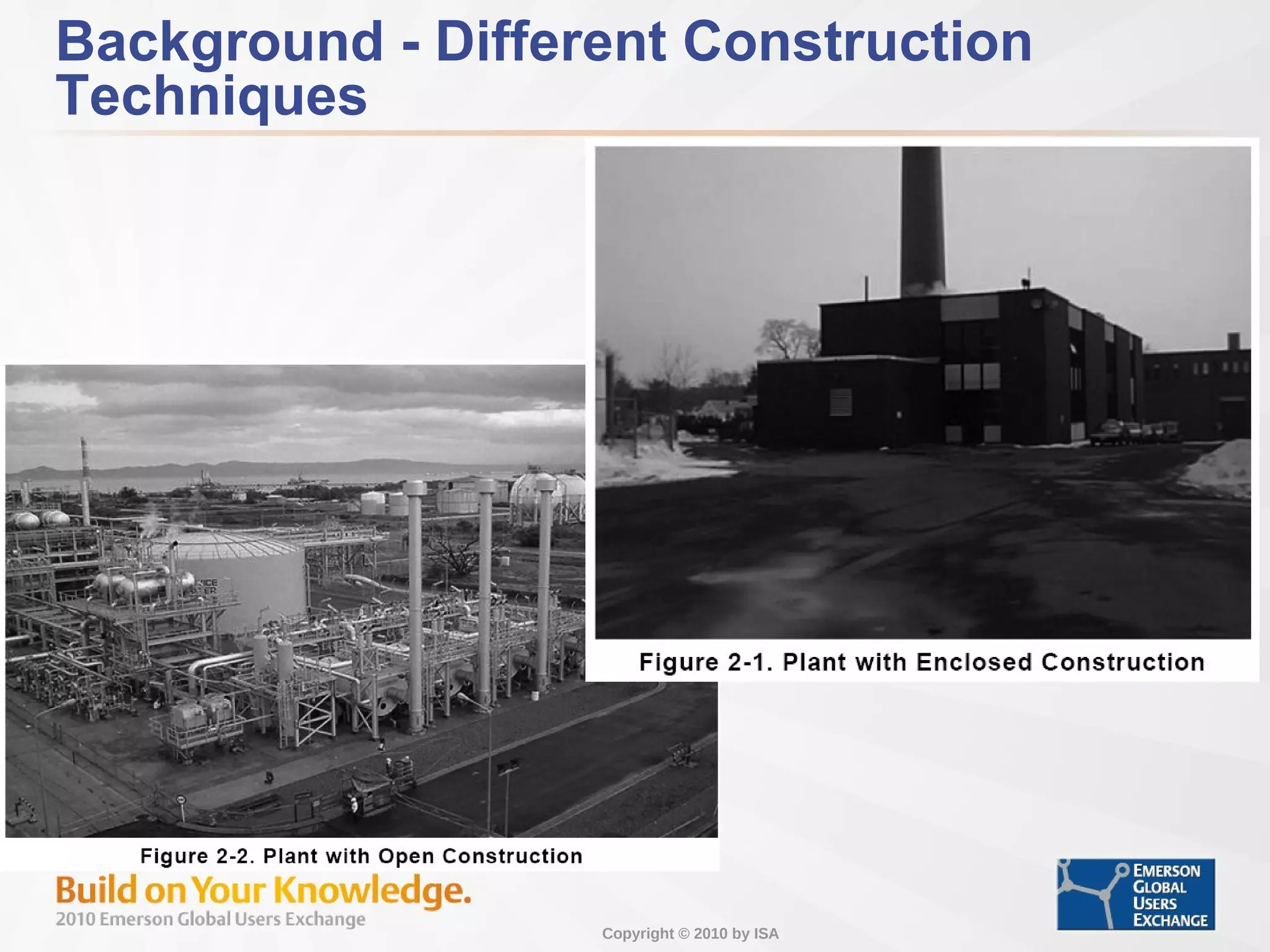

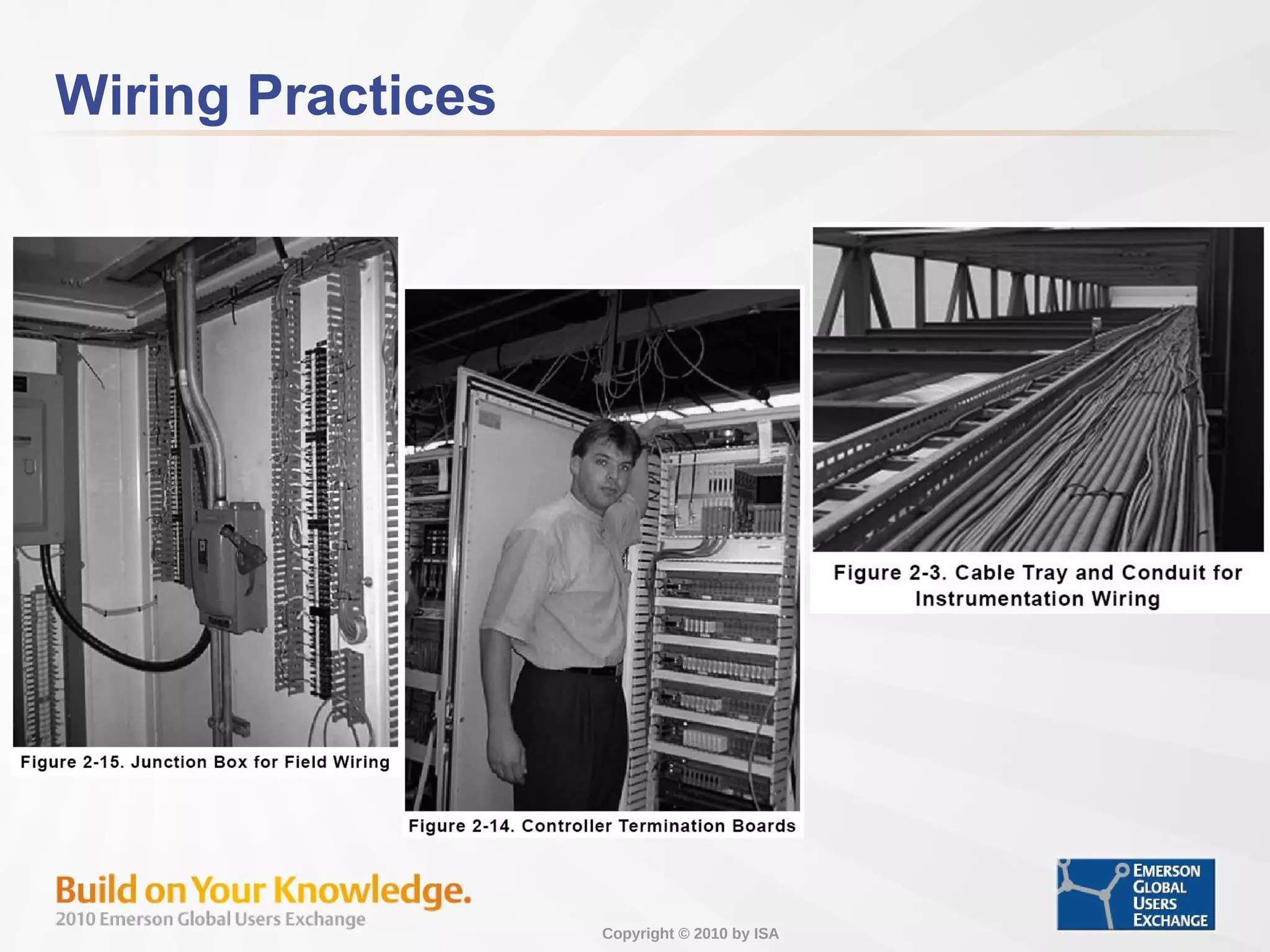

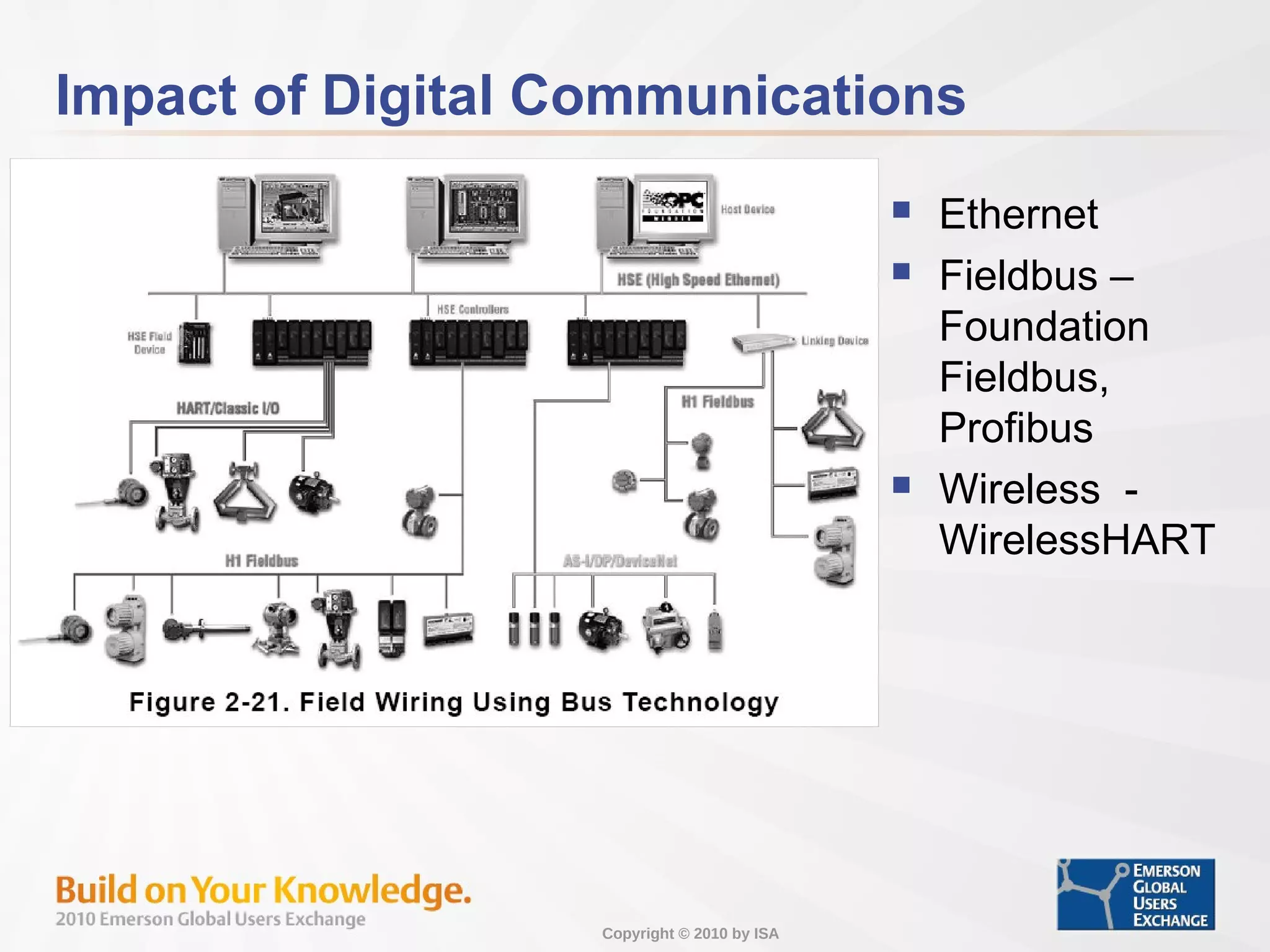

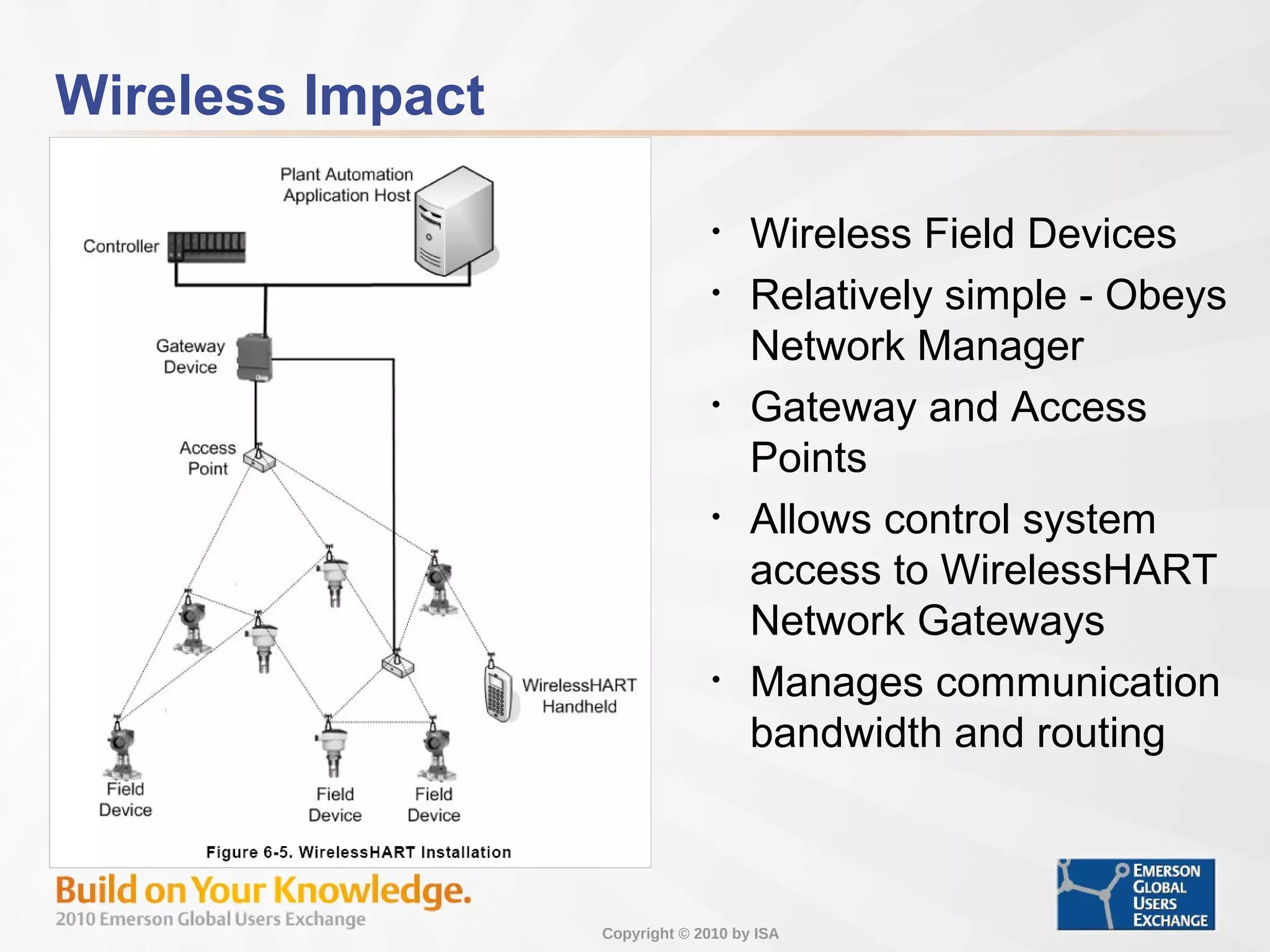

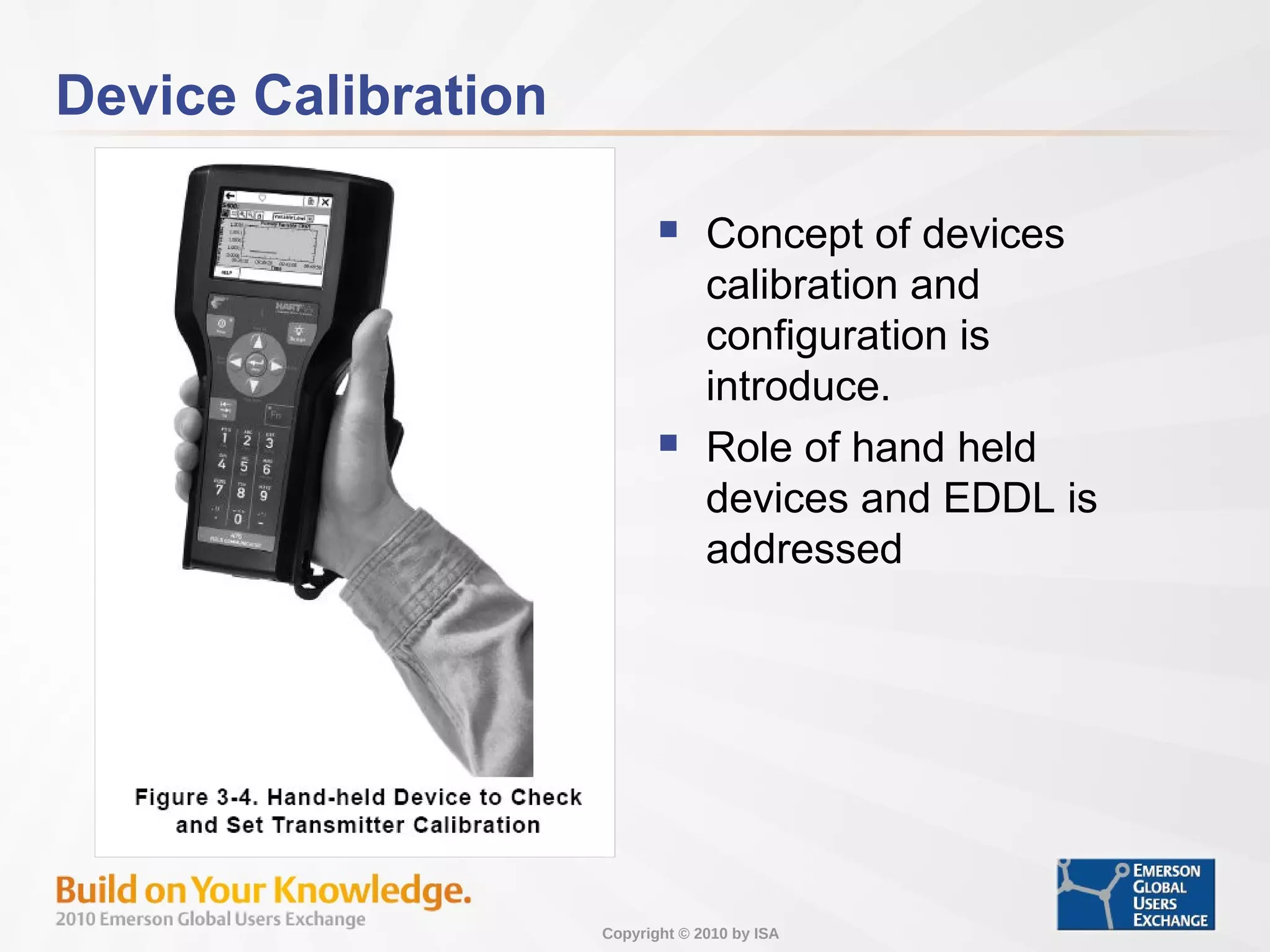

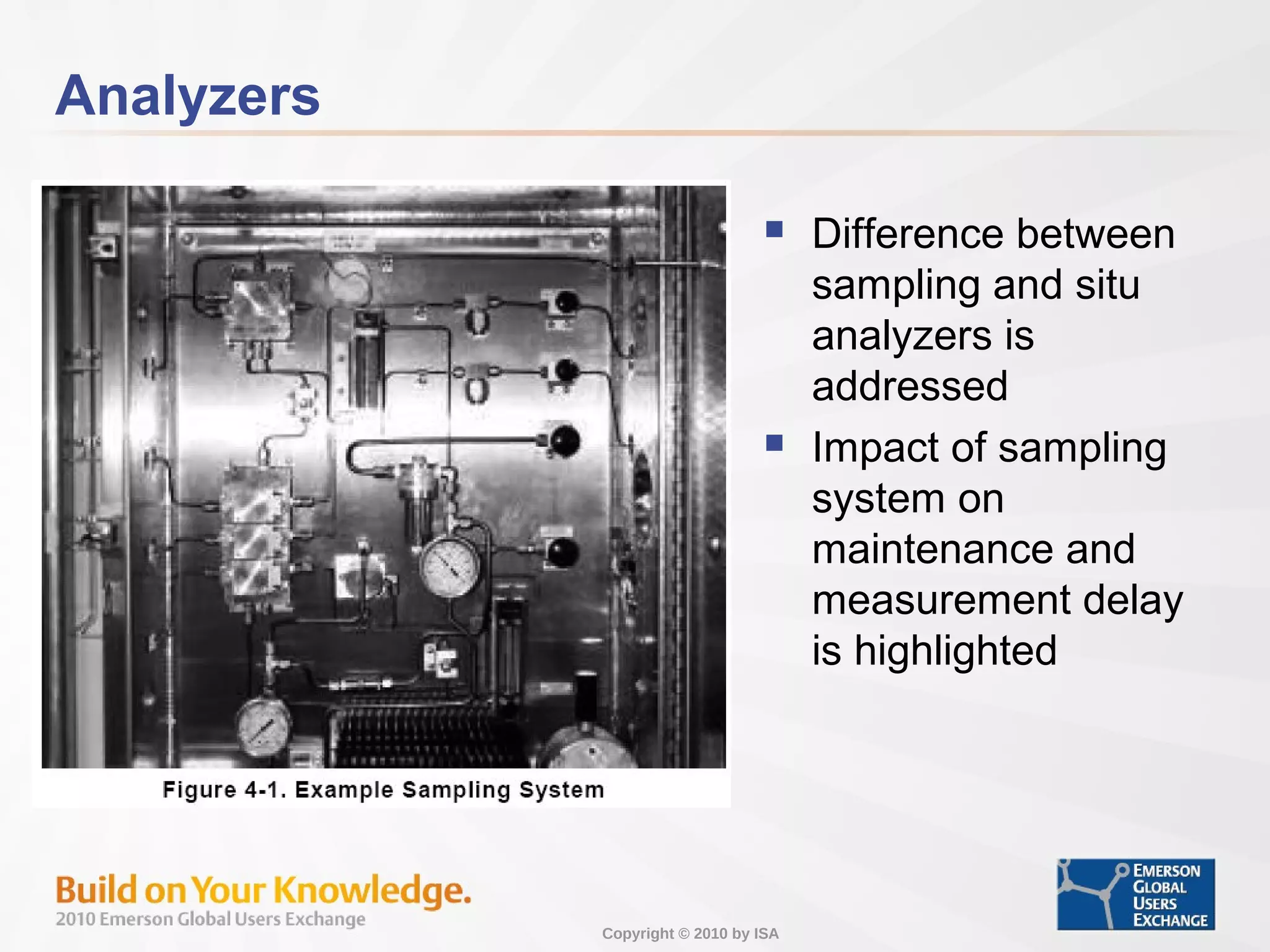

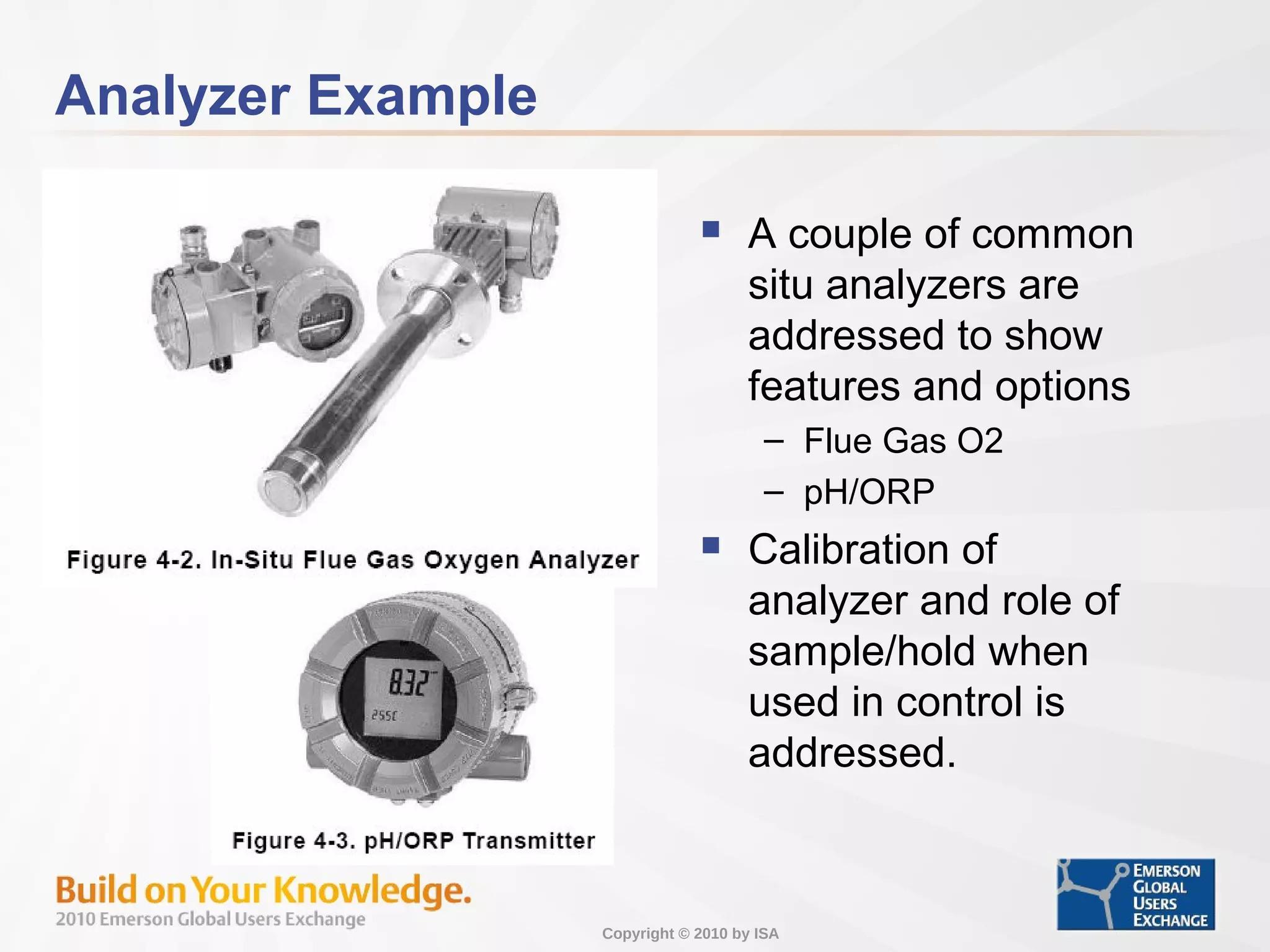

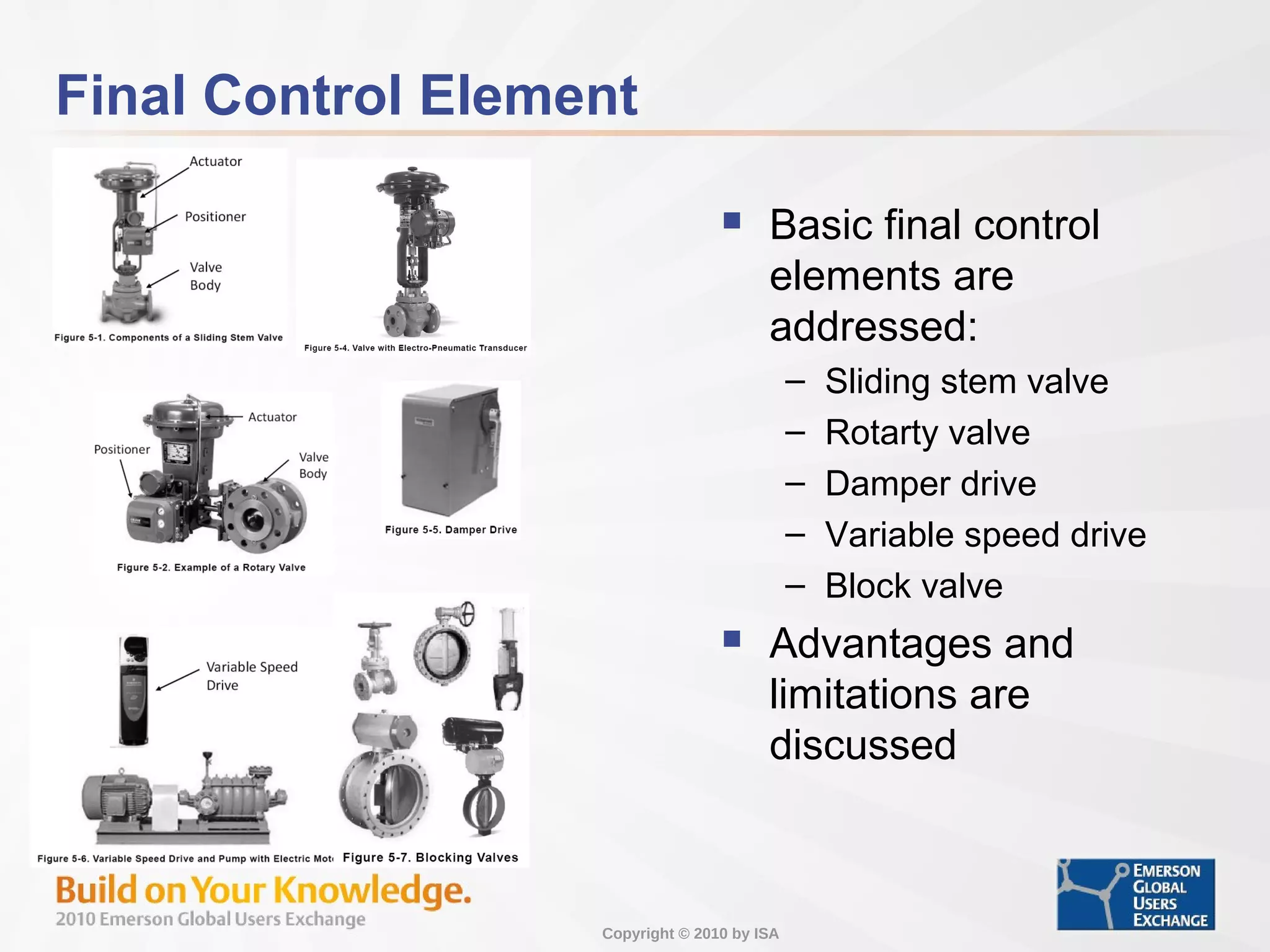

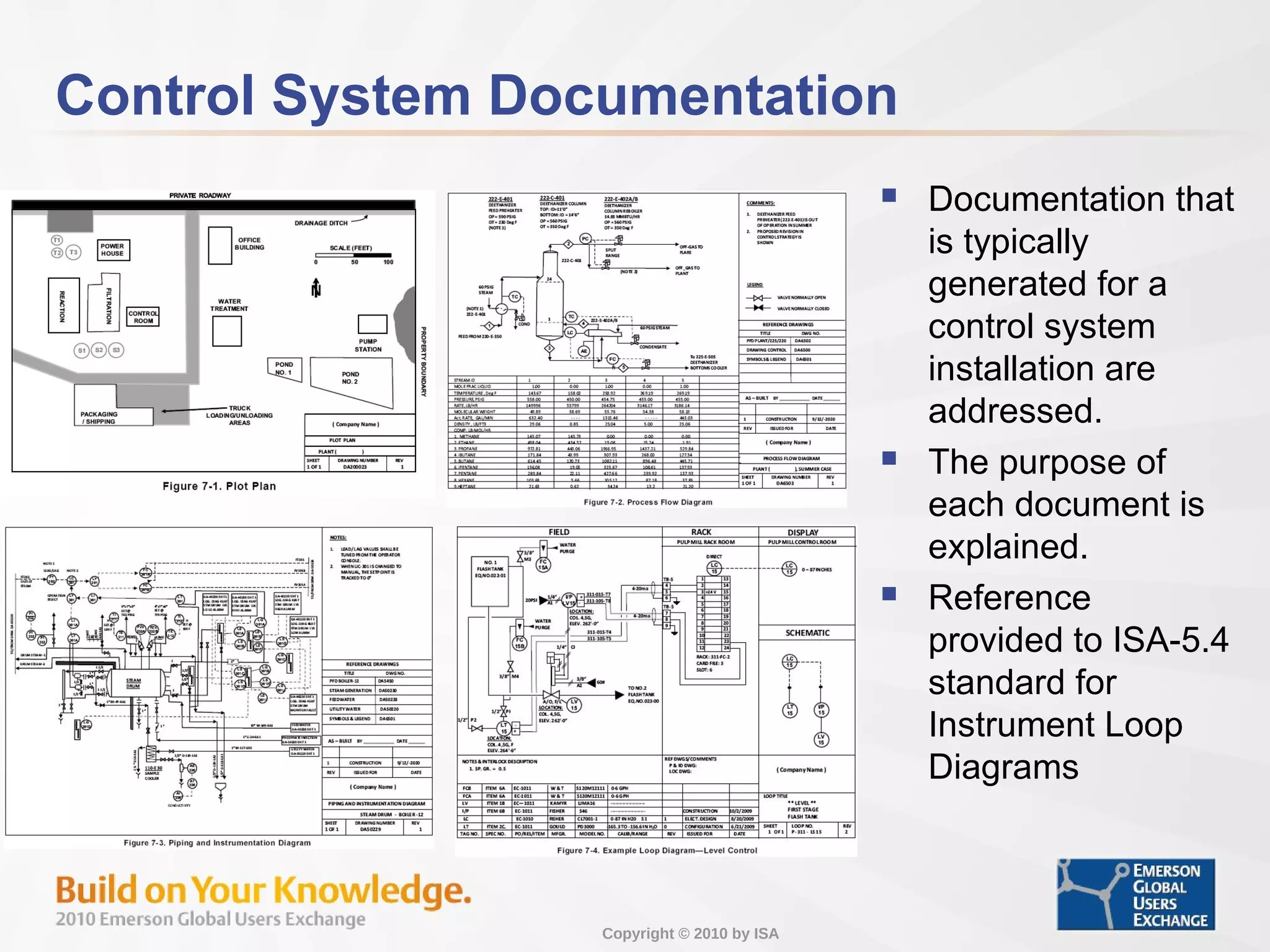

