1) The document discusses stresses in thin and thick cylinders, including circumferential (hoop), longitudinal, and radial stresses. It also covers principal stresses.

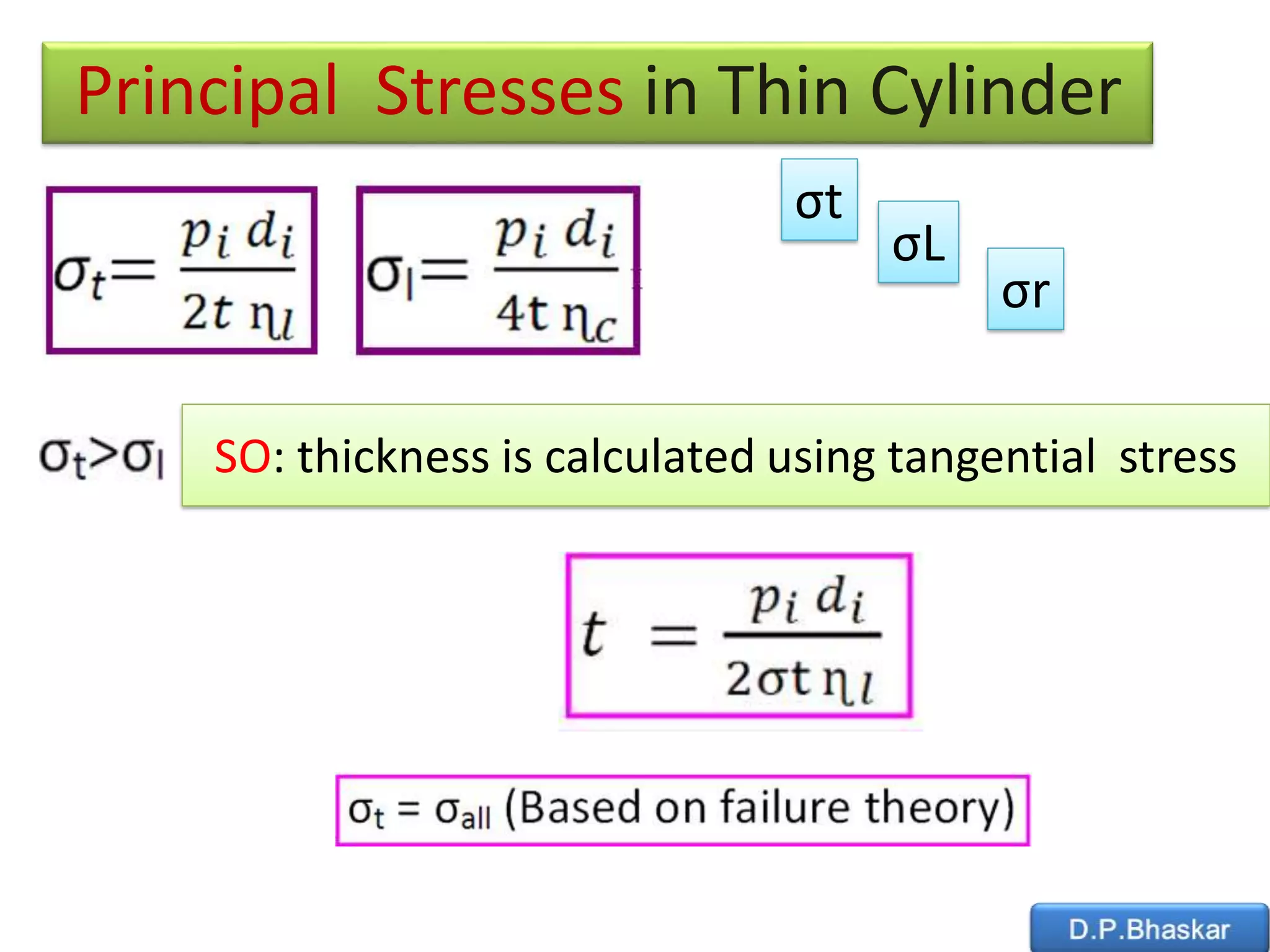

