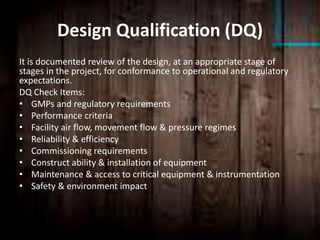

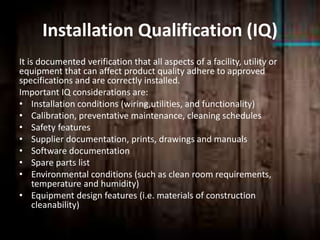

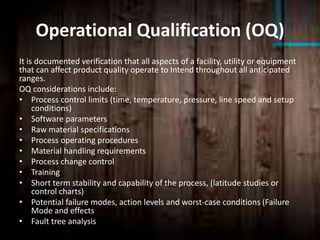

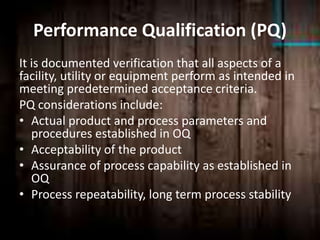

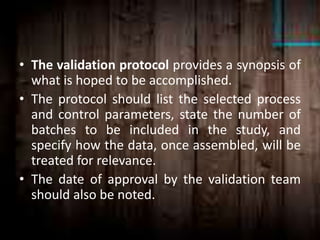

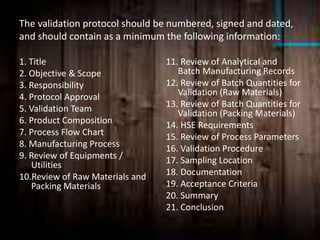

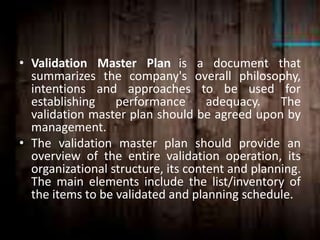

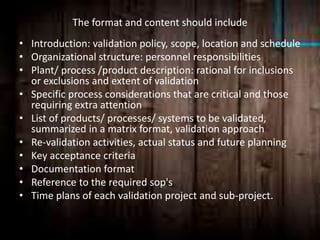

The document discusses validation of pharmaceutical processes. It describes the key elements of validation including design qualification, installation qualification, operational qualification and performance qualification. It discusses different types of validation such as prospective validation, concurrent validation and retrospective validation. It also discusses revalidation which is needed when any changes are made that could impact quality. The validation process involves three phases - pre-validation, process validation and validation maintenance. A validation protocol and validation master plan are developed to document the validation activities and ensure a systematic approach.