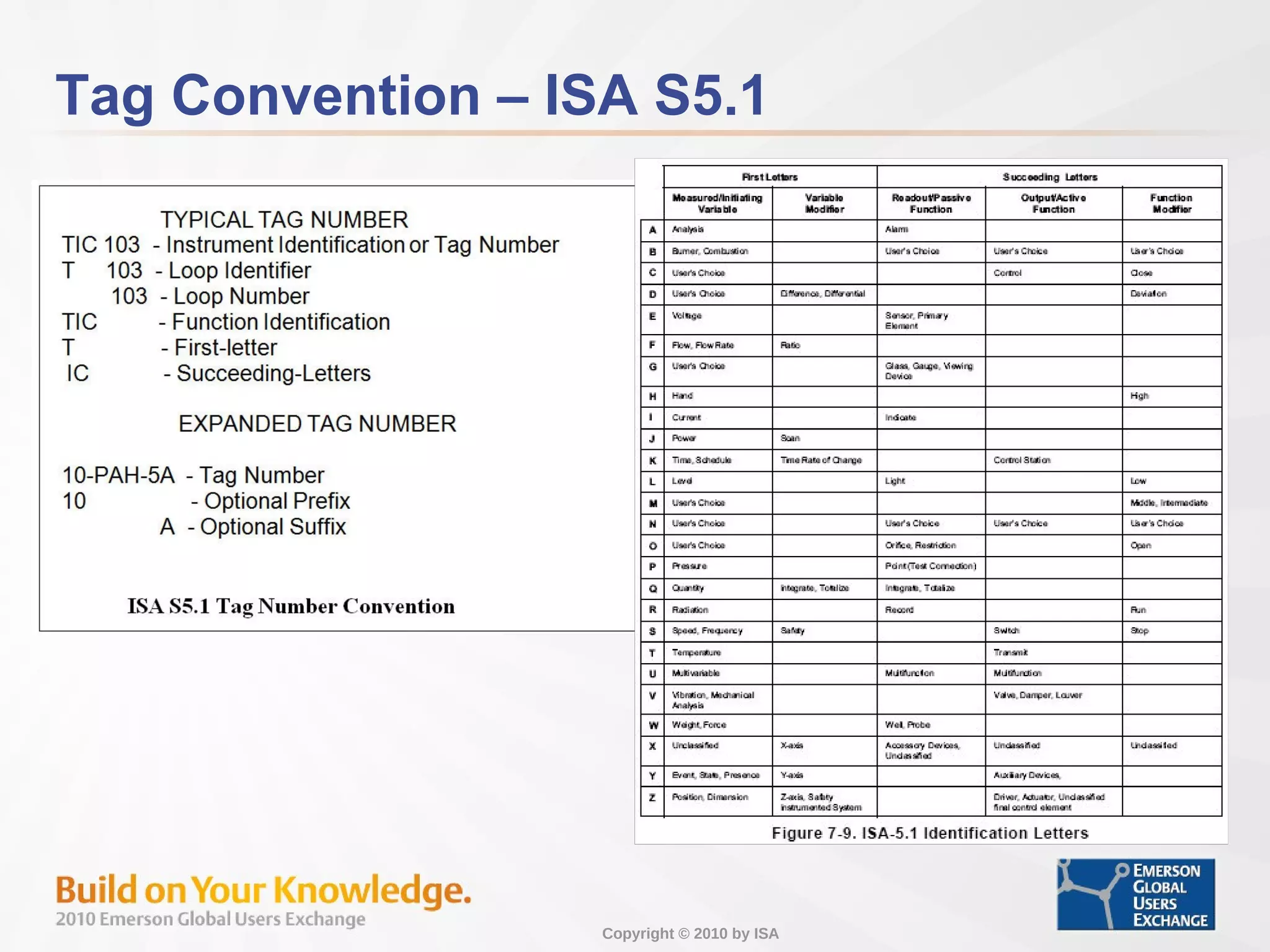

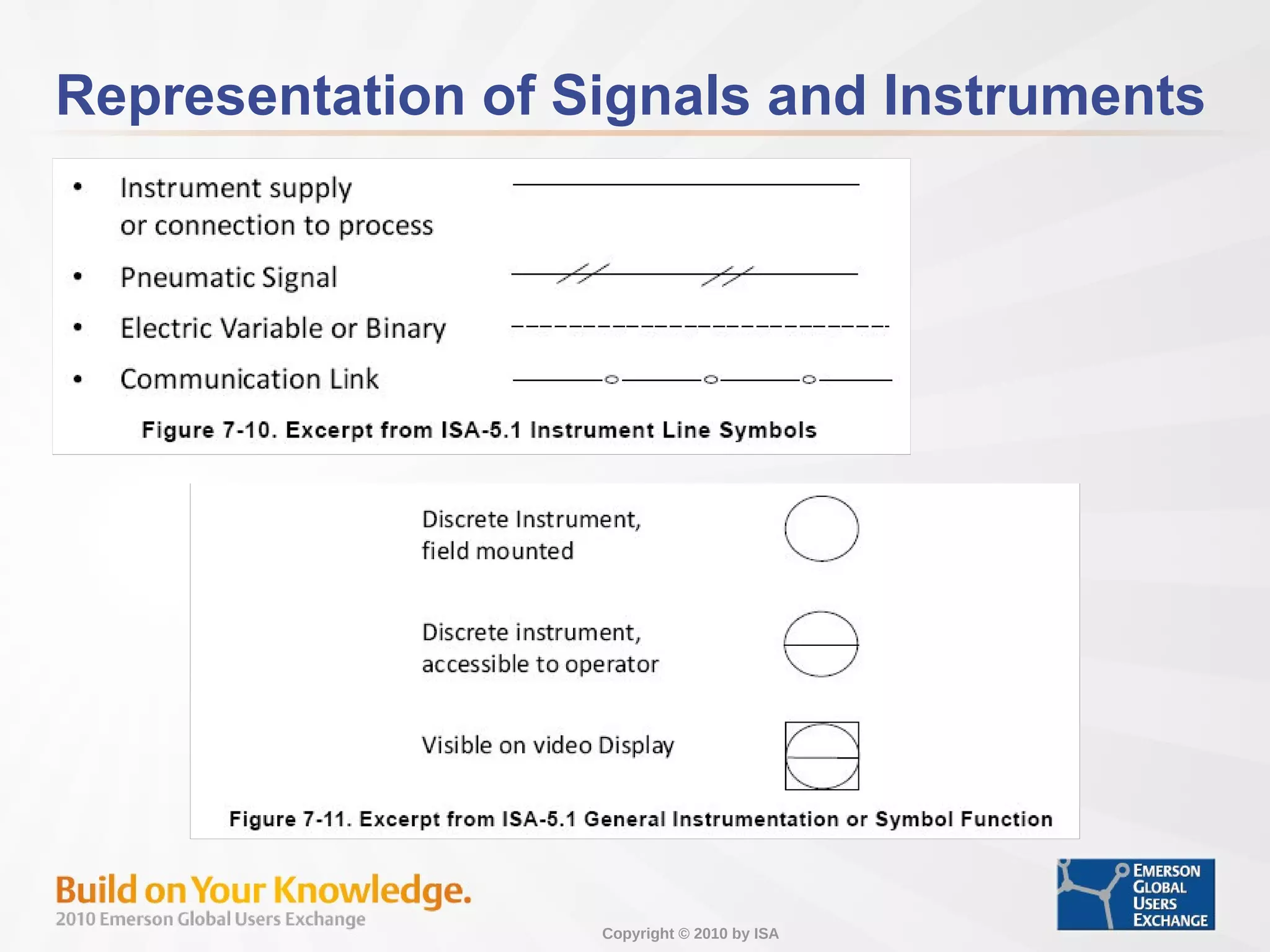

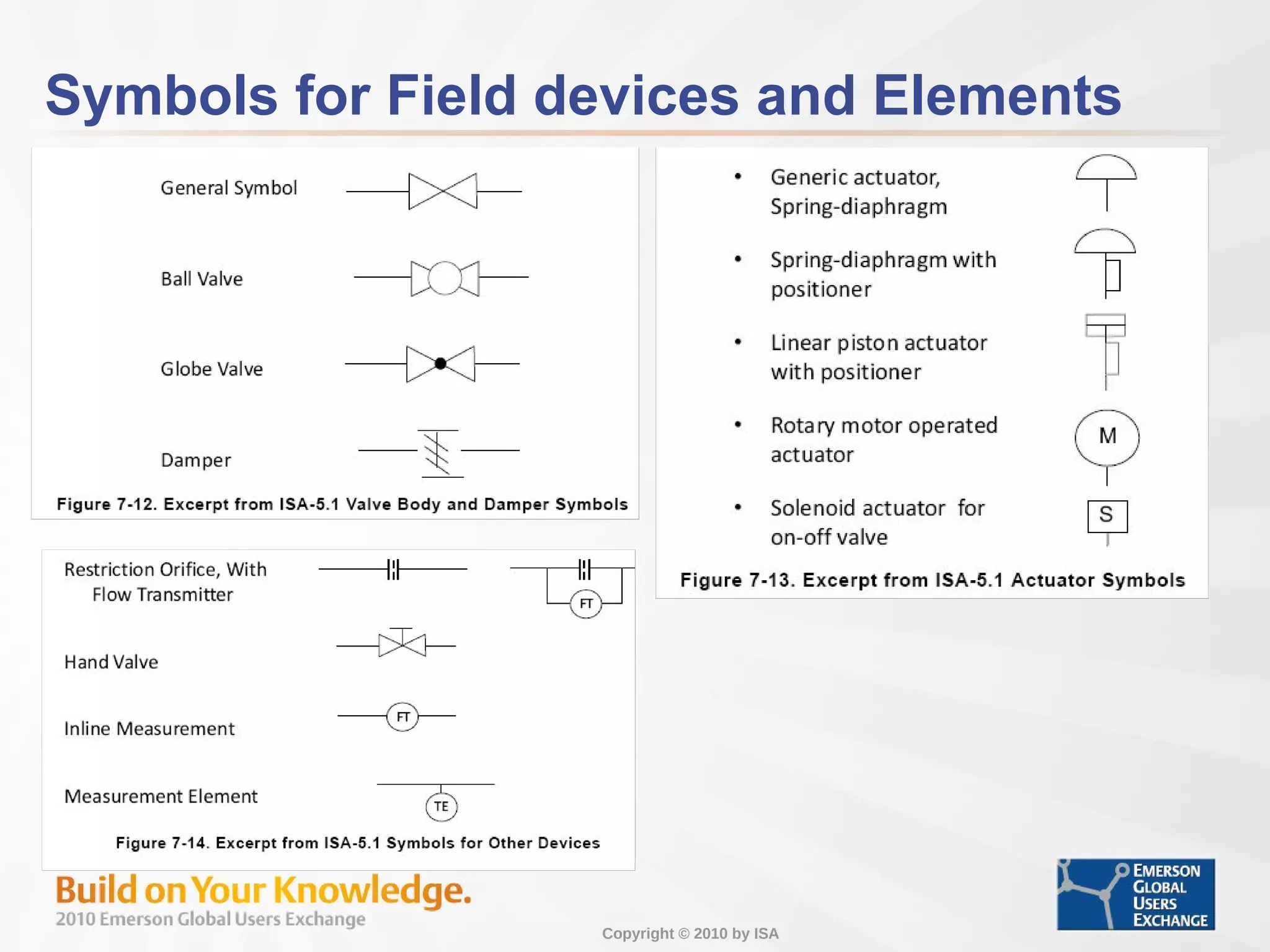

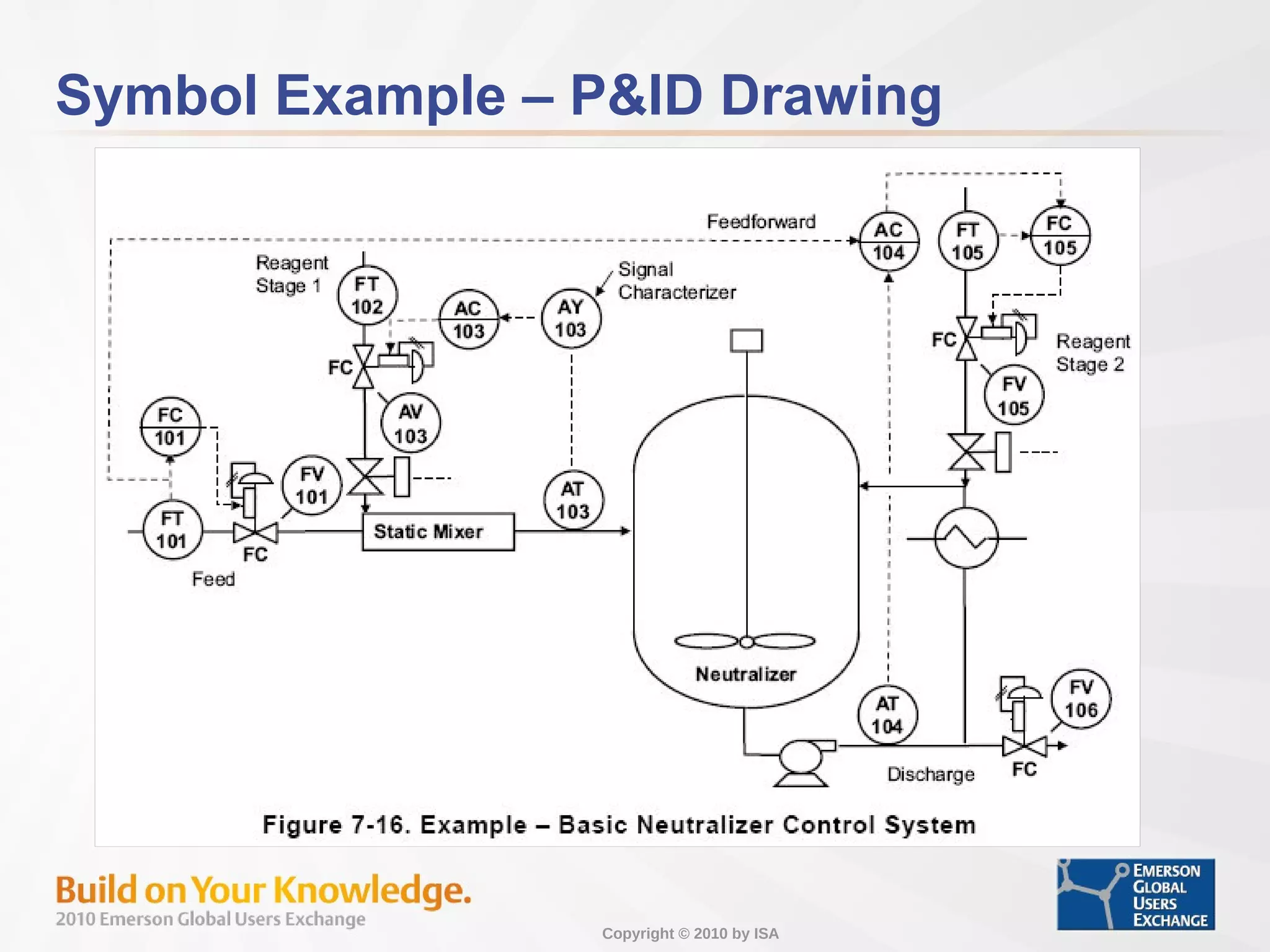

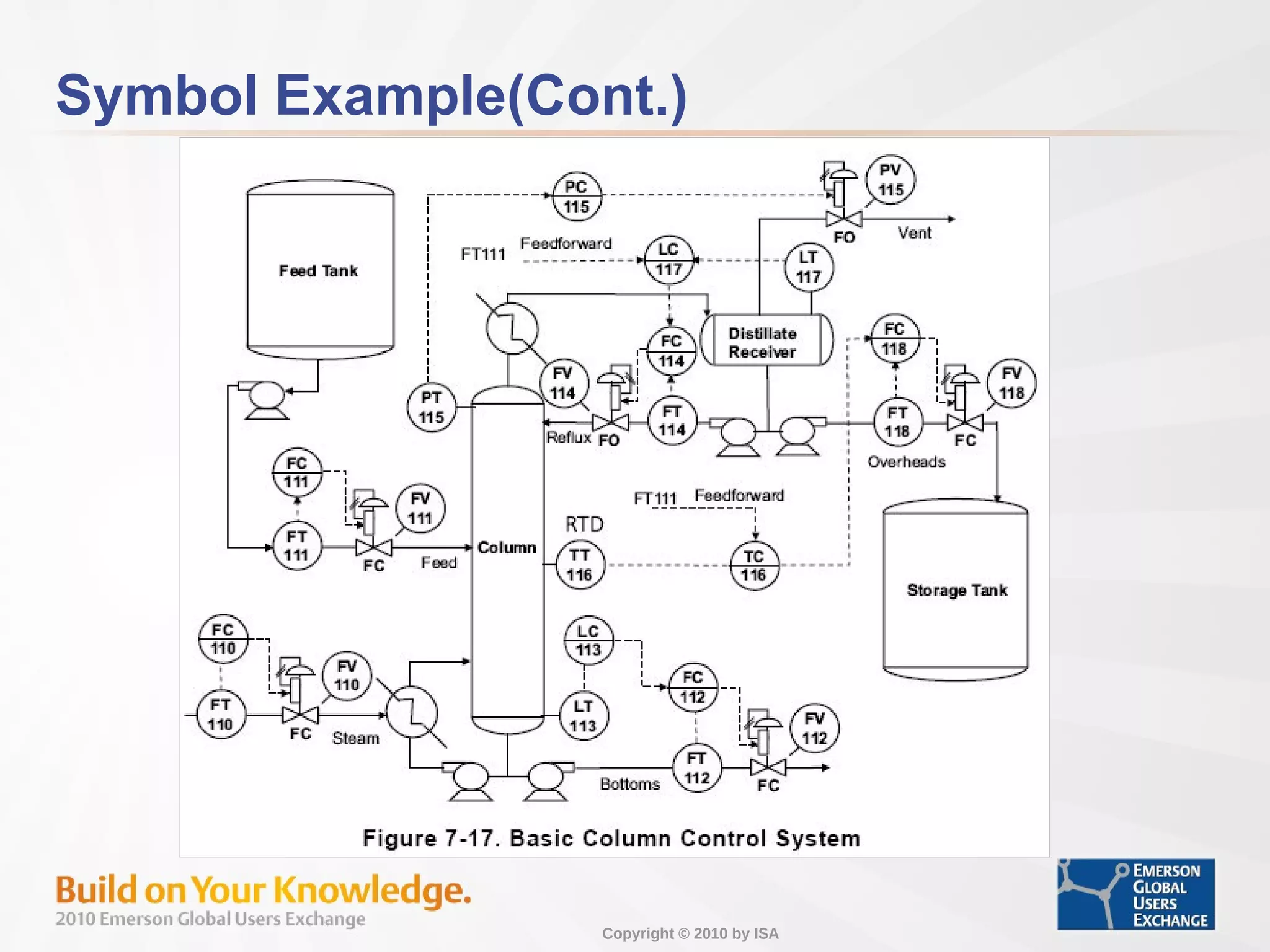

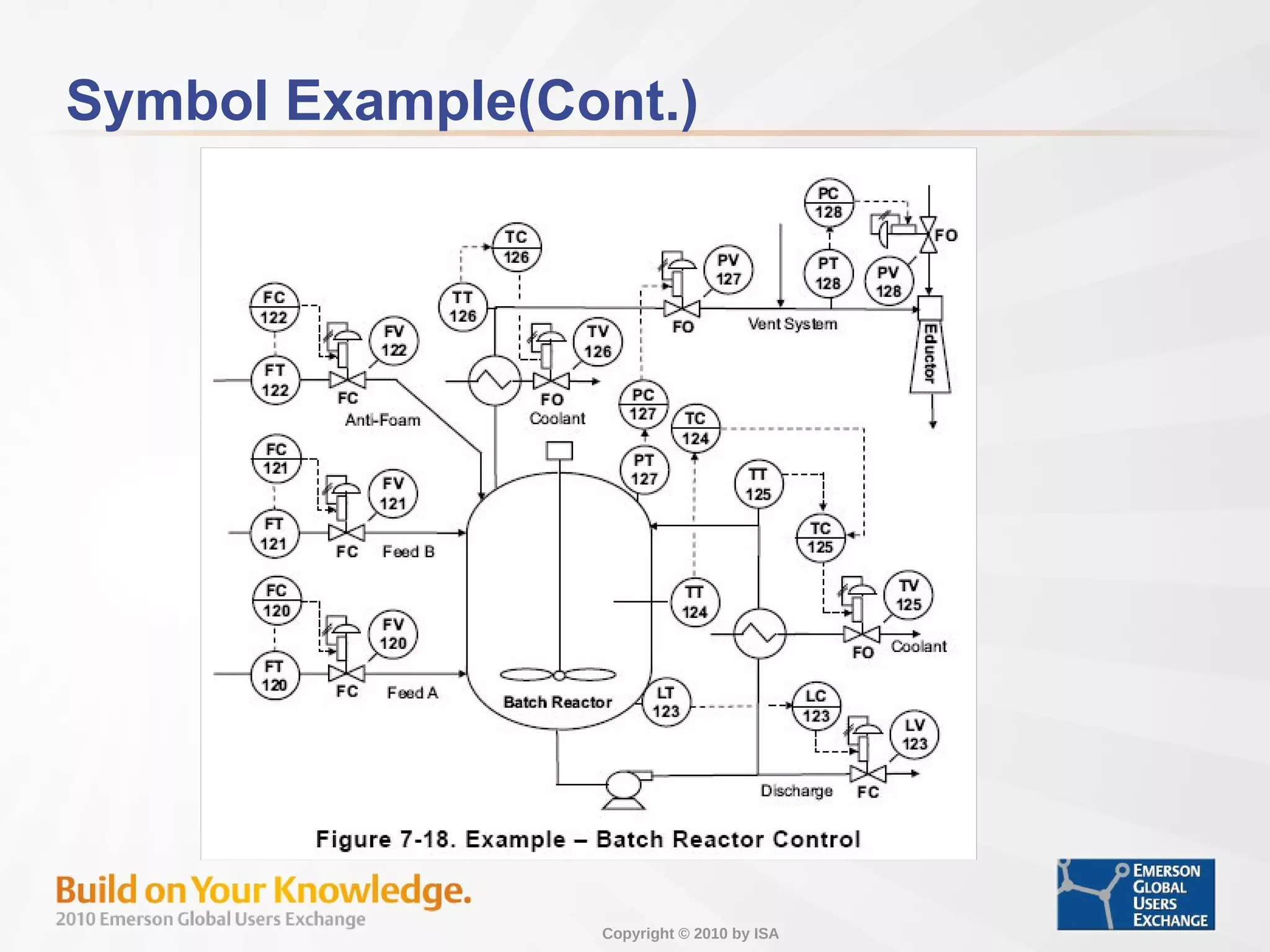

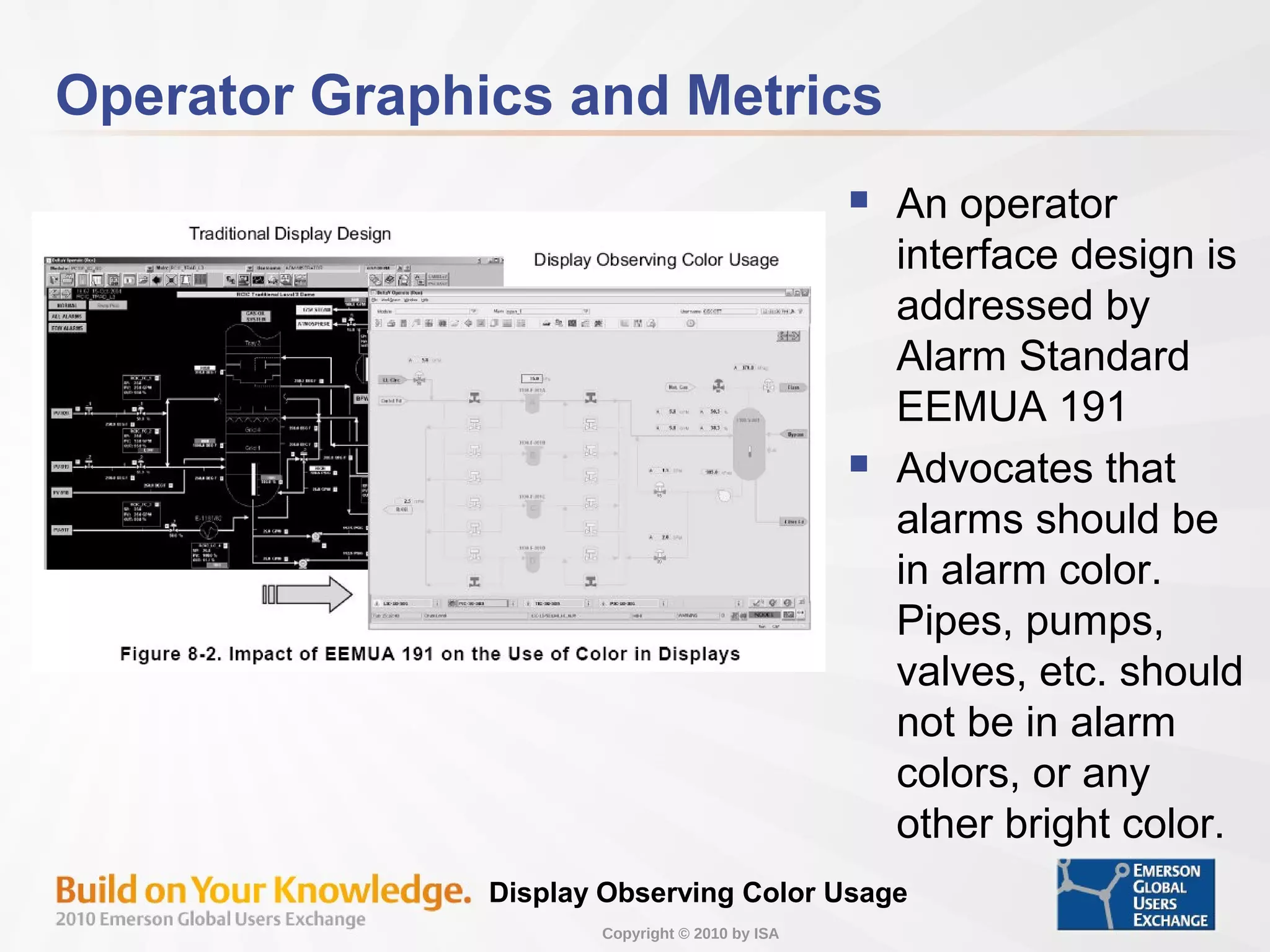

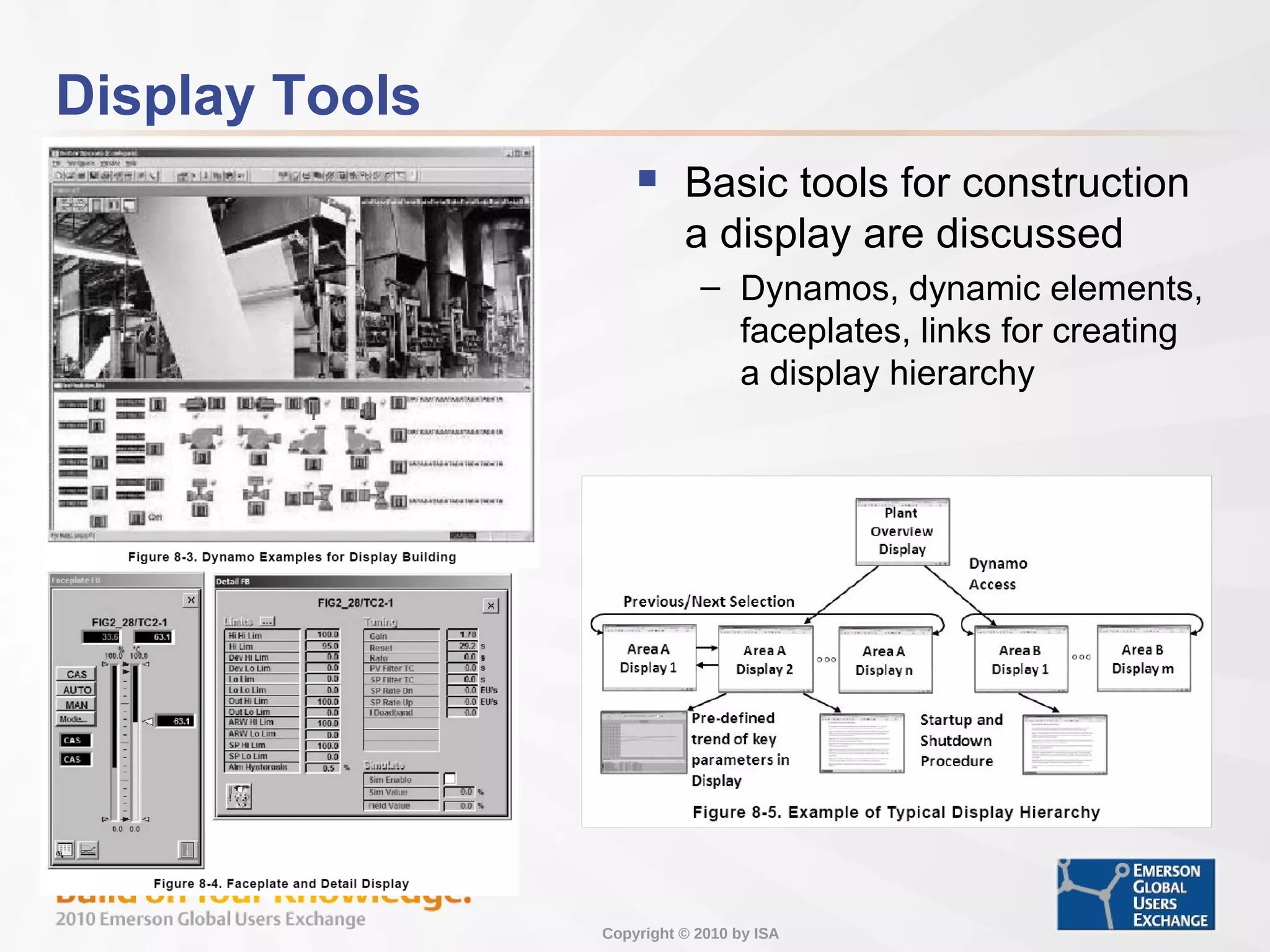

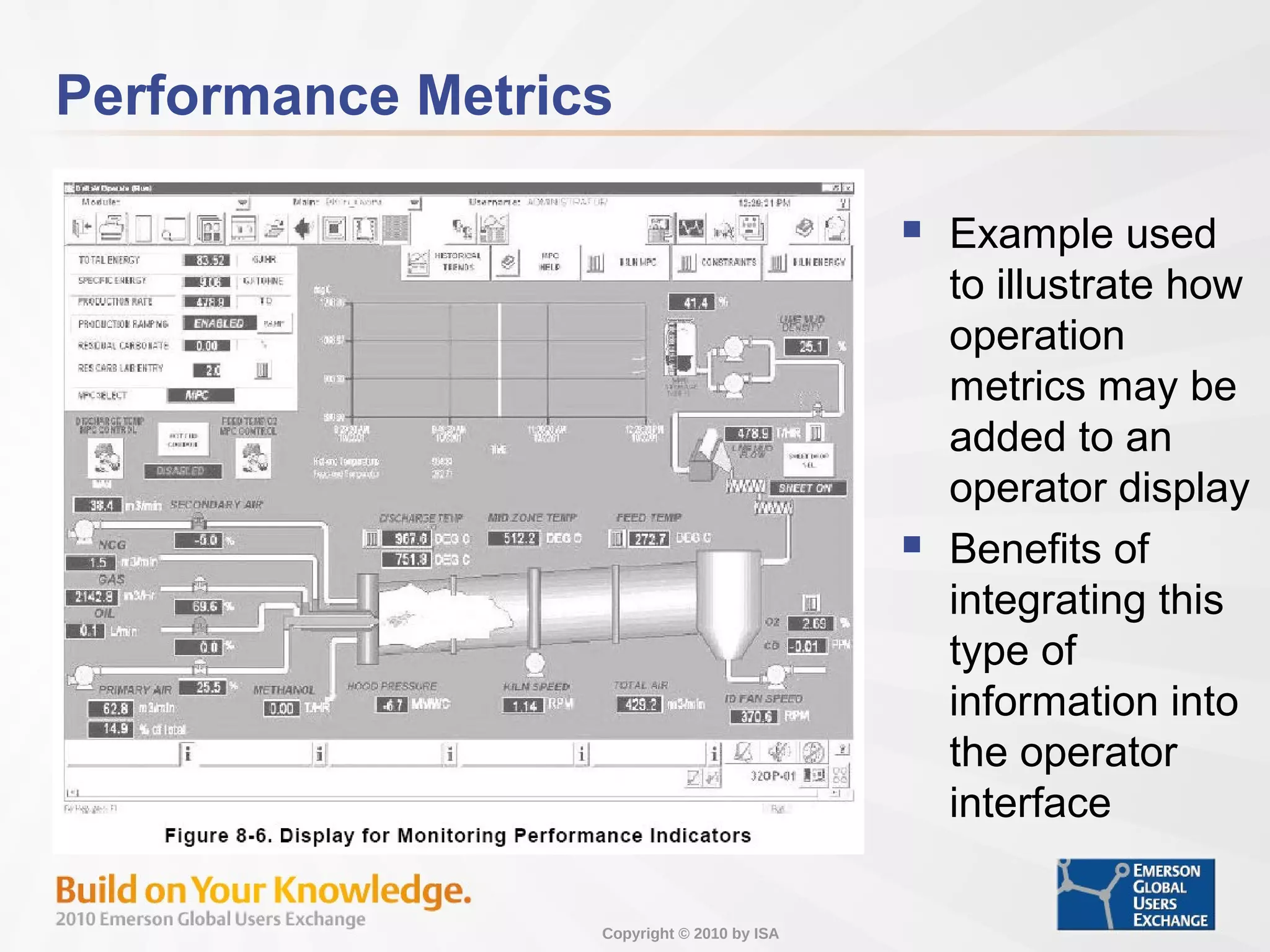