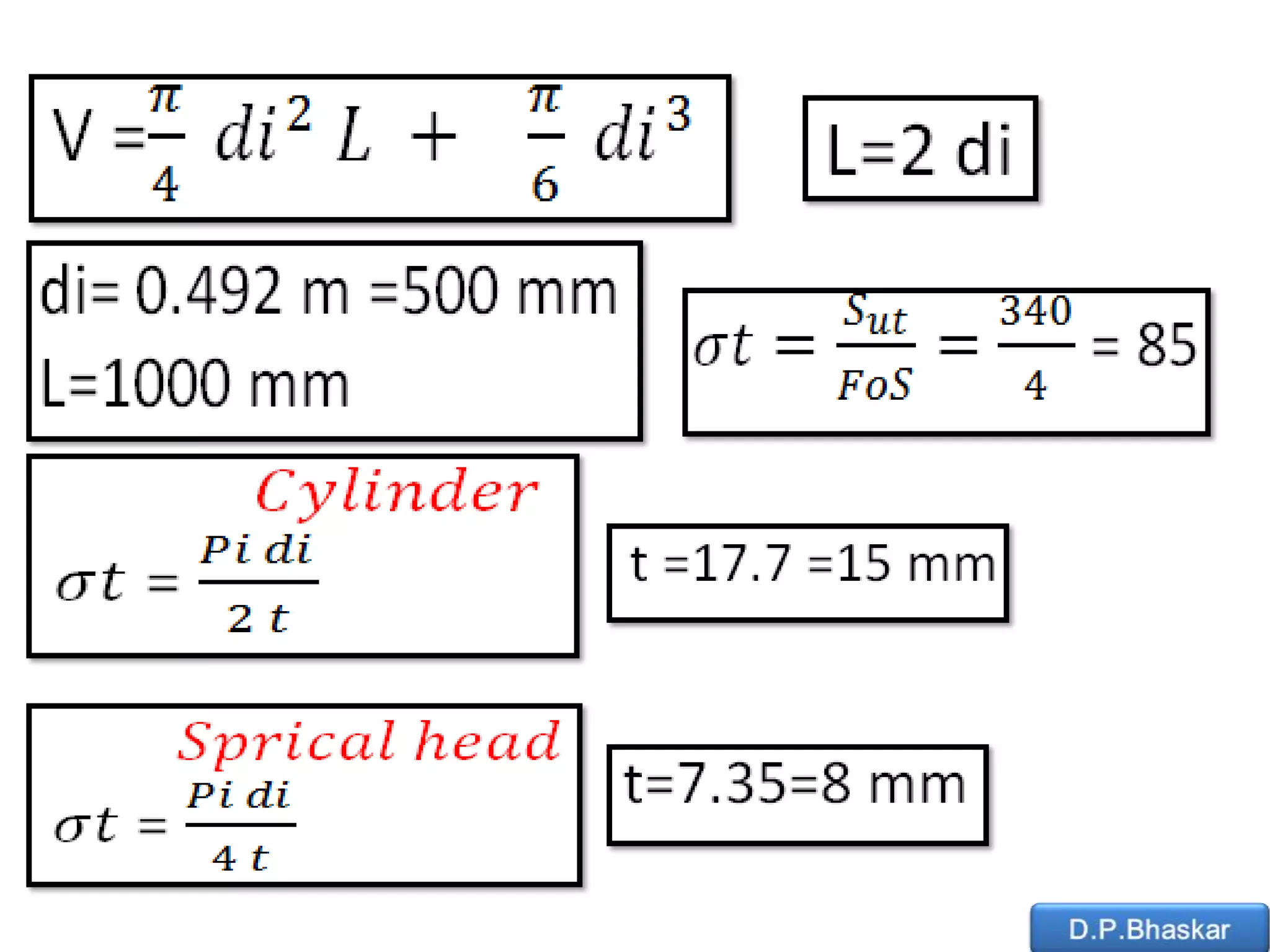

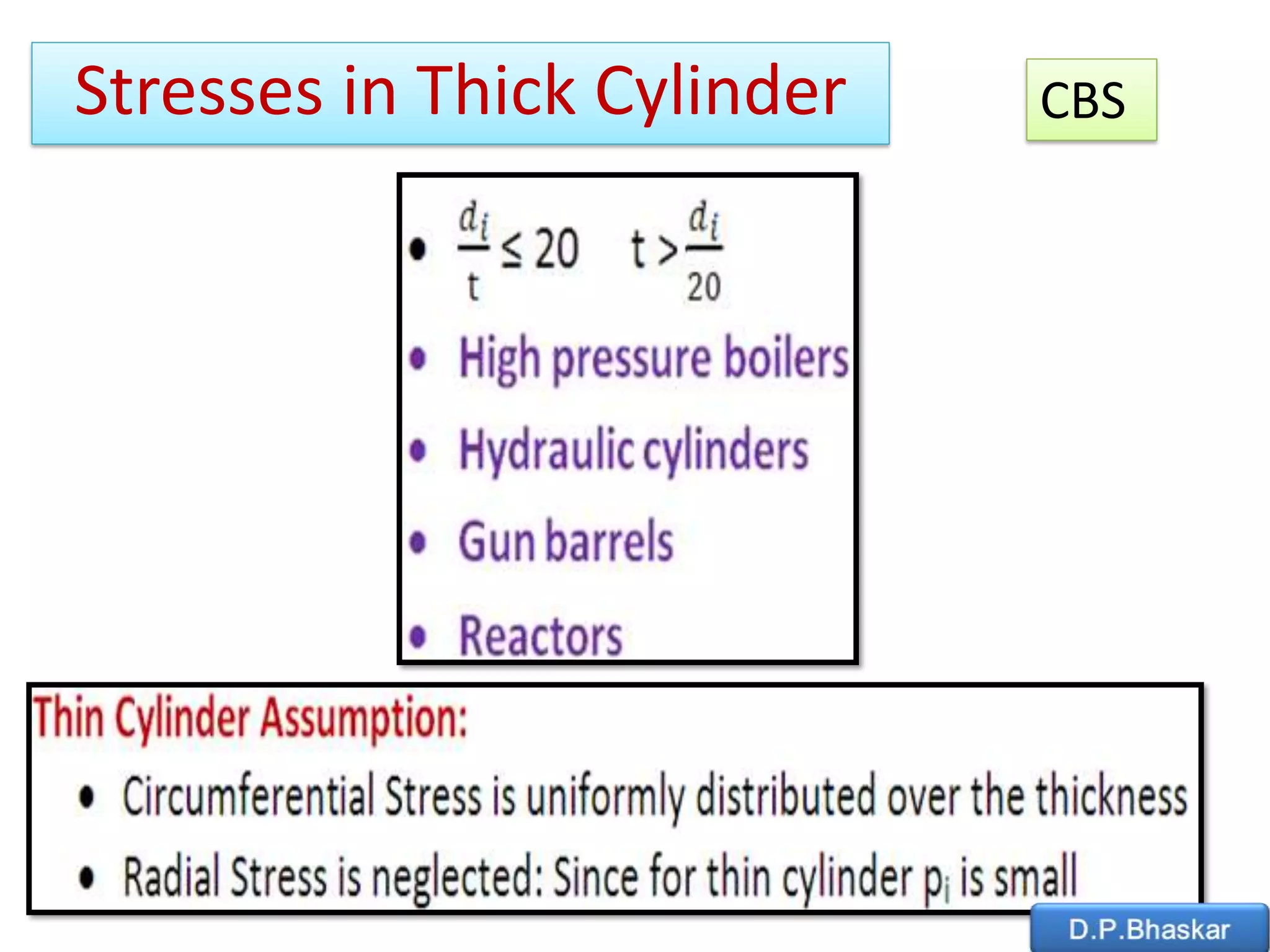

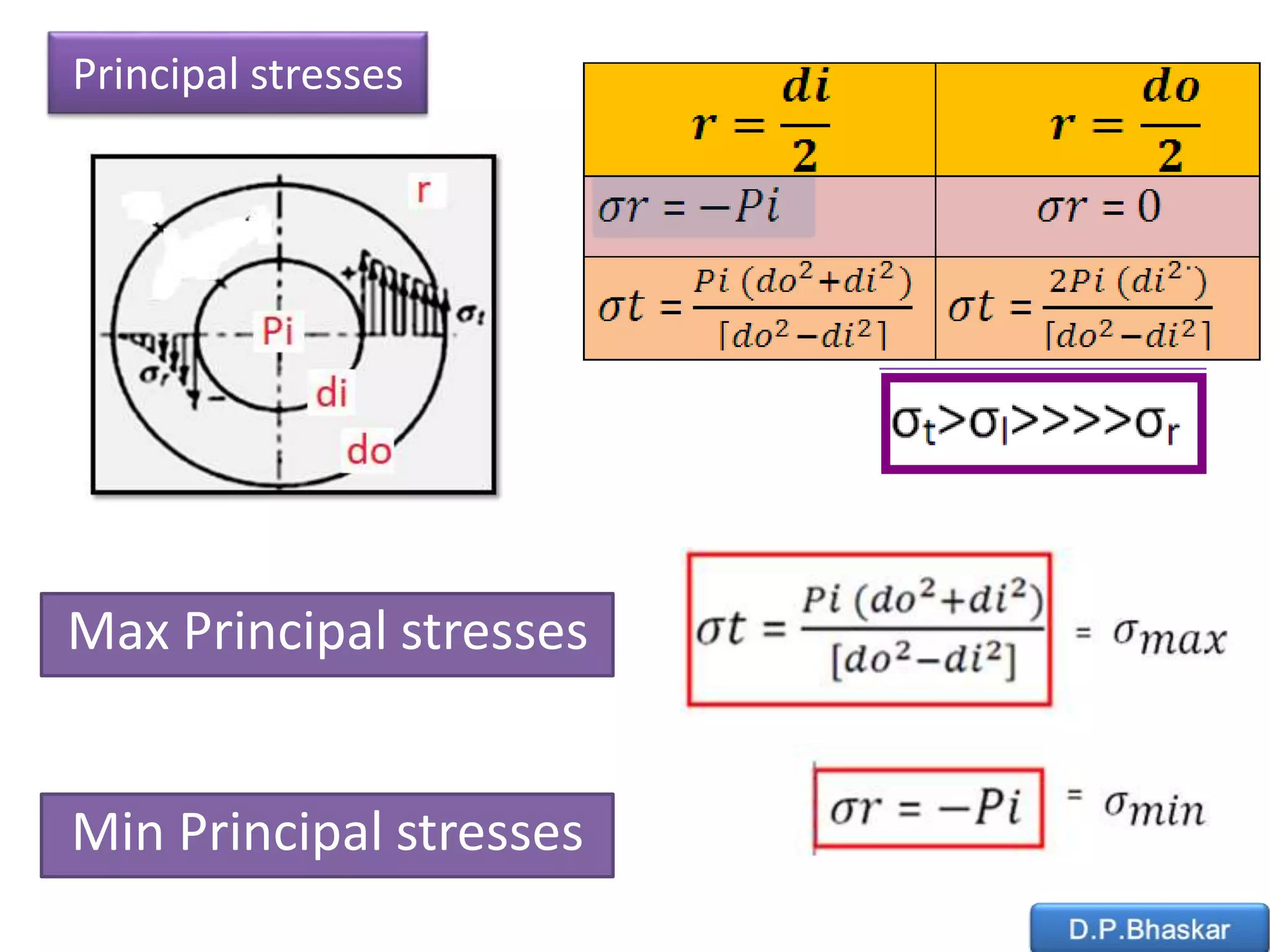

