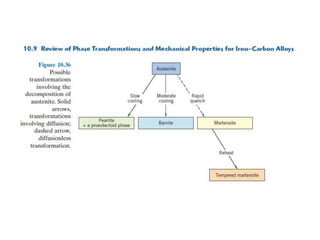

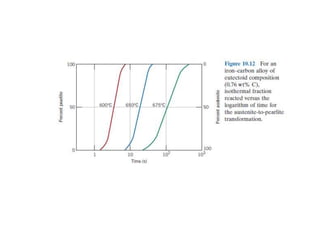

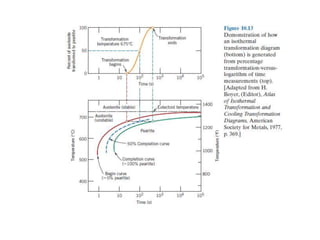

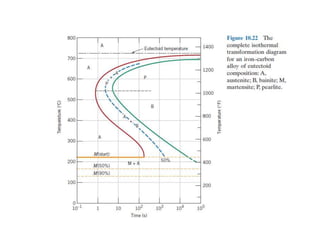

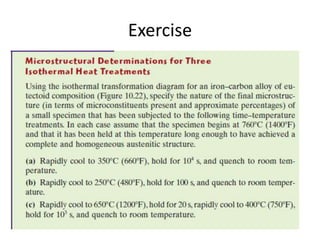

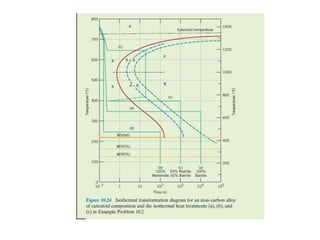

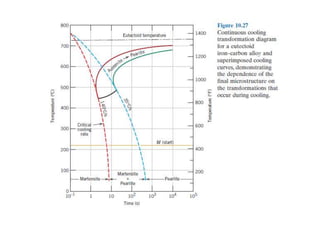

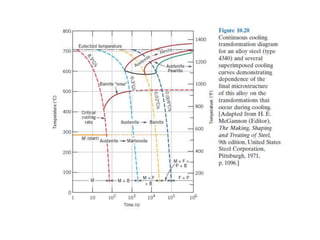

The document discusses various microstructural transformations in steel alloys as a function of temperature and time. It introduces time-temperature-transformation (TTT) diagrams and continuous cooling transformation (CCT) diagrams as tools to predict microstructures resulting from different heat treatments. TTT diagrams apply to isothermal heat treatments where temperature is held constant, while CCT diagrams apply to continuous cooling processes. The document outlines various microstructures including pearlite, bainite, martensite, and spheroidite and how they form on these diagrams. It also discusses how alloying elements can shift the transformation curves and impact critical cooling rates required to form martensite.

![• These curves were generated from a series of

plots of the percentage transformation versus

the logarithm of time taken over a range of

temperatures.

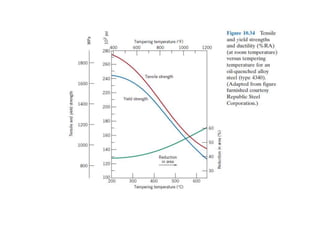

• The S-shaped curve [for 675 C], in the upper

portion of Figure 10.13, illustrates how the

data transfer is made.](https://image.slidesharecdn.com/ttt-cct-180403181308/85/Ttt-cct-diagrams-8-320.jpg)

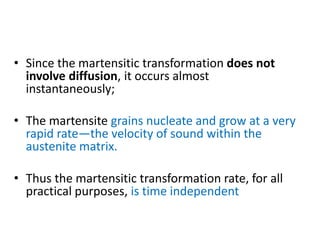

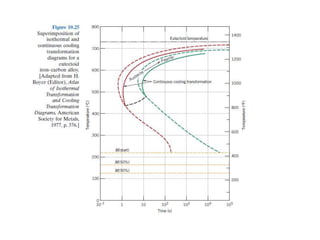

![Interpreting TTT diagram

• In interpreting this diagram, note first that the eutectoid

temperature [727 C] is indicated by a horizontal line; at

temperatures above the eutectoid and for all times, only

austenite will exist, as indicated in the figure.

• The austenite-to-pearlite transformation will occur only if an

alloy is super cooled to below the eutectoid; as indicated

by the curves.

• The time necessary for the transformation to begin and then

end depends on temperature.](https://image.slidesharecdn.com/ttt-cct-180403181308/85/Ttt-cct-diagrams-10-320.jpg)

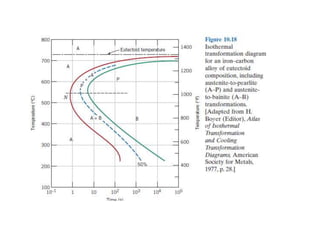

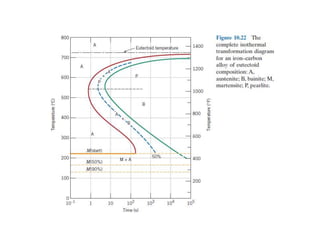

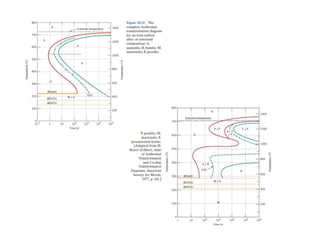

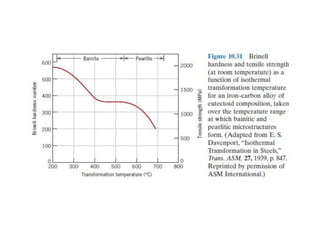

![• All three curves are C-shaped and have a “nose”

at point N, where the rate of transformation is a

maximum.

• As may be noted, whereas pearlite forms above

the nose [i.e., over the temperature range of

about 540 to 727 C]

• At temperatures between about 215 to 540 C,

bainite is the transformation product](https://image.slidesharecdn.com/ttt-cct-180403181308/85/Ttt-cct-diagrams-22-320.jpg)

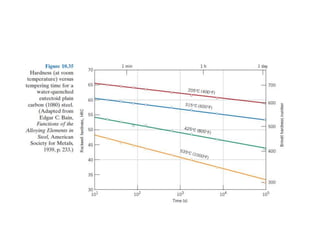

![• With increasing time the hardness decreases, which

corresponds to the growth and coalescence of the

cementite particles.

• At temperatures approaching the eutectoid [ 700 C]

and after several hours, the microstructure will have

become spheroiditic (Figure 10.19),

• with large cementite spheroids embedded within the

continuous ferrite phase. Correspondingly,

overtempered martensite is relatively soft and ductile.](https://image.slidesharecdn.com/ttt-cct-180403181308/85/Ttt-cct-diagrams-105-320.jpg)