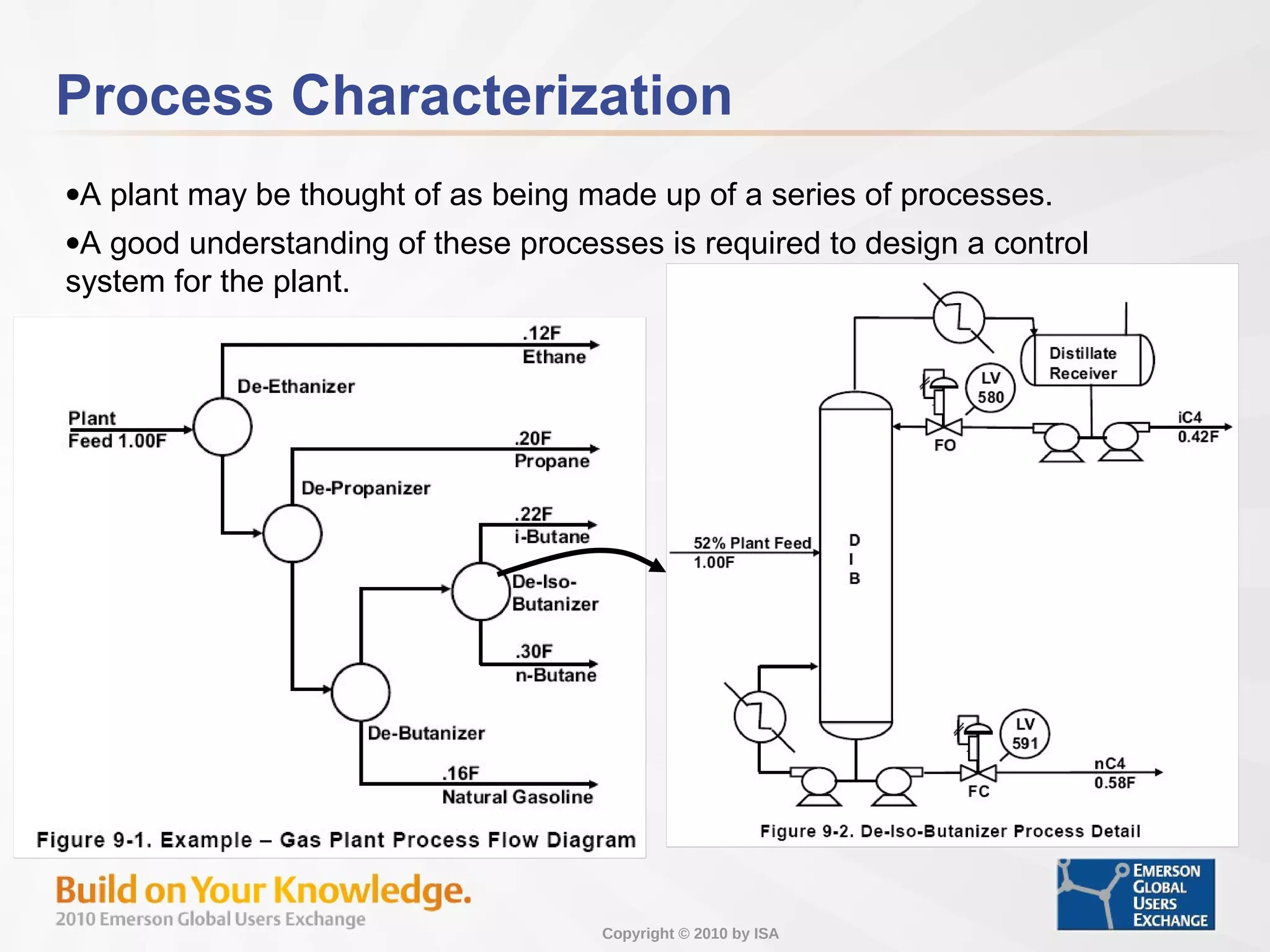

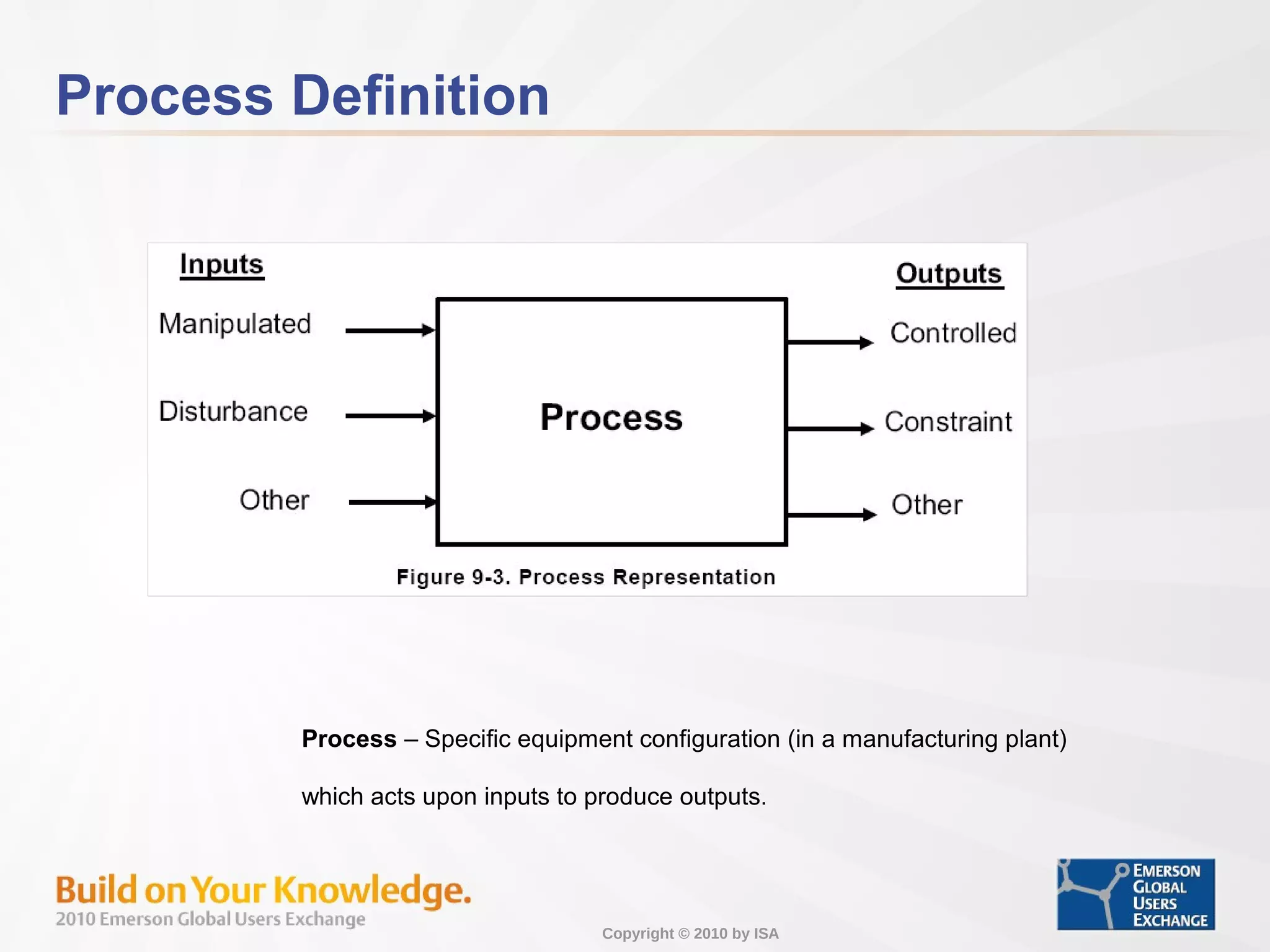

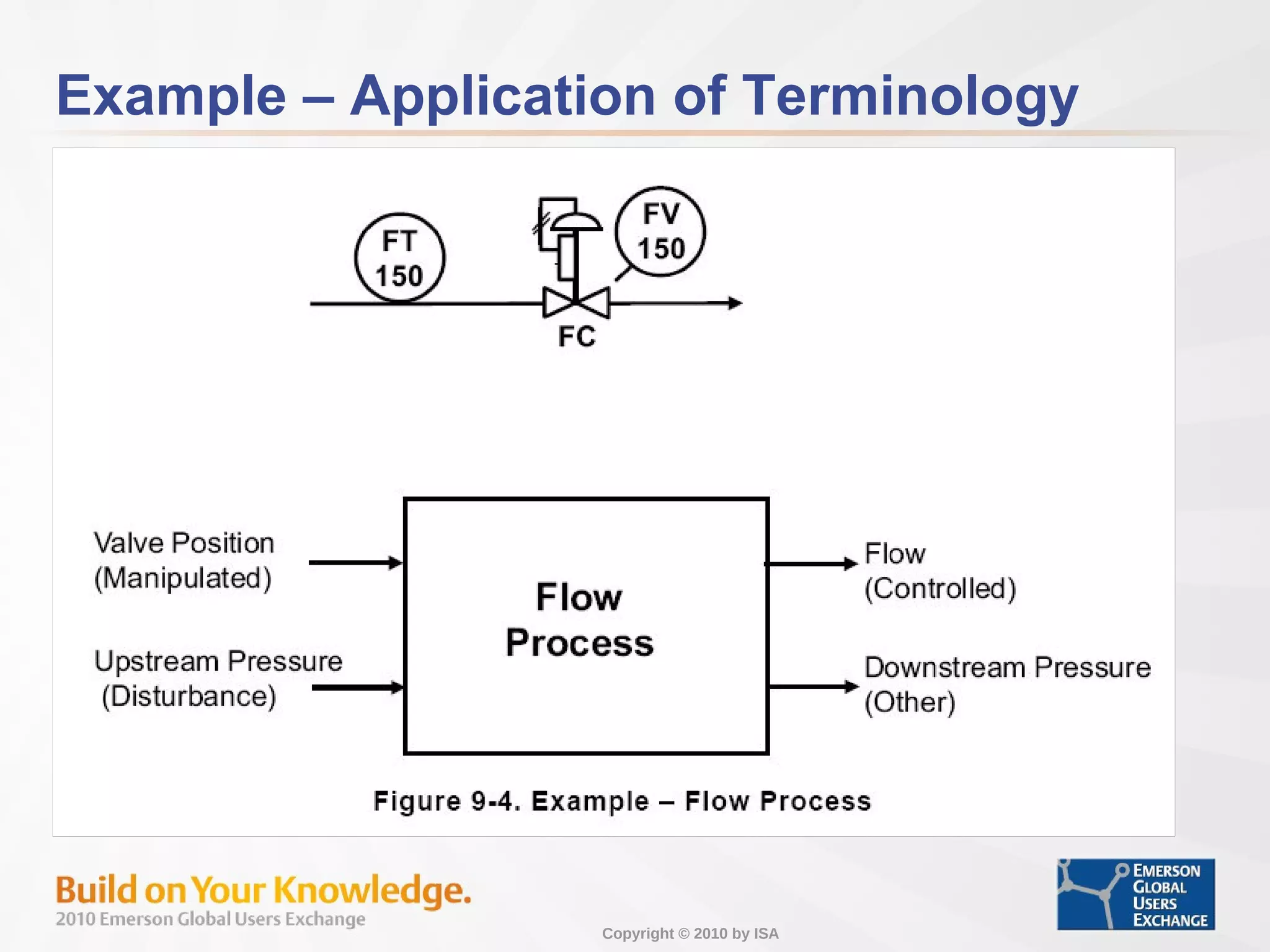

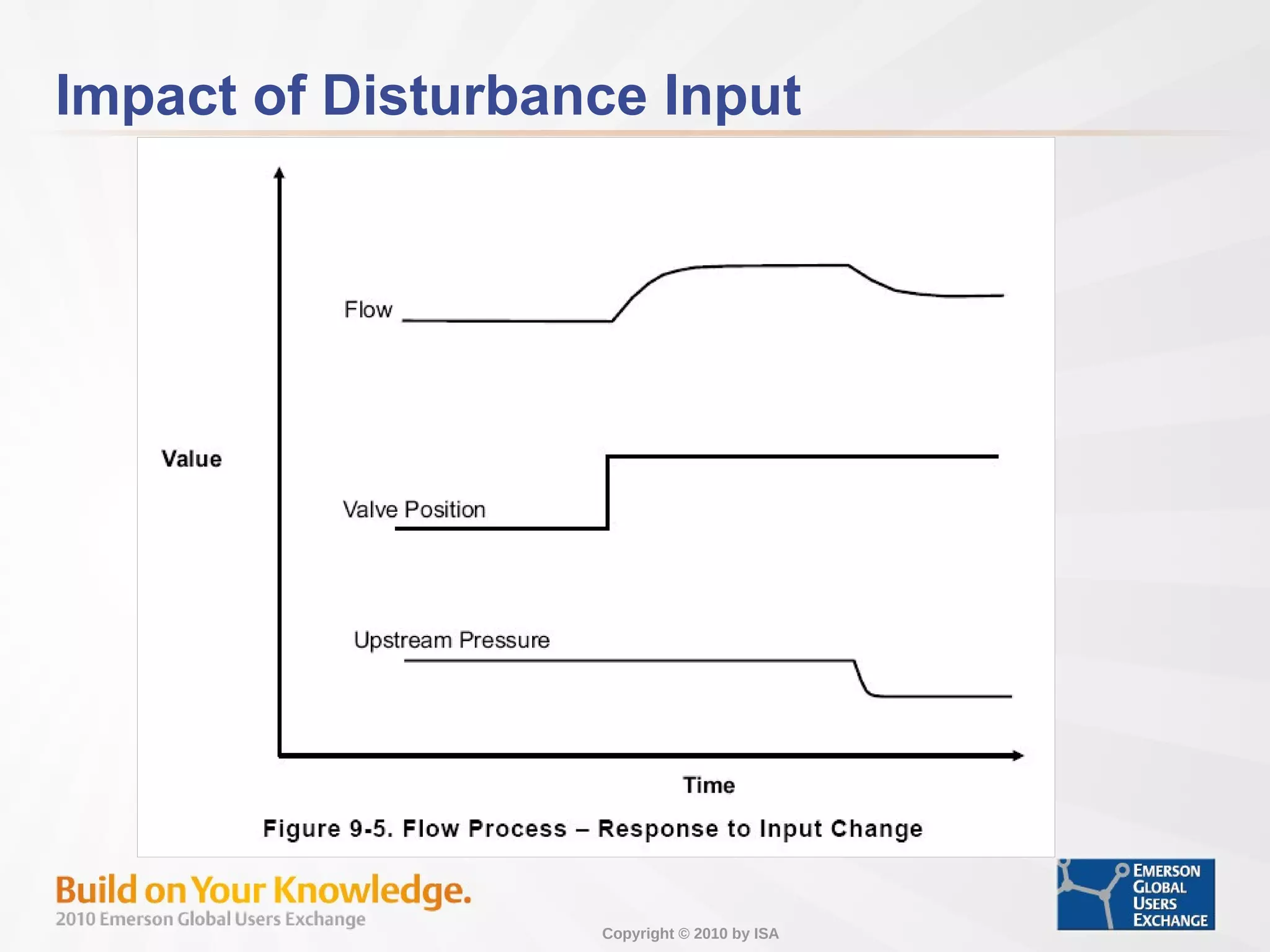

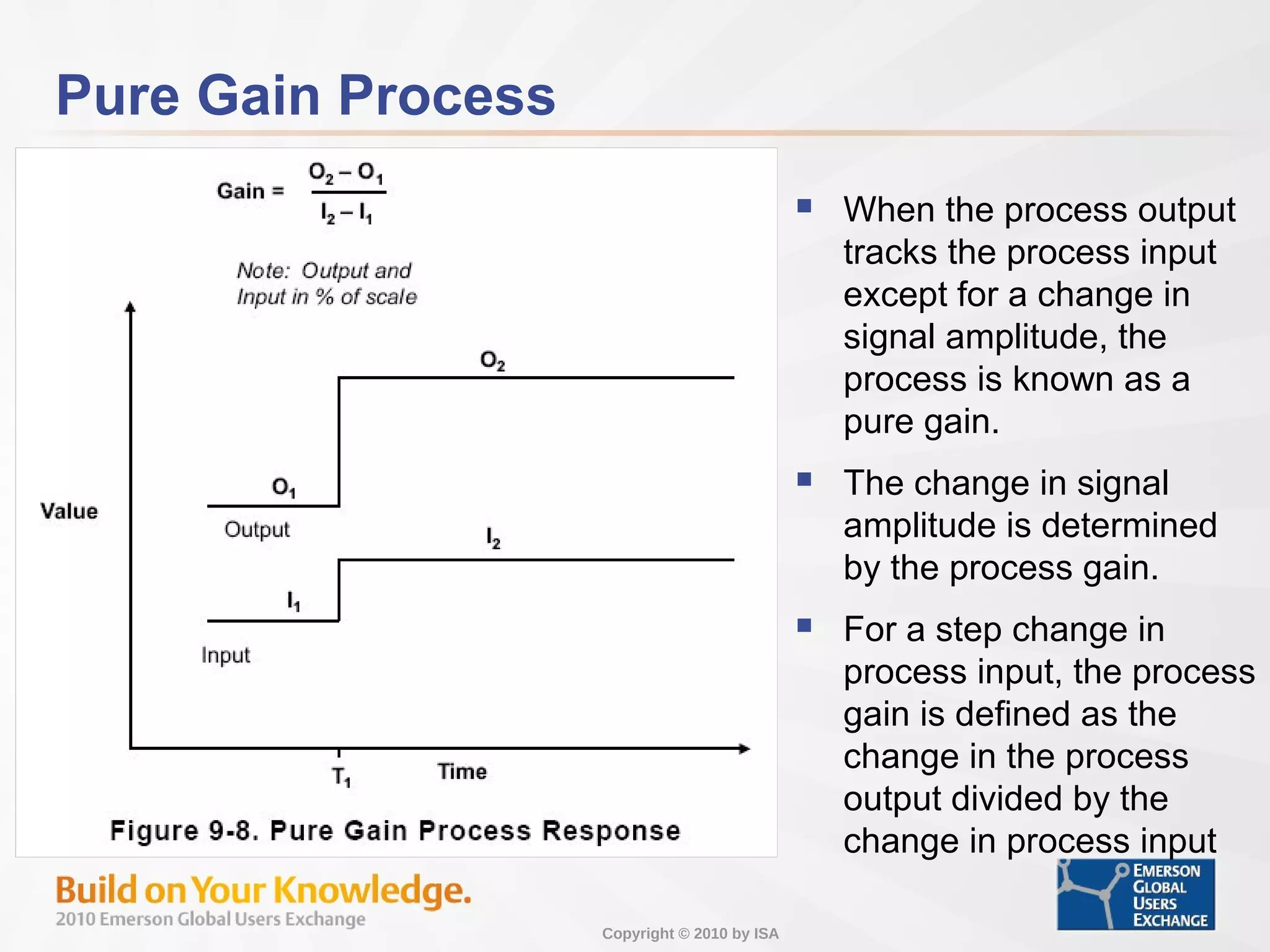

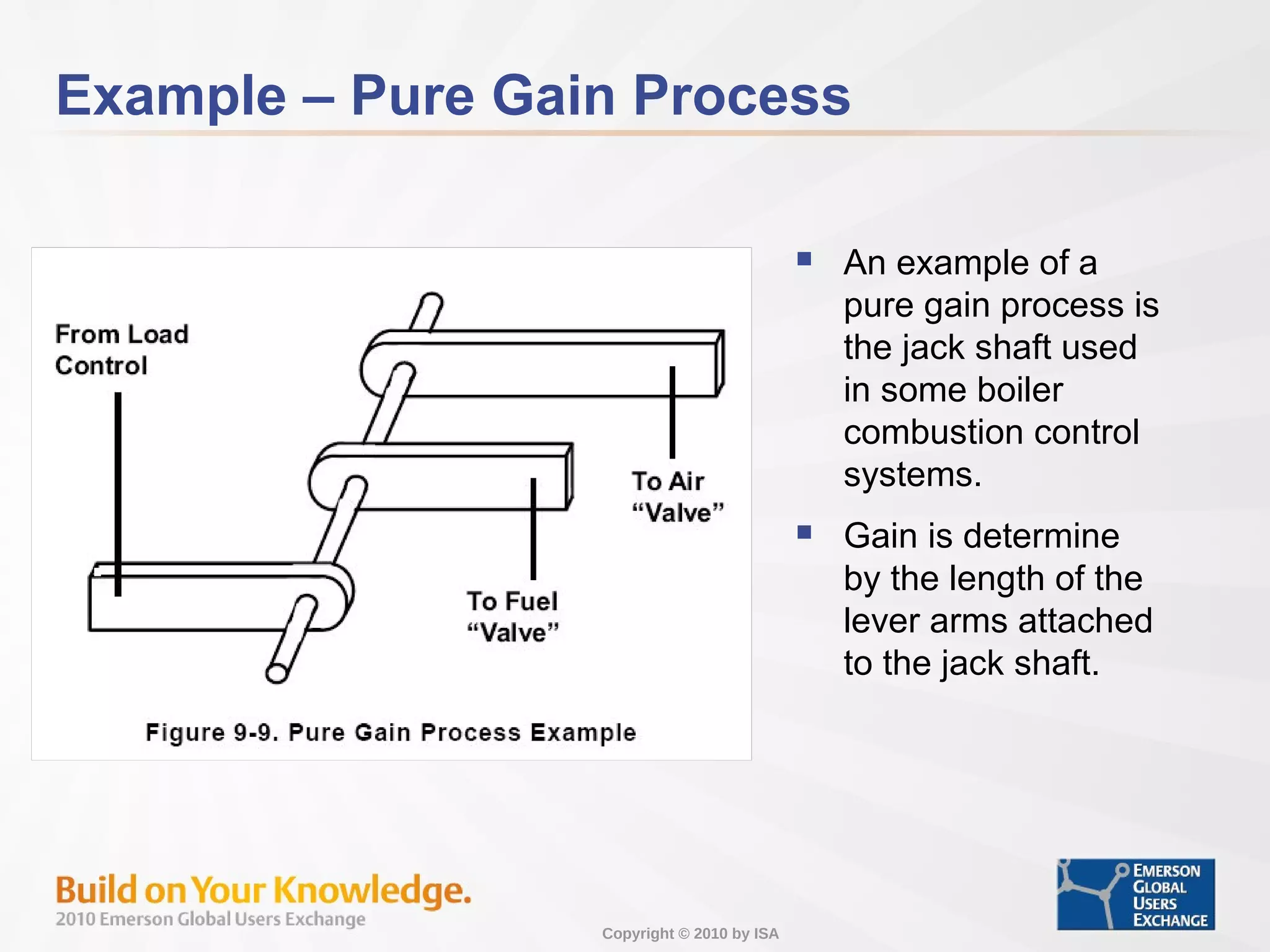

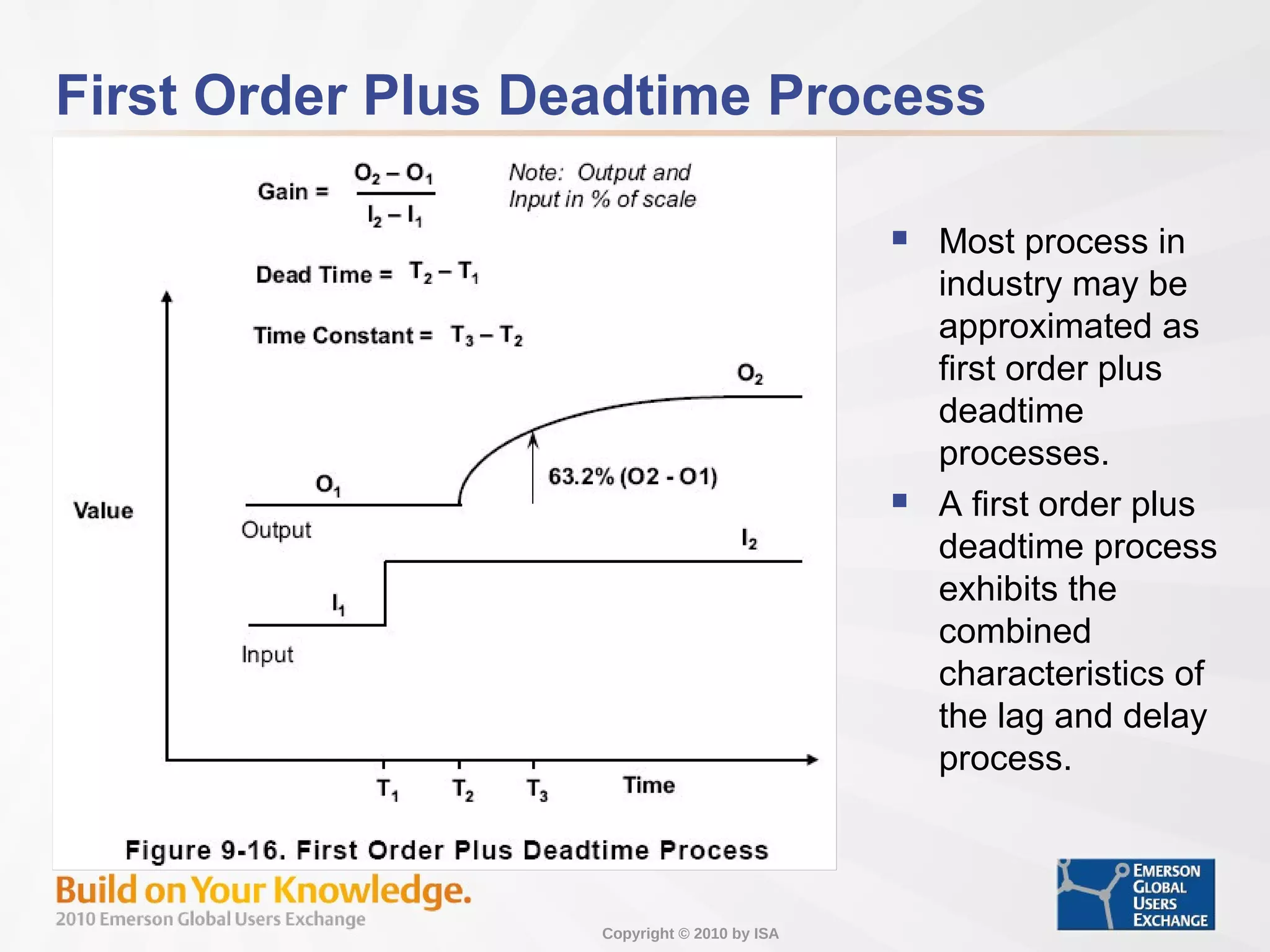

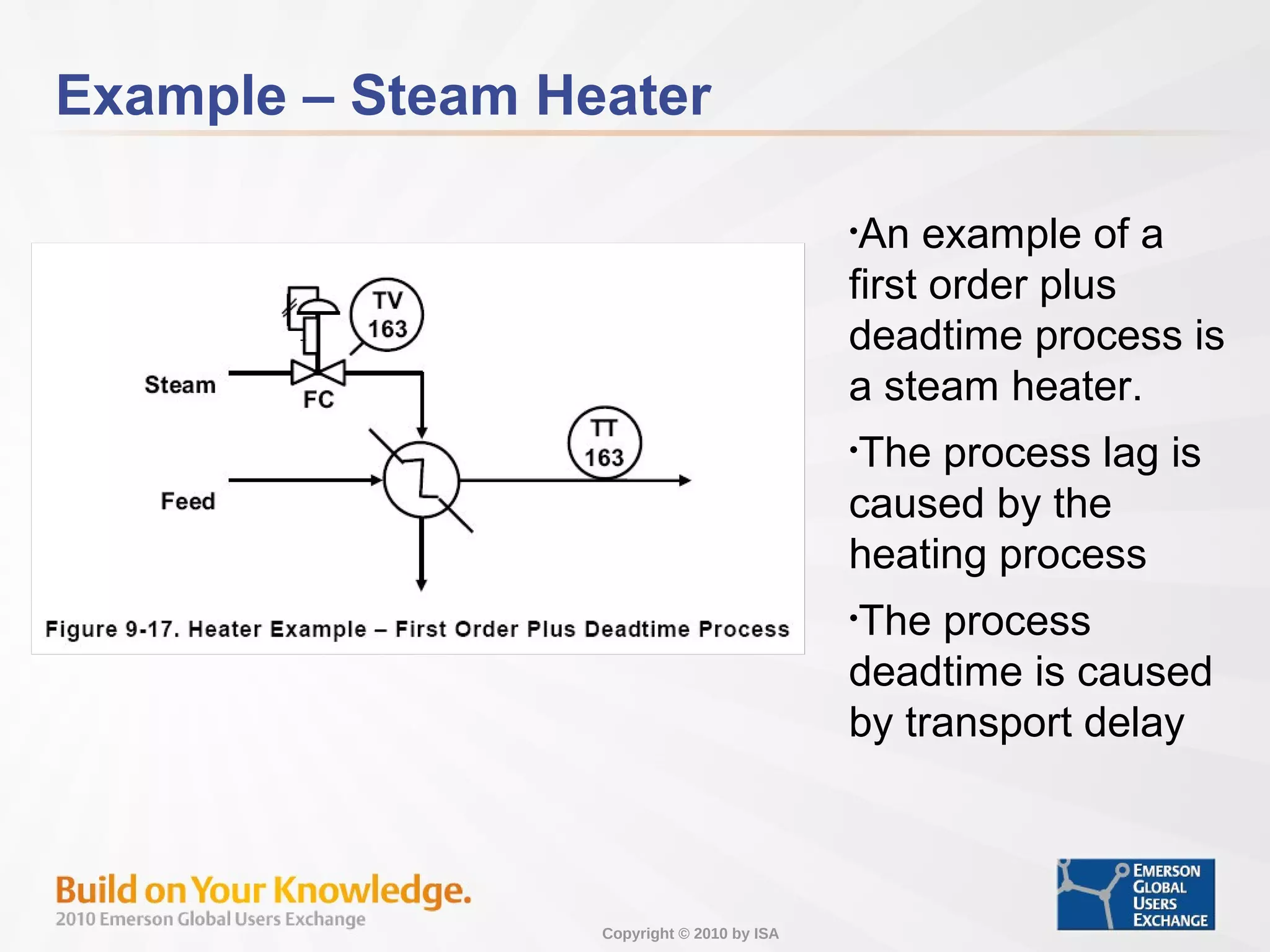

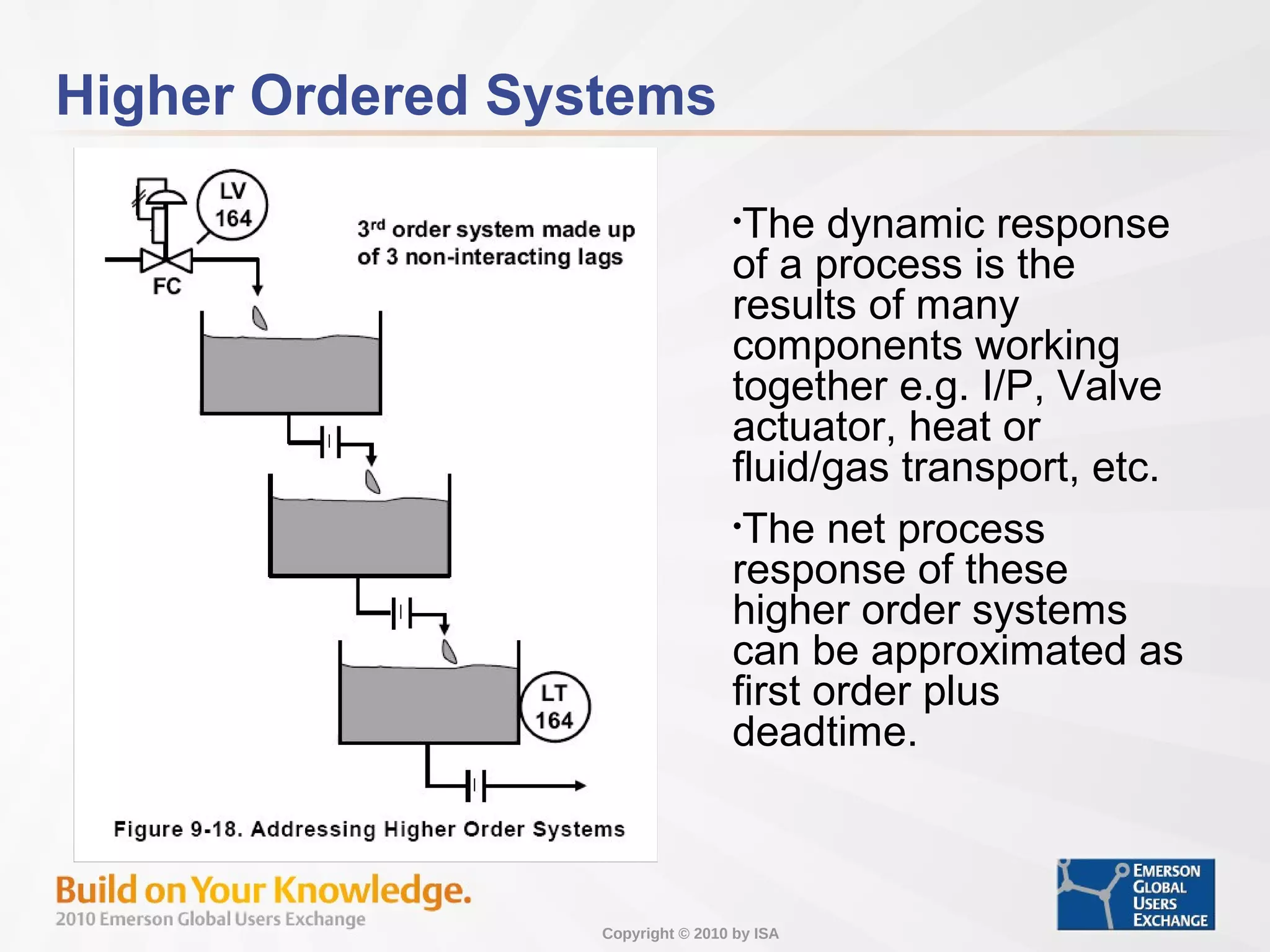