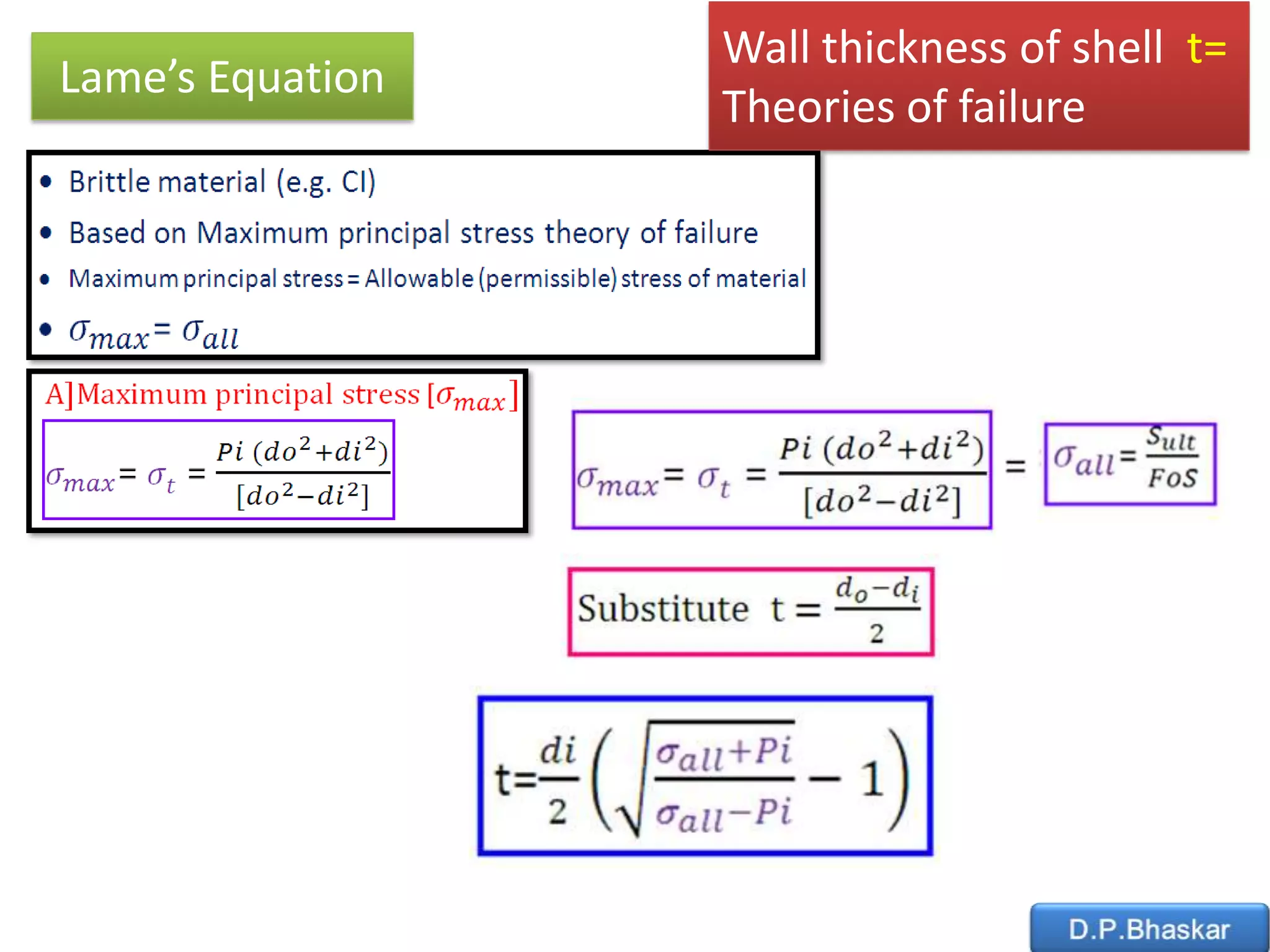

2) Formulas are provided for calculating wall thickness based on tangential stress in thin cylinders, and Lame's equation is introduced for thick cylinders.

