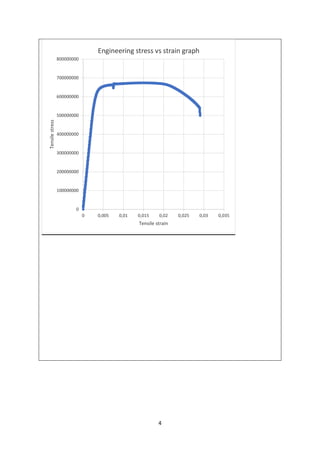

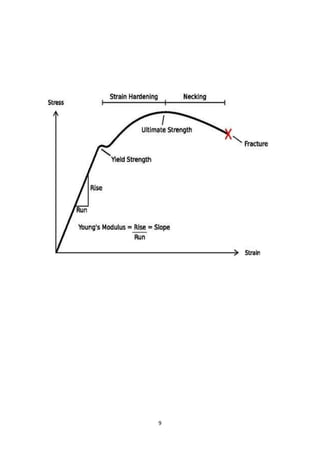

The document outlines the procedures and equipment necessary for conducting a tensile test on materials, specifically focusing on determining key properties such as yield strength, ultimate tensile strength, and ductility. It details the test setup using an Instron testing machine, the specific specimen requirements, and safety precautions to ensure accurate results. Additionally, it includes calculated results from a steel sample, illustrating the relationships between stress and strain and emphasizing the importance of tensile testing in assessing material quality.

![10

REFERENCES

Clausin, D. P., 1966. The Tensile Fracture of Mild Steel, California: Carlifonia

Institute of Technology.

COLLINS, D., 2019. Linear Motiontips. [Online]

Available at: http://www.linearmotiontips.com

[Accessed 19 april 2020].

Commitee, A., 2016. Standard Test Methods for Tension Testing of Metallic

Metarials, West Coshohoken: ASTM International.

Davis, J. R., 2004. Tensile testing. 2nd ed. Ohio: ASM International.

Hibbeler, R. C., 2011. Mechanics of materials. 8th ed. New York: Cloth.

Spiret, M., 2019. How to perfom a tension strength test on metals according to

ASTM

E8/E8M. The definitive guide to ASTM E8/E8M tension testing of metals, iii(11), p.

90.

Spiret, M., 2020. INSTRON. [Online]

Available at: http://www.instron.com

[Accessed 21 APRIL 2020].

Wikipedia, 2019. wikipedia. [Online]

Available at: http://www.wikipedia.com

[Accessed 26 April 2020].](https://image.slidesharecdn.com/tensiletest-200705115646/85/Tensile-test-10-320.jpg)