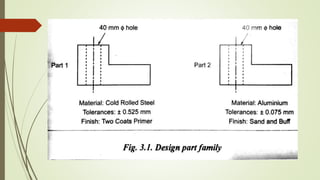

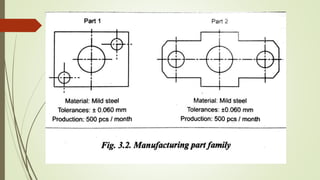

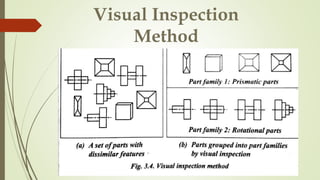

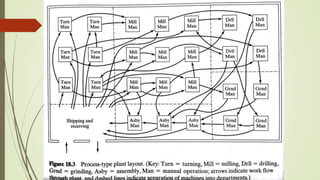

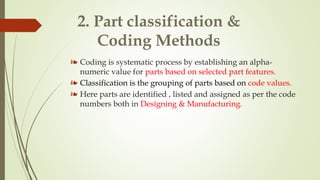

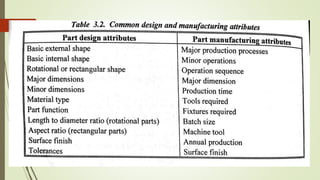

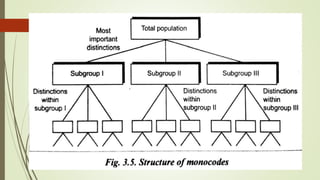

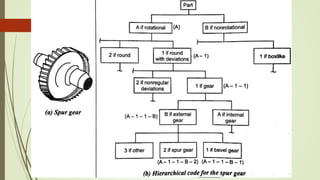

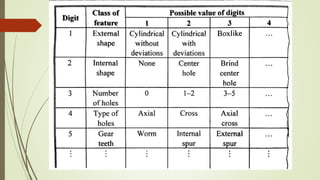

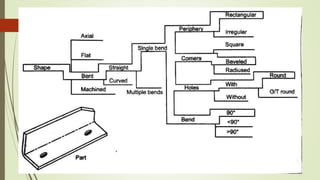

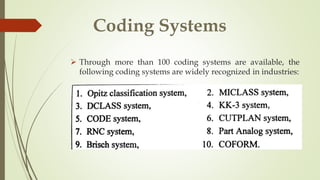

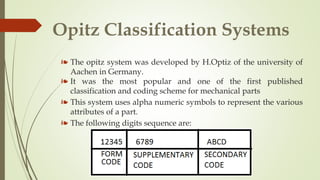

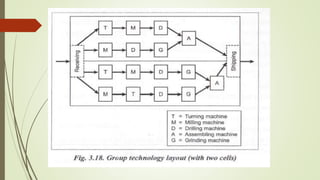

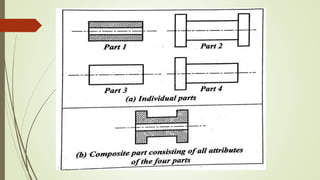

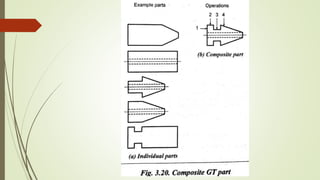

Group technology is a manufacturing philosophy that increases production efficiency by grouping parts with similar design and manufacturing attributes into families. Parts within a family will be produced together in batches on the same machines to reduce setup times. Common coding systems are used to classify parts into families based on their attributes, which facilitates automated process planning and machine cell design in CAD/CAM systems. Production flow analysis is a method to identify part families and machine groupings based on similarities in their production routing sheets. The composite part concept provides a hypothetical part that embodies all attributes of a family and defines what machines are needed in a manufacturing cell to produce that family.