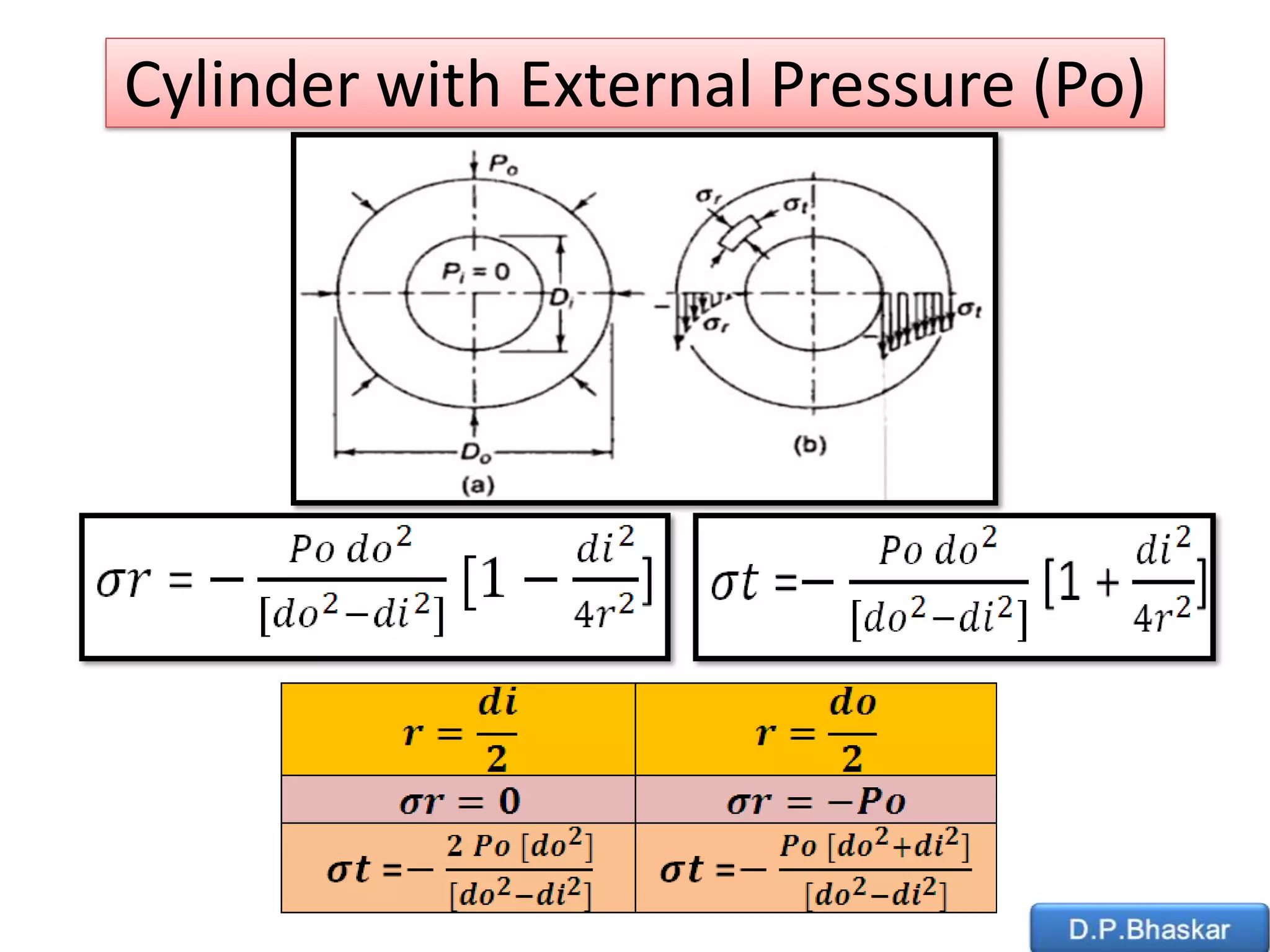

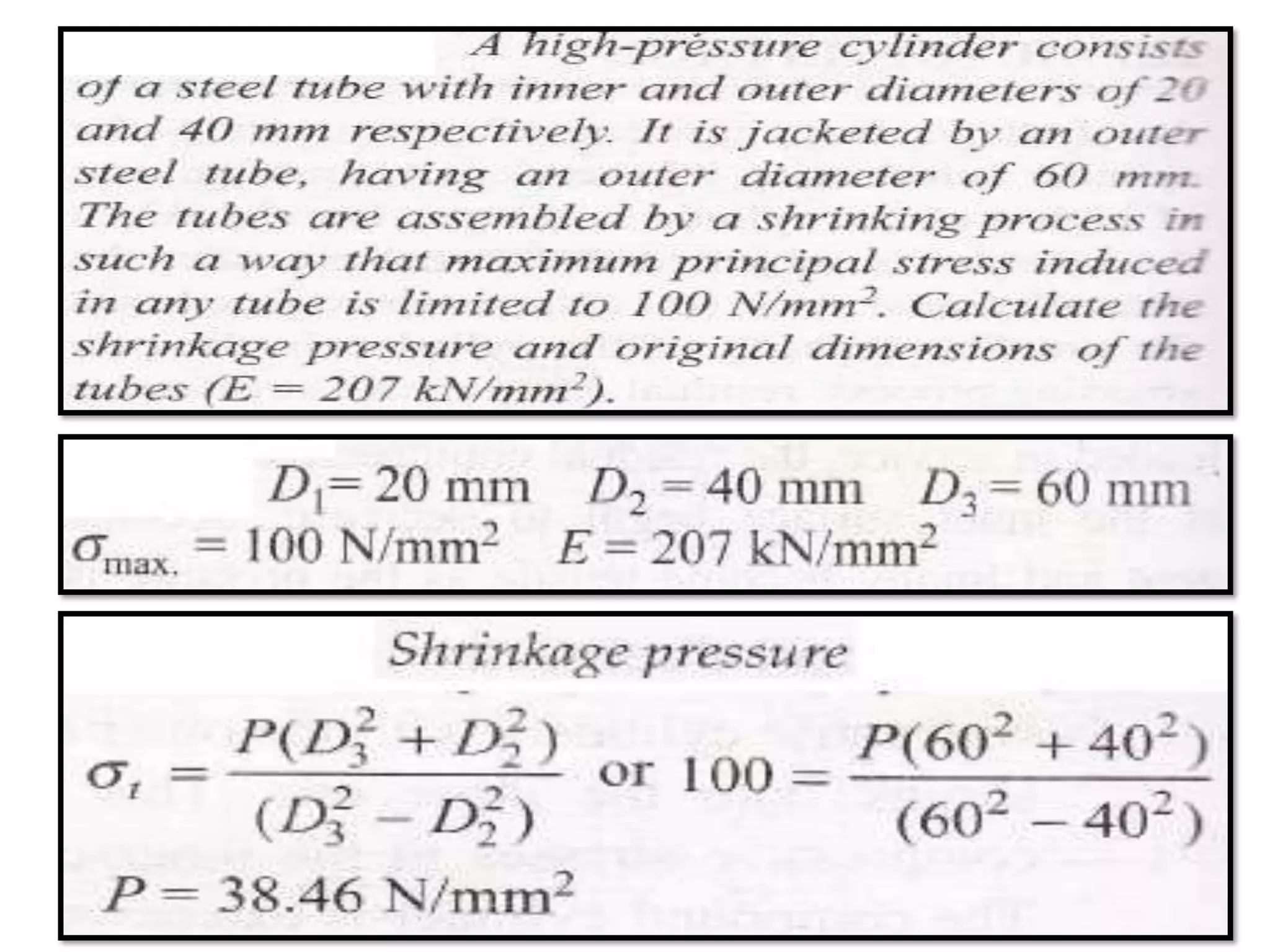

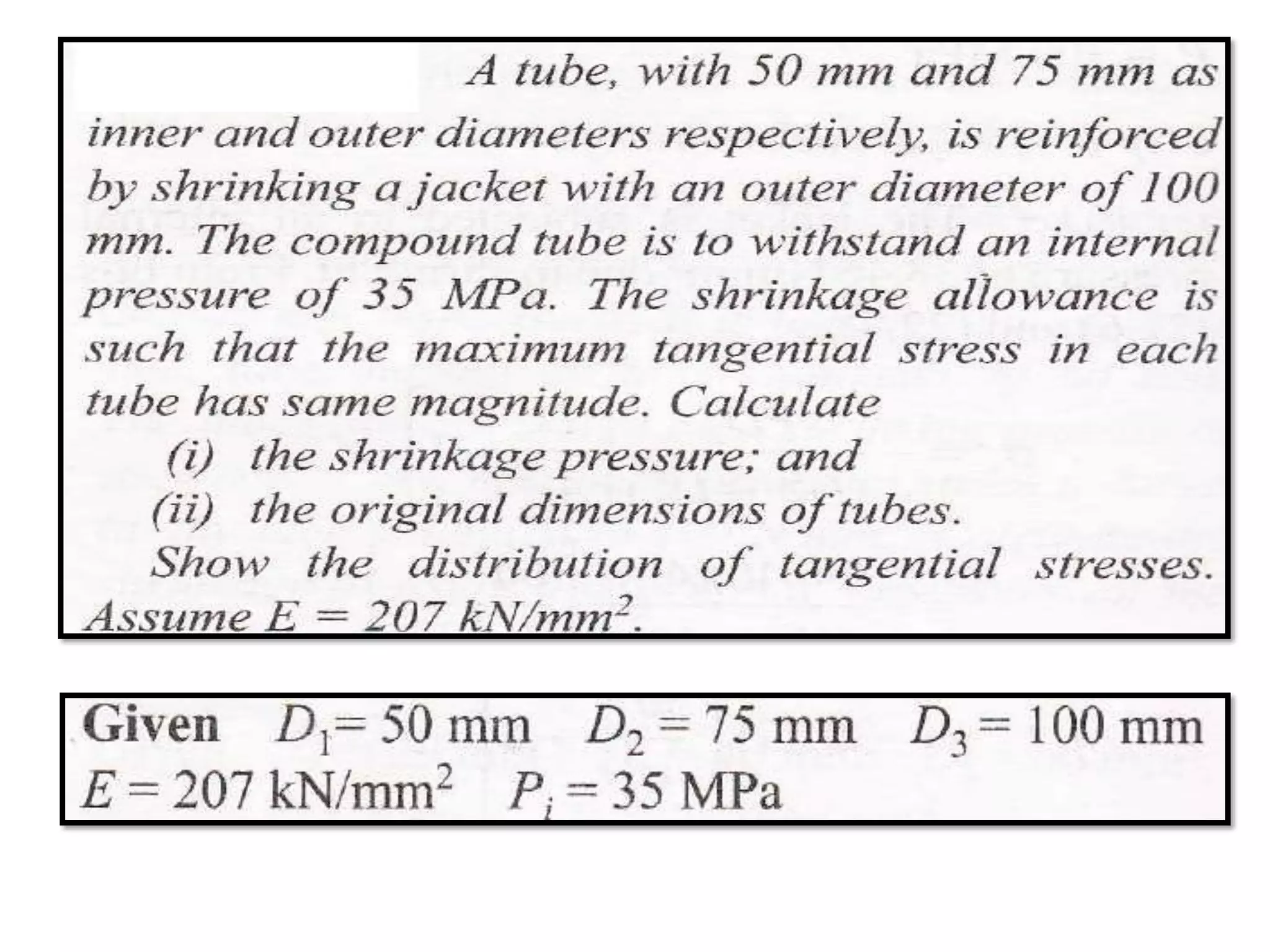

3) Additional concepts covered include stresses in spherical vessels, pre-stressing techniques like autofrettage to increase pressure capacity, and stresses in cylinders under external pressure or combined internal and shrink pressures.

![1]Circumferential /Hoop stress/Tangential:

Exerted circumferentially on every particle in the cylinder wall.

• Can be imagined as a band surrounding a barrel.

• When barrel expands, the band stretches and undergoes stress.

3]Radial stress: (Compressive)

Caused by the design pressures acting through the wall thickness

(neglected). As P small

2]Longitudinal stress:

Parallel to the axis of cylindrical

Stretching the shell

circumferentially

Stresses in Thin Cylinder](https://image.slidesharecdn.com/4a-200321045424/75/Thin-and-Thick-Cylinders-2-2048.jpg)

![Stress due to Shrink Pressure [P=38.46] Jacket

Stress due to Shrink Pressure [P=38.46] Cylinder](https://image.slidesharecdn.com/4a-200321045424/75/Thin-and-Thick-Cylinders-27-2048.jpg)

![Stress due to Internal Pressure [Pi=300]](https://image.slidesharecdn.com/4a-200321045424/75/Thin-and-Thick-Cylinders-29-2048.jpg)

![Stress due to Internal Pressure [Pi]](https://image.slidesharecdn.com/4a-200321045424/75/Thin-and-Thick-Cylinders-33-2048.jpg)

![Stress due to Shrink Pressure [P]

Cylinder

Jacket](https://image.slidesharecdn.com/4a-200321045424/75/Thin-and-Thick-Cylinders-34-2048.jpg)