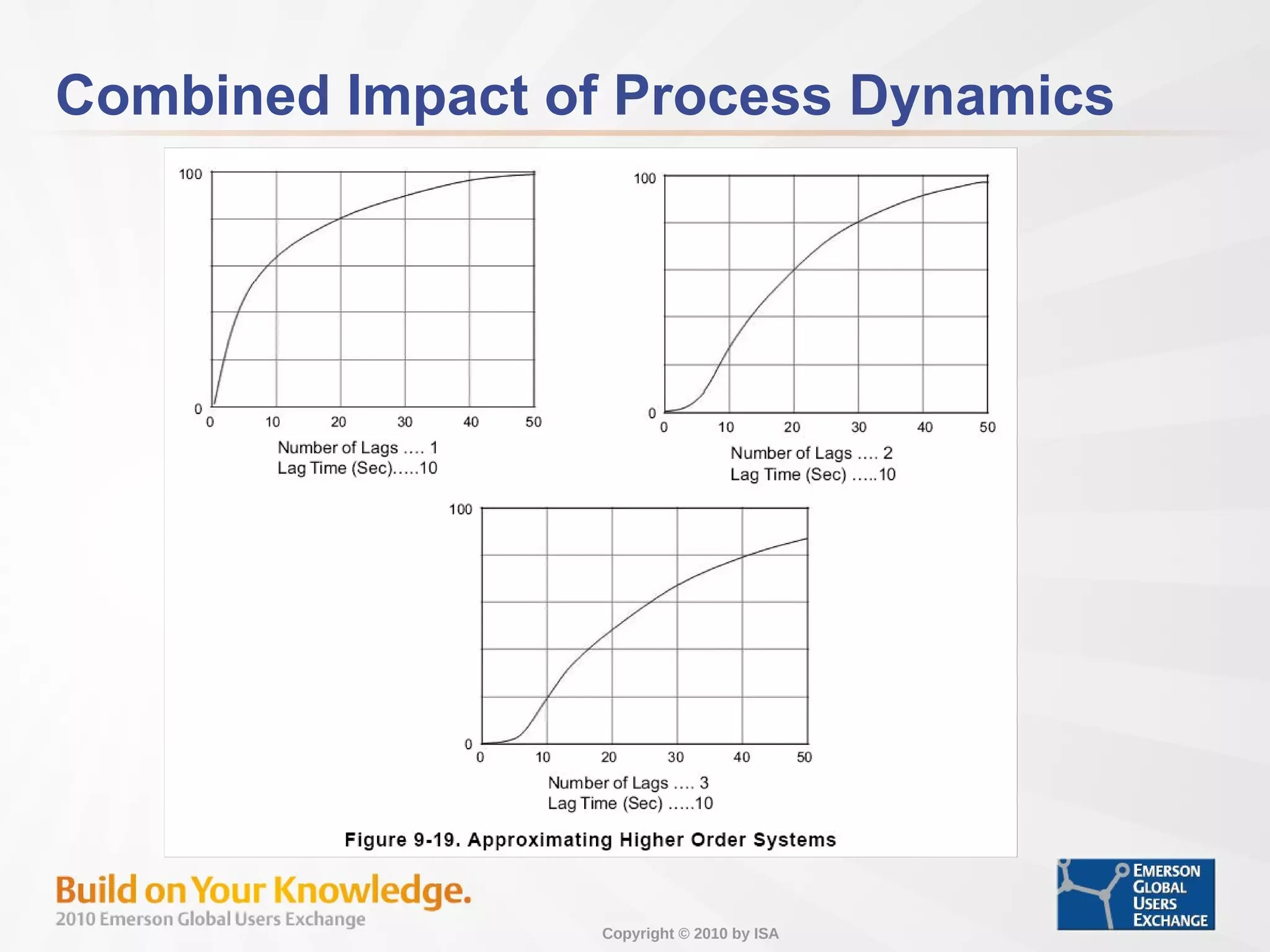

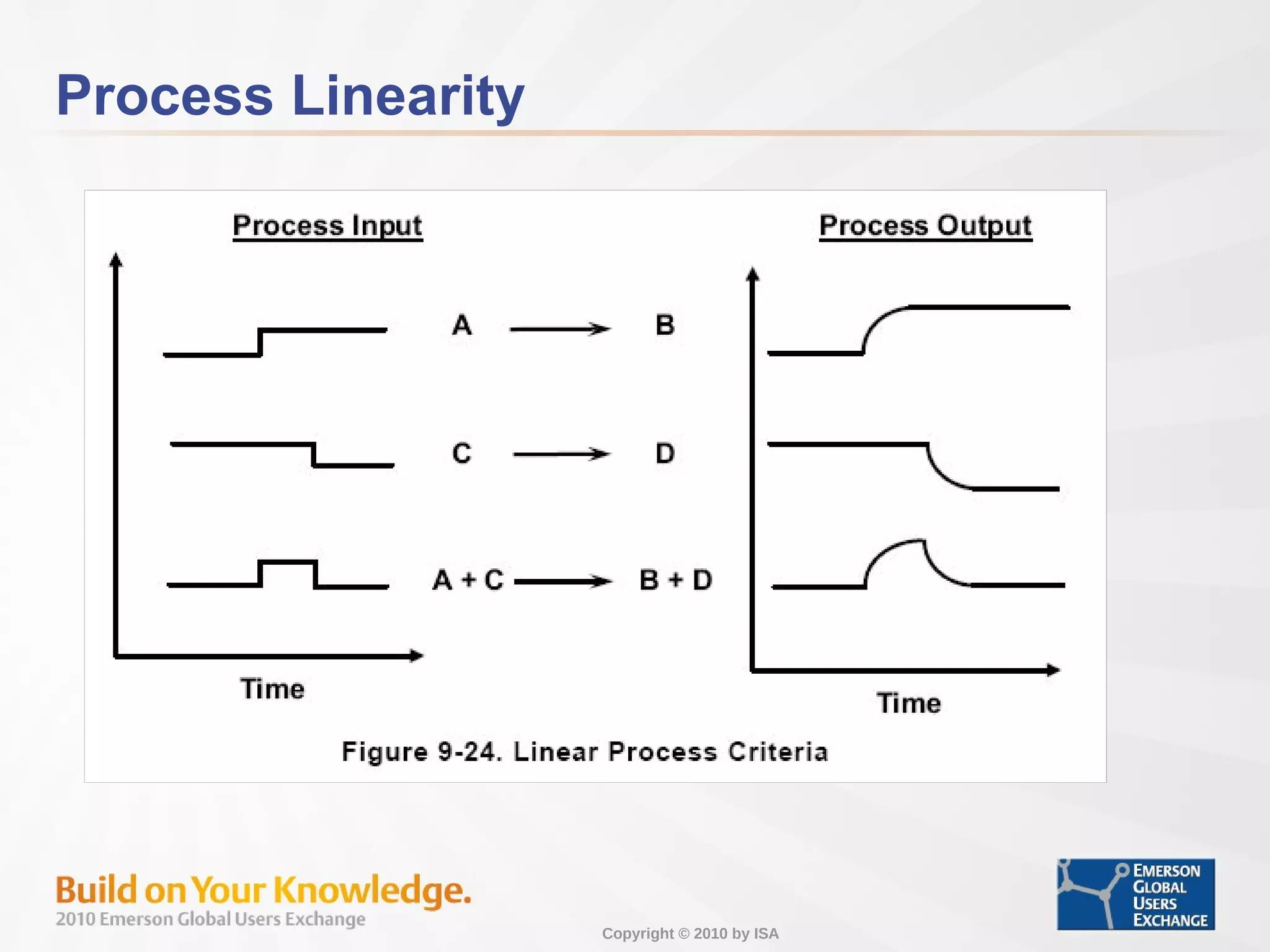

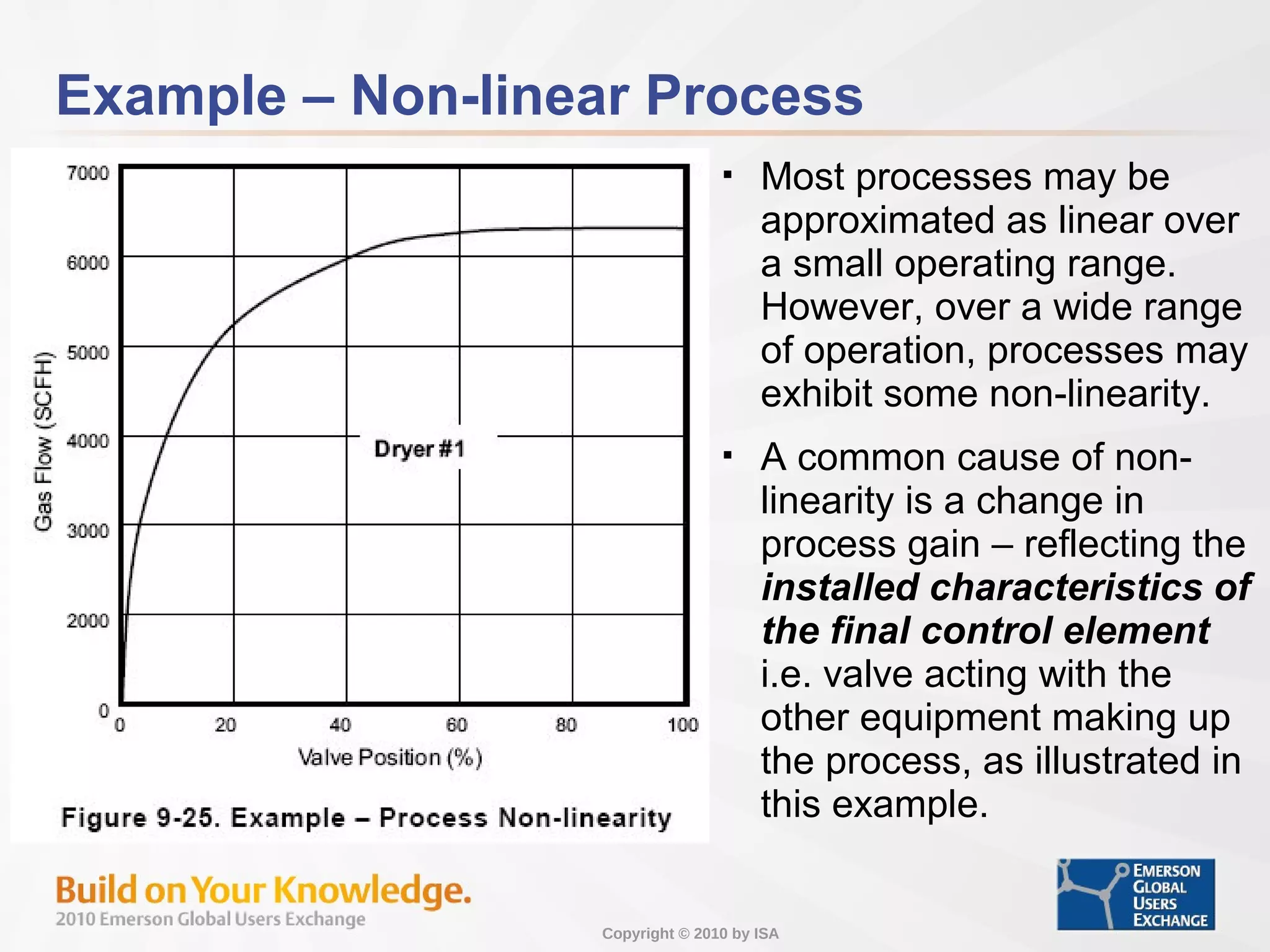

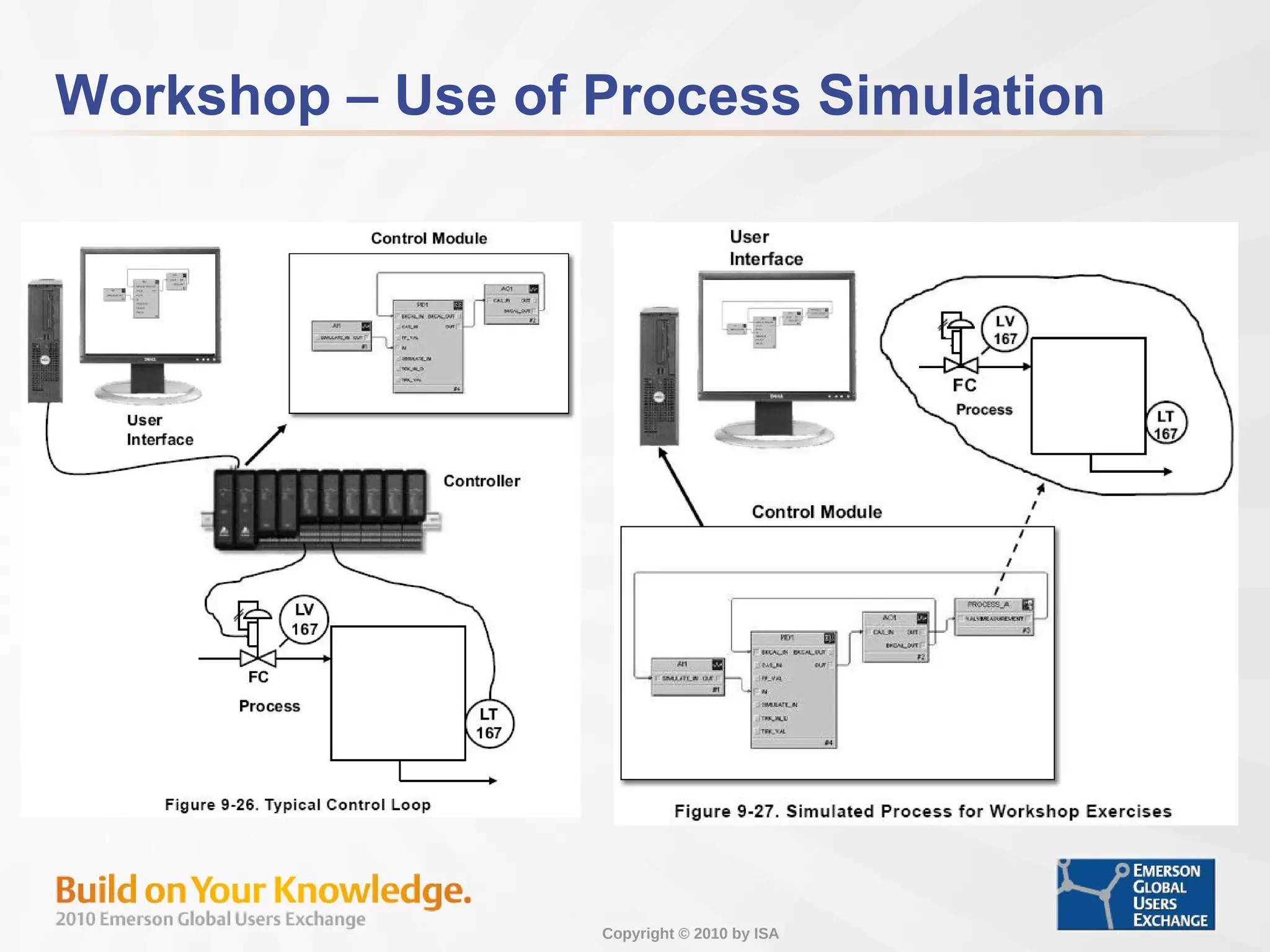

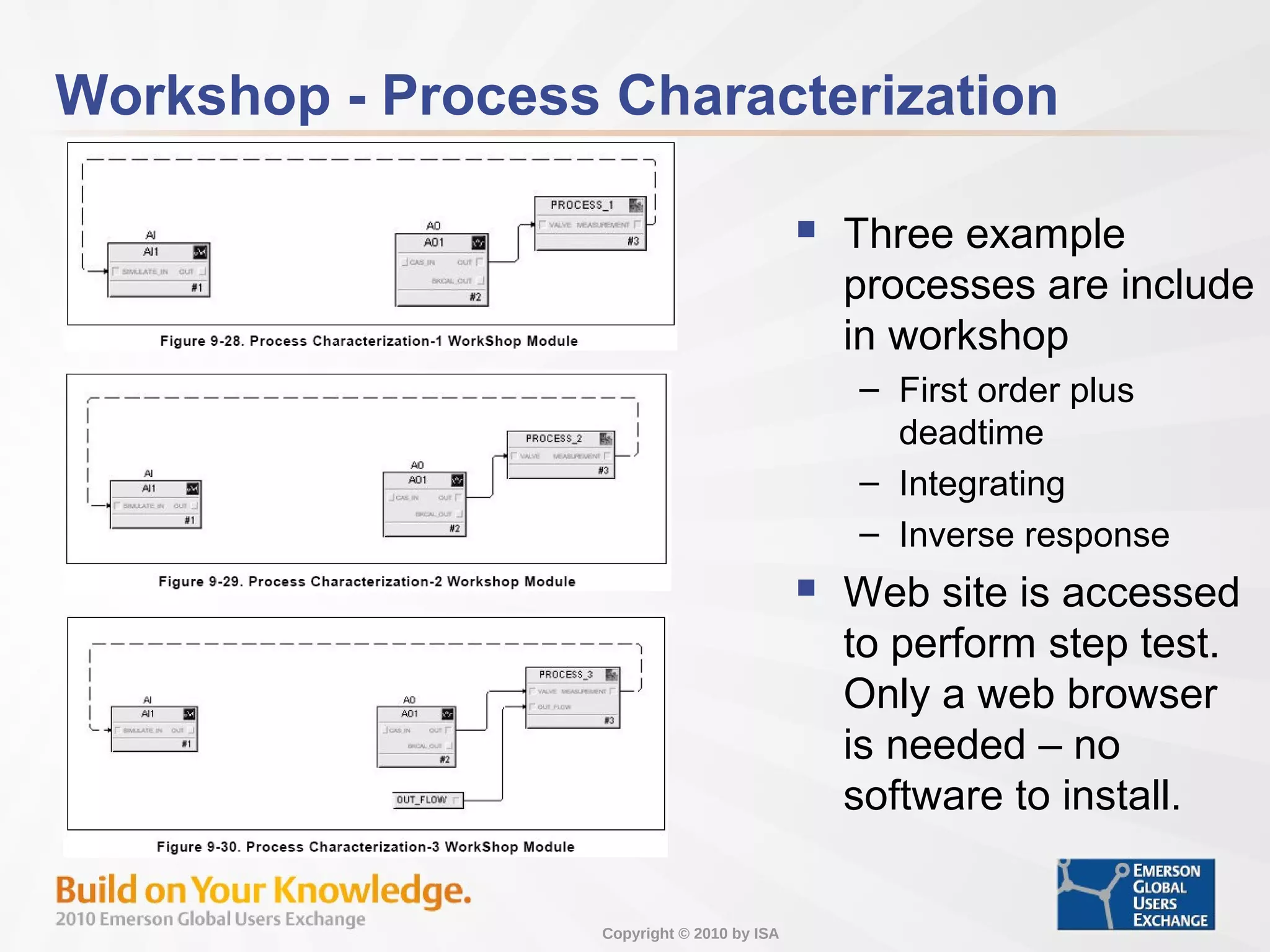

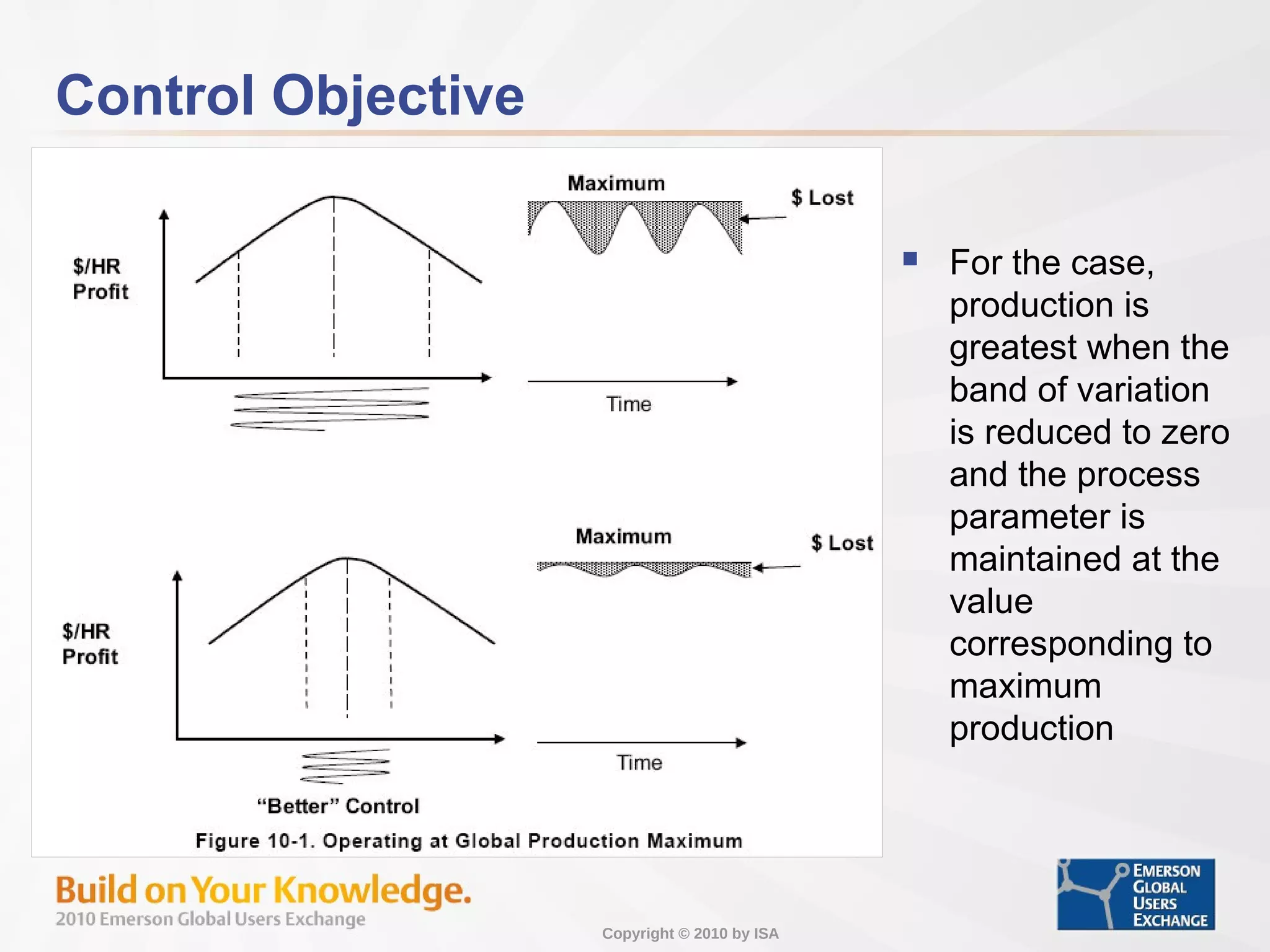

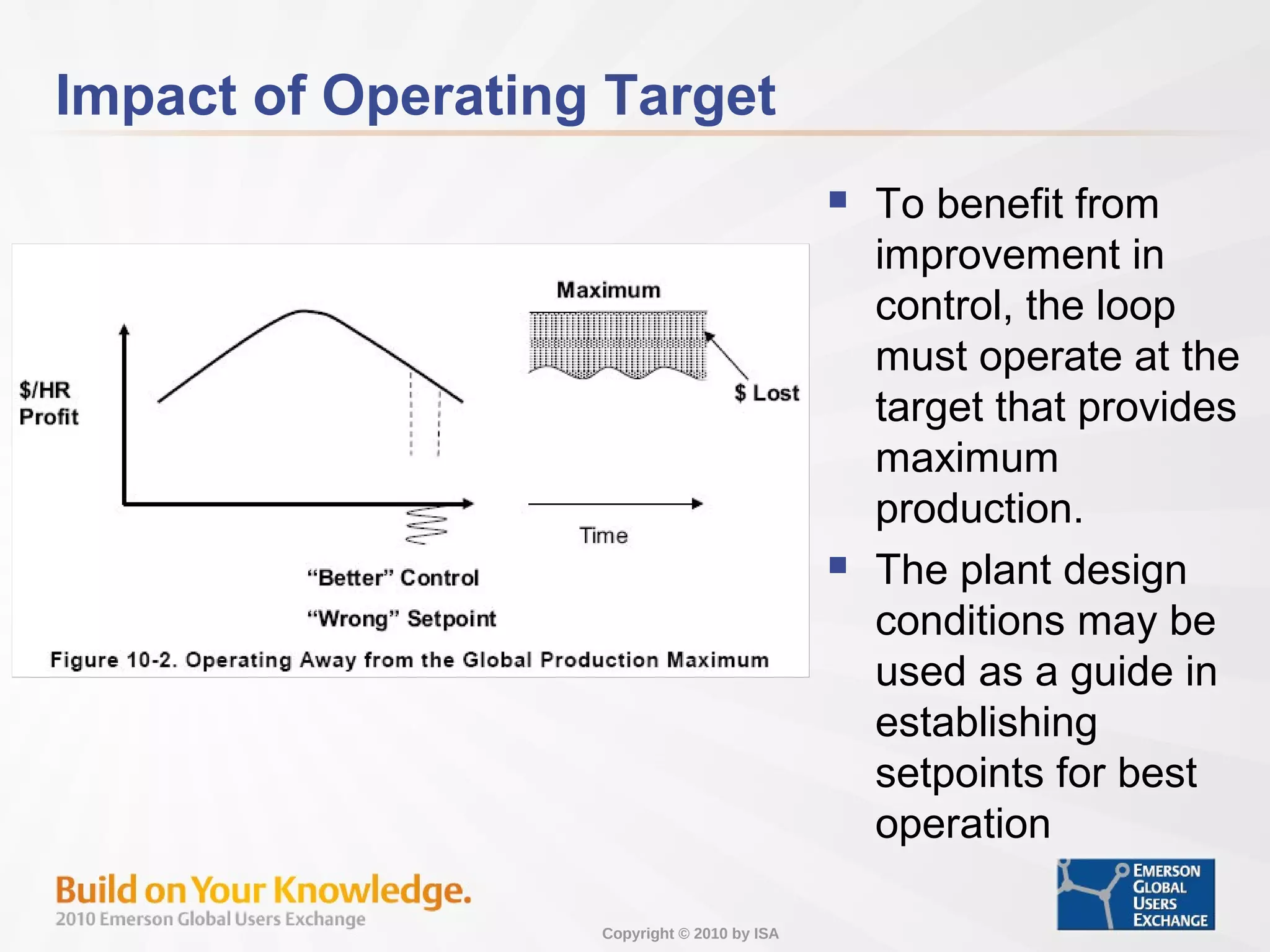

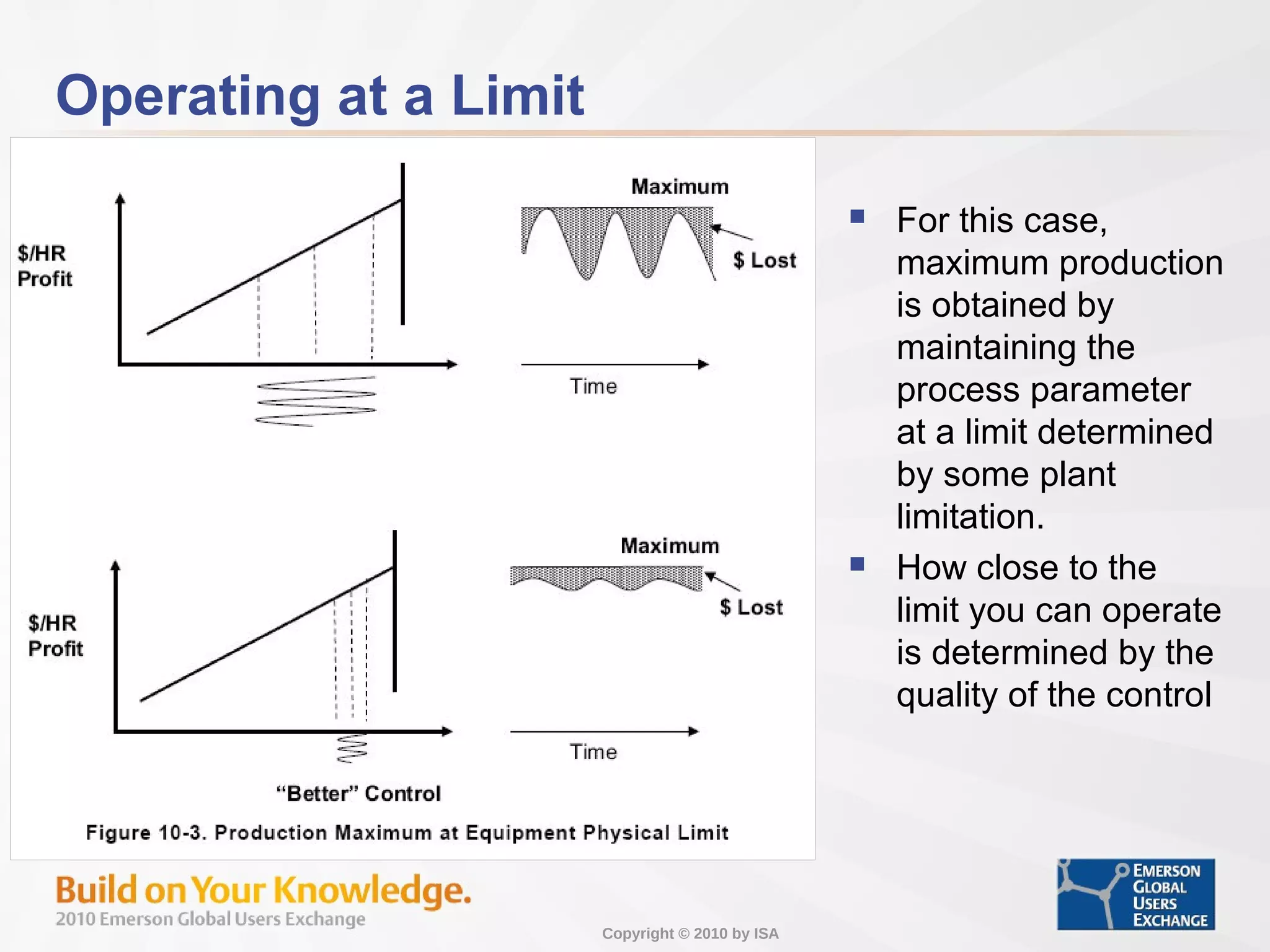

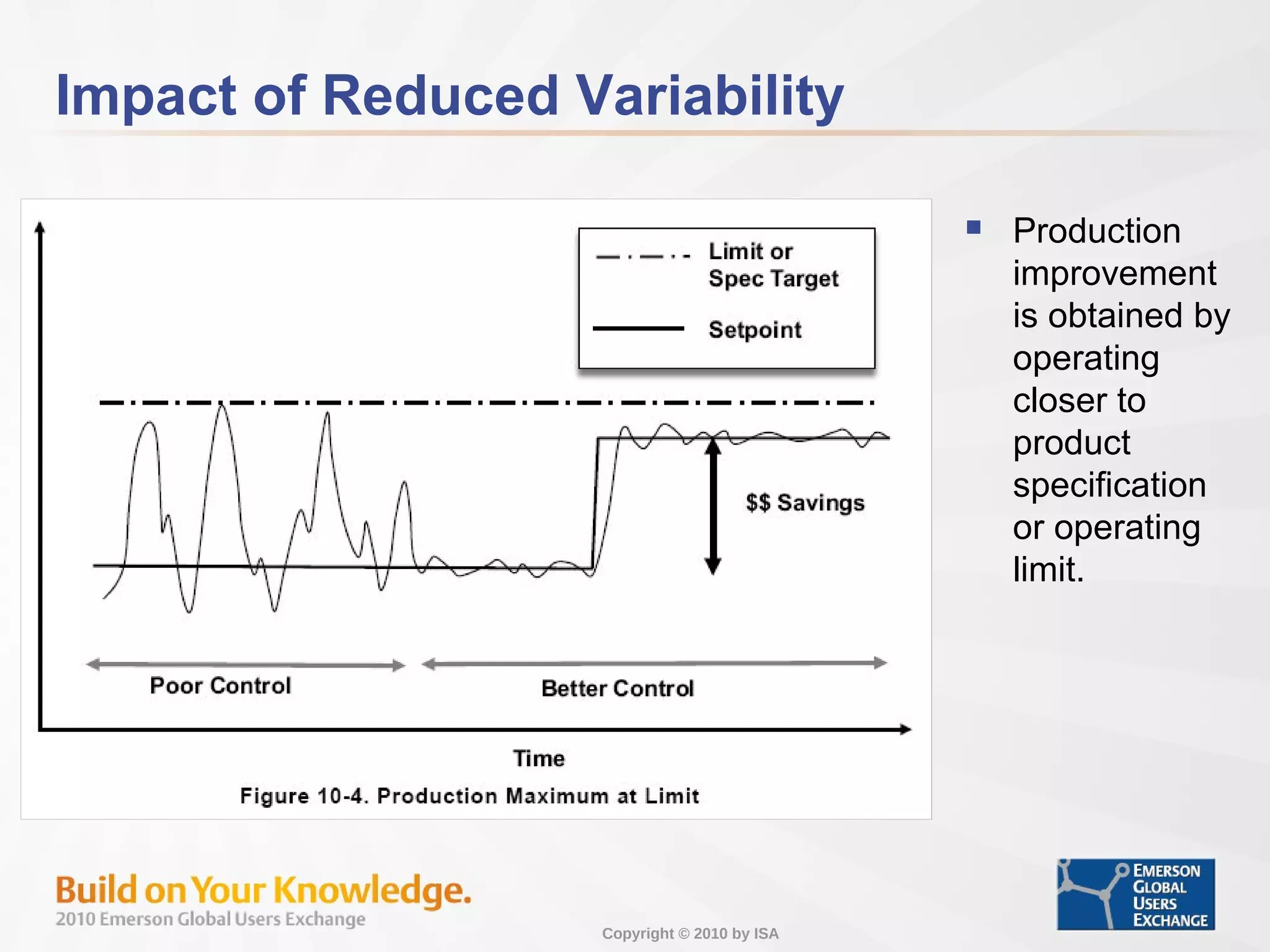

