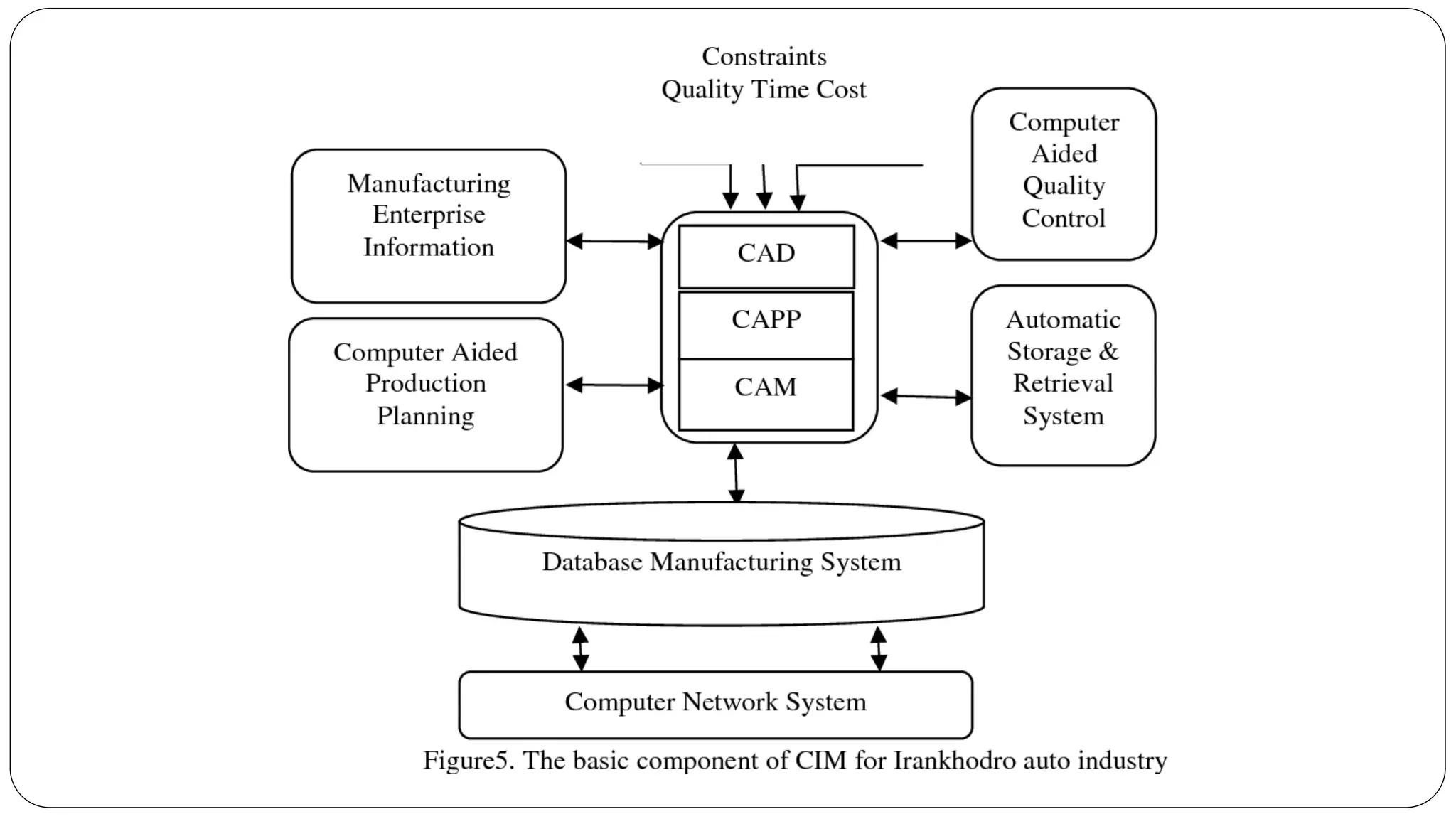

Computer-integrated manufacturing (CIM) is a manufacturing approach that utilizes computer-controlled systems and automation to enhance efficiency and reduce manual labor. It encompasses various processes such as computer-aided design and manufacturing, and benefits from components including real-time sensors and data management systems. While CIM has advantages like error reduction and increased speed, it also faces limitations such as high initial costs and maintenance challenges.

![Relationship between automation and CIM by developing a

conceptual model of manufacturing

In the figure Model of

manufacturing, showing

(a] the factory as a processing

pipeline where the physical

manufacturing activities are

performed

(b) the information- processing

activities that support

manufacturing as a ring that

surrounds the factory concerned

more with the information-

processing functions that are

required to support the](https://image.slidesharecdn.com/cim-210312081832/75/CIM-Computer-Integrated-Manufacturing-12-2048.jpg)