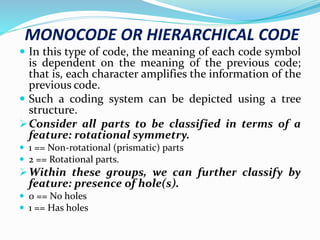

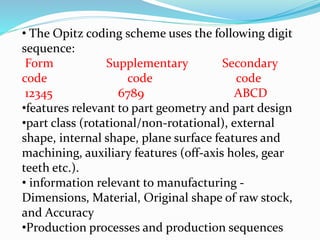

This document discusses group technology and computer-aided process planning. It defines group technology as a manufacturing technique that groups similar parts together to take advantage of their common design and production needs. It describes methods for forming part families and coding systems. It also discusses two types of computer-aided process planning systems: retrieval systems that store and retrieve standard process plans, and generative systems that create process plans using logical procedures similar to human planners.