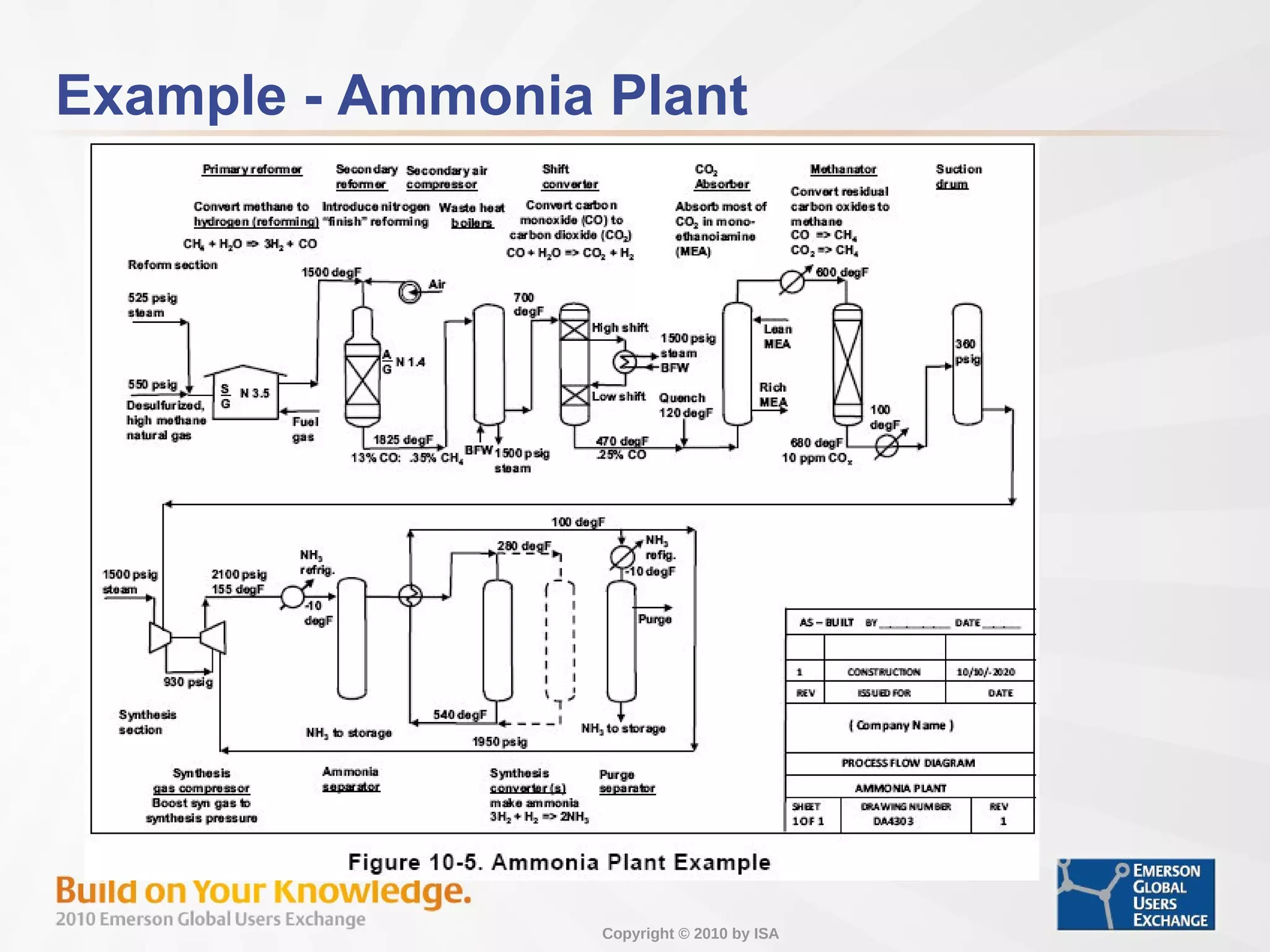

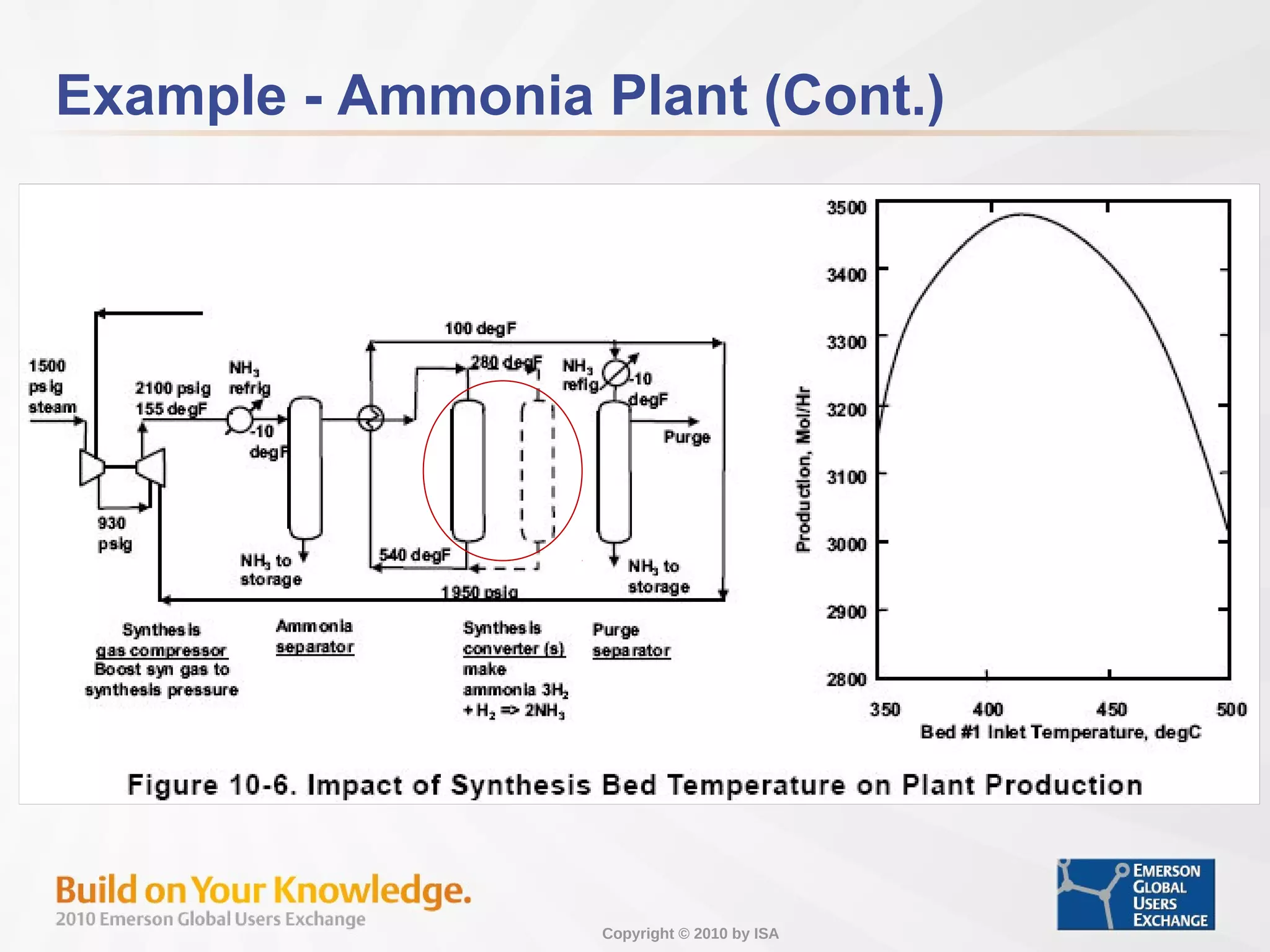

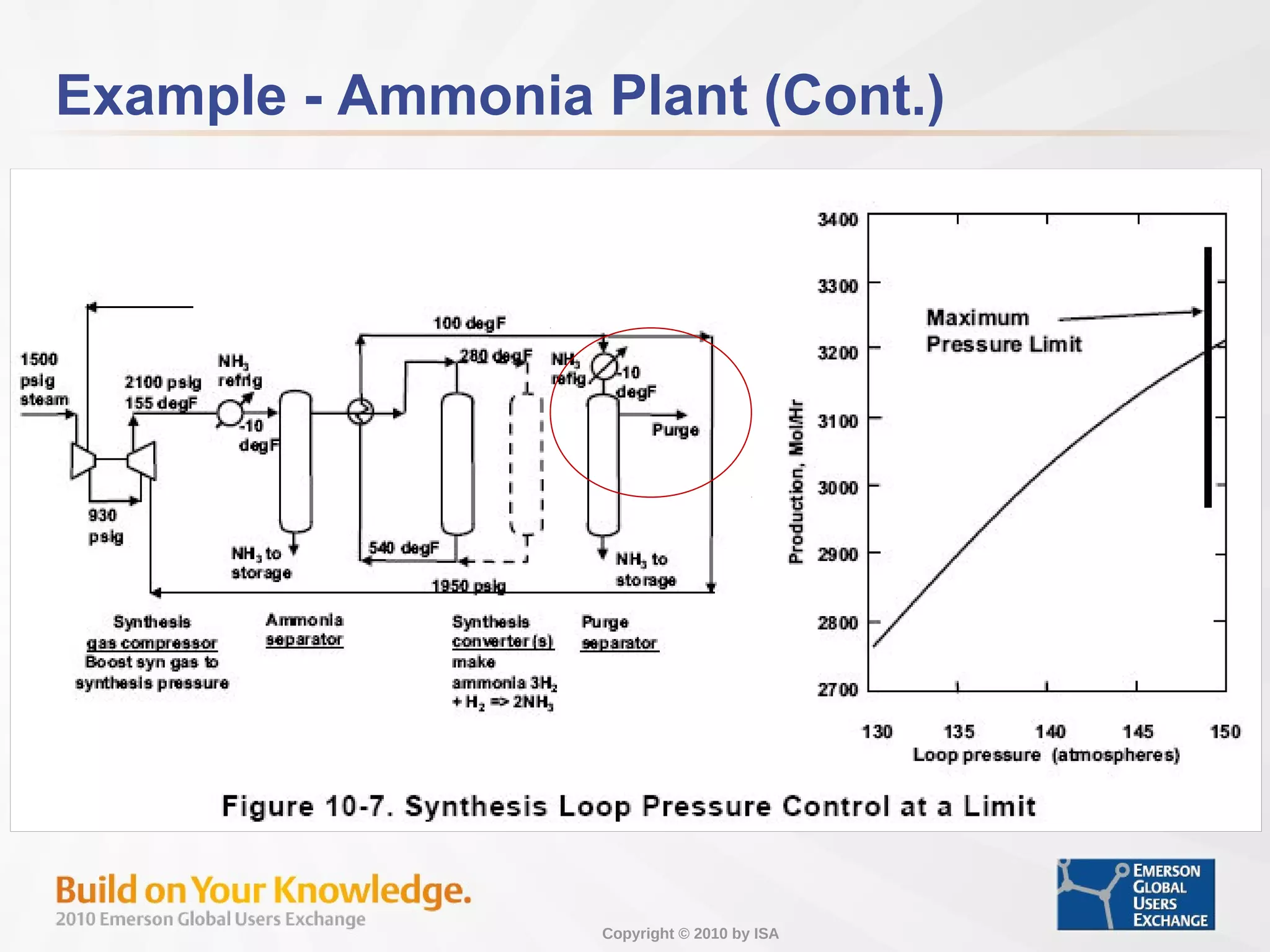

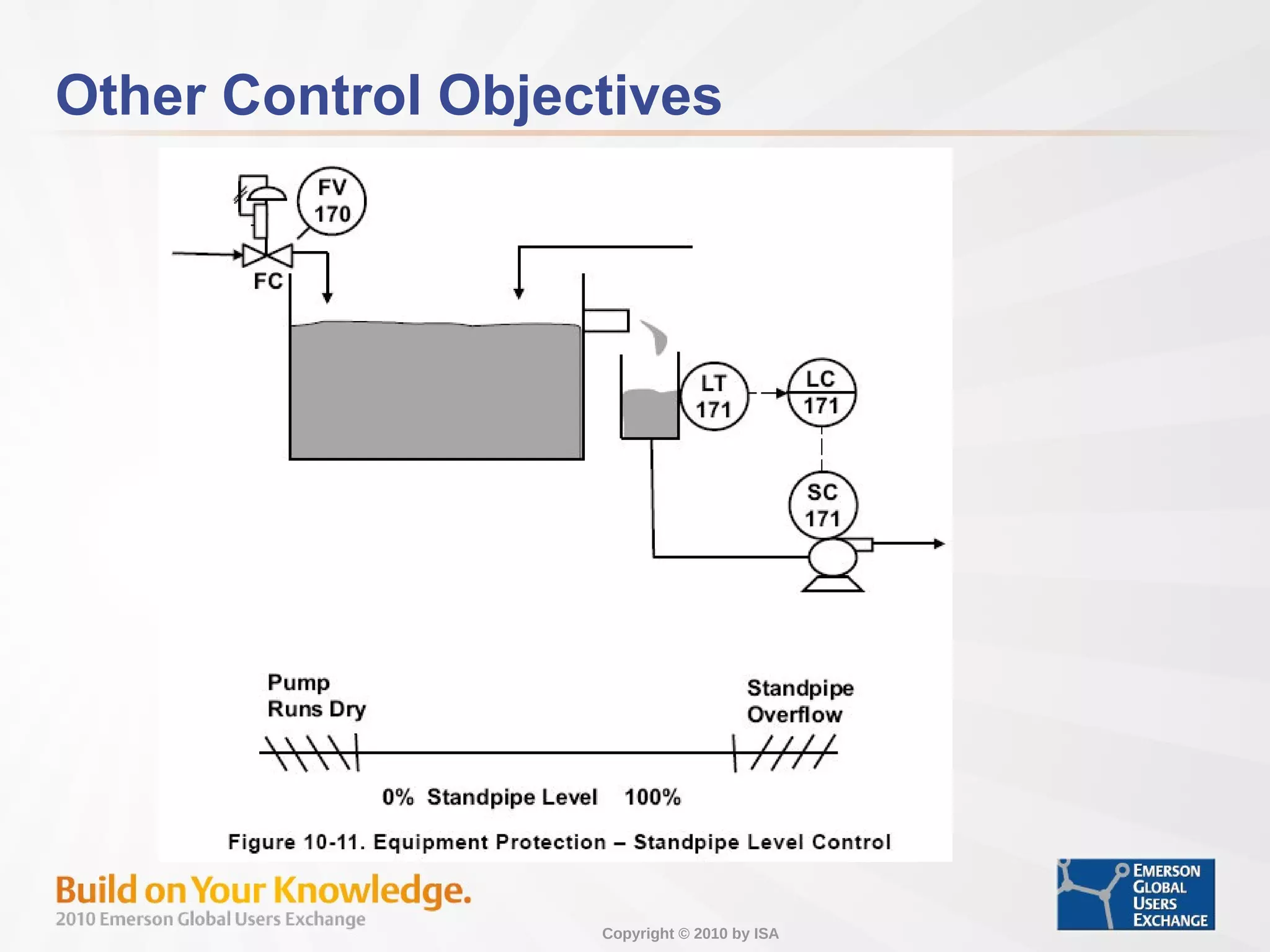

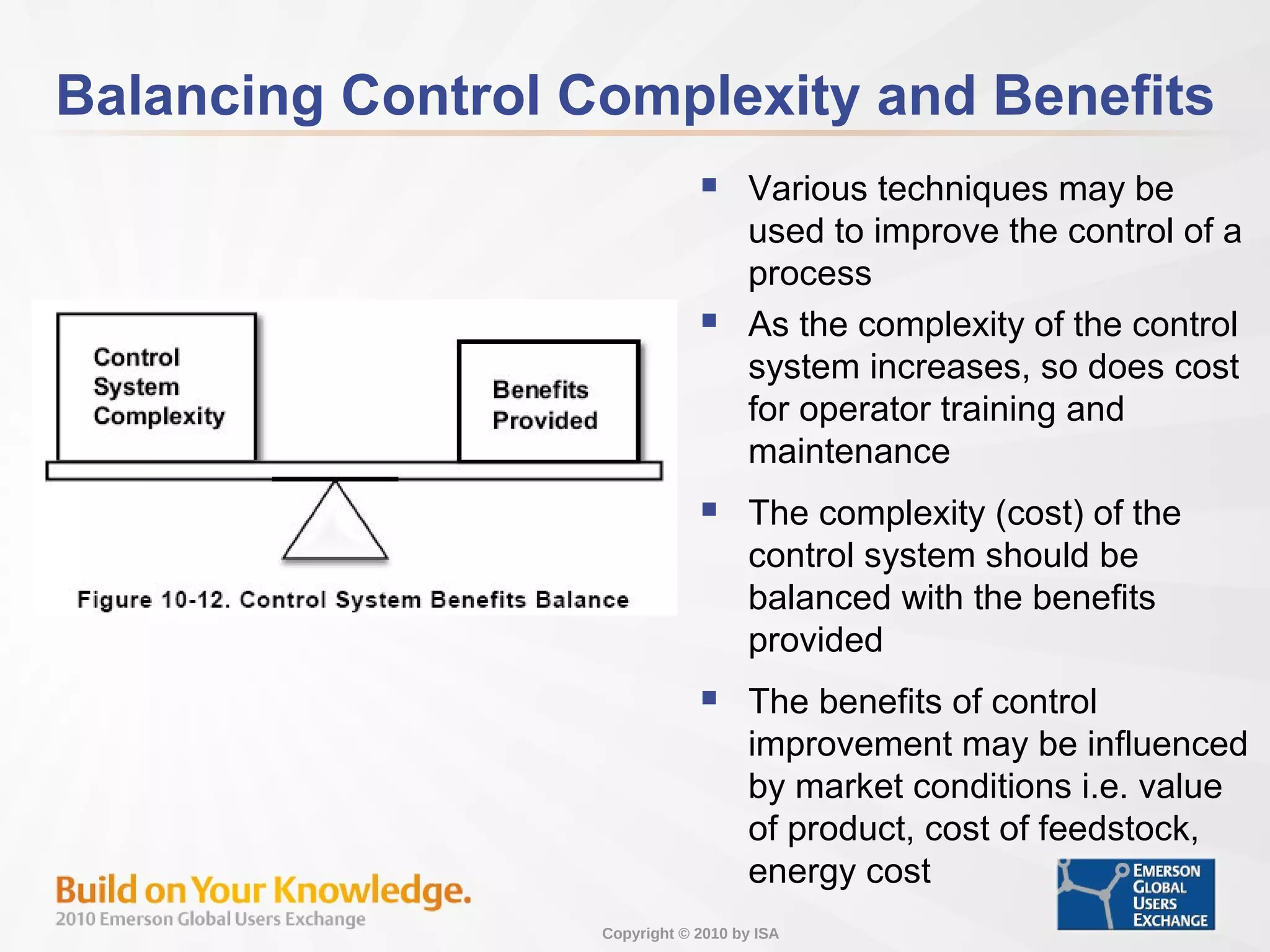

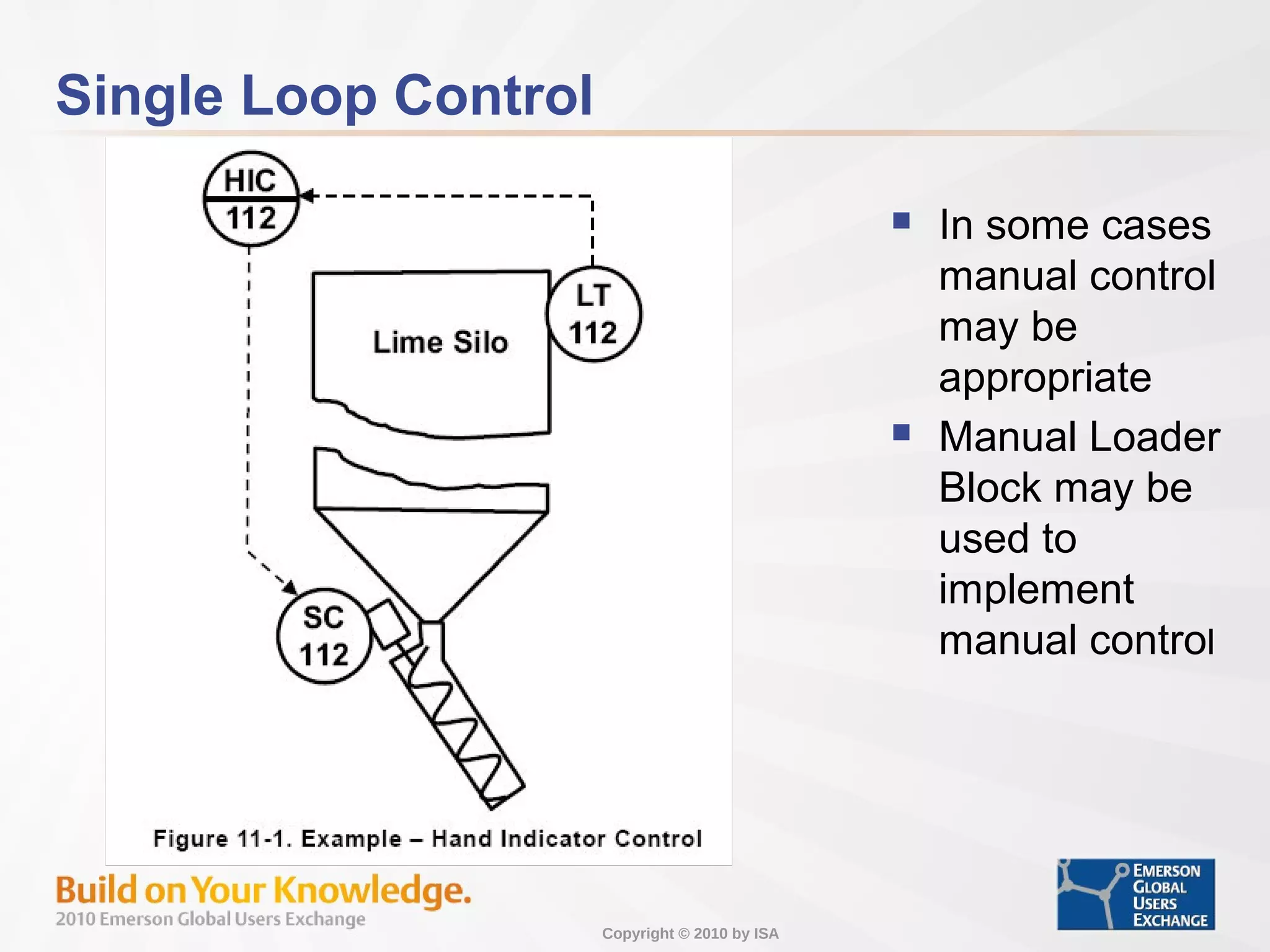

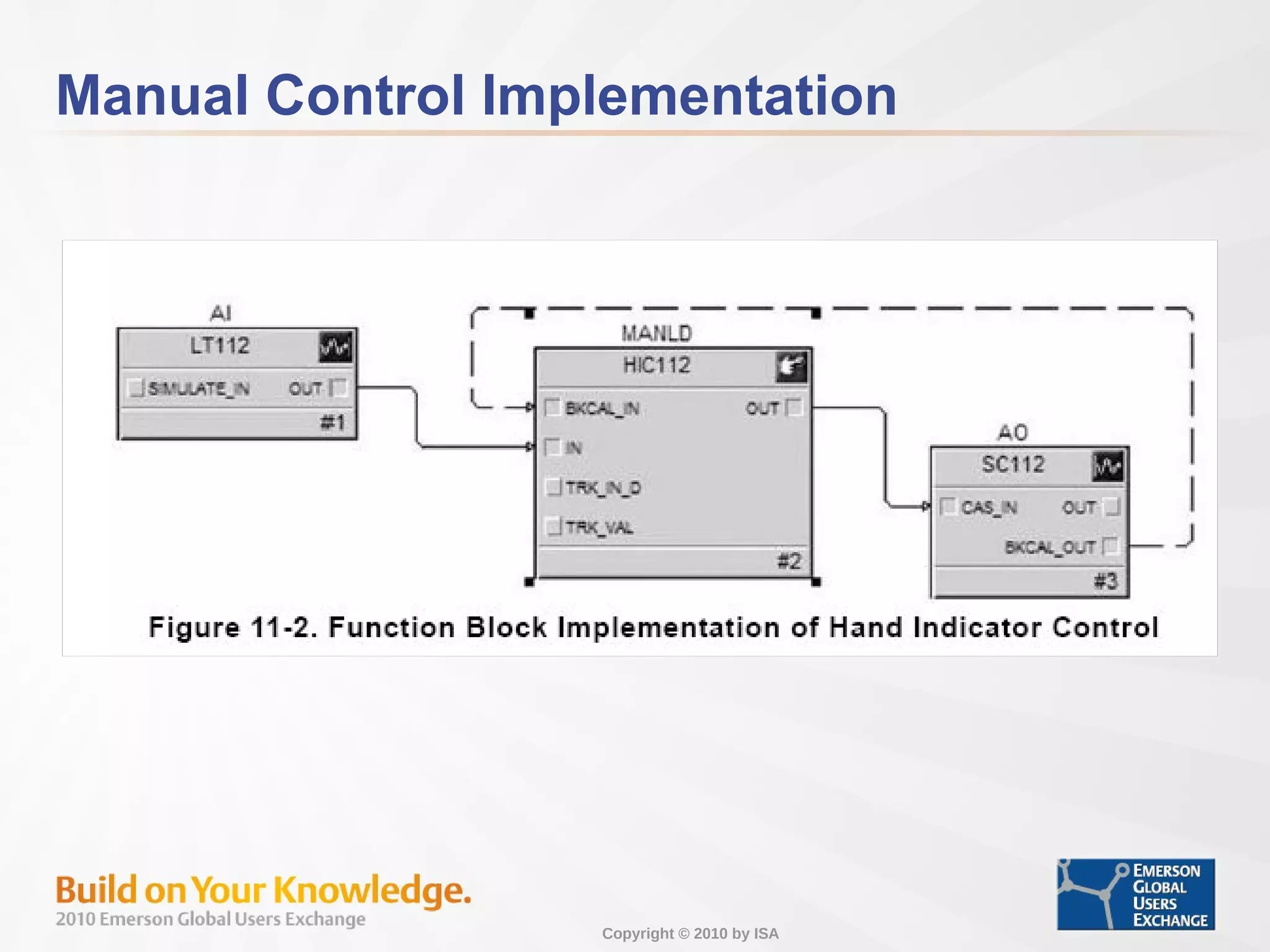

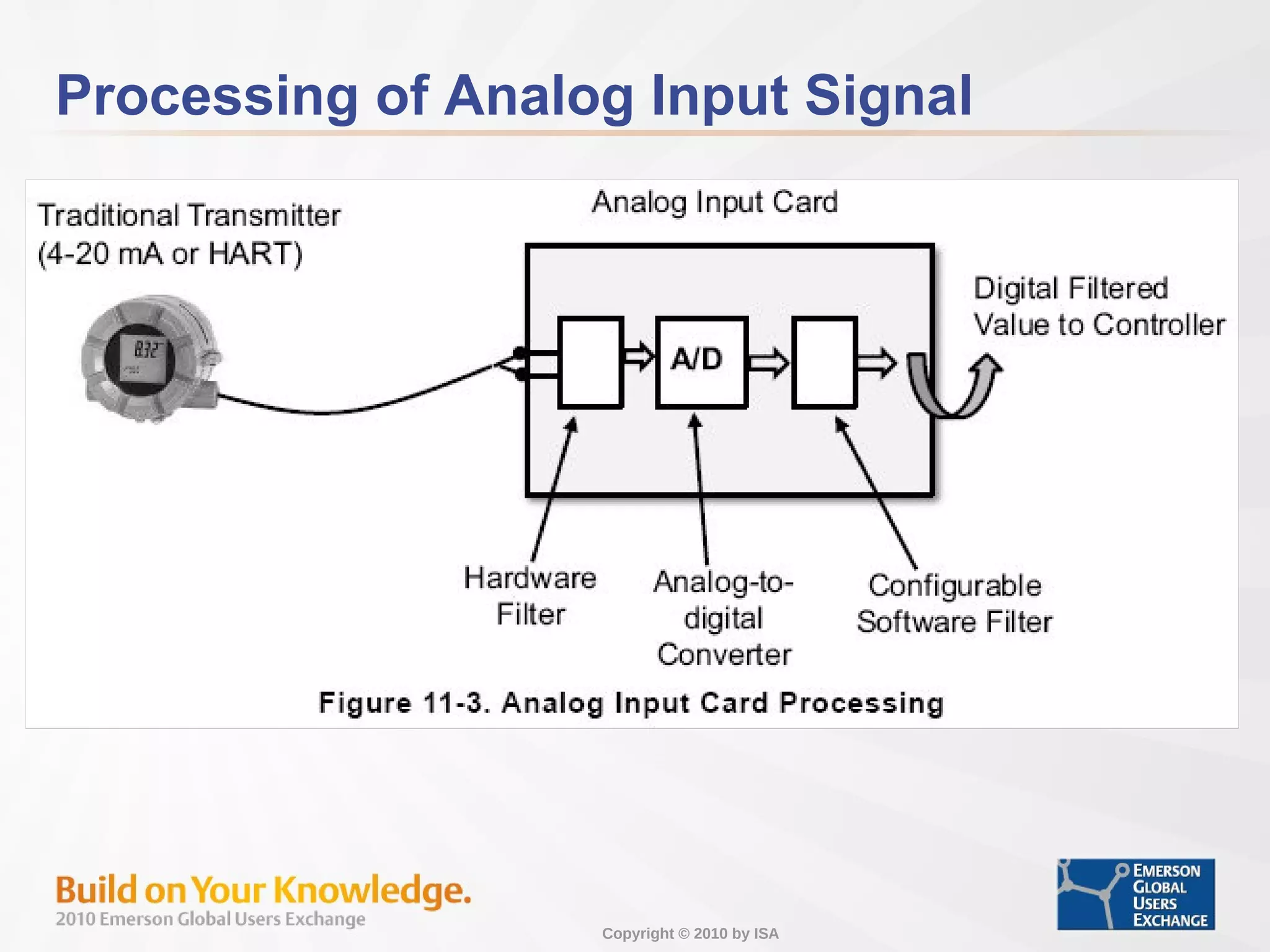

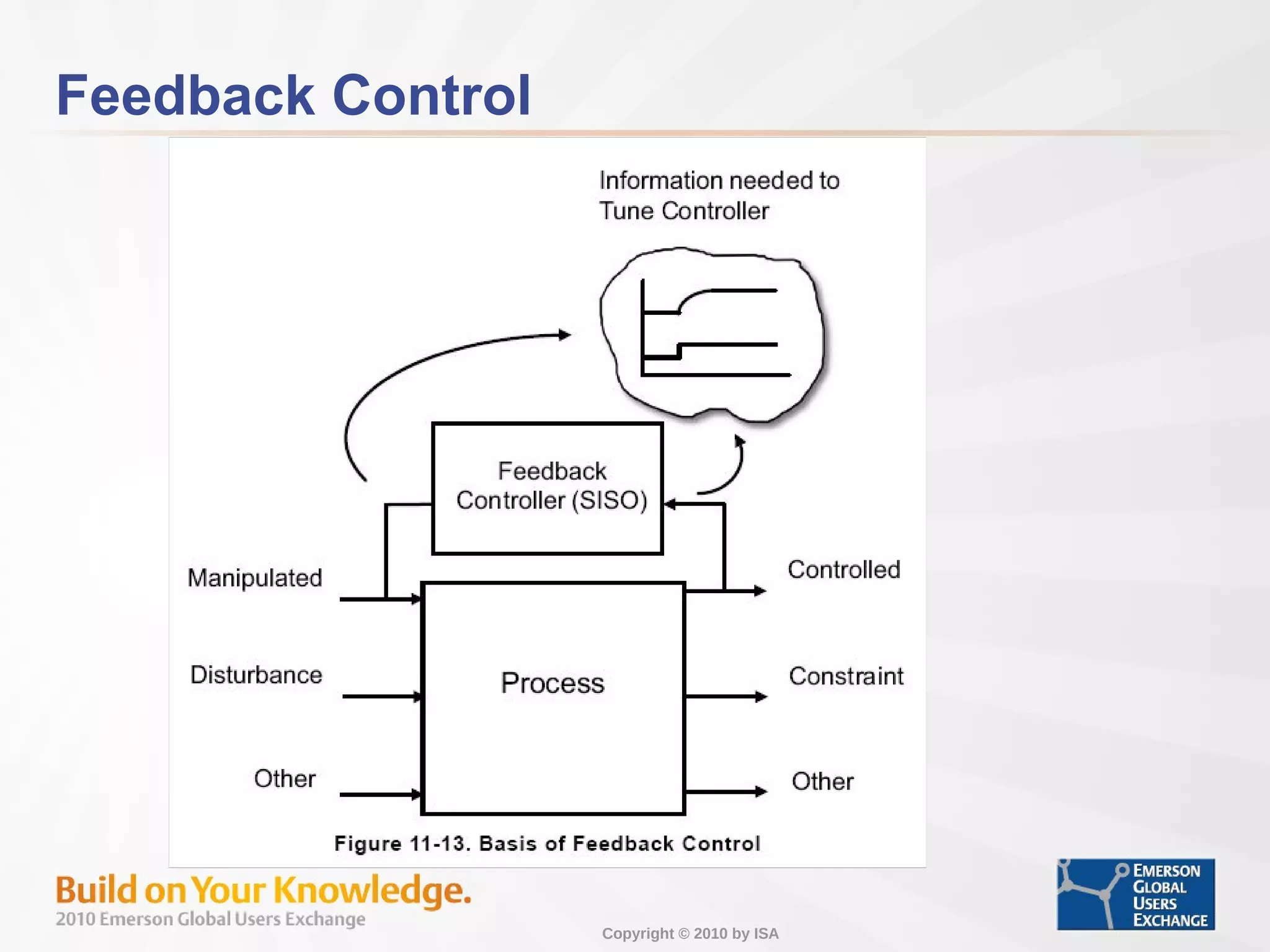

