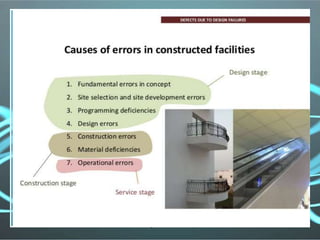

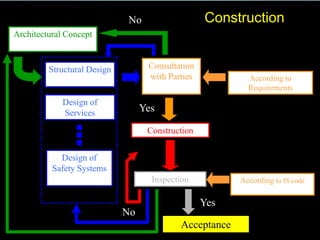

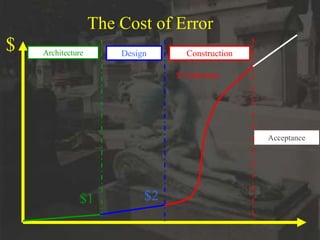

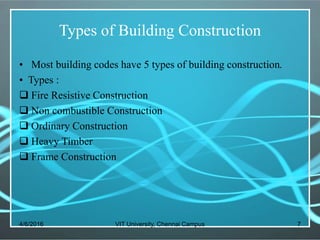

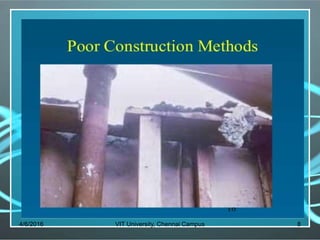

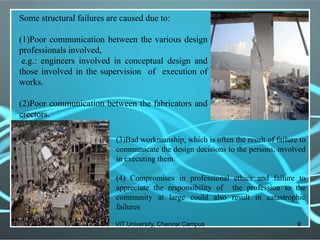

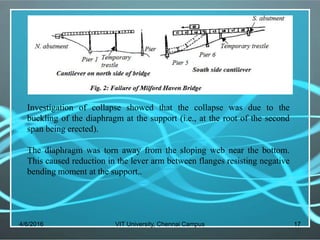

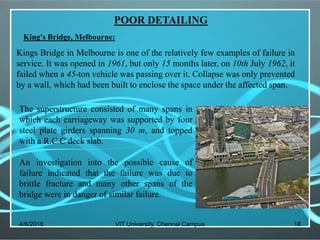

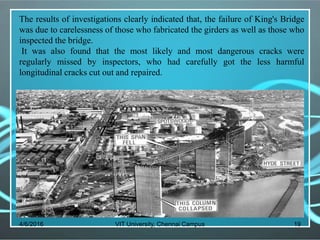

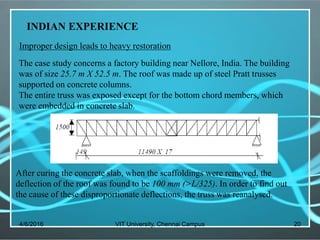

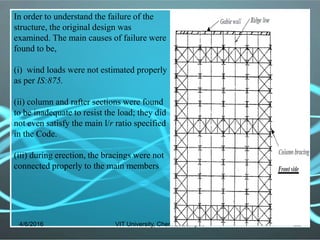

The document discusses the challenges of learning from design errors in construction, highlighting their role in catastrophic accidents and stressing the importance of effective communication among design and construction professionals. It presents various case studies of structural failures due to poor design, inadequate methodologies, and oversight, including notable examples like the Tacoma Narrows Bridge and Cleddau Bridge. Overall, the document emphasizes the need for continuous learning and improvement in design practices to prevent future failures and enhance safety in the construction industry.