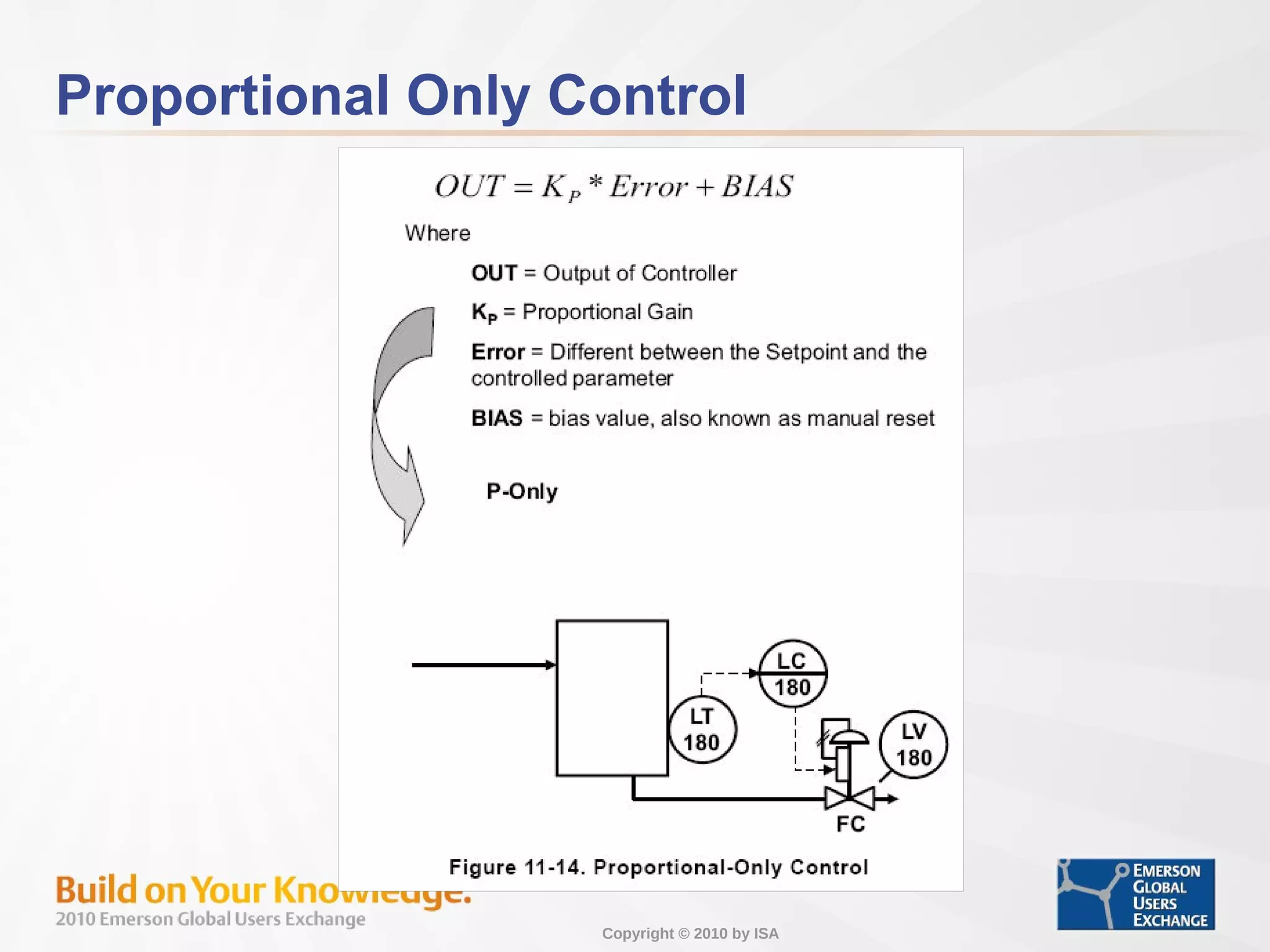

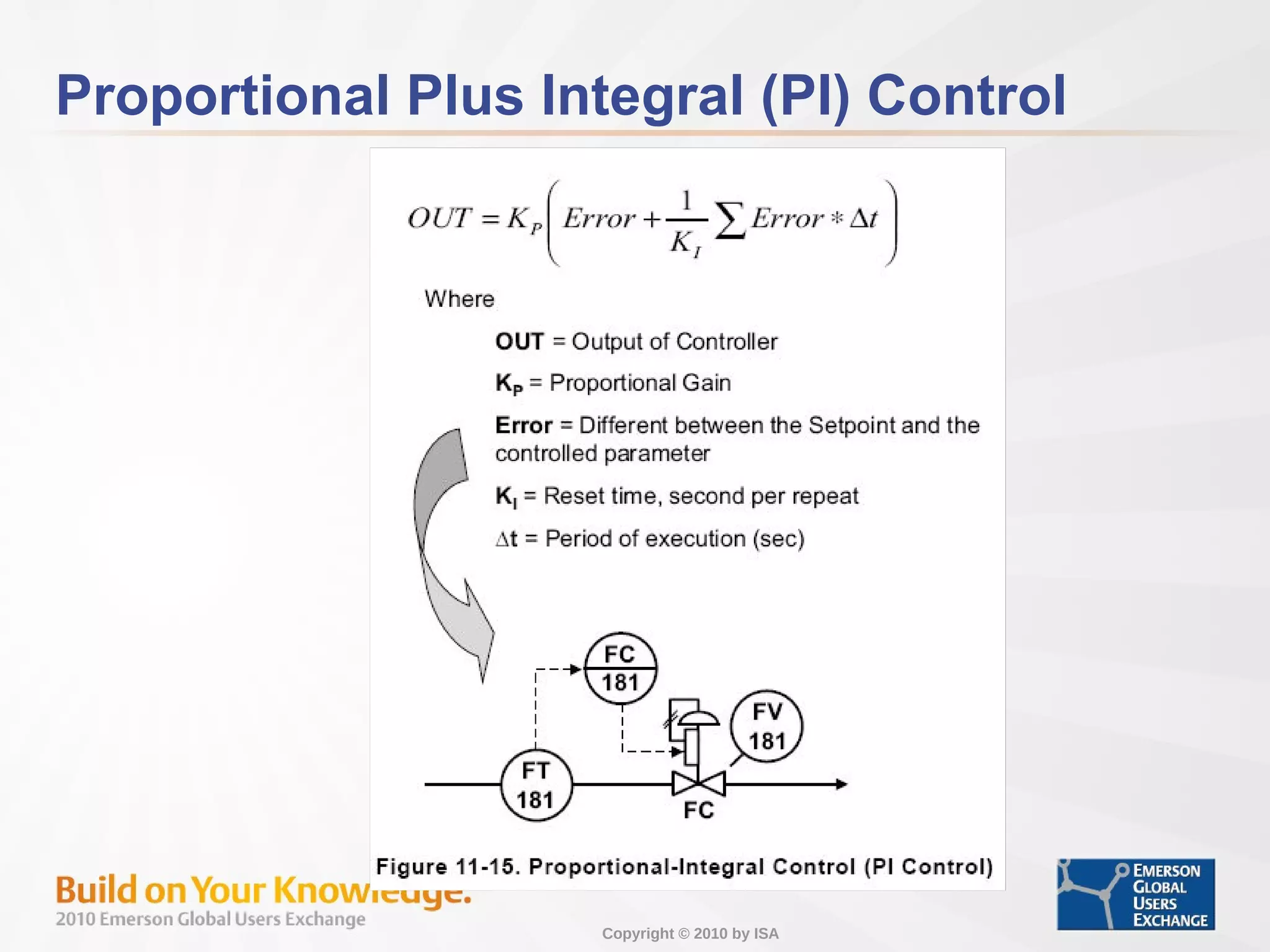

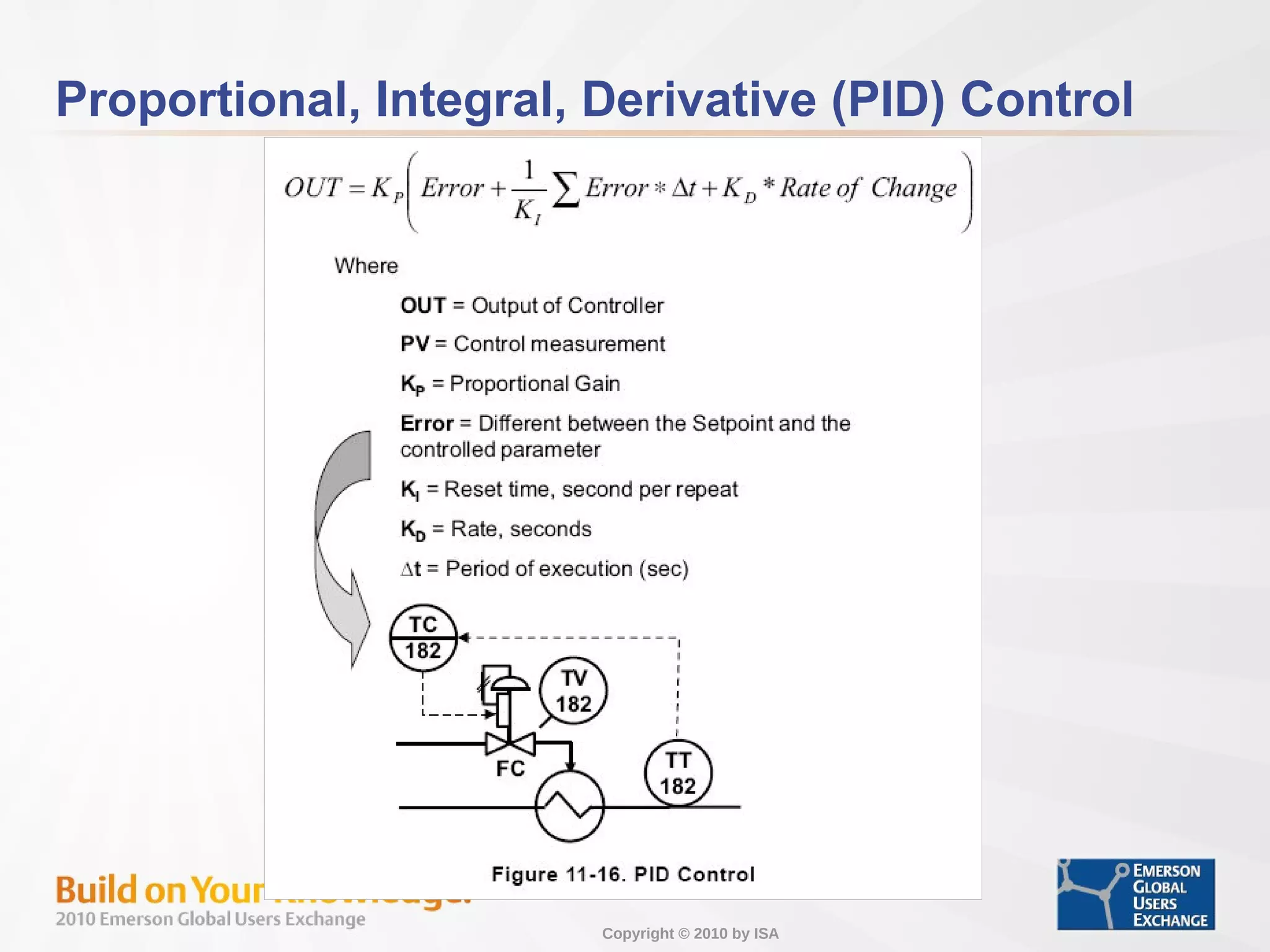

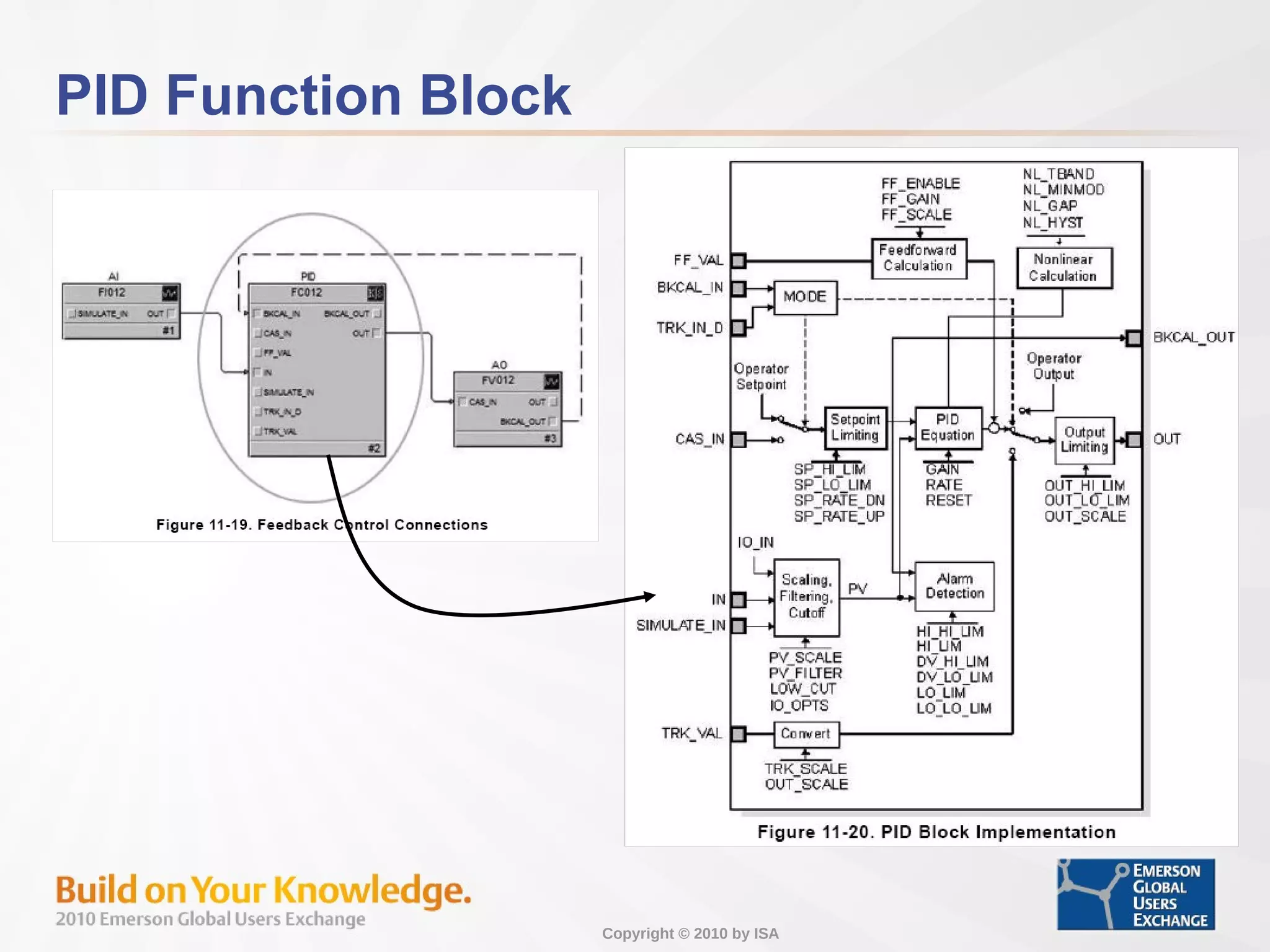

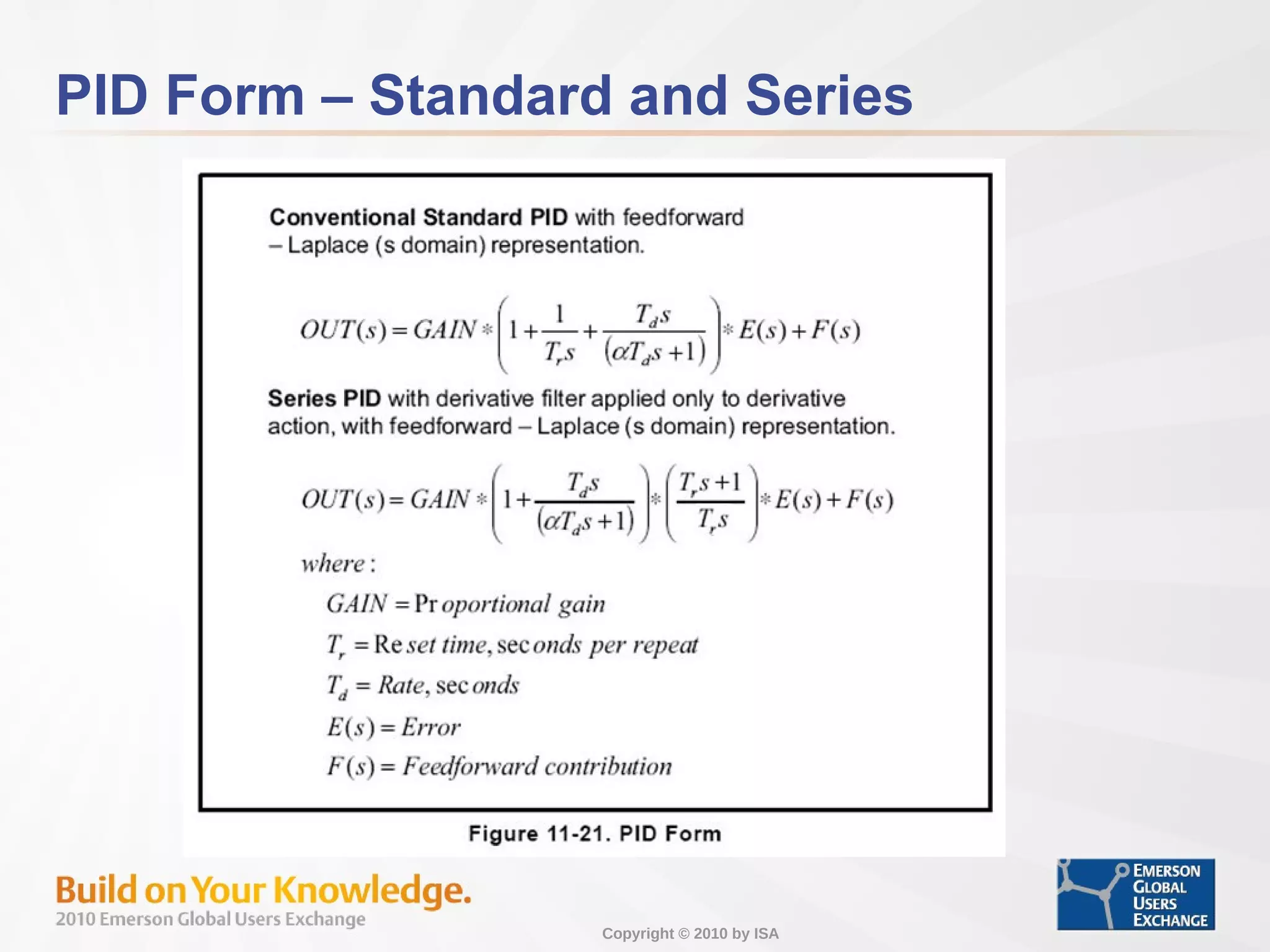

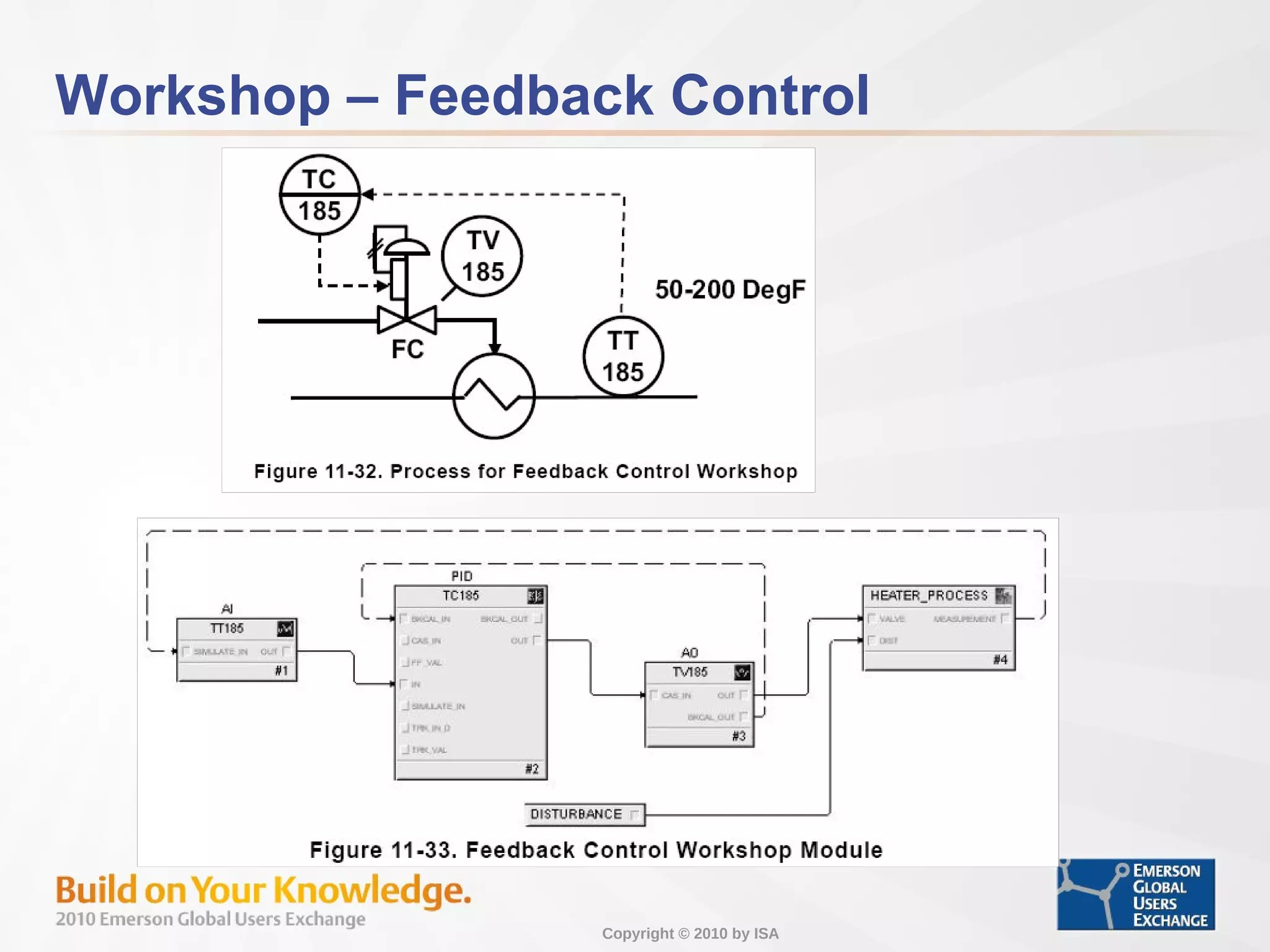

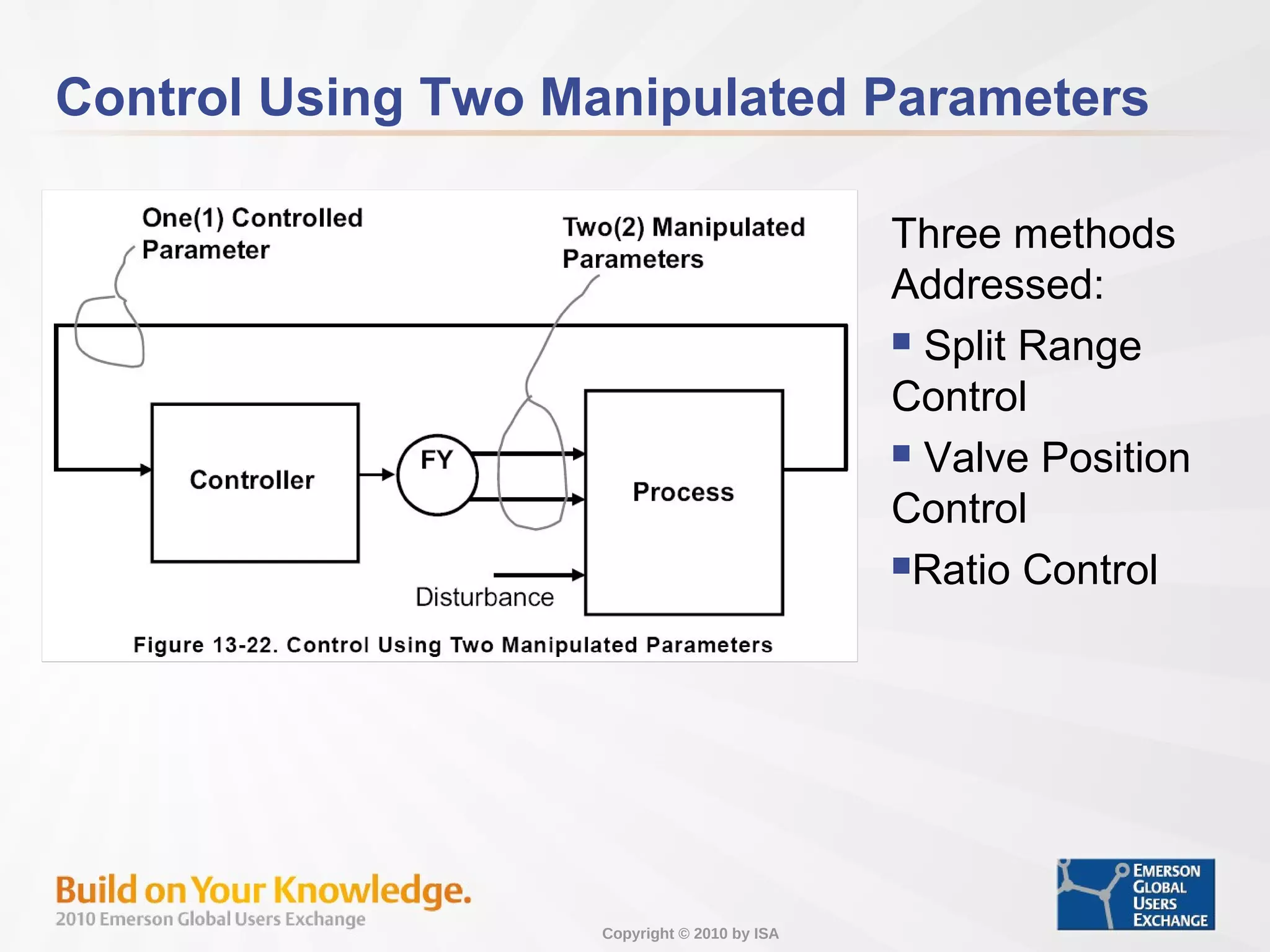

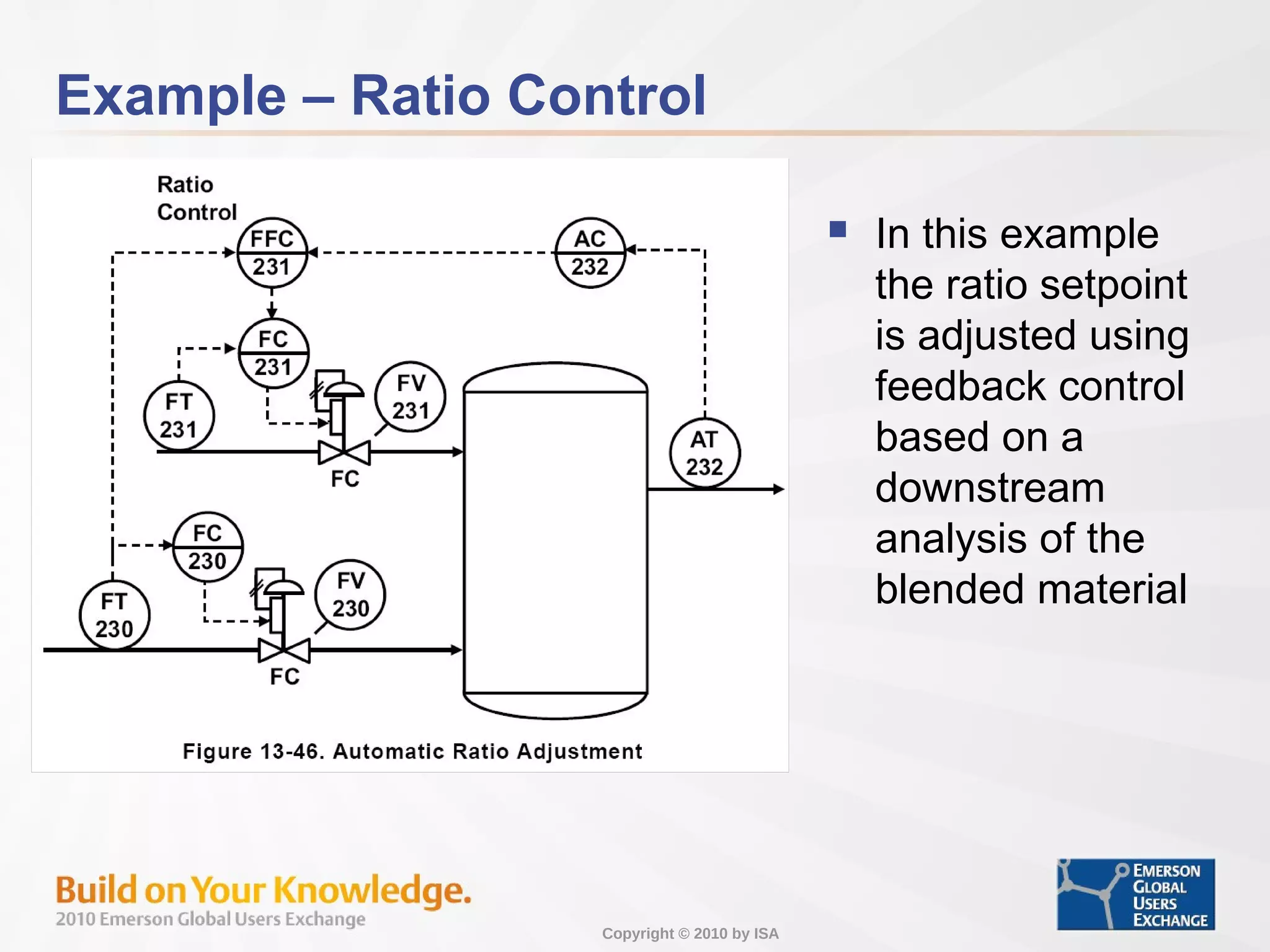

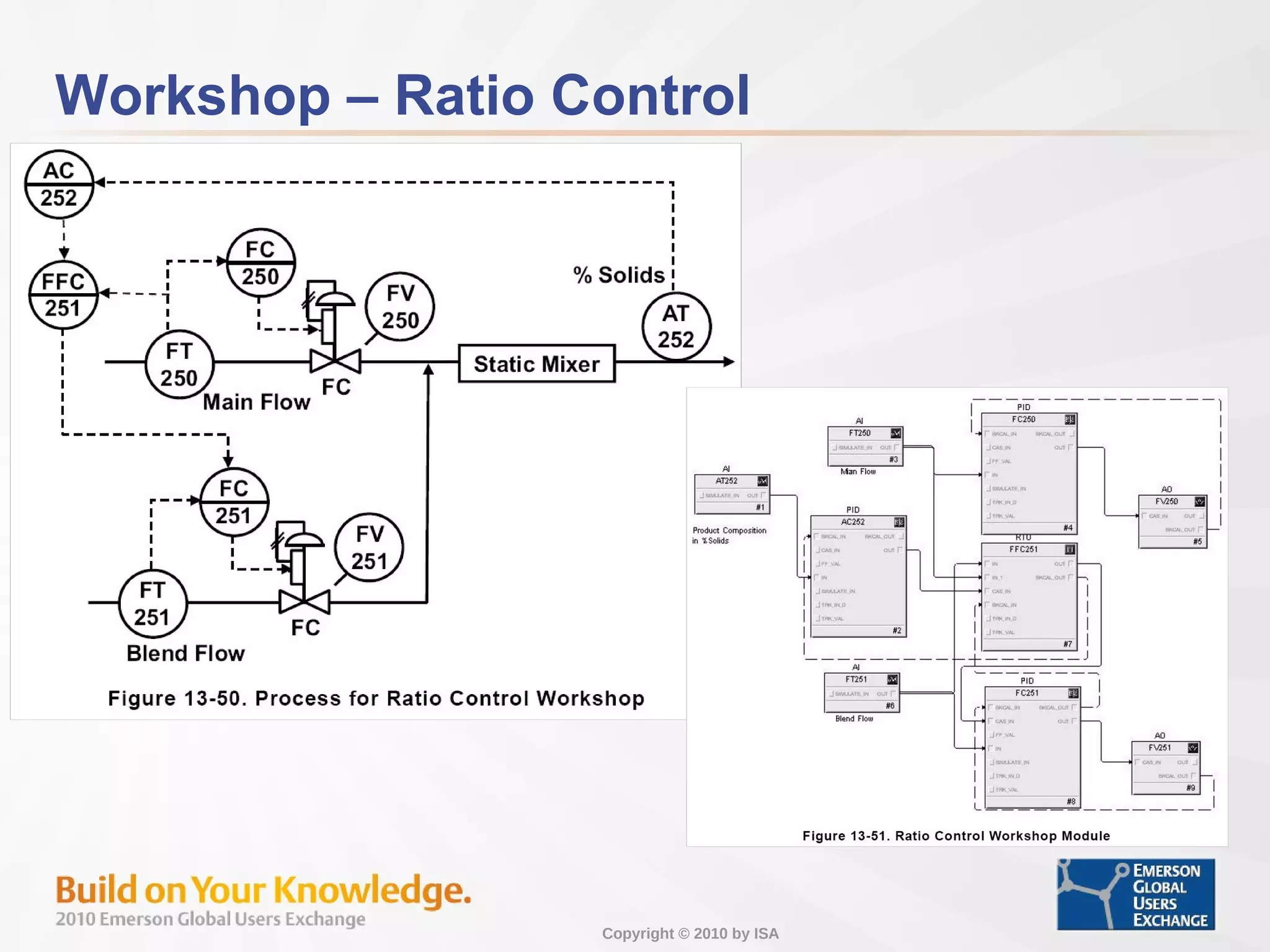

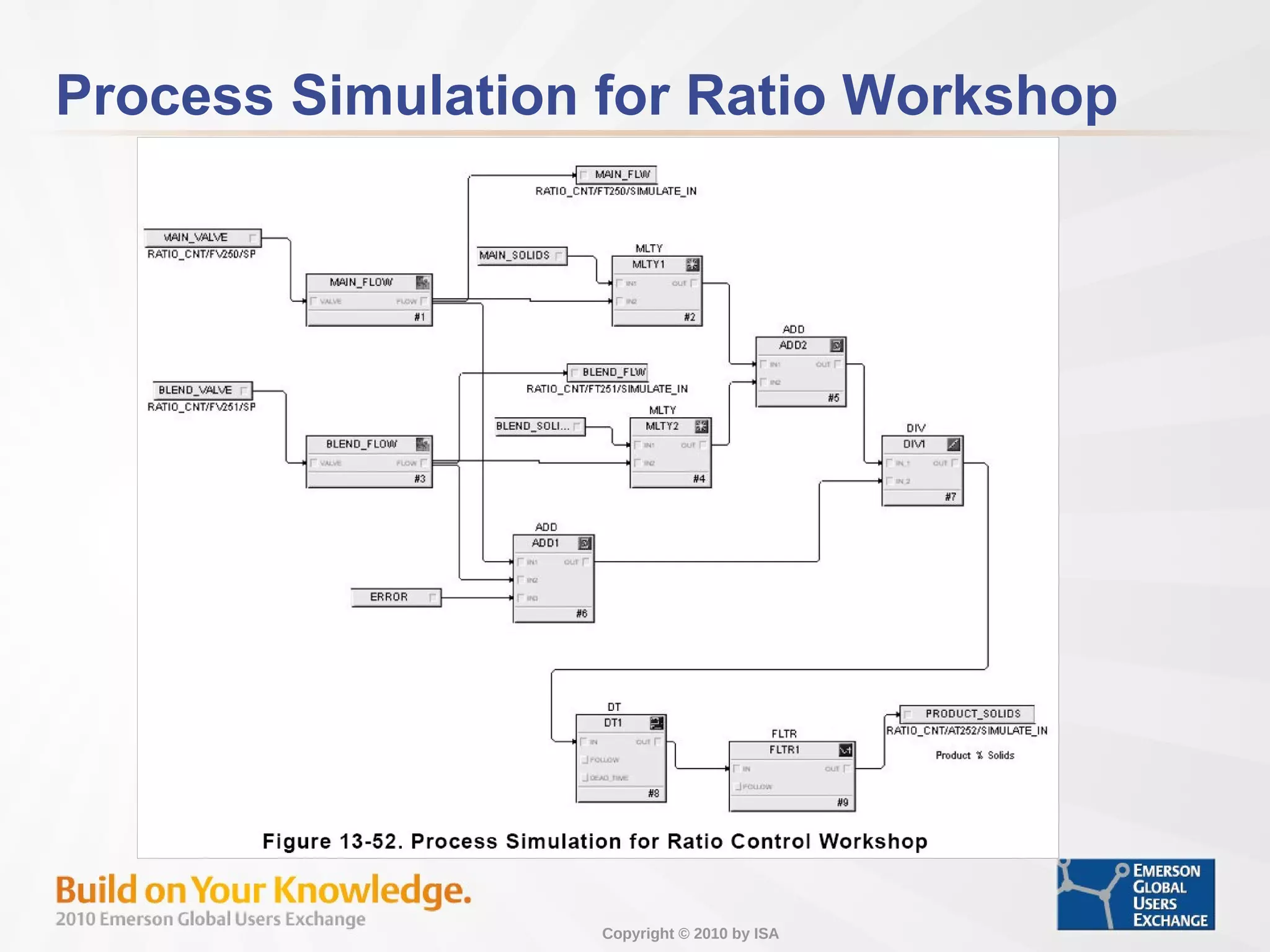

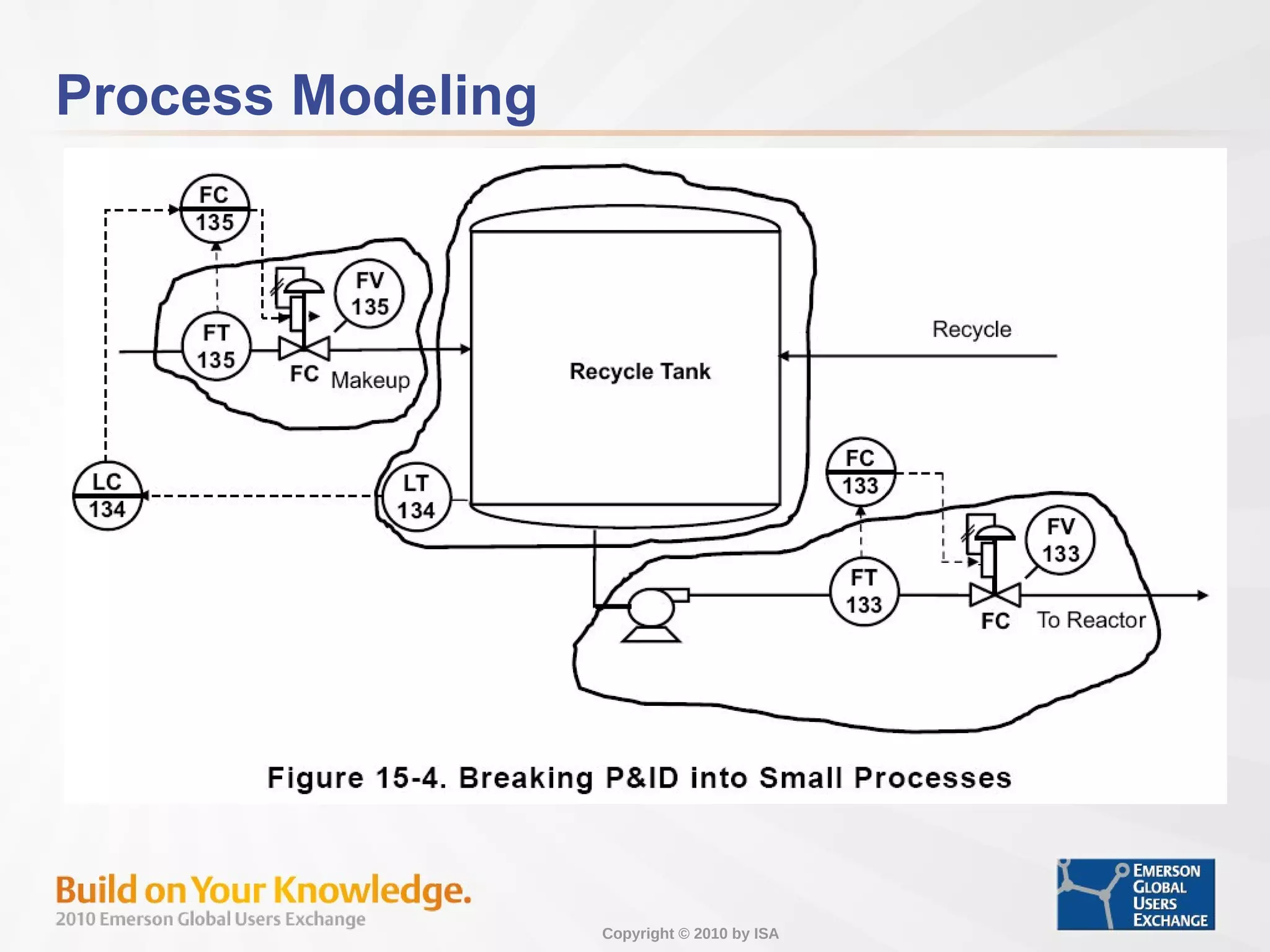

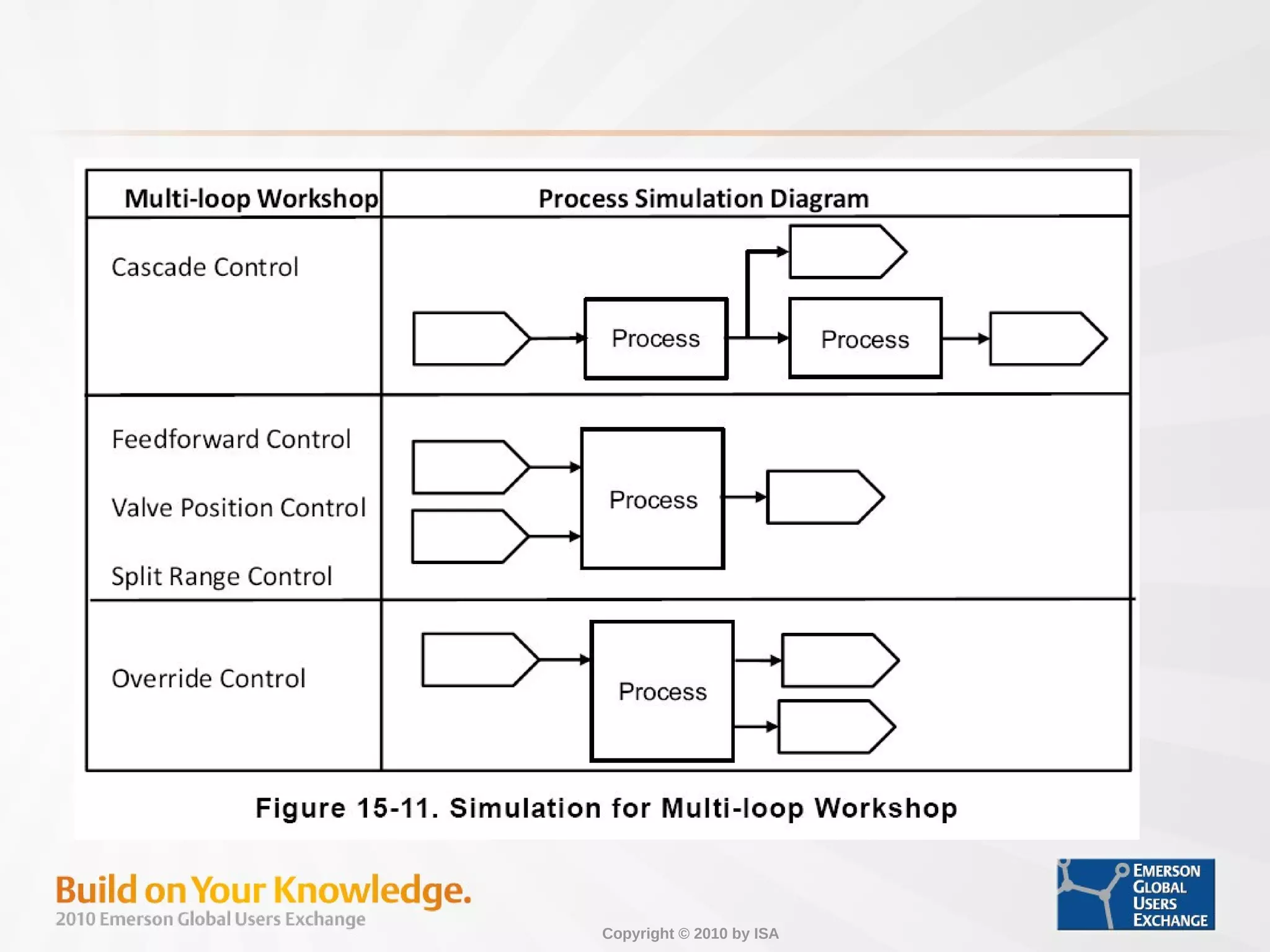

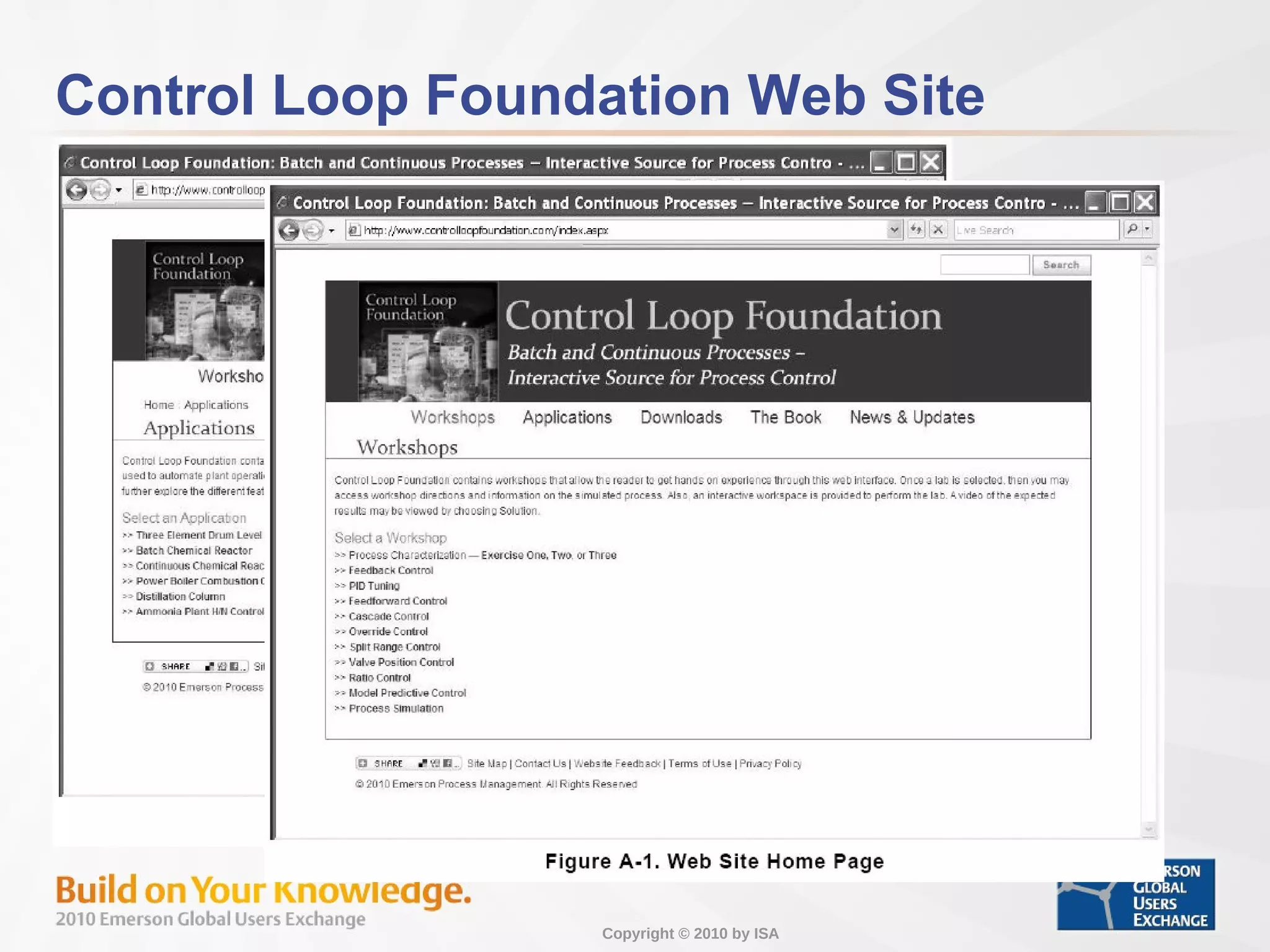

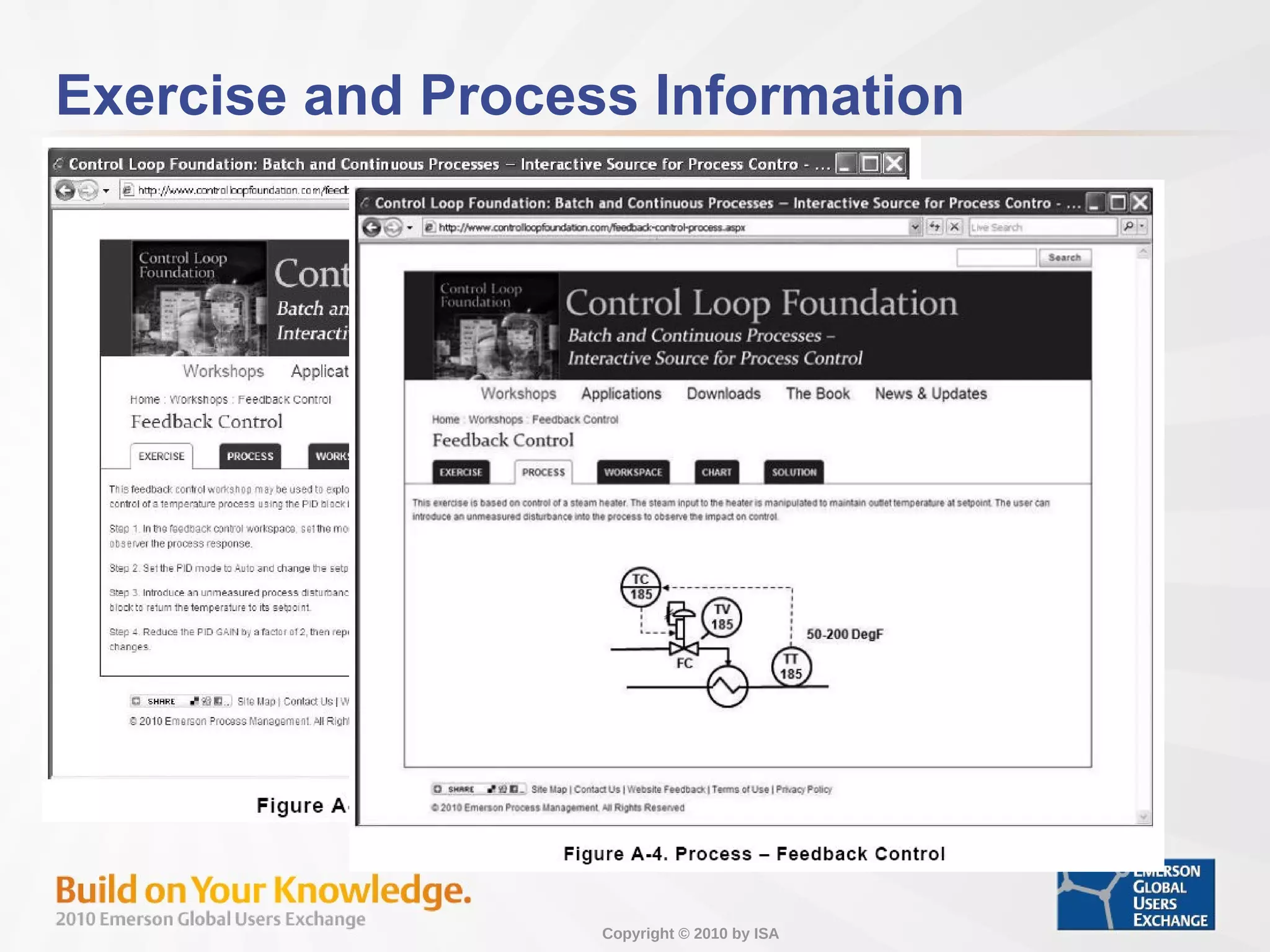

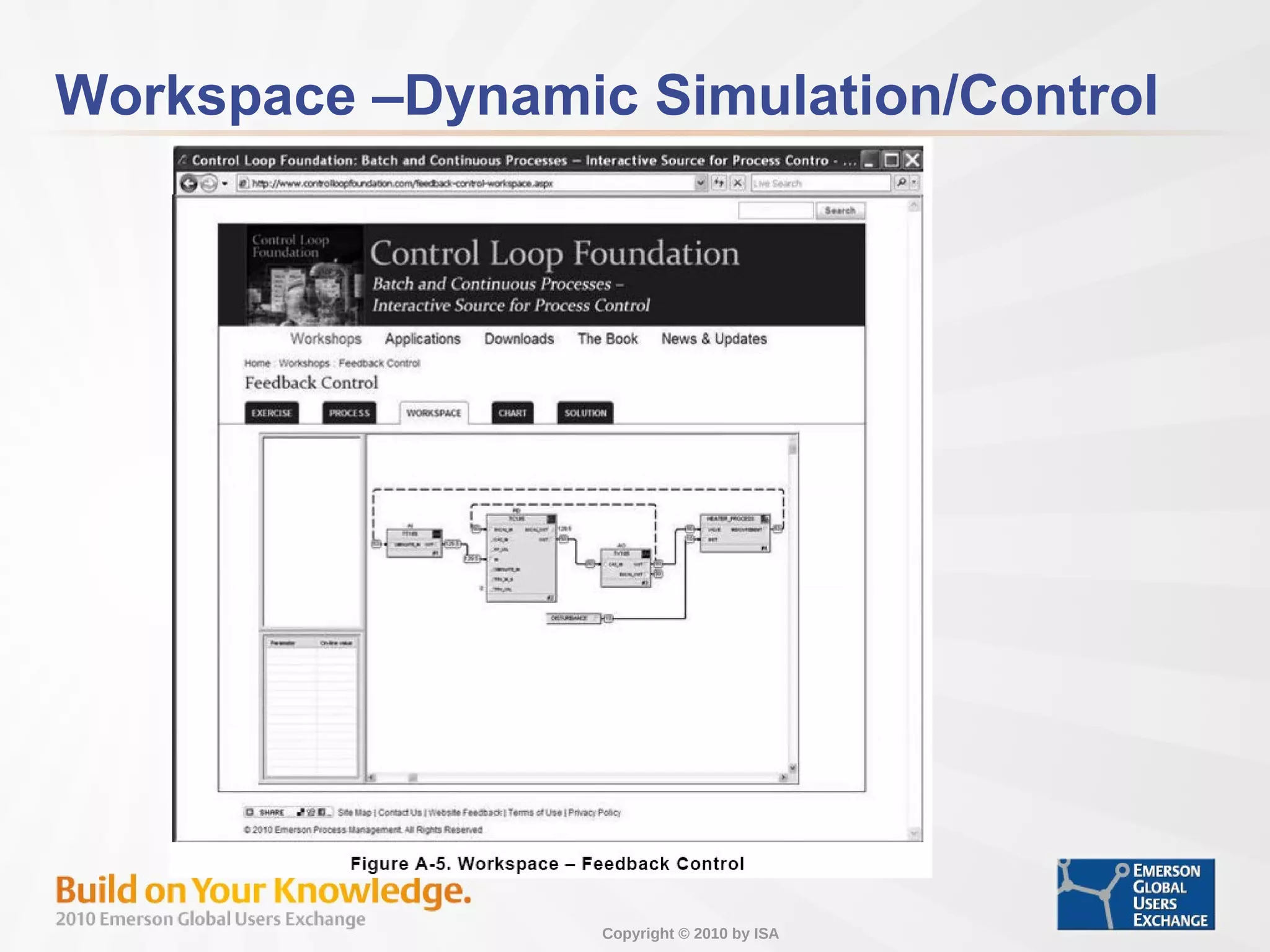

The document serves as a comprehensive guide on process control concepts and terminology, covering various topics such as control strategies, measurement devices, and communication techniques in industrial automation. It emphasizes practical aspects of control design and includes application examples for engineers of all experience levels. Additionally, it introduces the use of simulation for process characterization and illustrates key control objectives and the importance of balancing system complexity with benefits.